Method for selectively depositing atom layer to film by spray head device

An atomic layer deposition and selective technology, applied in the coating, metal material coating process, gaseous chemical plating and other directions, can solve the problem of unable to grow thin film, can not form the region selection and other problems, to save photoresist, The effect of saving glue and saving expensive costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

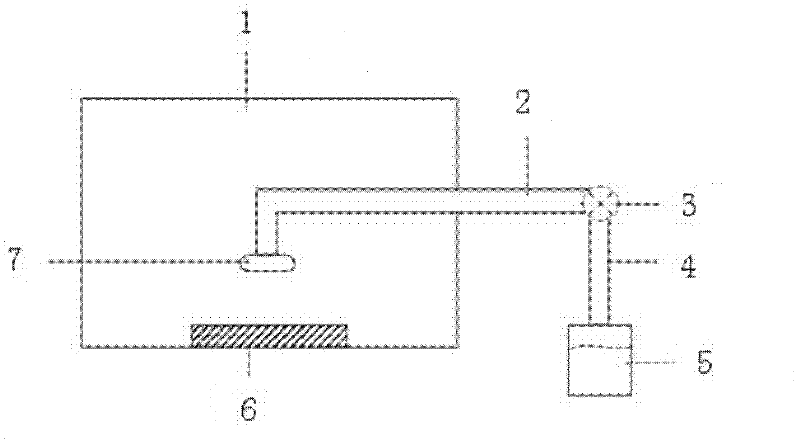

[0019] refer to figure 1 , a device used in the method of selective atomic layer deposition film formation with a nozzle device, the device includes a pretreatment reaction chamber 1, the bottom of the chamber 1 is equipped with a substrate 6, and the surface treatment source 5 passes through the delivery pipeline 4 and the source valve 3 In communication, the source valve 3 is connected to one end of the manipulator 2, and the other end of the manipulator 2 is equipped with a nozzle 7.

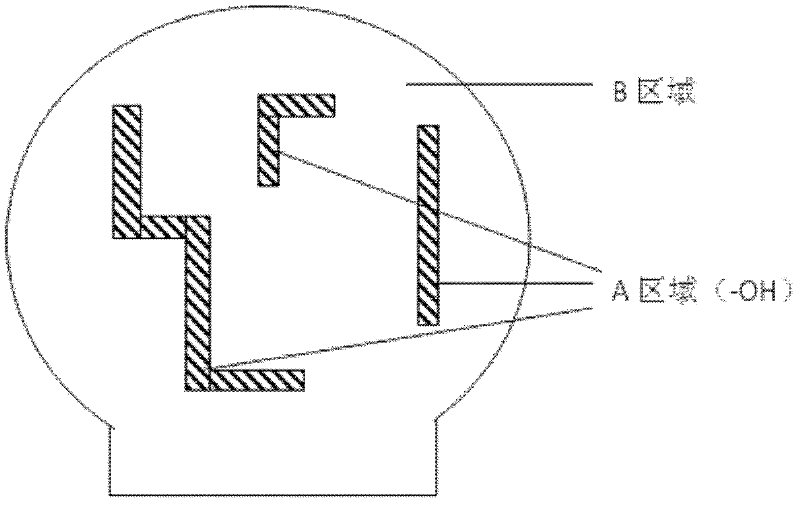

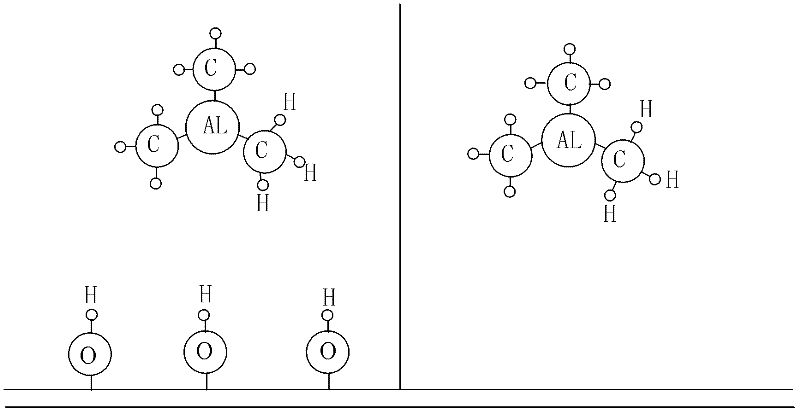

[0020] The method first sprays the surface treatment material source (alcohol) onto the surface of the substrate with a nozzle according to the designed circuit trajectory, and then passes the substrate into the precursor trimethylaluminum (Al(CH 3 ) 3 ) and precursor water (H 2 O), then Al is formed in the region of the substrate A 2 o 3 thin film, no thin film grows in area B.

[0021] Its specific methods and steps are:

[0022] 1. Clean the substrate and put it into the pretreatment...

Embodiment 2

[0033] Use the nozzle to spray the surface treatment material source on the surface of the substrate according to the designed circuit to make the circuit area and other areas have different conductivity. Access (CH 3 CH 2 ) 2 M (M represents a metal element) or M-N-(CH 3 ) 2 (M stands for metal elements) two precursors, these two precursors tend to adsorb on the surface area of the substrate with high conductivity, and grow a film on the surface, while the non-conductive surface area does not undergo any reaction, thus A method for realizing selective atomic layer deposition film formation by using a shower head device.

Embodiment 3

[0035] Use a nozzle to spray a polarized surface treatment material source on the surface of the substrate according to the designed circuit, so that the circuit area and other areas have different polarities. Access M-O-CH 3 (M stands for metal element) or M-OC 2 h 5 (M represents a metal element) two precursors, these two precursors tend to be adsorbed on the polar surface area of the substrate, and do not react with the non-polar surface area, so they react to form a film in the polar line area , to realize the method of selective atomic layer deposition film formation with shower head device.

[0036]The method of using nozzle device to realize selective atomic layer deposition film formation can be controlled by computer to move the nozzle or the substrate, use the nozzle device to pretreat the surface of the substrate, and directly spray the required lines on the surface of the substrate, so that different regions have different reaction characteristics . By select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com