A kind of magnetic sandwich structure metal-organic framework material and its preparation method

A metal-organic framework and sandwich technology, applied in the direction of alkali metal compounds, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of poor regeneration performance of materials, achieve strong adsorption capacity, avoid loss, strong adsorption and immobilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

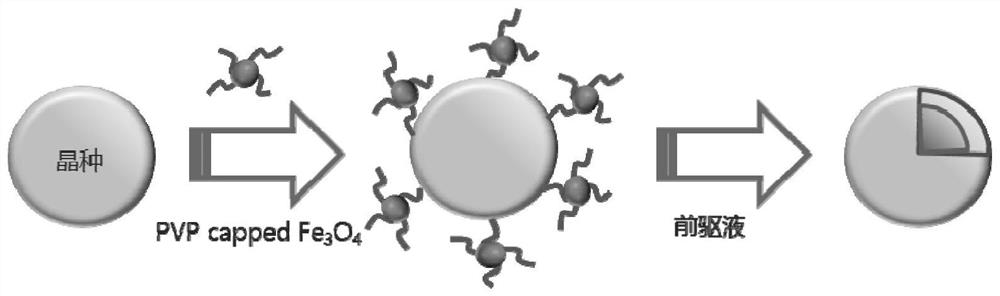

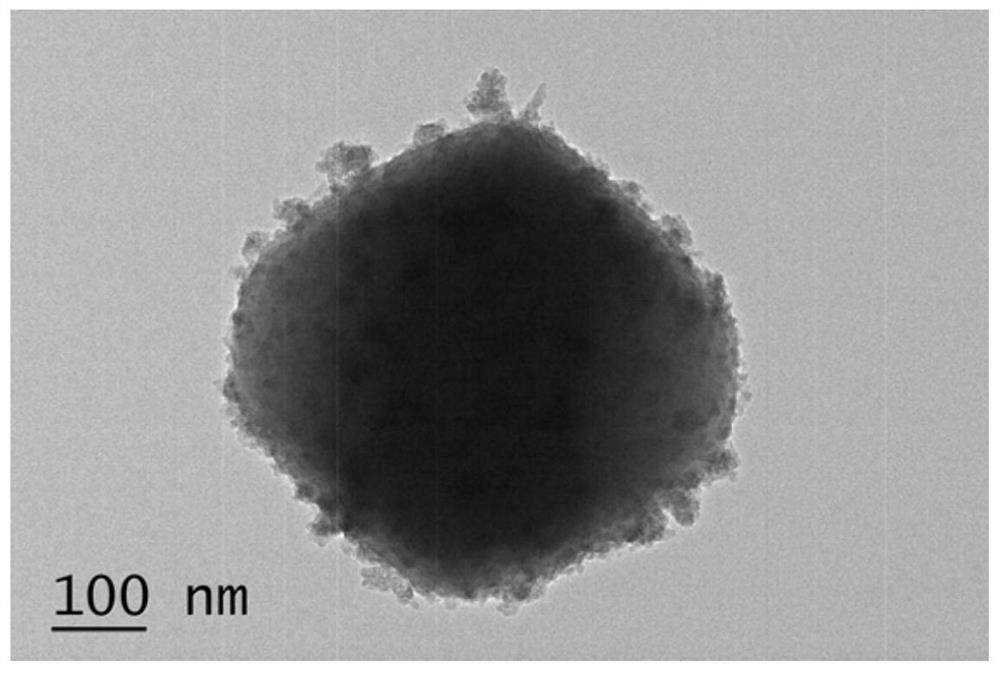

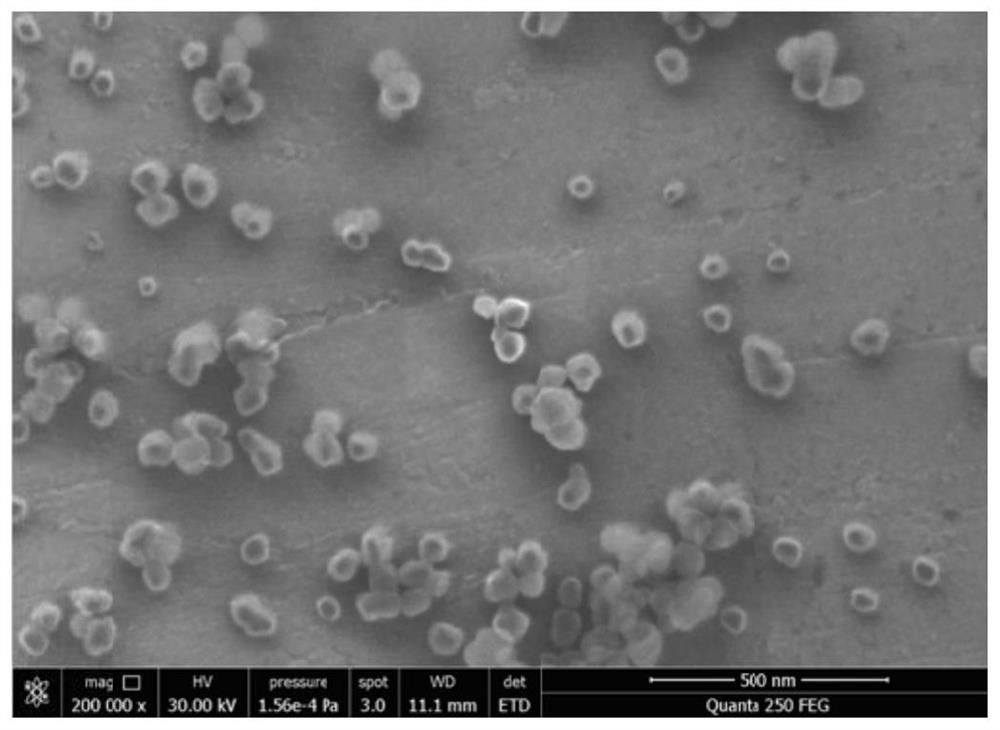

[0042] The preparation process of the magnetic sandwich structure metal-organic framework in this example includes the following steps:

[0043] 1) Dissolve 334mg of anhydrous zirconium chloride and 250mg of terephthalic acid in 100mL of N,N-dimethylformamide, add 5mL of acetic acid, and continue heating at 120°C for 24 hours in a hydrothermal reactor. The particles obtained from the reaction were washed with N,N-dimethylformamide and centrifuged three times. Washing with methanol three times, each time for 24 hours, and vacuum drying at 150° C. for 12 hours to obtain UiO-66 particles, using the UiO-66 particles in step 1) as the inner core of the metal-organic framework with a sandwich structure;

[0044] 2) Dissolve 1.625g of anhydrous ferric chloride and 1g of trisodium citrate in 76mL of polyethylene glycol and 4mL of ethylene glycol solution. Add 4.1g of anhydrous sodium acetate to the solution, heat and stir in an oil bath at 120°C for 1 hour, place the resulting soluti...

Embodiment 2

[0055] The removal of tetracycline hydrochloride by using the magnetic sandwich structure metal-organic framework prepared in this example comprises the following steps:

