Packaging method for bonding-wire-free high-color-rendering-index LED lamp filaments and bonding-wire-free high-color-rendering-index LED lamp filaments

A technology of LED filament and packaging method, which is applied in the direction of electrical components, electric solid devices, circuits, etc., which can solve the problems of product display and phosphor excitation efficiency reduction, poor heat dissipation and reliability, and low product yield, so as to improve packaging Reliability and production yield, improve product reliability, reduce the effect of LED leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A packaging method for a wire-free high CRI LED filament, comprising:

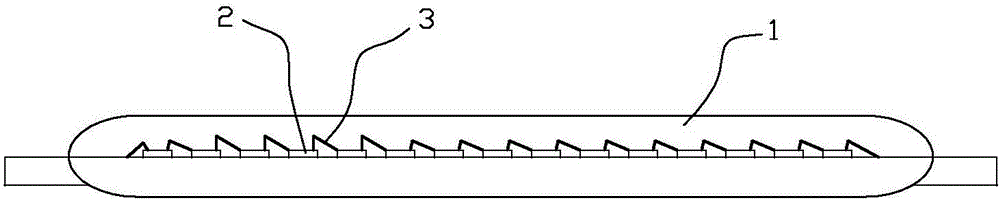

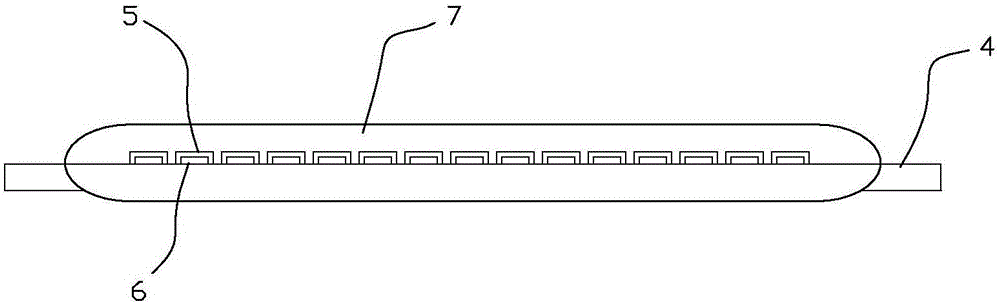

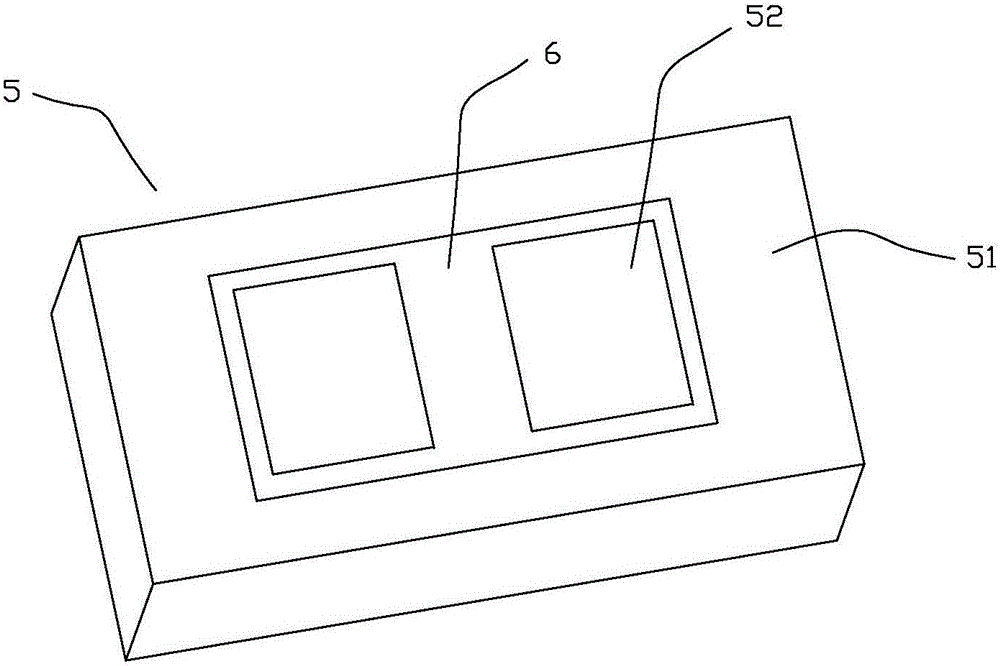

[0028] Step a: the manufacture of a small package 5; the small package 5 is formed by uniformly coating a layer of fluorescent glue that is geometrically shaped and only contains red phosphor powder on the surface of the flip chip 6 except for the welding surface of the welding electrode 52. Made, the fluorescent glue that only contains red fluorescent powder is coated on the surface of flip-chip 6 to form inner fluorescent glue 51 (see attached image 3 , 4 ); the two welding electrodes 52 are eutectically welded on the flip chip 6, and the outer surface of the flip chip except the welding surface of the welding electrode is coated with only red phosphor by methods such as molding (plastic encapsulation), rubber cake pressing, etc. The fluorescent glue, so that the light emitted by the flip chip first enters the fluorescent glue containing the red phosphor to excite the red phosphor;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com