Patents

Literature

30results about How to "Reduced lifting requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

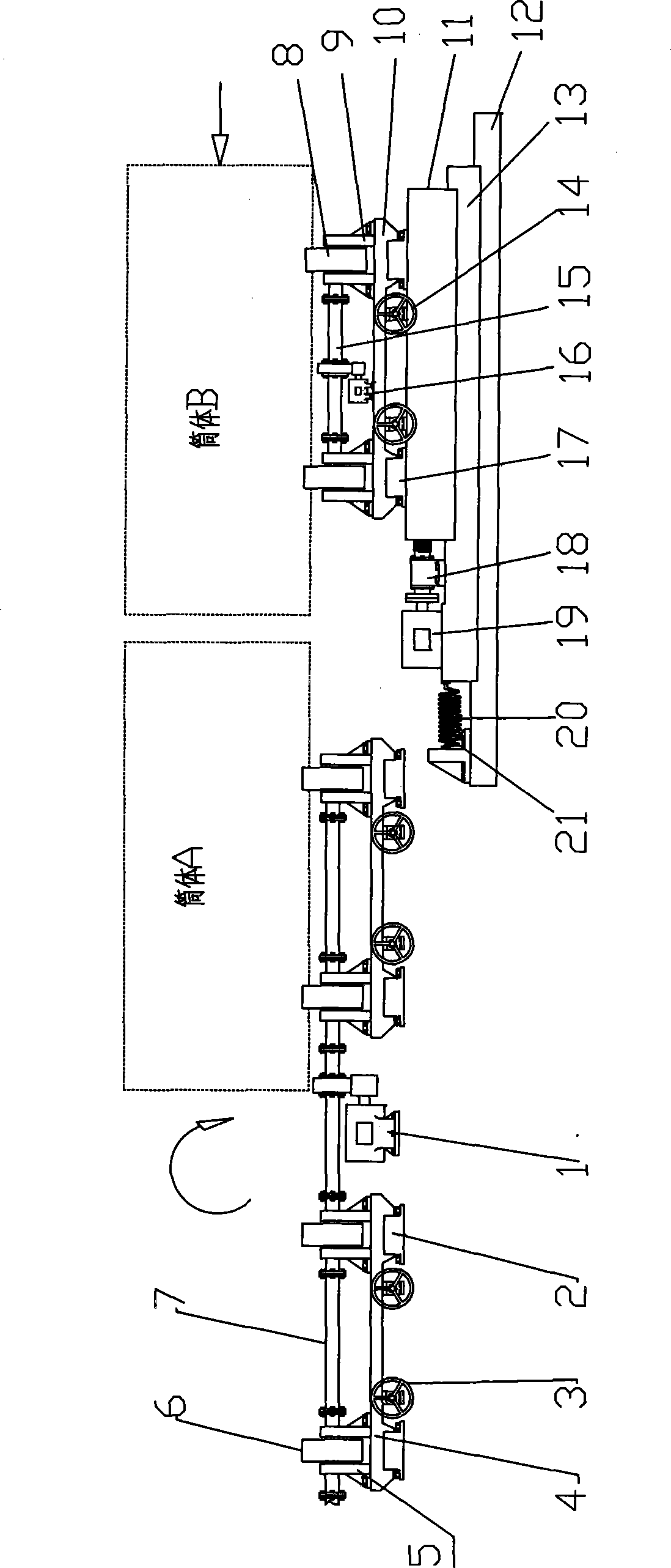

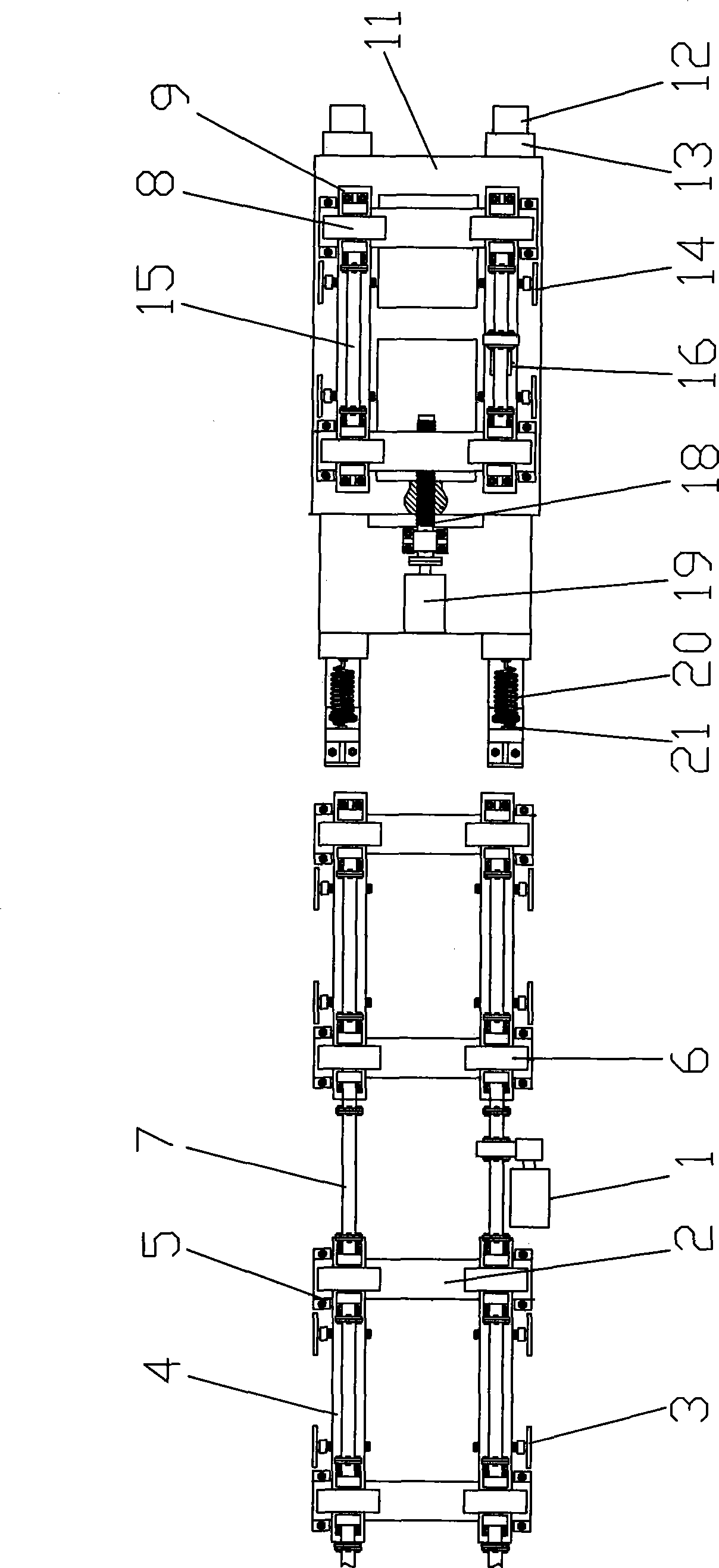

Hydraulic drive automatic gyrorotor butting tooling equipment

InactiveCN101992369AImprove docking accuracyReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderDrive shaft

