Pressure pad device for pressure machinery

A pressure pad and mechanical technology, applied in the direction of presses, fluid pressure actuators, mechanical equipment, etc., can solve the problems of high cost of pits, high production costs, heavy economic burdens on enterprises, etc., to reduce gas source consumption , save manufacturing cost, reduce the effect of using cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

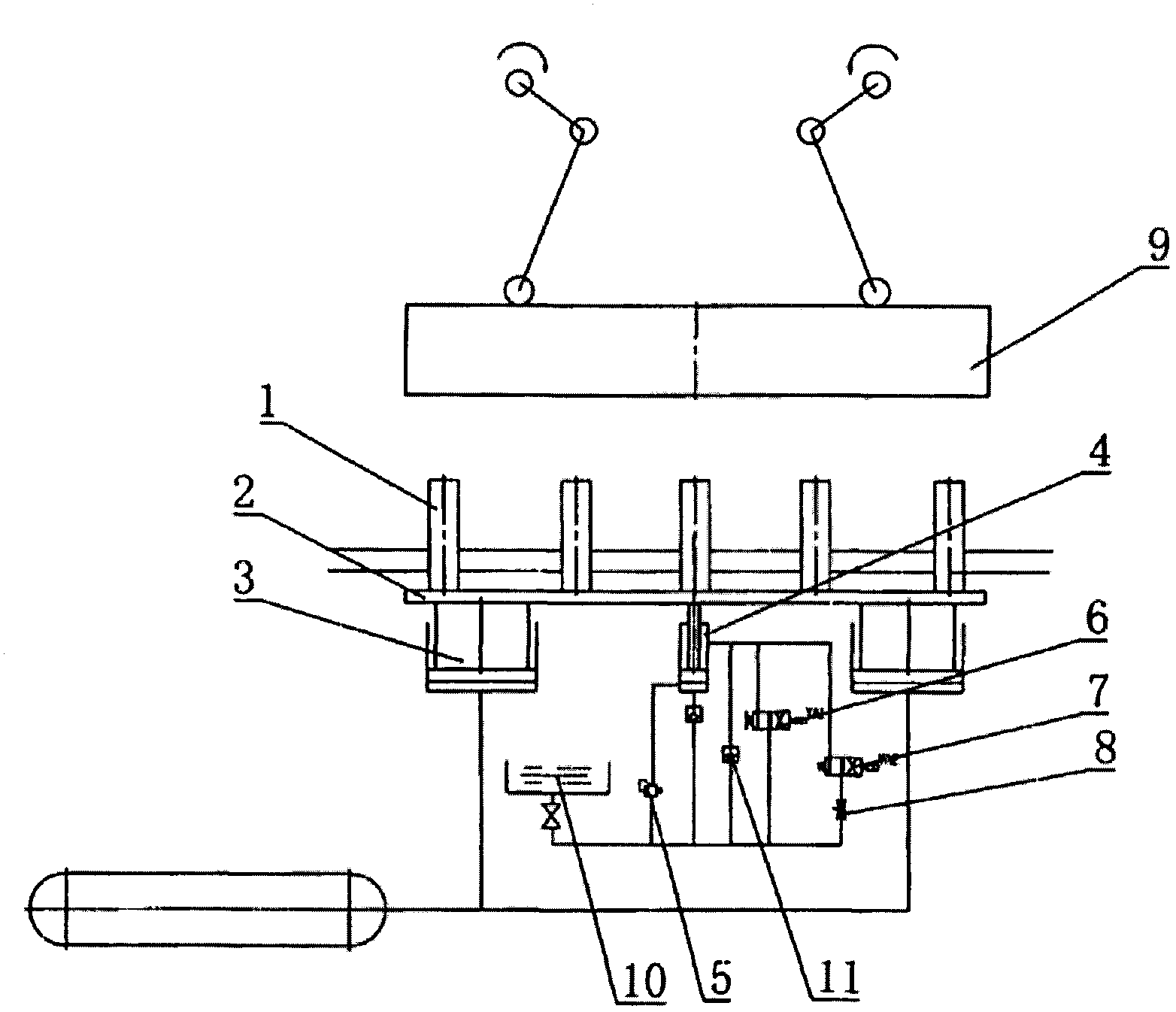

[0010] As shown in the figure, a pressure pad device of a press machine includes a ejector rod supporting plate 2 on which a ejector rod 1 is installed, and a slider 9 is arranged on the top of the ejector rod 1 to cooperate with it for pressing and forming a workpiece. The slider 9 is connected by a crank The rod mechanism drives to do periodic upward and downward movements.

[0011] It also includes a cylinder 3 with a power source and a hydraulic cylinder 4 without a power source. There are two cylinders 3, which are fixed on both sides of the lower end surface of the ejector rod support plate 2. The cylinder 3 is connected with the air compressor air storage tank through a gas pipe.

[0012] The hydraulic cylinder 4 is arranged between the two cylinders 3, and its piston rod is fixedly connected with the ejector support plate 2. The rod chamber and the rodless chamber of the hydraulic cylinder 4 are respectively connected to the oil tank 10 through the oil pipe, and the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com