Automatic positioning coil winder

An automatic positioning and reel technology, which is applied to the arrangement of the take-up reel/photosensitive drum, and the device that can bend the lead wire. The problem of messy knots and shortening the service life of the reel can achieve the effect of avoiding collision, stable and reliable multi-point positioning, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following preferred embodiments of the automatic positioning cord reel of the present invention do not limit the scope of protection of the present invention.

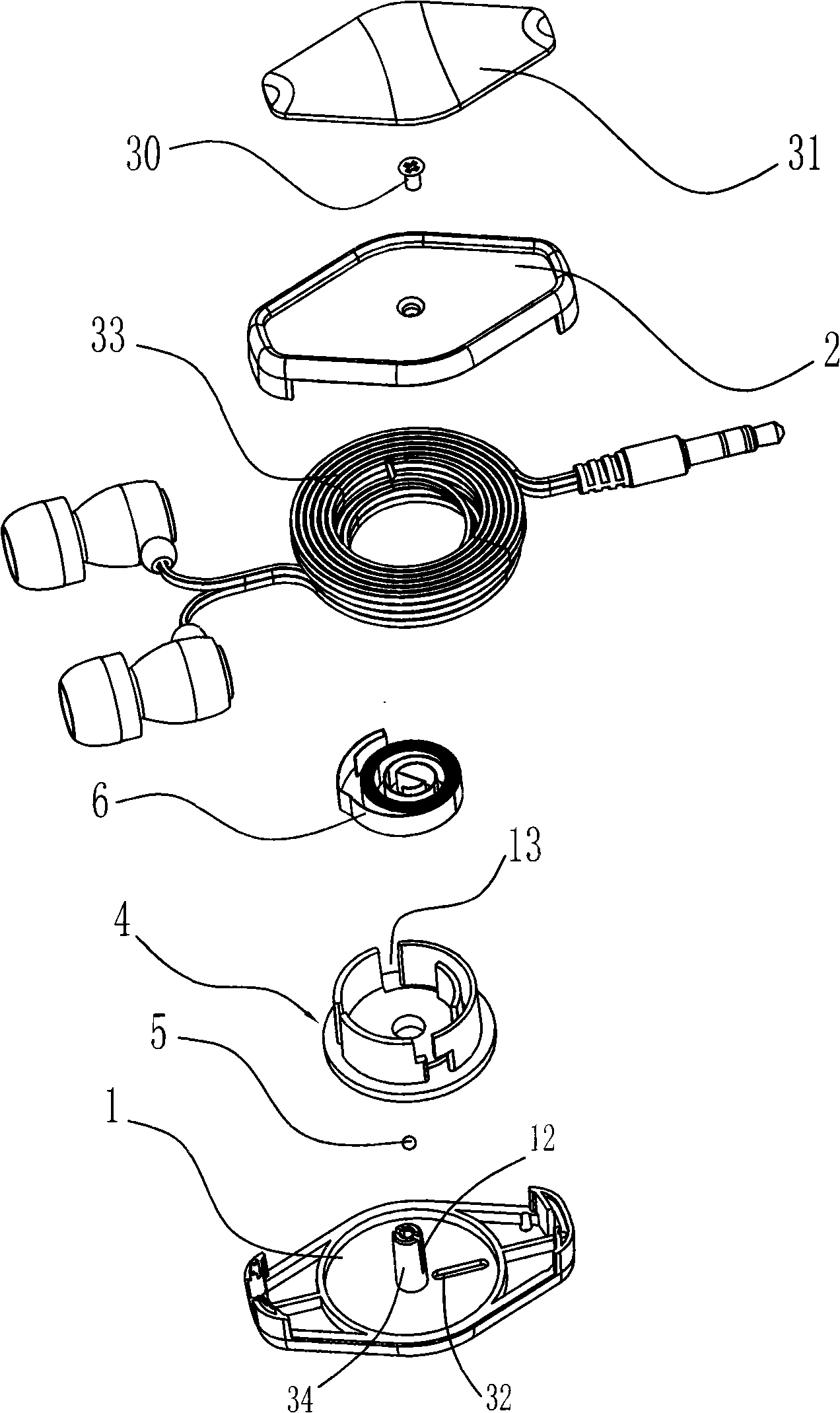

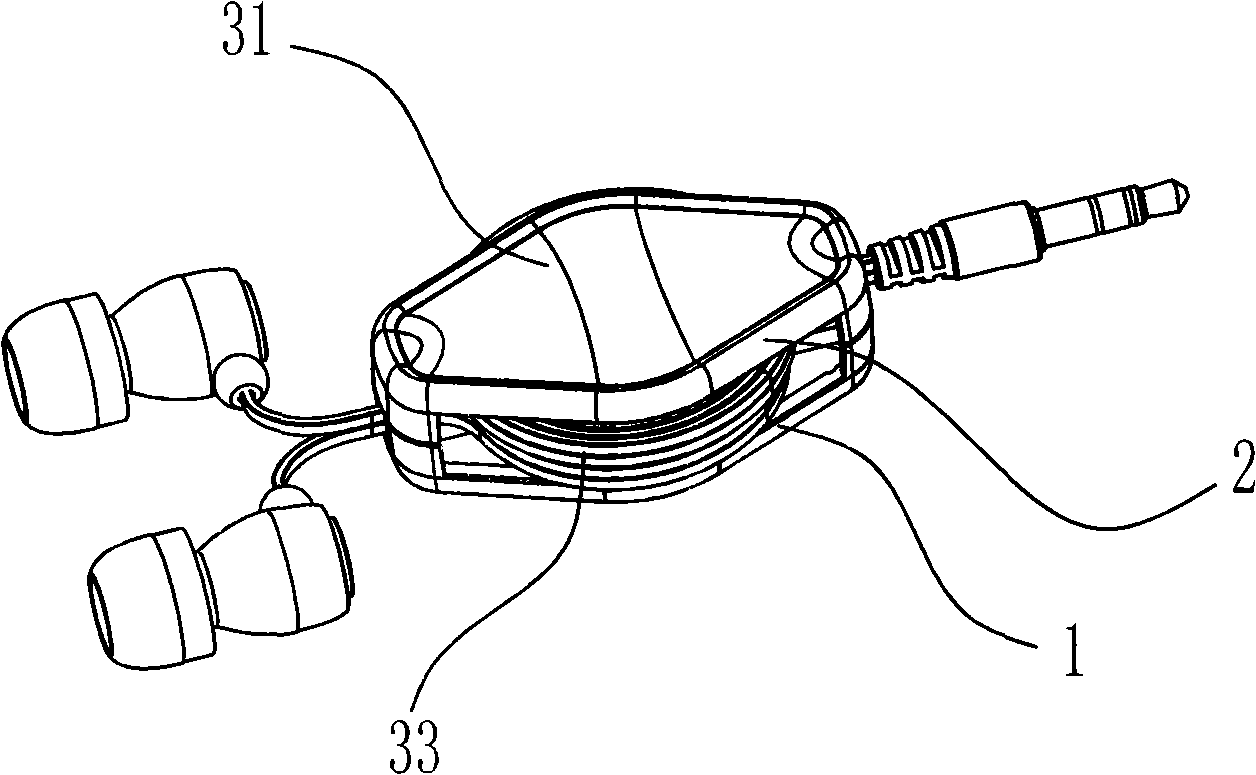

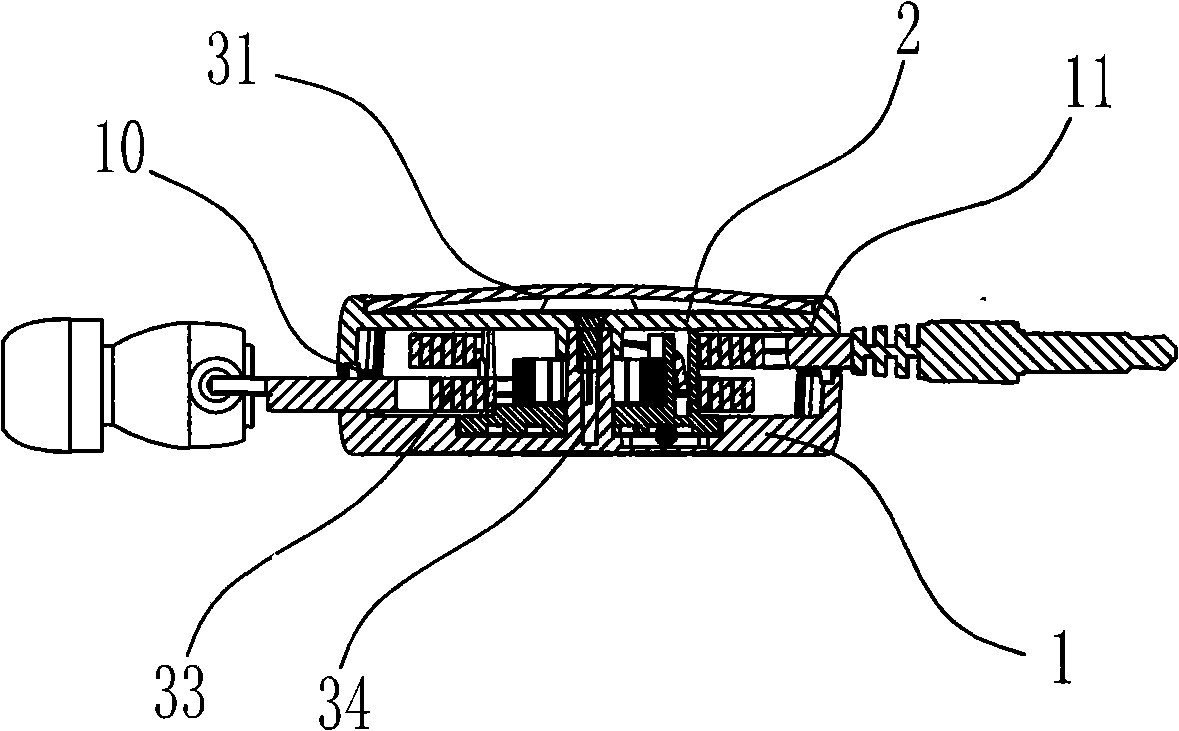

[0019] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , providing an automatic positioning cord reel, including a lower cover 1, an upper cover 2 fixedly connected to the lower cover 1, a cord winding device 3 arranged between the lower cover 1 and the upper cover 2, and a cord reel 3 arranged between the lower cover 1 and the upper cover 2 The wire inlet and outlet holes 10 on one side wall, and the wire inlet and outlet holes 11 on the other side wall, the wire winding device 3 is a center column 34 arranged at the center of the upper part of the lower cover 1, and a runner sleeved on the center column 34 4. The brake member 5 installed on the upper part of the lower cover 1 is composed of a vortex spring 6 arranged in the runner 4. The bottom of the runner 4 has an annular groove 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com