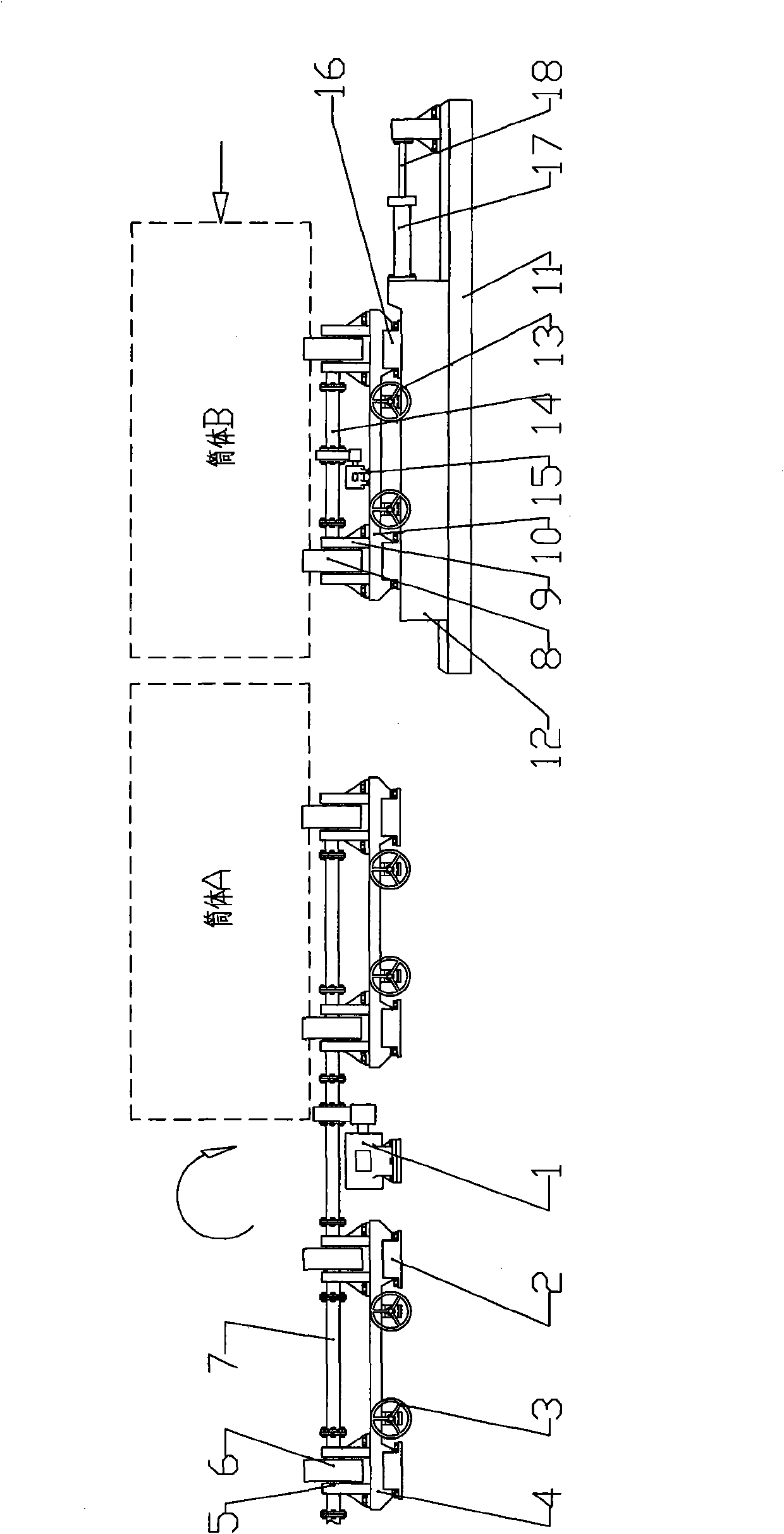

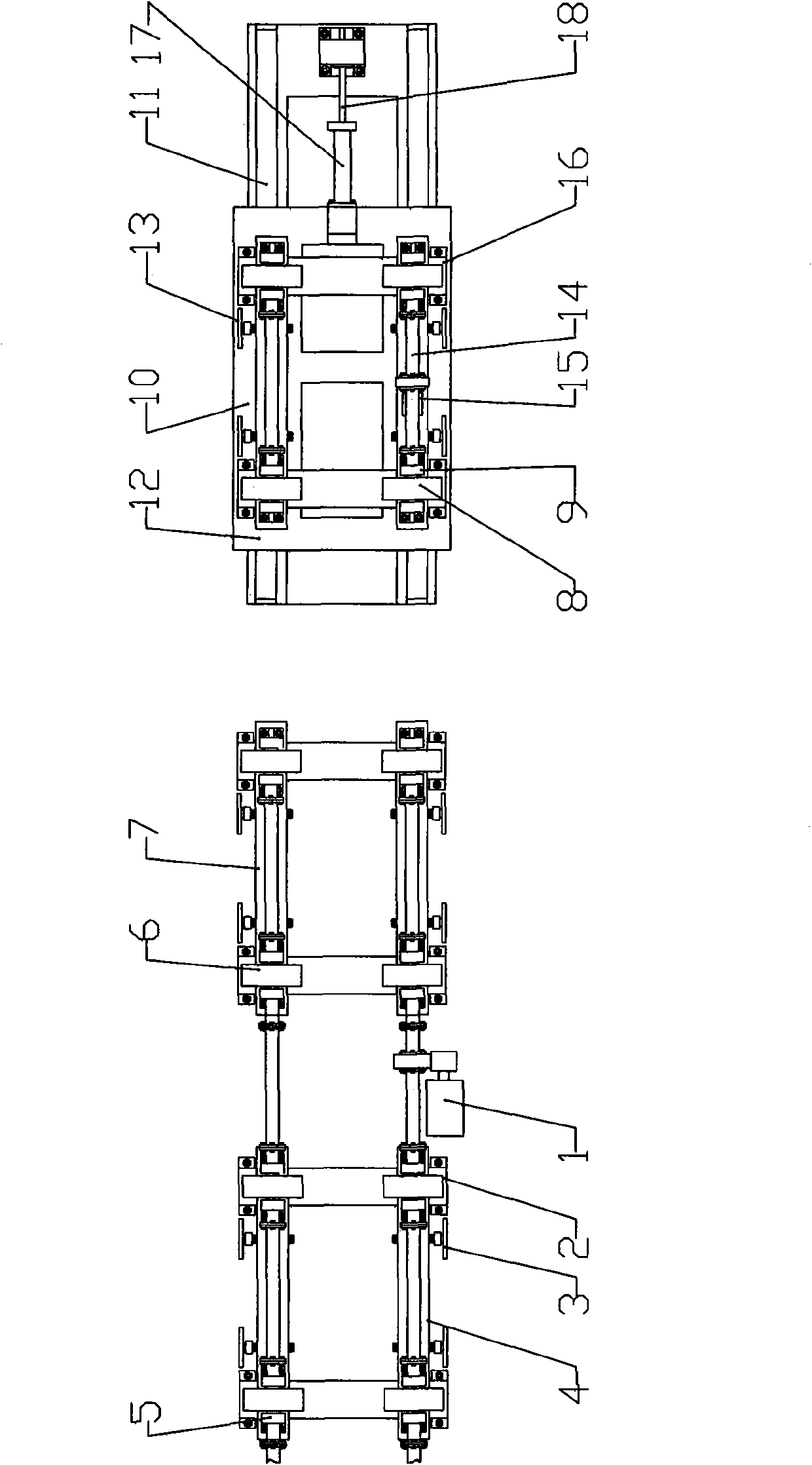

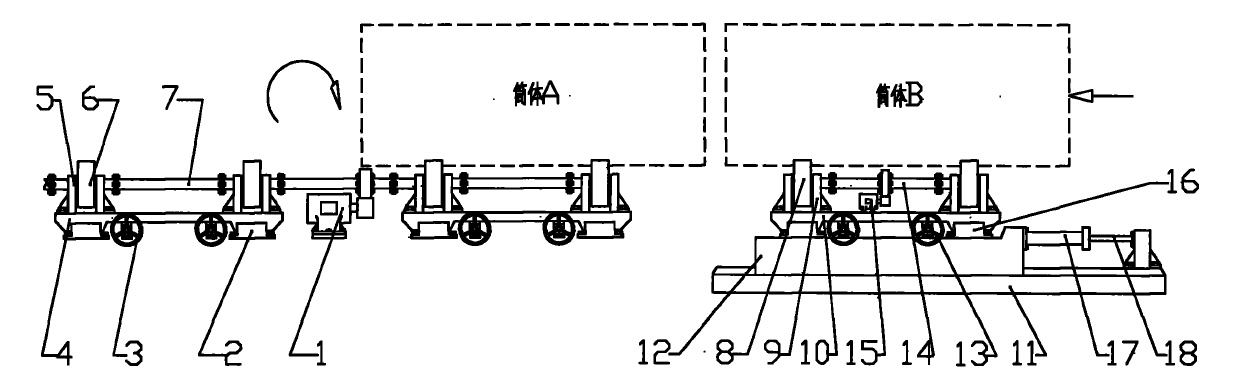

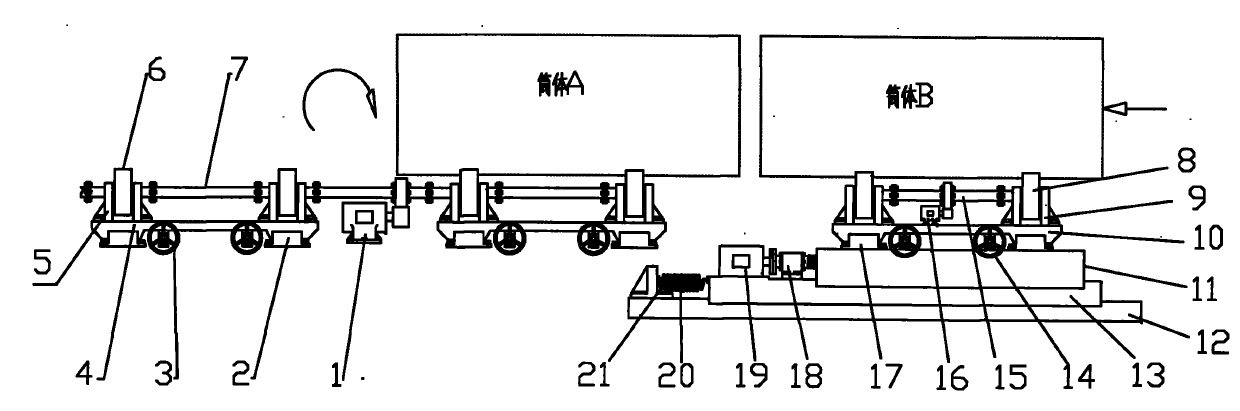

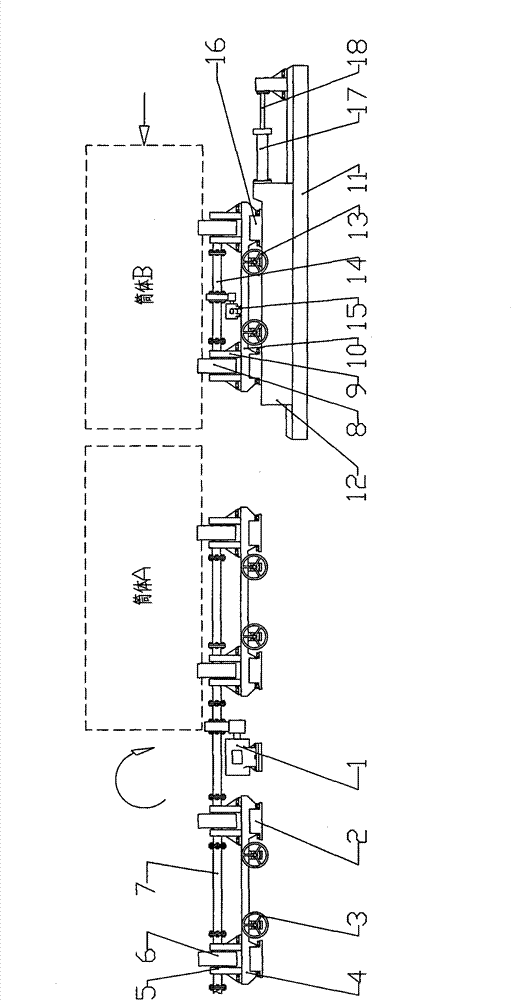

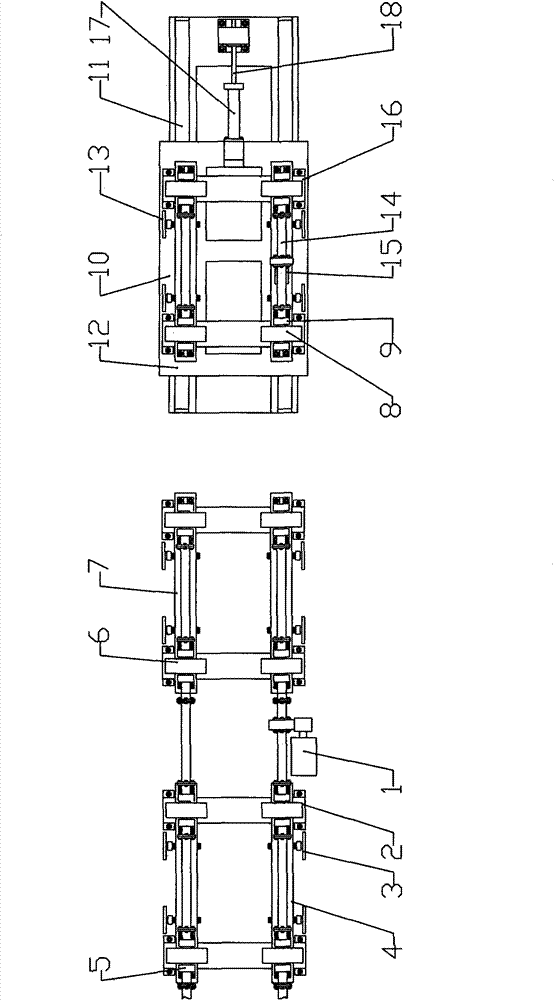

The invention discloses hydraulic drive automatic gyrorotor butting tooling equipment, which mainly comprises a cylinder rolling rack and a cylinder moving rack. Axes of two rows of transmission shafts on the cylinder rolling rack and axes of two rows of transmission shafts on the cylinder moving rack are positioned on the same plane, and the axes of the transmission shafts on the same side of the two racks are collinear, so that cylinders are butted in the same axis; under the hydraulic driving of the moving rack, the cylinders on the moving rack are displaced linearly, automatically butted,and subjected to circumferential grinding-in, and the butting accuracy of two cylinders is improved; and under the transmission of the hydraulic cylinder of the moving rack, the butted cylinders are driven to displace linearly, circumferentially roll on the rolling rack, and form relative spiral butting-grinding-in motion with the cylinders linearly displacing on the moving rack. The service lifeof the equipment is prolonged, the energy consumption is reduced, and the accuracy is improved; and the equipment has a simple structure, high reliability, high butting accuracy and high speed, is time-saving, labor-saving, safe and high-efficiency, and reduces equipment investment.