[0056] a) 50mg UiO-66@Fe 3 o 4 @UiO-66 particles were added to 100mL tetracycline hydrochloride solution with a concentration of 1mg / L, shaken at 180rpm for 24 hours, after adsorption saturation, the particles were recovered by a magnet, and the surface layer of the particles was washed with water. Detect the concentration of tetracycline hydrochloride remaining in the solution, and the removal rate of tetracycline by the material is 99%;

[0057] b) Add the particles after adsorption in step a) to 100mL of distilled water, adjust the pH to 3.5 with 0.1mmol / L hydrochloric acid, and then add 1mL of 0.2mol / L H 2 o 2 Solution, shaking at 150rpm for 2 hours for Fenton-like reaction; cleaning UiO-66@Fe 3 o 4 @UiO-66 particle surface, dry at 100°C for 12 hours;

[0058] Utilize Fe in the material sandwich st...

Embodiment 3

[0075] The preparation process of the magnetic sandwich structure metal-organic framework in this example includes the following steps:

[0076] 1) Dissolve 334mg of anhydrous zirconium chloride and 250mg of terephthalic acid in 100mL of N,N-dimethylacetamide, add 7mL of acetic acid, and continue heating at 120°C for 24 hours in a hydrothermal reactor. The particles obtained from the reaction were washed with N,N-dimethylacetamide and centrifuged three times. Then wash with ethanol three times, each time for 24 hours, and vacuum-dry at 150°C for 12 hours to obtain UiO-66 particles.

[0077] 2) Dissolve 1.219g of anhydrous ferric chloride and 0.75g of trisodium citrate in 74mL of polyethylene glycol and 8mL of ethylene glycol solution. Add 3 g of anhydrous sodium acetate to the solution, heat and stir in an oil bath at 120° C. for 1 hour. The resulting solution was placed in a hydrothermal reactor and heated at 180°C for 12 hours. Wash with ethanol, centrifuge, and vacuum dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com