Fabricated toilet construction method in hospital ward

A bathroom and prefabricated technology, applied in cable installation, building construction, construction, etc., can solve the problems of easy leakage, construction period, many wet operations, and large number of installations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further illustrated by specific examples below.

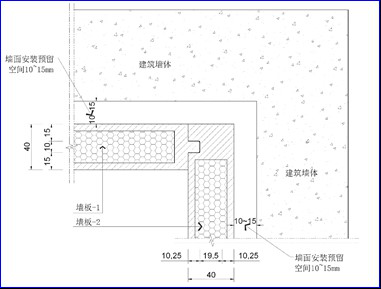

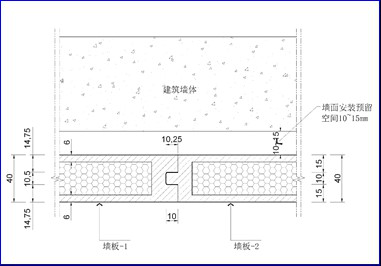

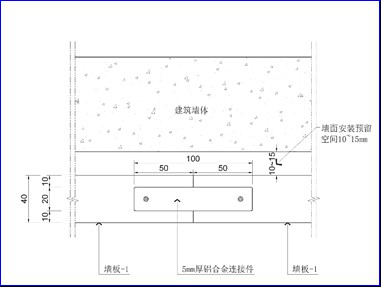

[0037] like Figure 1 to Figure 9 As shown, a construction method of a prefabricated toilet in a hospital ward, including

[0038] Step 1. Positioning and laying out:

[0039] Step 1.1. Carry out in-depth design and factory processing according to the actual size of the on-site measurement feedback, and decompose the ward bathroom into several sections, including waterproof floor, waterproof wall panel, plumbing, electrical and mechanical pipelines, ceiling, and sanitary ware parts;

[0040] Step 1.2. After the location of the waterproof platform is determined, install the rest of the plates according to the location of the platform; install the waterproof wall panels, plumbing and electrical pipelines, ceilings, and sanitary ware parts in sequence. After each plate is installed, seal the gaps with sealant. deal with;

[0041] Step 1.2.1. During the installation process, locate according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com