Owner:SINOMA TECH (XUZHOU) HEAVY MASCH CO LTD +1

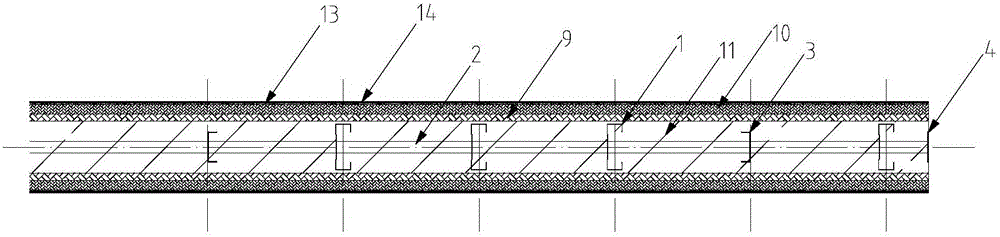

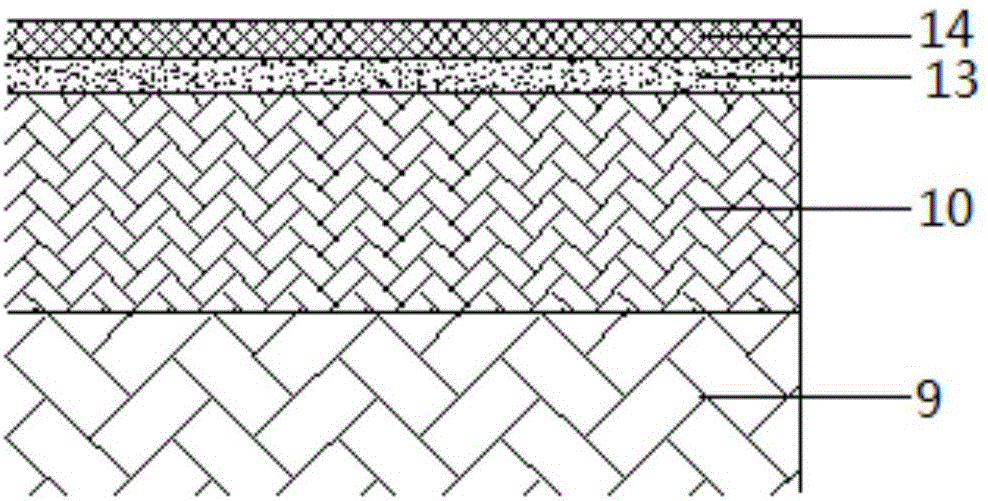

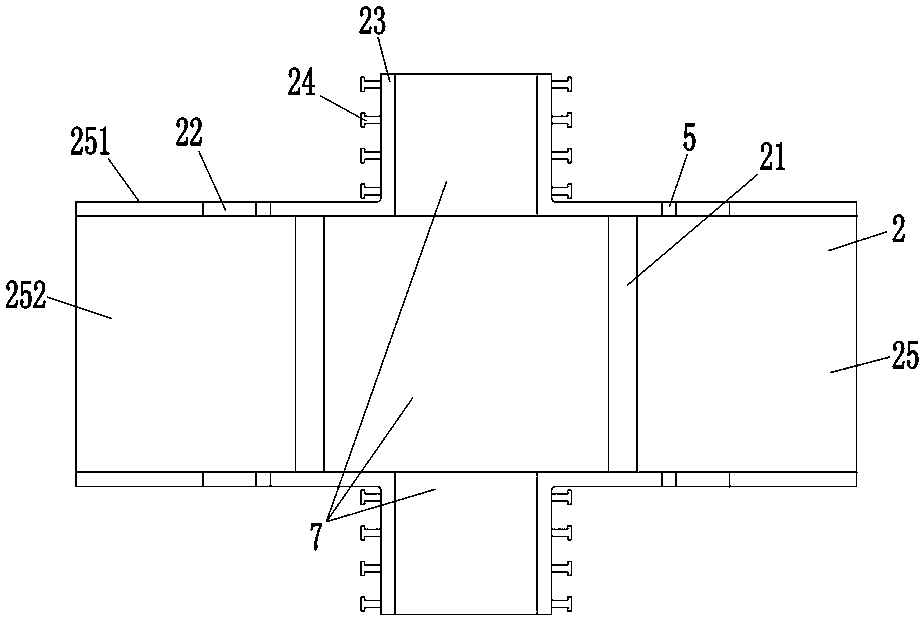

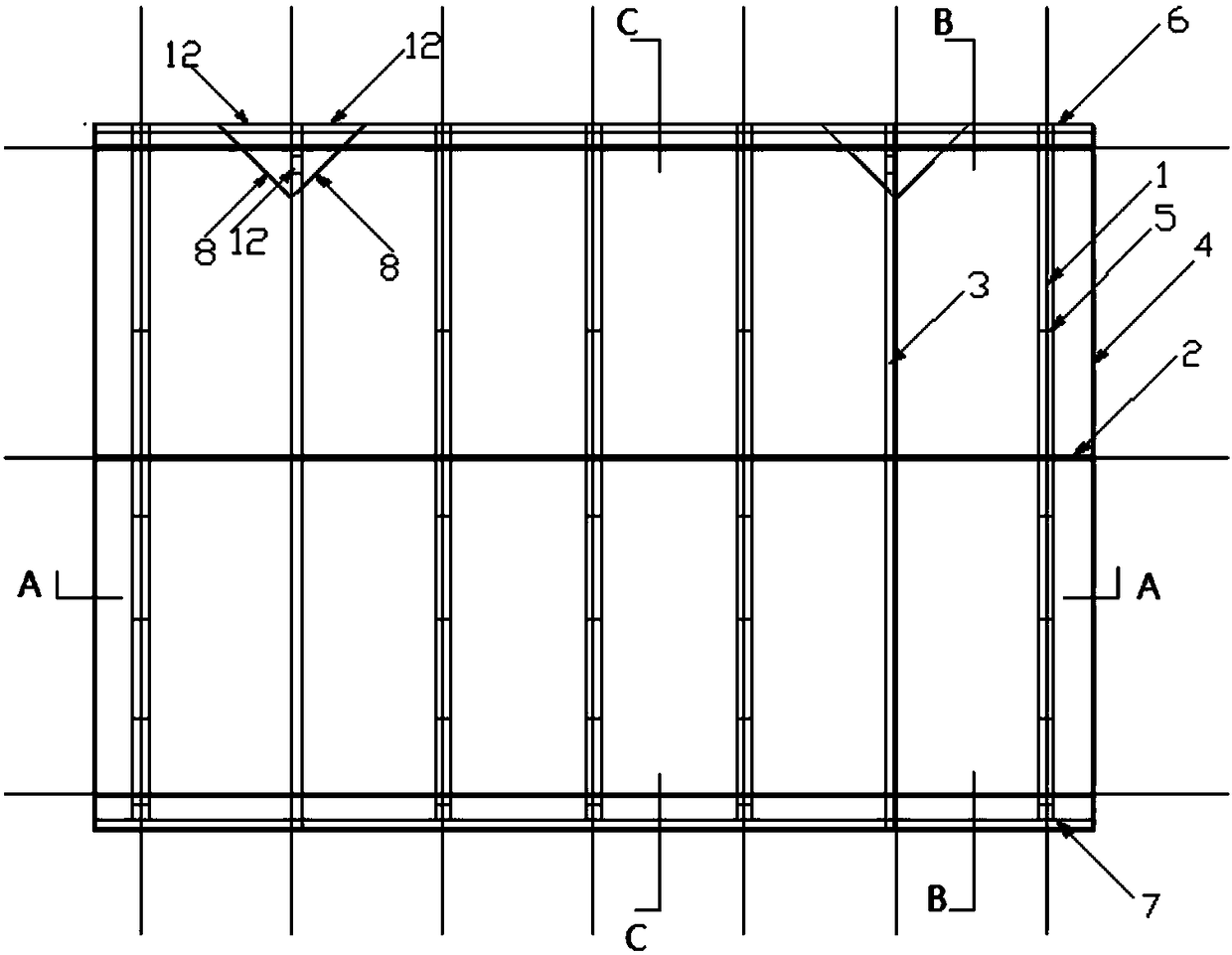

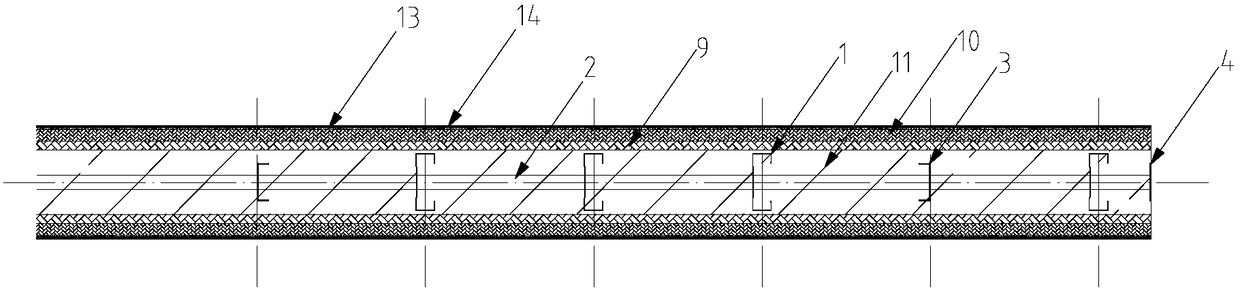

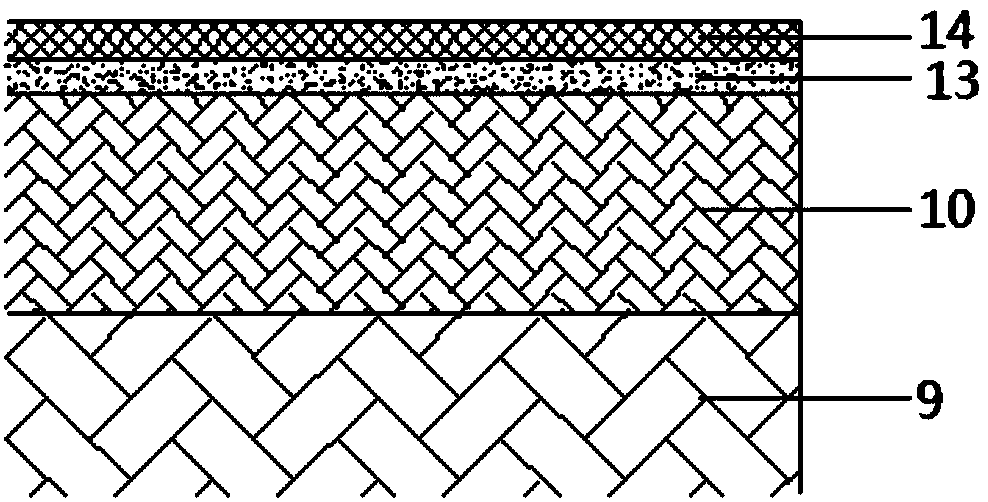

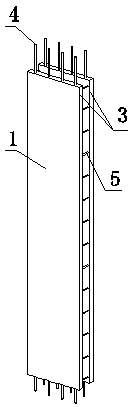

Externally-hung wallboard manufactured by compounding light steel keels and wood wool slabs, and manufacturing method of externally-hung wallboard

InactiveCN106223529ALow costEnvironmentally friendly materialsBuilding componentsCorrosion resistantWall plate

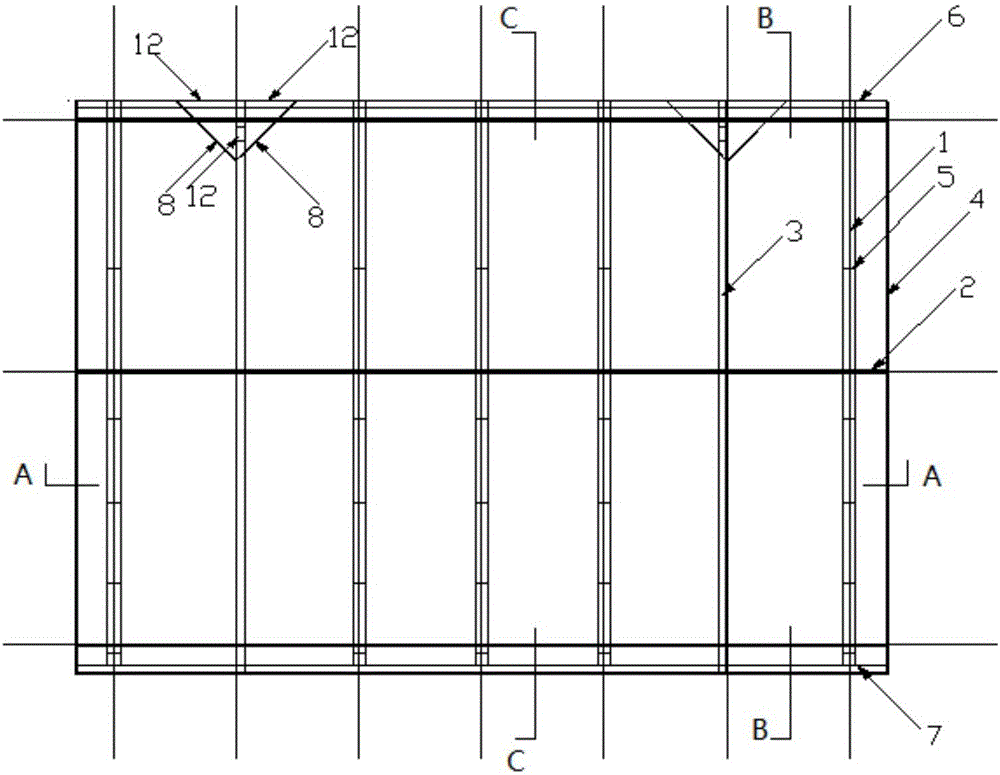

The invention relates to an externally-hung wallboard manufactured by compounding light steel keels and wood wool slabs, and a manufacturing method of the externally-hung wallboard. The externally-hung wallboard comprises a light steel keel skeleton, the wood wool slabs and foam concrete, wherein the light steel keel skeleton has a fence structure formed by a plurality of vertical keels and horizontal through keels; the wood wool slabs are respectively connected with the two sides of the surface of the light steel keel skeleton, so that a wallboard structure is formed; the parts between the light steel keel skeleton and the wood wool slabs are filled with the foam concrete, and the externally-hung wallboard is formed after the foam concrete is solidified. Compared with the prior art, the externally-hung wallboard has the advantages that the wallboard is low in manufacturing cost and environmentally-friendly in materials; the wallboard has excellent functions of heat preservation, heat insulation and noise absorption; the externally-hung wallboard is light in structure, high in rigidity, firm and durable; the externally-hung wallboard is simple in construction and low in hoisting requirement; the surface of the wallboard has a waterproof function and is corrosion-resistant.

