Layered perovskite type catalyst compounding method and composite catalyst

A composite catalyst and perovskite-type technology, which is applied in the direction of heterogeneous catalyst chemical elements, catalyst protection, chemical instruments and methods, etc., can solve the problems of perovskite-type catalysts such as easy poisoning and deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

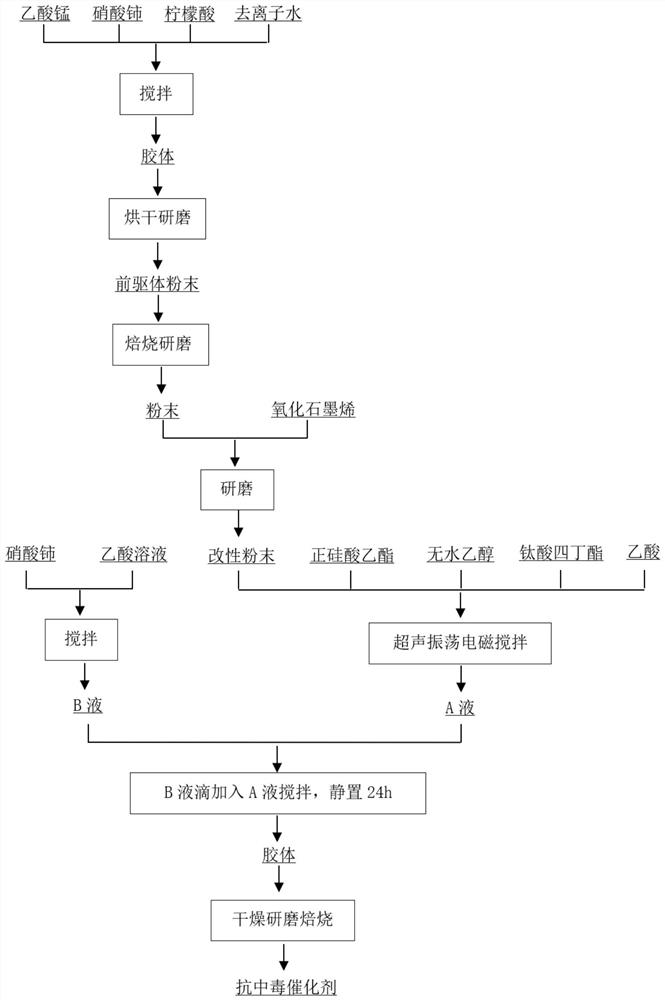

[0048] A kind of layered perovskite type catalyst composite method of the present embodiment, its specific preparation process is as follows:

[0049] Step 1, preparation of perovskite type composite oxide powder.

[0050] (1) Preparation of powder precursor: Weigh 0.1mol of cerium nitrate, 0.1mol of manganese acetate and 0.15mol of citric acid and dissolve them in 1000ml of deionized water. After completely dissolving, stir at 90°C at a speed of 250r / min, and stir the mixture for 4h It appears as a colloid, baked in an oven at 105°C for 24 hours to obtain a dry precursor, and grinds the dried precursor powder to obtain a precursor powder with a mesh size of less than 400;

[0051] (2) Precursor calcination: The precursor powder is roasted in a muffle furnace, and the temperature is raised to 300°C at a heating rate of 10°C / min in an air atmosphere, kept for 1h, and then heated to 1000°C at a heating rate of 2°C / min. ℃ and keep it warm for 2 hours, after the heat preservation...

Embodiment 2

[0077] This embodiment is used as a benchmark experiment, and the experimental process of this comparative example is the same as that of Example 1, except that: (4) powder modification in step one is not adopted, and all steps of step two are not adopted. The experimental results are recorded in Table 3 as a benchmark for later experiments.

[0078] table 3

[0079]

Embodiment 3

[0081] The experimental process of this embodiment is the same as that of Example 1, except that: (4) powder modification in step 1 is not used, and cerium nitrate is not added in the preparation of mixed solution B in step 2 (2). The experimental results are recorded in Table 4.

[0082] Table 4

[0083]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com