Reinforcement cage for drilled press-grouting piles and molding device thereof

A technology of forming device and reinforcement cage, which is applied in application, sheet pile wall, household appliances, etc., can solve the problems of destroying the continuity of concrete layer and insufficient structural strength at the connection of reinforcement cage units, and achieves convenient assembly, simple structure, and improved The effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

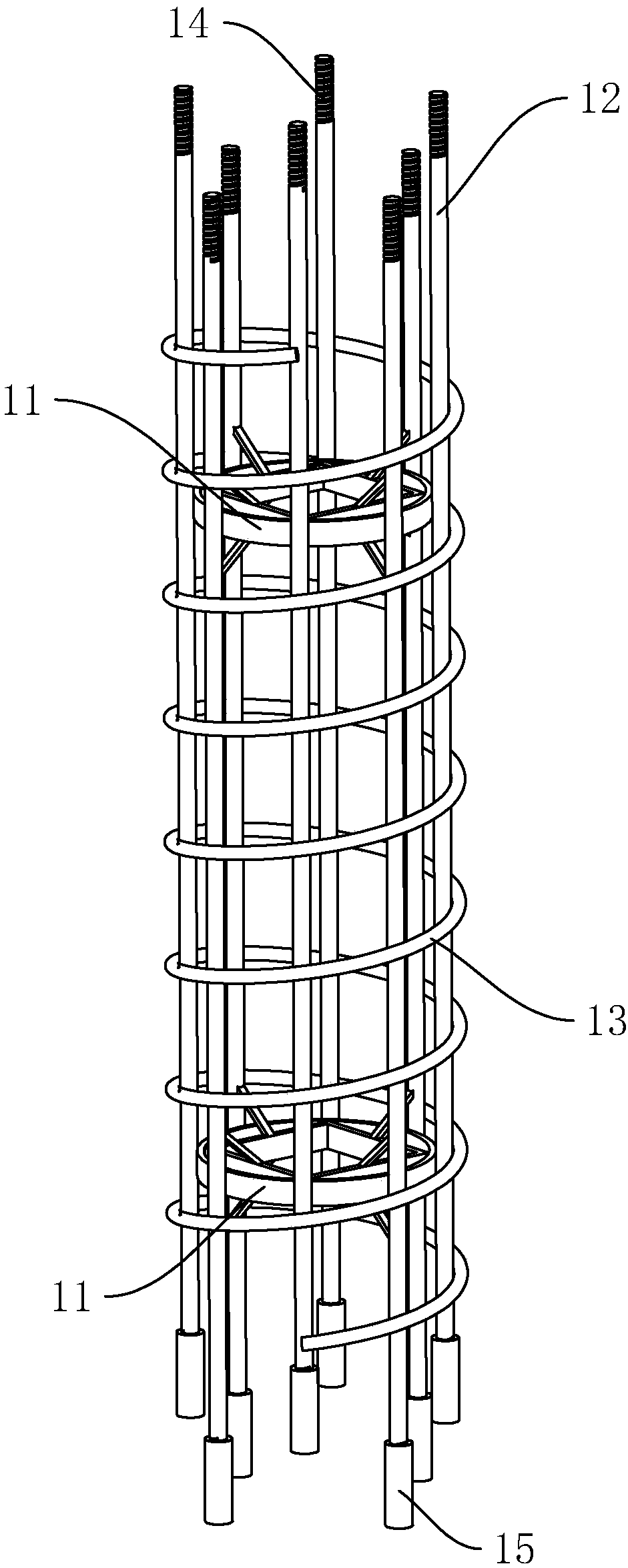

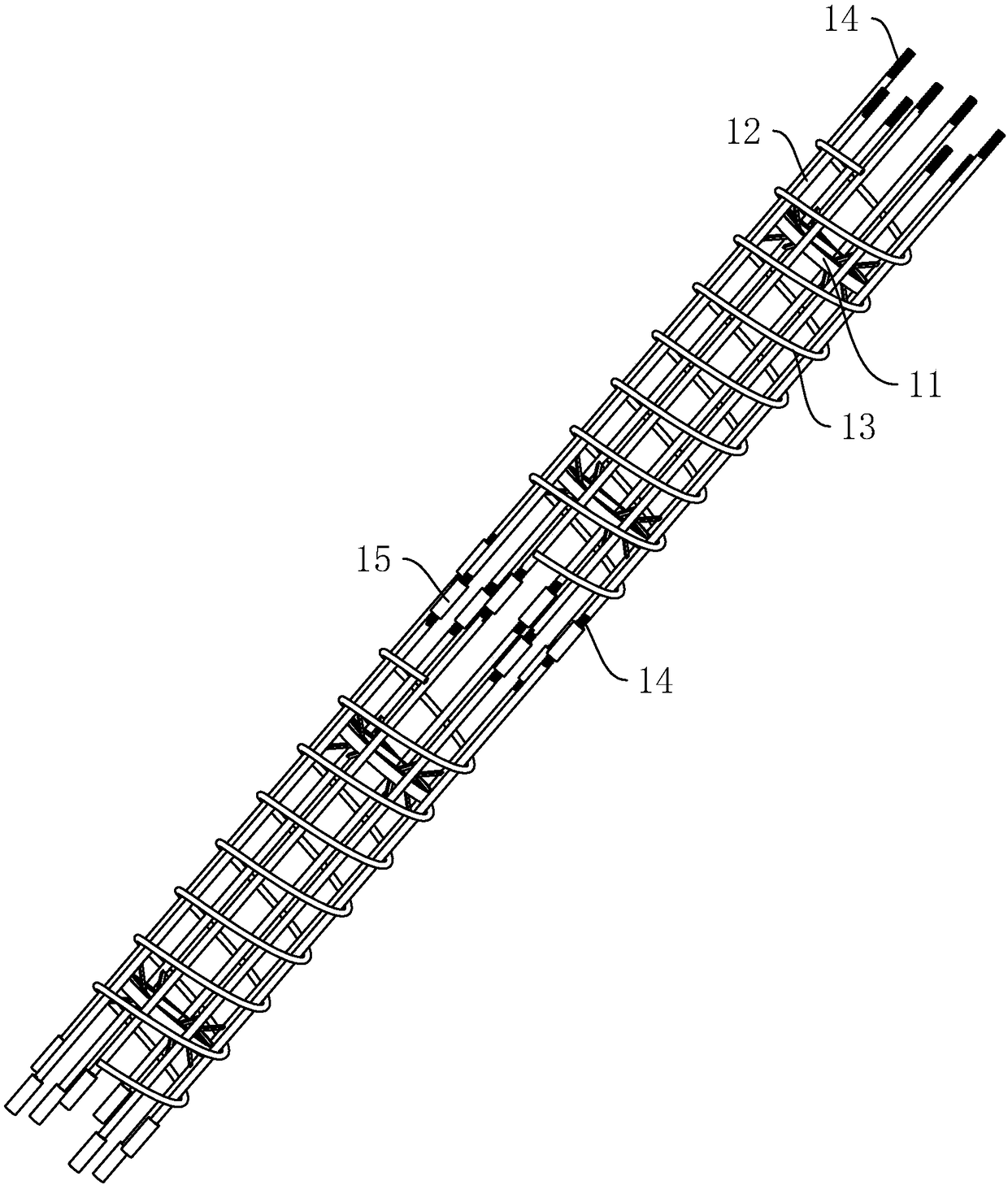

[0045] Example 1: Reinforcement cage used for bored piles, such as figure 1 As shown, it includes at least two steel cage units, which are connected end to end. The steel cage unit includes two stiffening hoops 11 arranged oppositely, eight main steel bars 12 welded and fixed to the two stiffening hoops 11 at the same time, and spiral coils. Spiral hoops 13 wound around eight main steel bars 12 and welded and fixed. Each main steel bar 12 is provided with external threads 14 at the upper and lower ends. The lower external threads 14 are threaded with a connecting sleeve 15, and the upper and lower ends of the connecting sleeve 15 are For the opening structure.