Owner:TONGJI UNIV

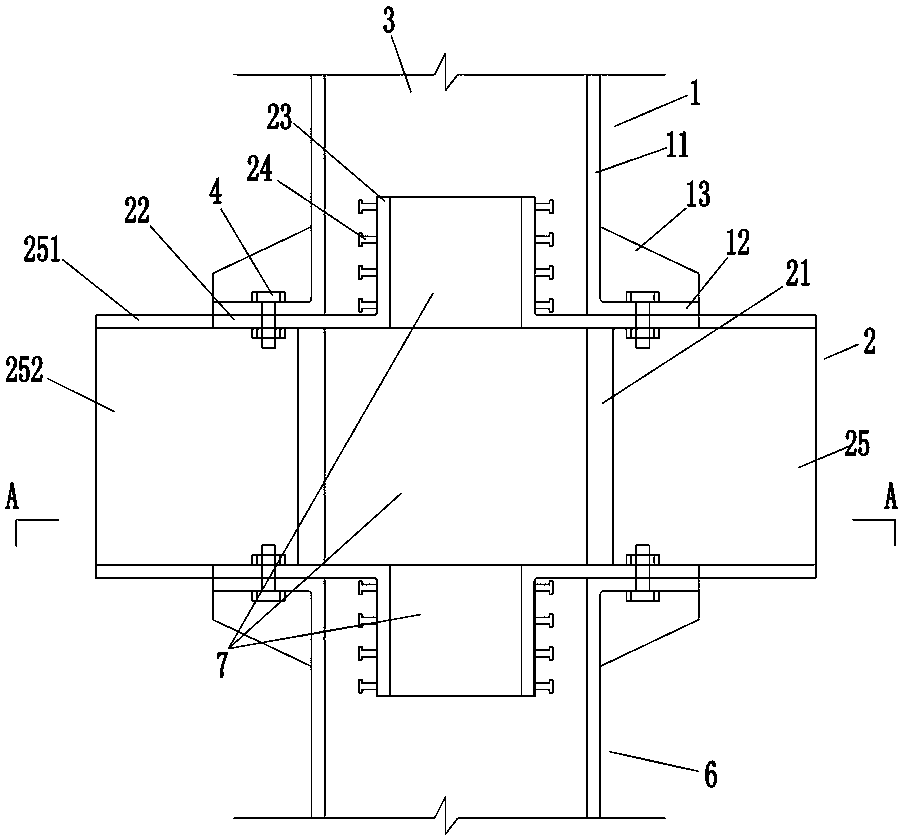

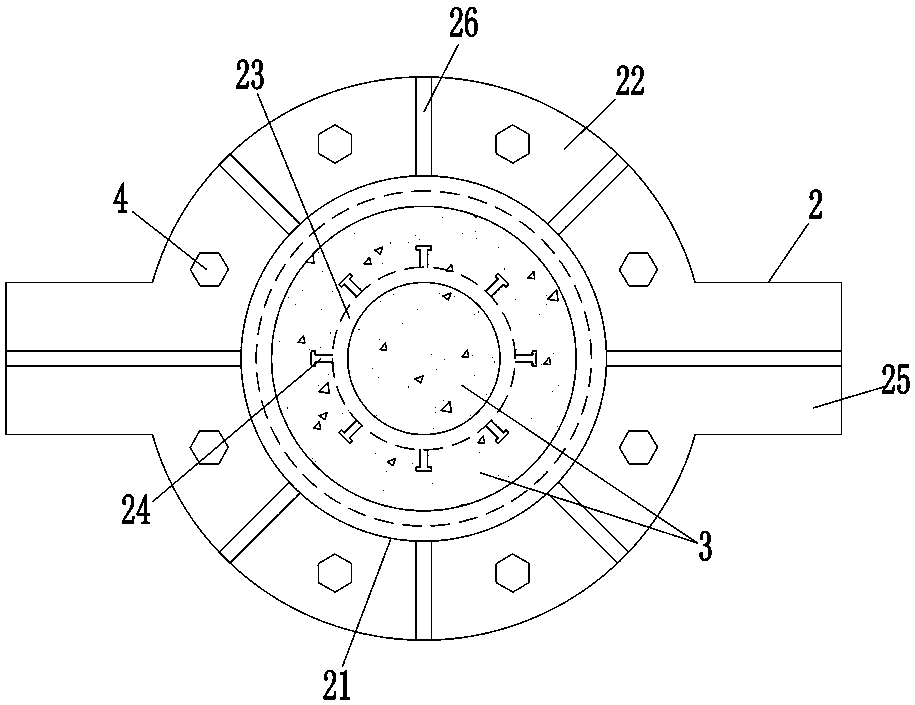

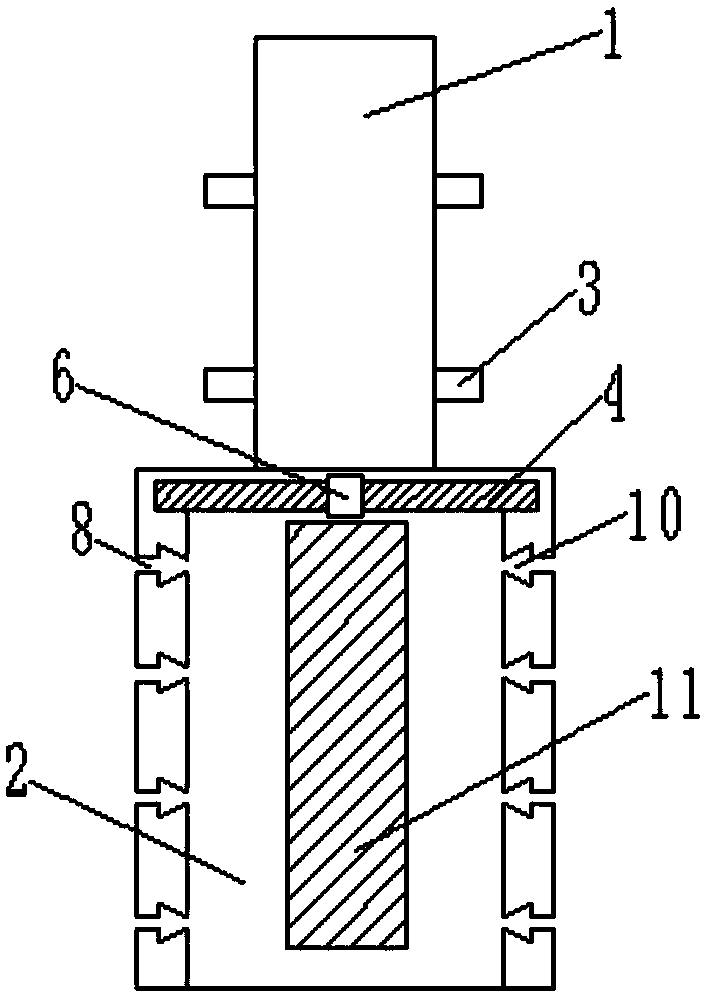

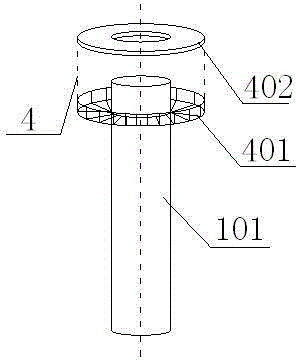

Joint reinforced type fabricated steel pipe concrete connecting structure and construction method thereof

PendingCN109339250ASimple structureReasonable structureBuilding constructionsSteel tubeMaterials science

The invention relates to a joint reinforced type fabricated steel pipe concrete connecting structure and a construction method thereof. The joint reinforced type fabricated steel pipe concrete connecting structure comprises an upper steel pipe column, a lower steel pipe column and a joint connecting piece used for connecting the upper steel pipe column and the lower steel pipe column through bolts, wherein the upper and lower ends of the joint connecting piece separately extend into the inner parts of the upper steel pipe column and the lower steel pipe column; through holes penetrating vertically and used for connecting the upper steel pipe column and the lower steel pipe column in a communicating mode are arranged in the joint connecting piece; and the upper steel pipe column, the lowersteel pipe column and the through holes are filled with concrete. The joint reinforced type fabricated steel pipe concrete connecting structure has simple and reasonable structure, low hoisting requirement, no welding operation on site, fast and reliable connection, convenient construction and good construction quality; and meanwhile, steel pipes at the joint can achieve locally reinforcing, the columns can be easily changed into section, and the stress performance and integrity are good.

