Boroxol titanocene metal catalyzer and preparation method and application thereof

A technology of titanocene catalyst and boron oxygen, which is applied in the field of boroxy titanocene catalyst and its preparation, can solve the problems of poor solubility and difficulty, and achieve the effects of simple method, guaranteed catalytic efficiency, increased solubility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

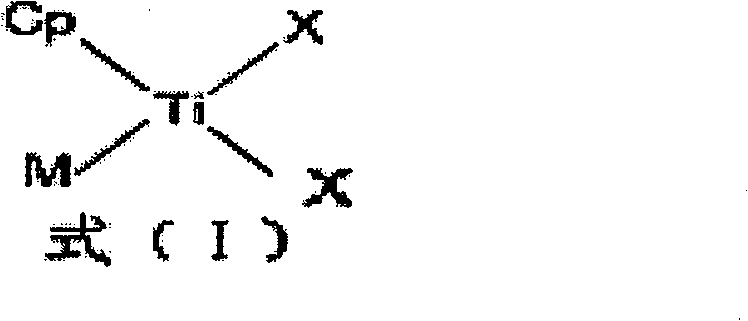

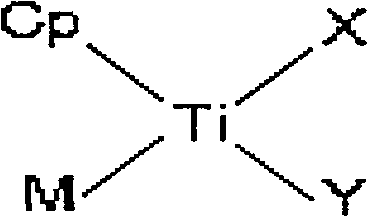

Method used

Image

Examples

Embodiment 1

[0018] Preparation of diisooctyl borate titanium trichloride.

[0019] Add 50 milliliters of hexane, 1.90 grams of TiCl 4 (10 mmol) to 0.025M 3 Nitrogen gas was introduced at the flow rate of / h, and 2.86 g of di-isooctyl borate (10 mmol was diluted with 20 ml of hexane) was added dropwise at a constant speed within 20 minutes, and reacted for 2 hours to generate a red solution. Evaporation of the solvent gave 4.38 g of a reddish-brown liquid. Molecular formula C 16 h 34 BO 3 Cl 3 Ti, the molecular weight is 439.23. Elemental analysis: C (wt%), measured value (theoretical value): 43.70 (43.71); H (wt%), measured value (theoretical value): 7.75 (7.74); chemical analysis: Cl (wt%), measured value (Theoretical value): 24.28 (24.25).

Embodiment 2

[0021] Preparation of diisooctyl borate titanocene dichloride.

[0022] Add 50 milliliters of hexane, 0.2134 grams of 1,2,3,4-tetramethyl-5-trimethylsilyl-cyclopentadiene into a stirred reaction flask of 100 milliliters after anhydrous and oxygen-free treatment, and stir 0.4392 g of diisooctyl borate titanium trichloride (1 mmol) was added dropwise at room temperature, and after the dropwise addition was completed, it was reacted at 65° C. for 24 hours to form a red solution. The precipitate was filtered off, and the solvent was evaporated to obtain 0.5048 g of a reddish-brown liquid. Molecular formula C 25 h 47 BO 3 Cl 2 Ti, the molecular weight is 525. Elemental analysis: C (wt%), measured value (theoretical value): 57.18 (57.14); H (wt%), measured value (theoretical value): 8.96 (8.95); chemical analysis: Cl (wt%), measured value (Theoretical value): 13.53 (13.52).

Embodiment 3

[0024] Preparation of Diisooctyl Dichloromonoindene Titanium Borate.

[0025] Add 50 ml of hexane, 0.2068 g of 5-trimethylsilyl-indene (1.1 mmol) hexane to a 100 ml stirred reaction flask that has been treated with anhydrous and anaerobic treatment, to suspend the turbid and turbid liquid, and drop it at room temperature under stirring. Add 0.4754 g diisooctyl borate titanium trichloride (1 mmol), and react at 65° C. for 24 hours after the dropwise addition to form a red solution. The precipitate was filtered off, and the solvent was evaporated to obtain 0.4302 g of a reddish-brown liquid with a yield of 77.5%. Molecular formula C 25 h 41 BO 3 Cl 2 Ti, the molecular weight is 519. Elemental analysis: C (wt%), measured value (theoretical value): 57.83 (57.81); H (wt%), measured value (theoretical value): 7.89 (7.90); chemical analysis: Cl (wt%), measured value (Theoretical value): 13.70 (13.68).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com