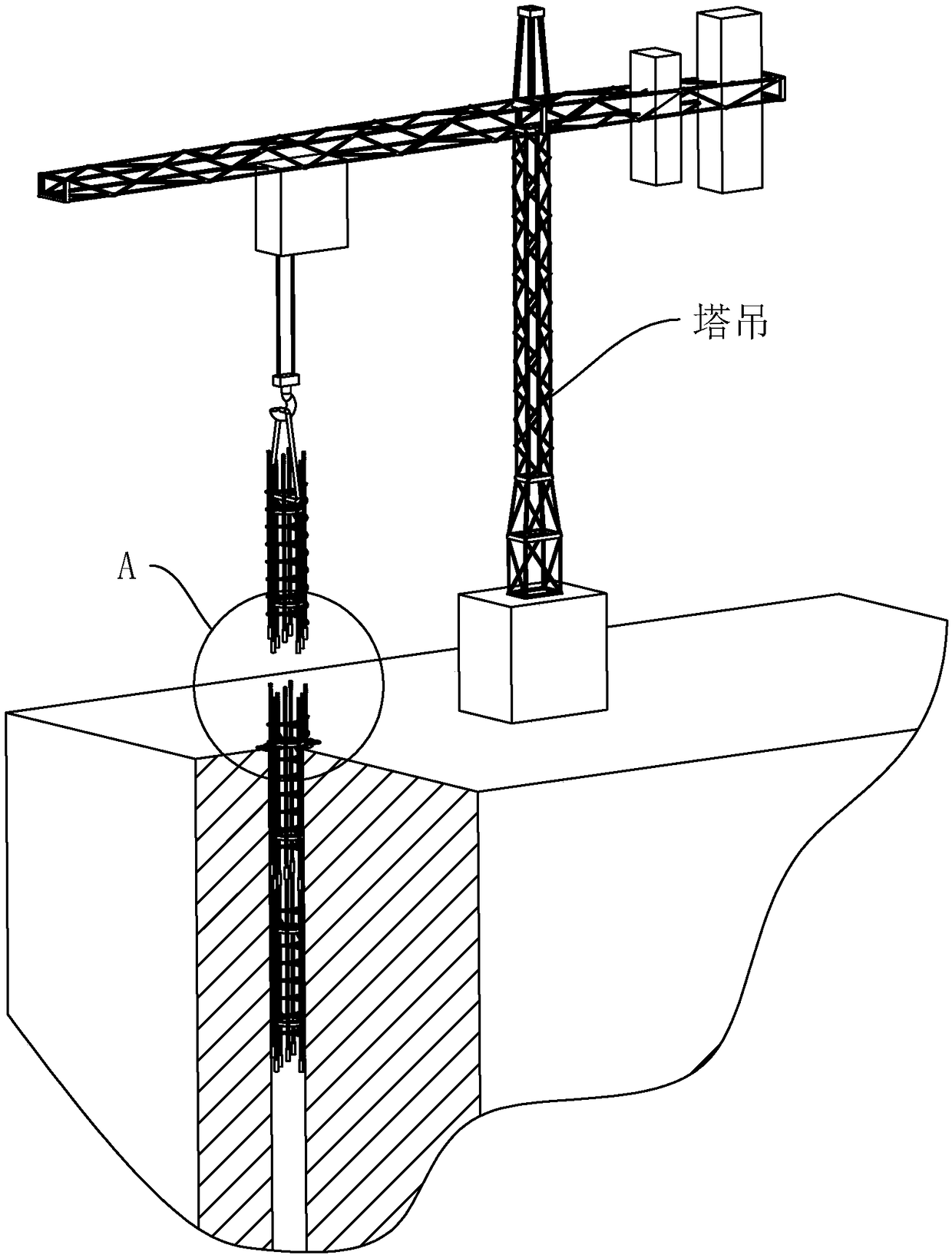

[0046] When the pile hole is drilled and the reinforcement cage needs to be buried, such as Figure 2-4 As shown, the first steel cage unit is vertically hung by a tower crane. When the first steel cage unit is lowered to the upper stiffener 11 and 10 cm from the ground, the suspension stops, and two rectangular steel bar...

Embodiment 2

[0051] Example 2: Molding device, such as Figure 8-10 As shown, it includes two horizontal guide rails 2, a fixing frame 21 fixedly arranged at one end of the horizontal guide rail 2, a sliding frame 22 sliding along the horizontal guide rail 2 and a hoop mechanism; the fixing frame 21 is rotatably connected with a disc 23 with a round surface There are eight sockets 24 for inserting and mating with the main steel bars 12; the sliding frame 22 is rotatably connected with a turntable 27, the turntable 27 is opposite to the circular surface of the disk 23, and eight main steel bars 12 are welded and fixed along the circumference of the turntable 27. The plug sleeve 28 passing through, the plug sleeve 28 and the socket 24 correspond one-to-one; the circular disc 23 and the turntable 27 are respectively horizontally provided with extension posts 25 at the center of the circle, and the adjacent ends of the two extension posts 25 are respectively welded and fixed with four The arm 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com