Owner:FUJIAN UNIV OF TECH

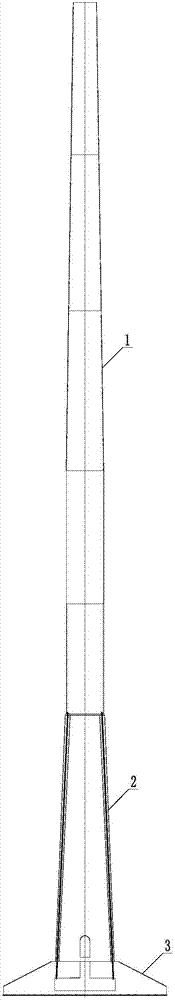

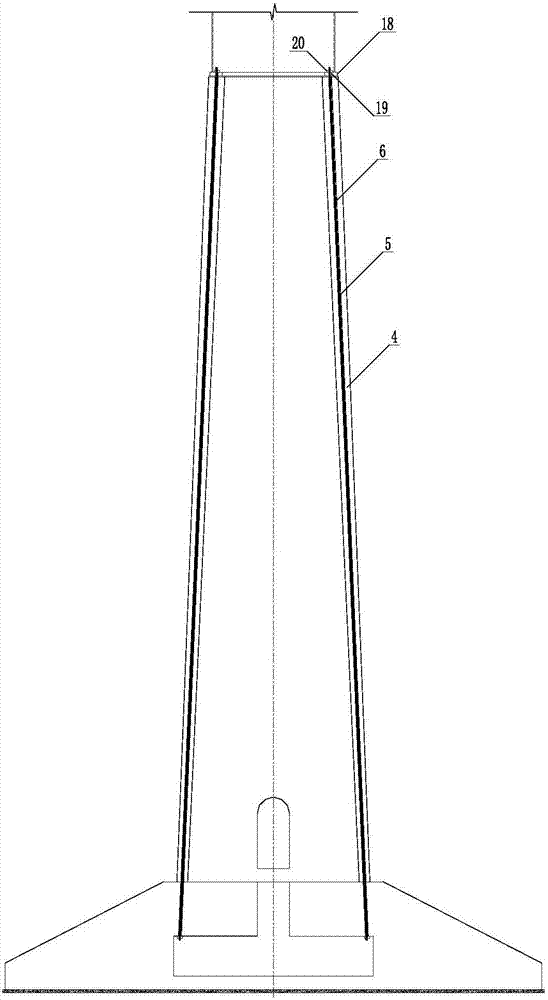

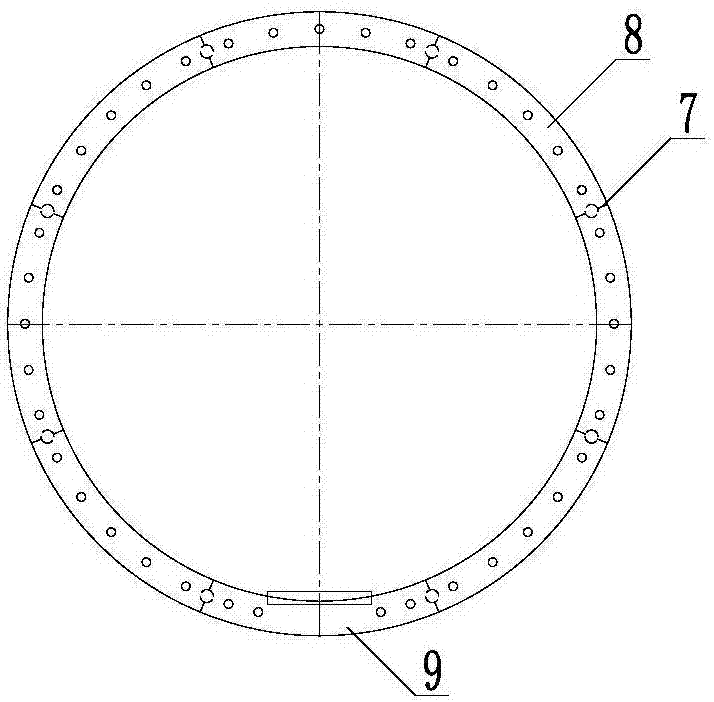

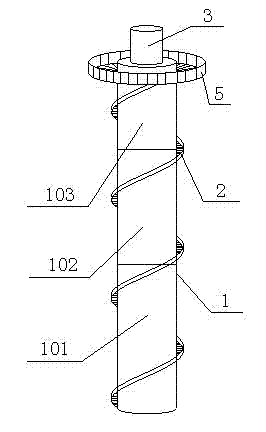

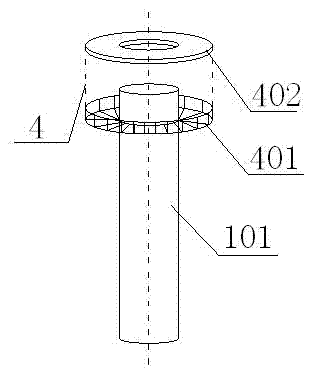

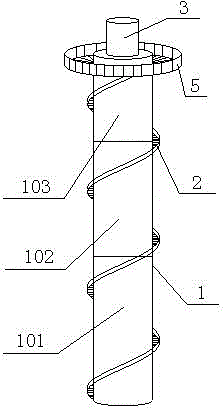

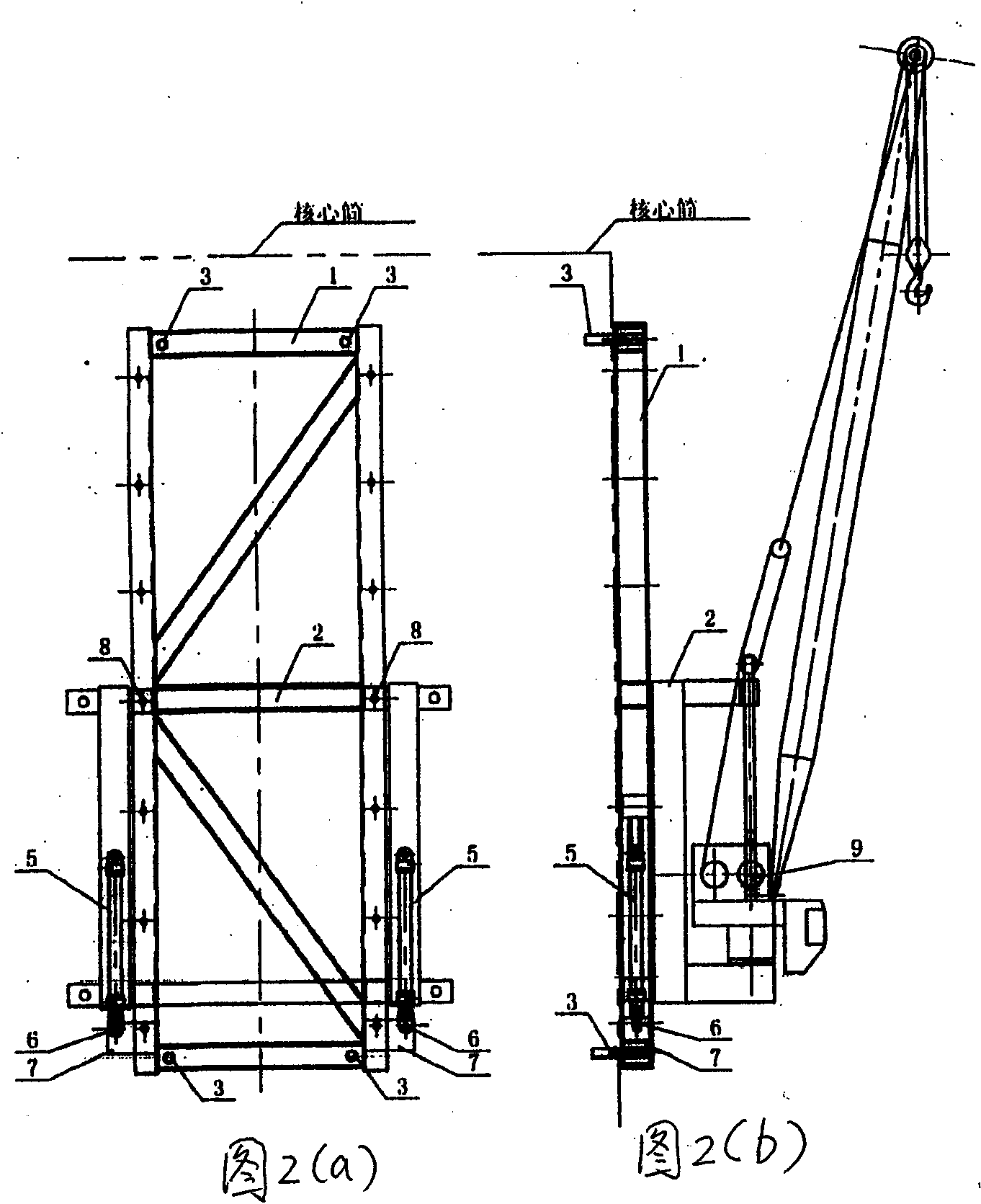

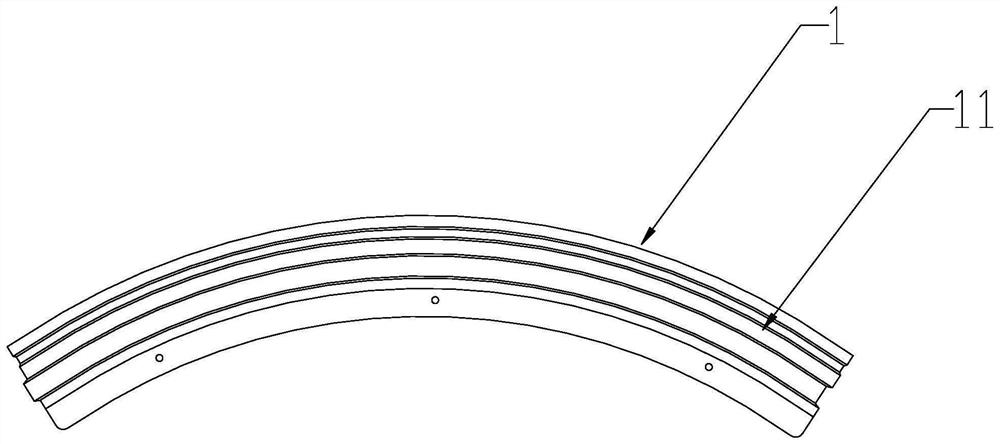

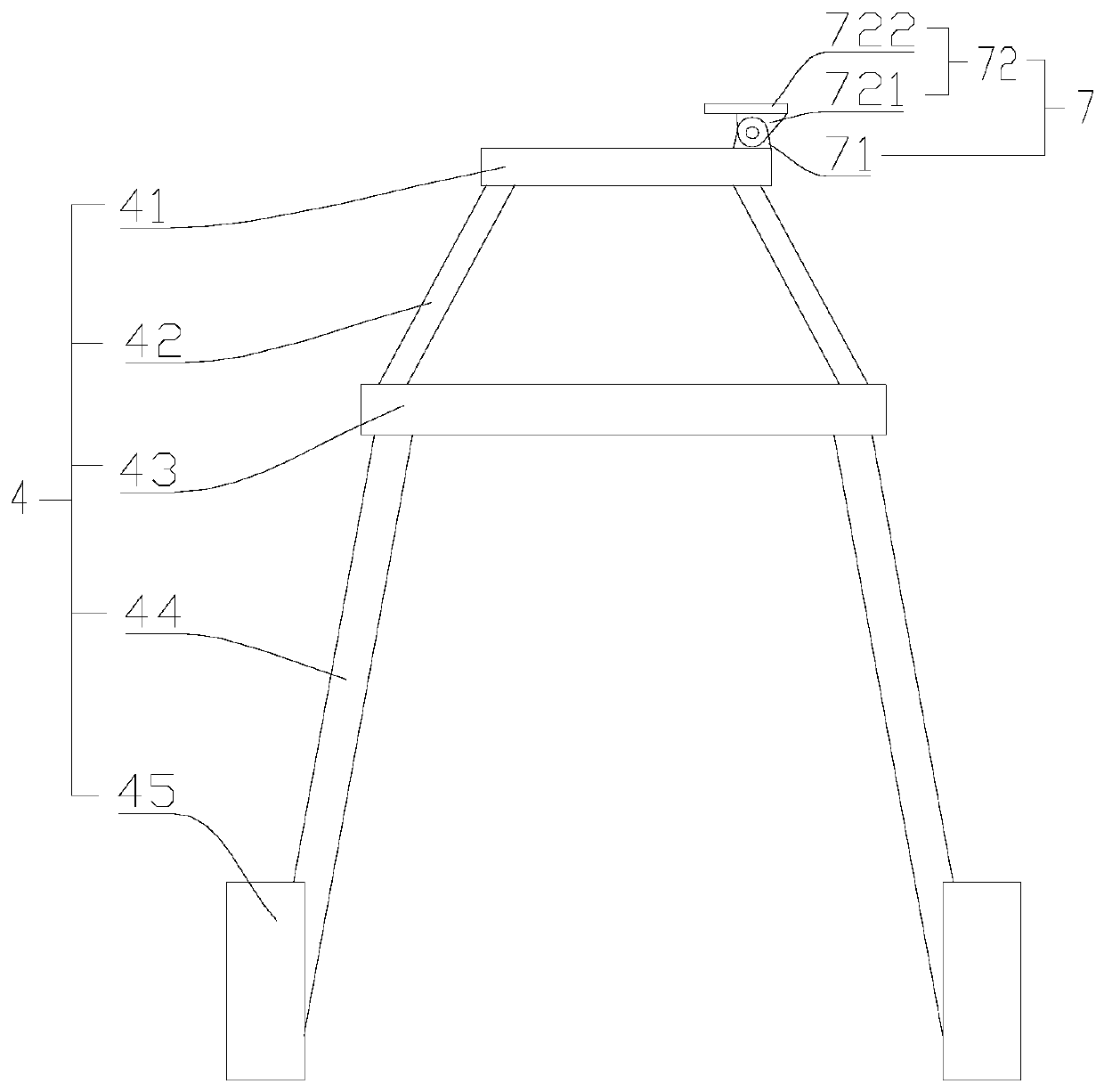

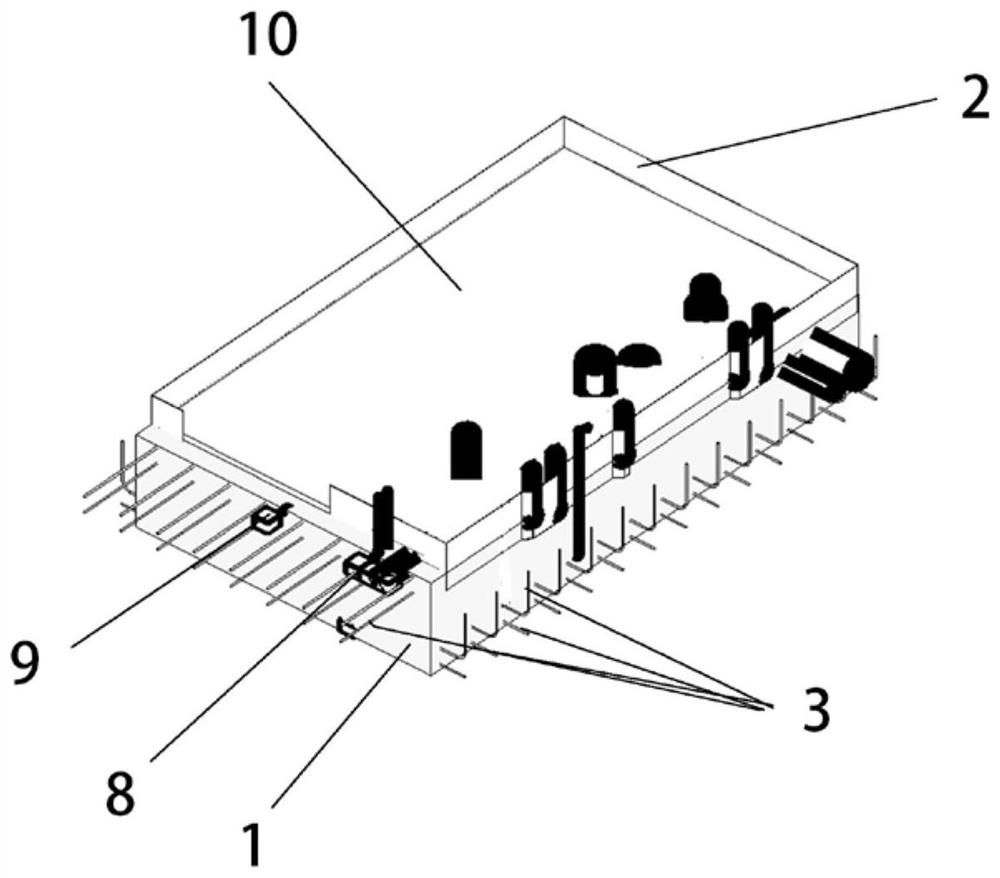

Lower portion laminate prefabricated hybrid tower frame of wind power generator

PendingCN106949017AReduce weightFast installationEngine manufactureWind motor assemblyElectricityReinforced concrete

The invention relates to a lower portion laminate prefabricated hybrid tower frame of a wind power generator. A prestress concrete tower is arranged on the lower portion of the tower frame, and a steel tower drum is arranged on the upper portion of the tower frame. Embedded flange parts are embedded in the inner walls of prefabricated laminate units and edges of longitudinal joints, and every two adjacent units are connected with high-strength bolts. An annular groove is embedded in the outer wall of each prefabricated laminate unit every a certain distance, annular prestress cables are arranged in the annular grooves, and the annular grooves are filled with filling materials. After the annular prestress cables are tensioned, the laminate units are connected into a whole through cooperation of the annular prestress cables and the high-strength bolts on the inner walls. A lower portion laminate prefabricated prestress concrete section is temporarily fixed through a tool truss and adjusted when being installed. The tool truss is composed of a stand column and web members. A flange plate is arranged at the bottom of the tool truss and corresponds to a foundation embedded part embedment adjusting means. A platform is arranged on the top of the tool truss and serves as an operating platform in the installation stage. According to the lower portion laminate prefabricated hybrid tower frame of the wind power generator, a reinforced concrete structure with high rigidity is fully utilized for resisting high loads on the lower portion, and the prestress concrete structure has the characteristics of long anti-fatigue life, high damping ratio, great durability and the like.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

