Mobile mortar production equipment

A kind of production equipment and mobile technology, applied in the direction of clay preparation equipment, mixing operation control, mixing plant, etc., can solve the problems of long construction period, troublesome dismantling and transition, prefabricated foundation, etc., achieve high-quality anti-corrosion and anti-rust performance, and ensure anti-corrosion Anti-rust performance and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

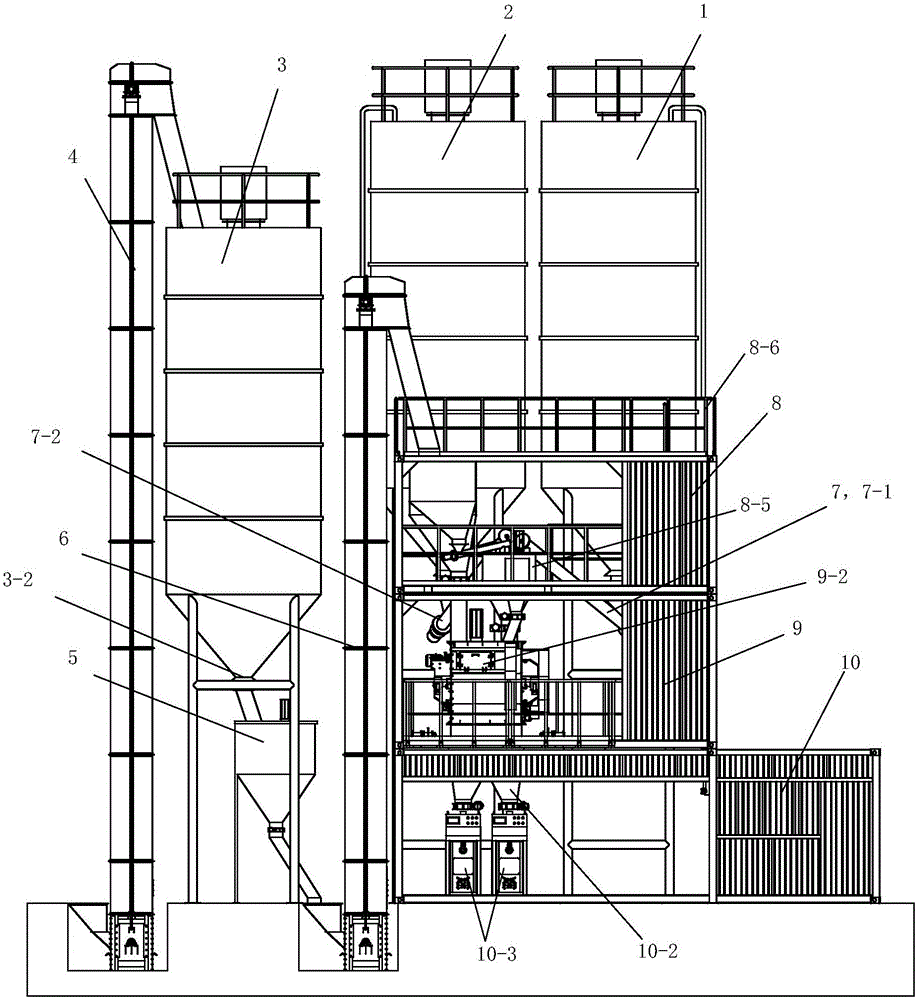

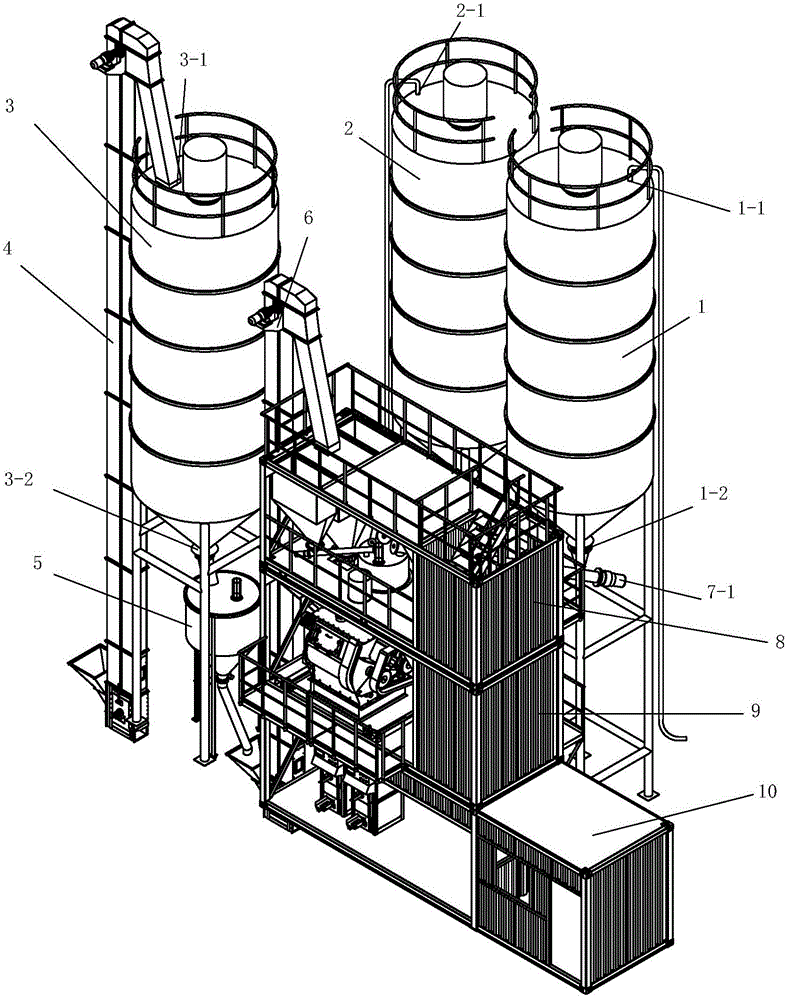

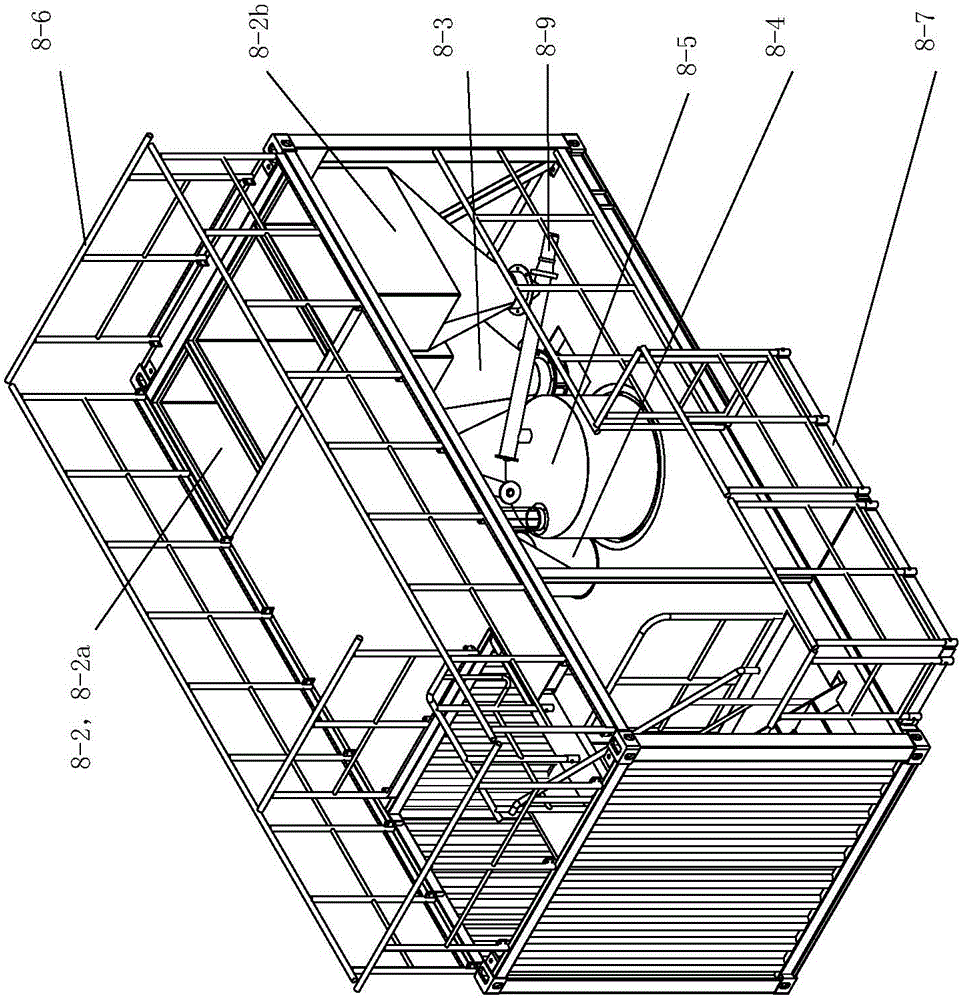

[0049] See figure 1 with figure 2 , according to the mortar production process: raw material storage ----- raw material proportioning and weighing -- mixing treatment ----- packaging, the movable mortar production equipment of the present invention mainly includes a metering box 8 and a mixing box 9 And packing control box 10, can coordinate corresponding fly ash bin 1, cement bin 2, sand bin 3, sand bin elevator 4, sand metering scale 5, metering sand elevator 6 and screw conveyor 7 on the site during use.

[0050] See figure 1 with figure 2 , the fly ash bin 1 is vertically suspended on the ground through a corresponding installation frame. The upper end of the fly ash bin 1 is provided with a fly ash feed port 1-1, and the lower end of the fly ash bin 1 is provided with a fly ash discharge port 1-2. The fly ash is directly pumped into the fly ash bin 1 by the corresponding pump truck and the corresponding pipeline through the fly ash feeding port 1-1 at the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com