Spherical bearing arrangement

A spherical bearing, spherical bearing technology, applied in the direction of bearings, shafts and bearings, bearing components, etc., can solve problems such as the use of interference fit bushings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

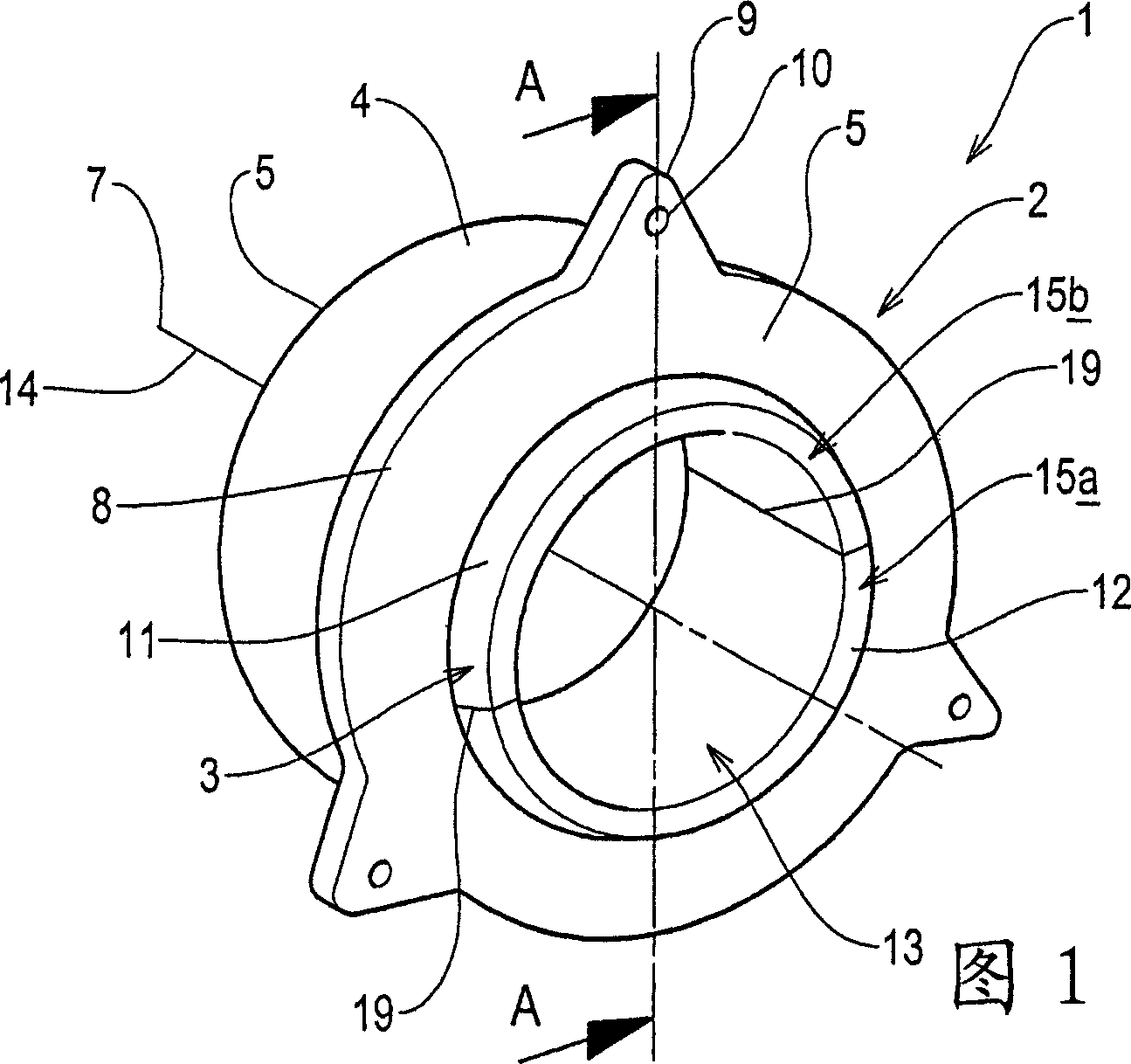

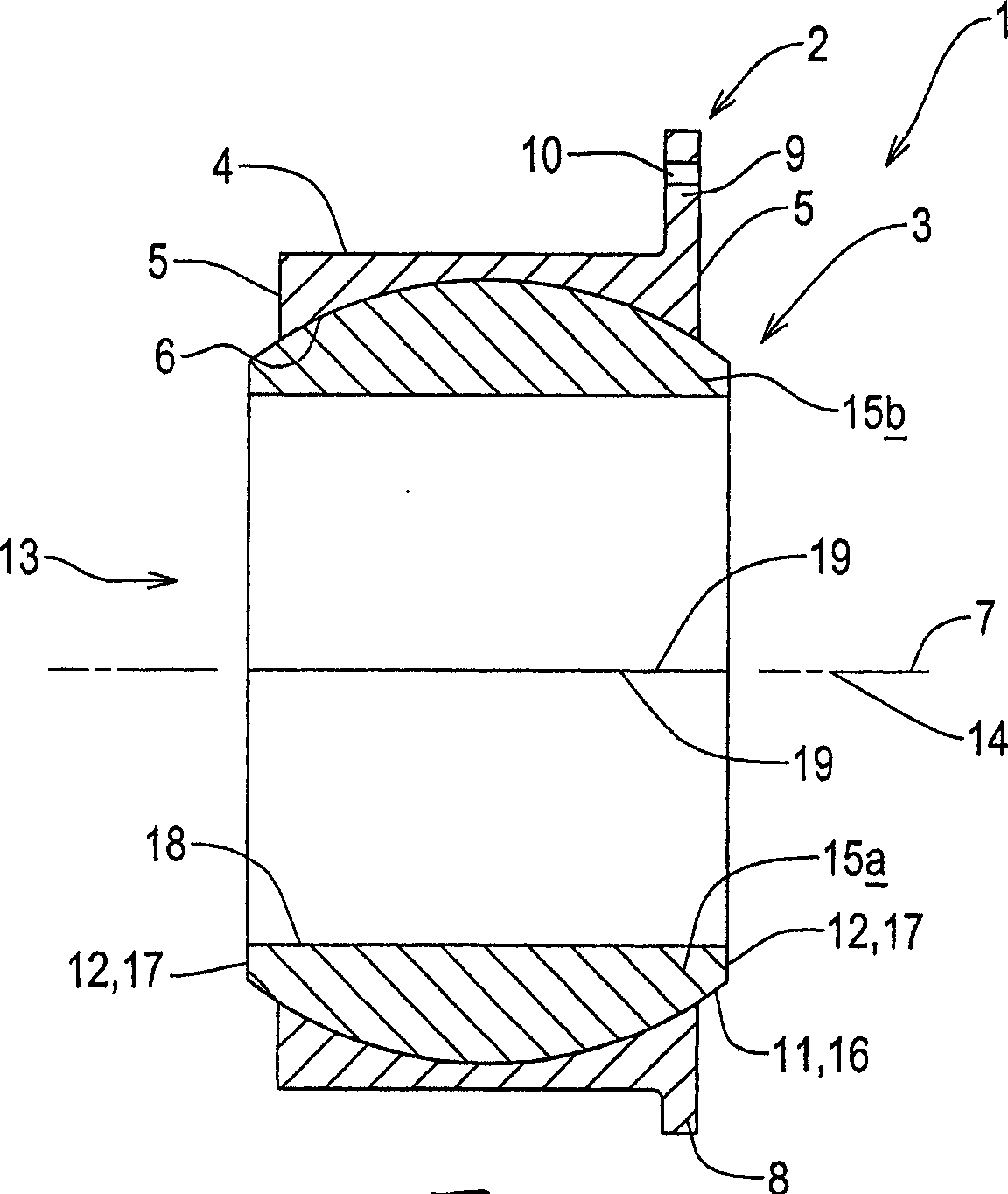

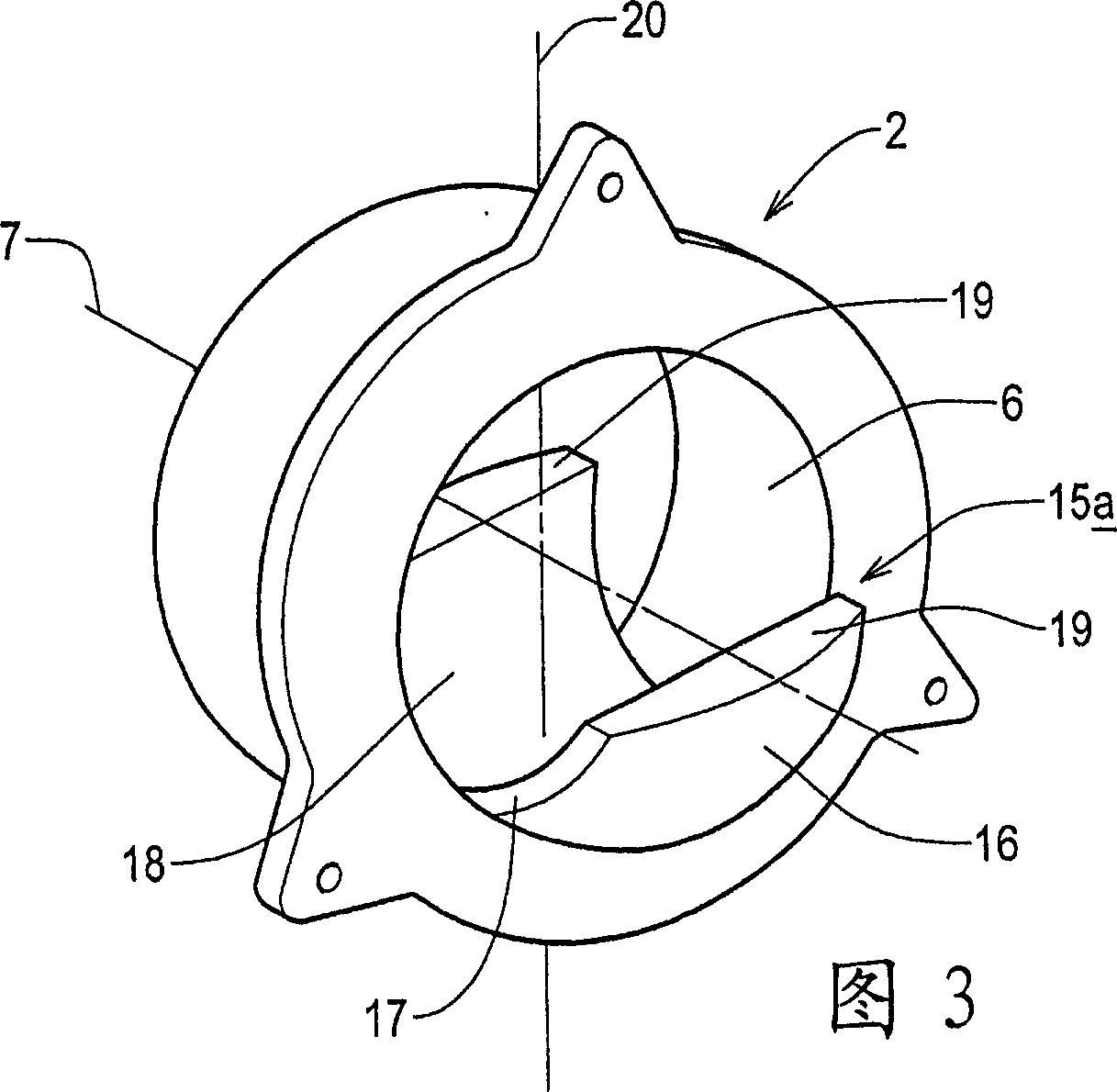

[0030] Figure 1 and figure 2 Shown is a spherical bearing arrangement 1 comprising a bearing housing 2 in which a composite sphere 3 is mounted. The bearing seat 2 is substantially annular and comprises: a cylindrical outer surface 4 ; two axial end faces 5 ; and an inner surface comprising a spherical bearing seat support surface 6 . The bearing housing 2 also has a central axis 7 . The bearing seat 2 has a circumferential, radially extending flange 8 which approaches the axial end face 5 of the bearing seat 2 . The flange 8 has three equally spaced lugs 9 each protruding from the flange 8 . Each equally spaced lug 9 is provided with a hole 10 through which a bolt or the like can pass to fix the bearing housing 2 to another object via the lug 9 .

[0031] The composite sphere 3 is substantially spherical in shape and is provided with: a spherical composite sphere bearing surface 11 ; two axial end faces 12 ; and a hole 13 with a central axis 14 . The combined ball bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com