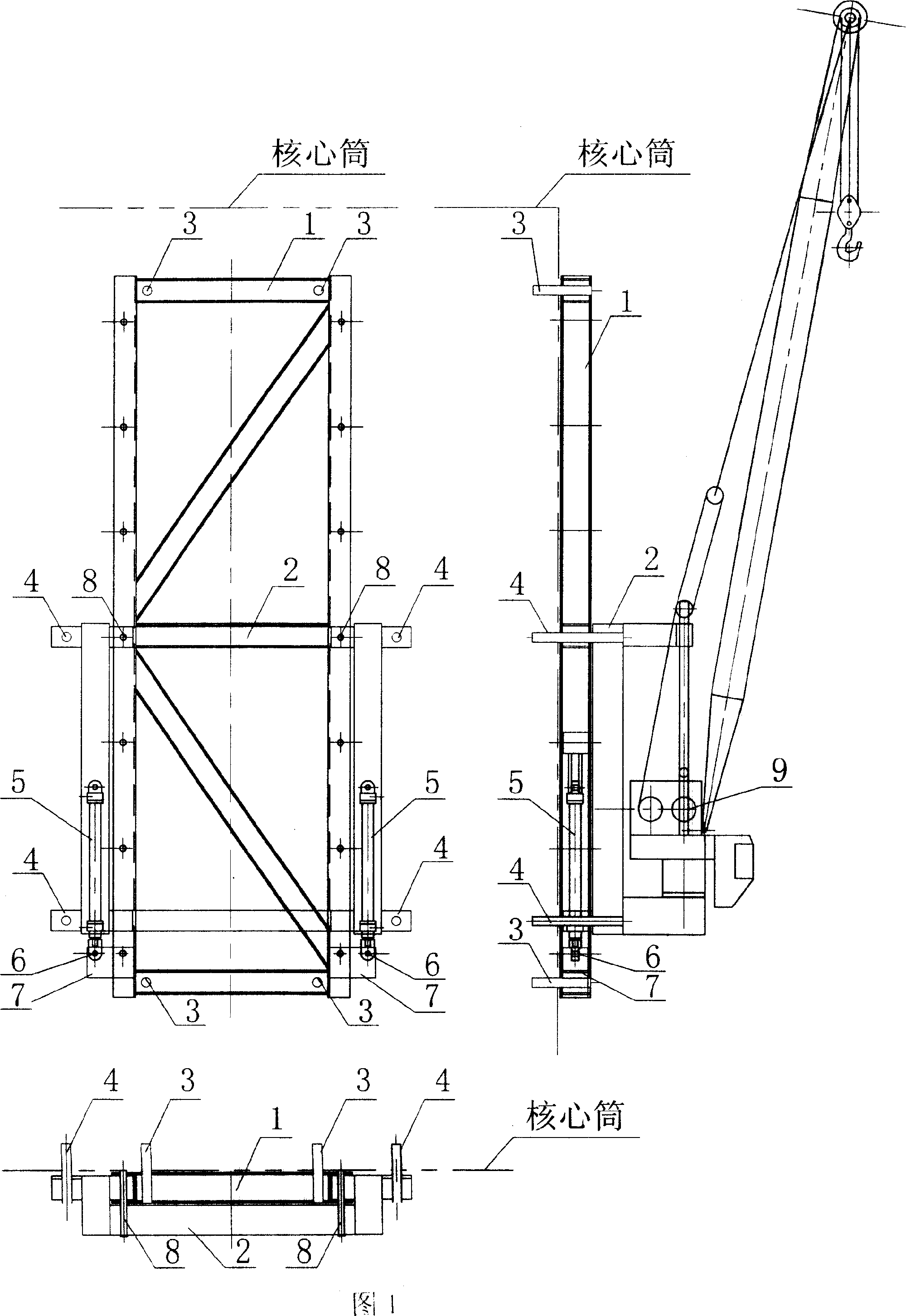

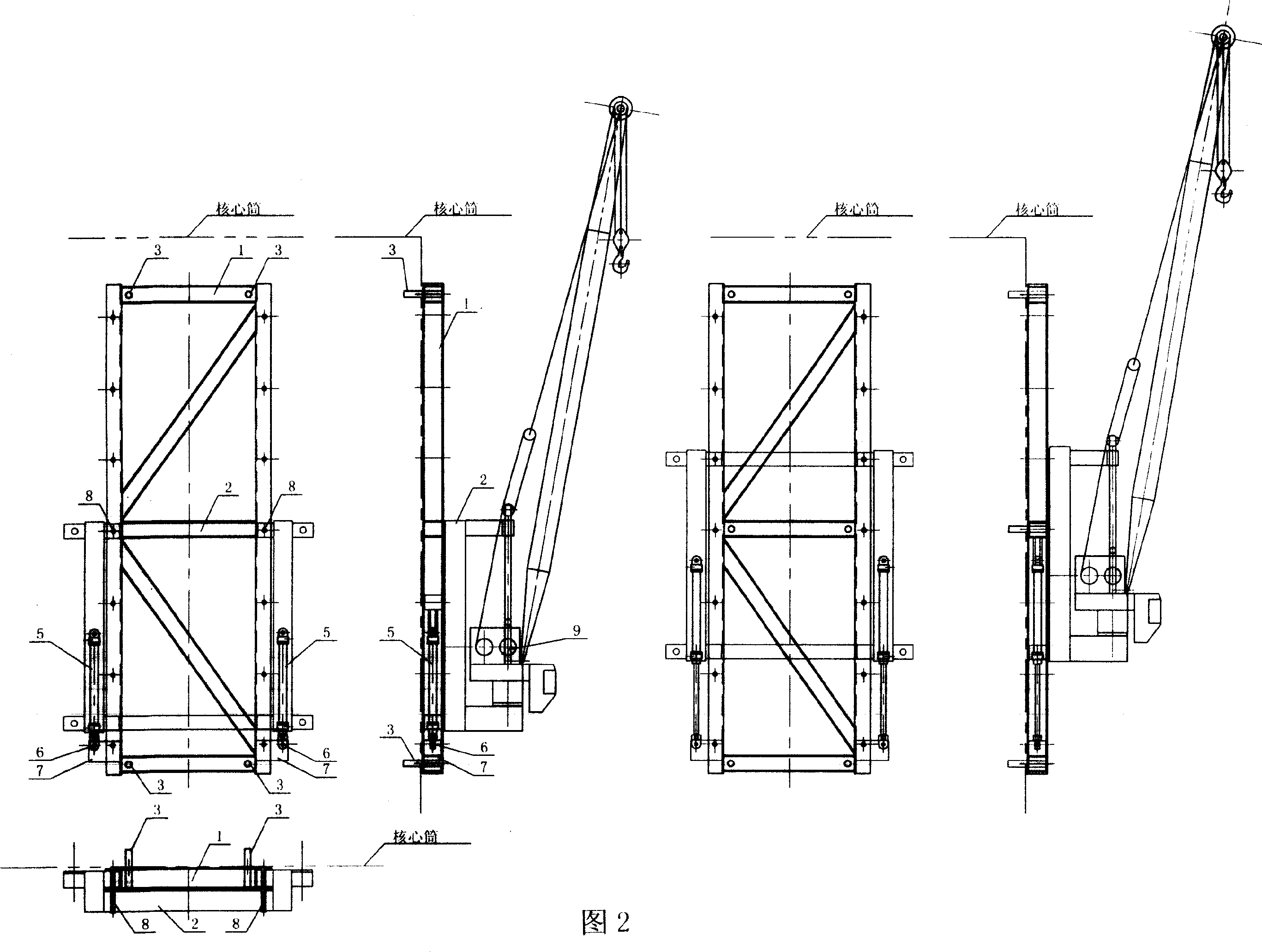

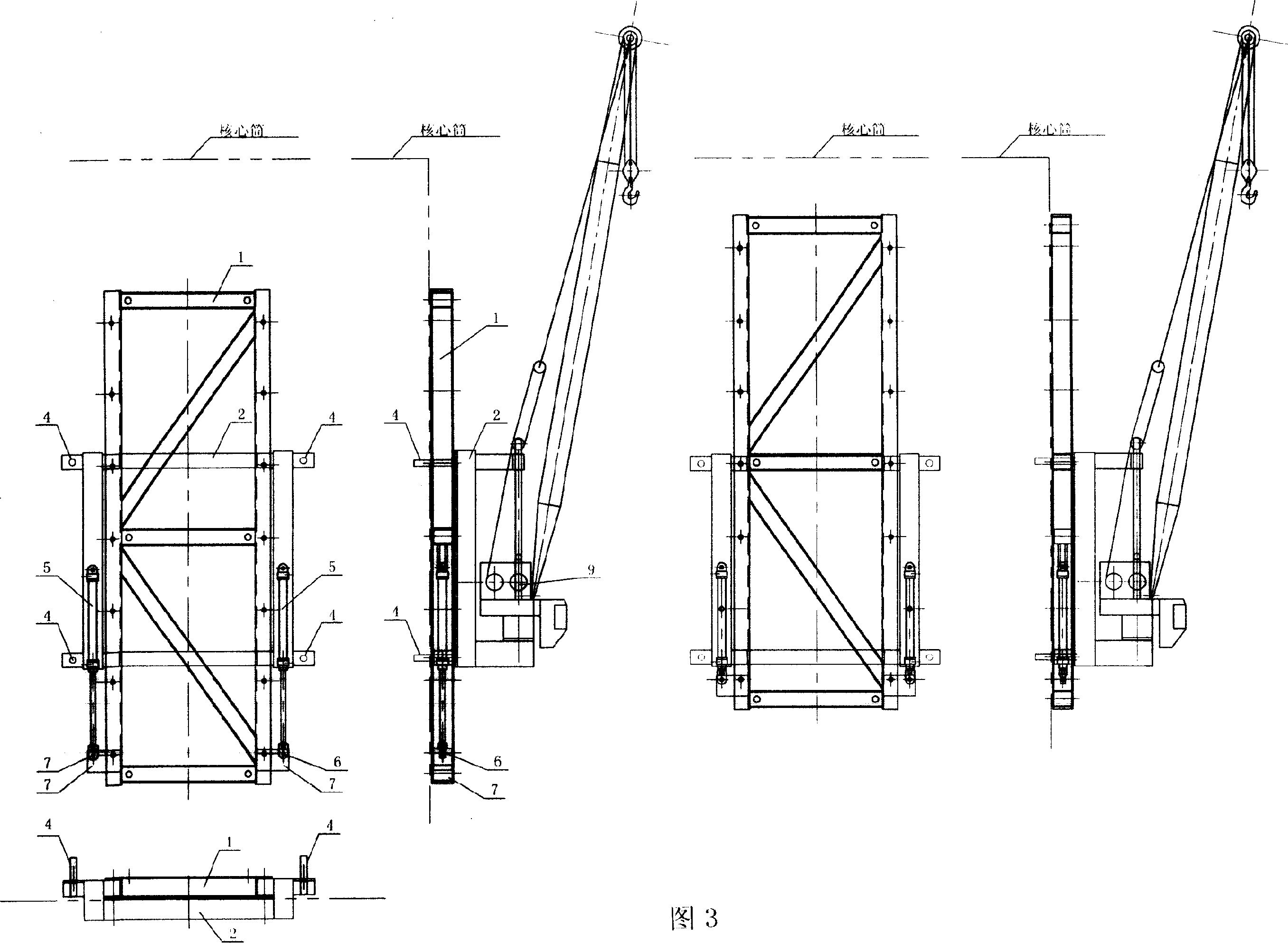

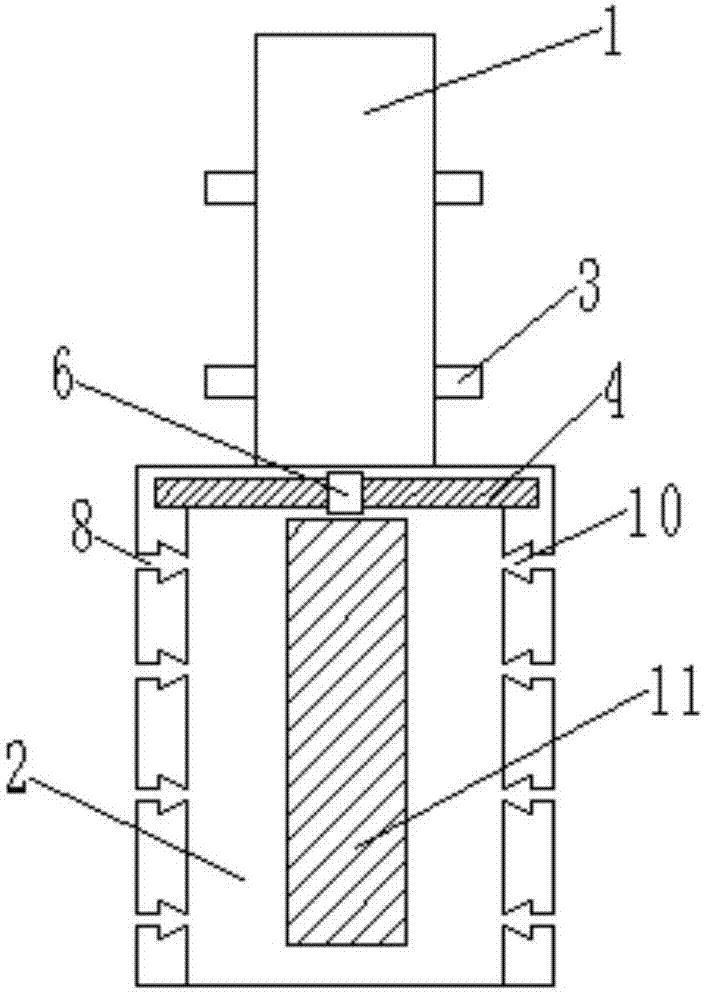

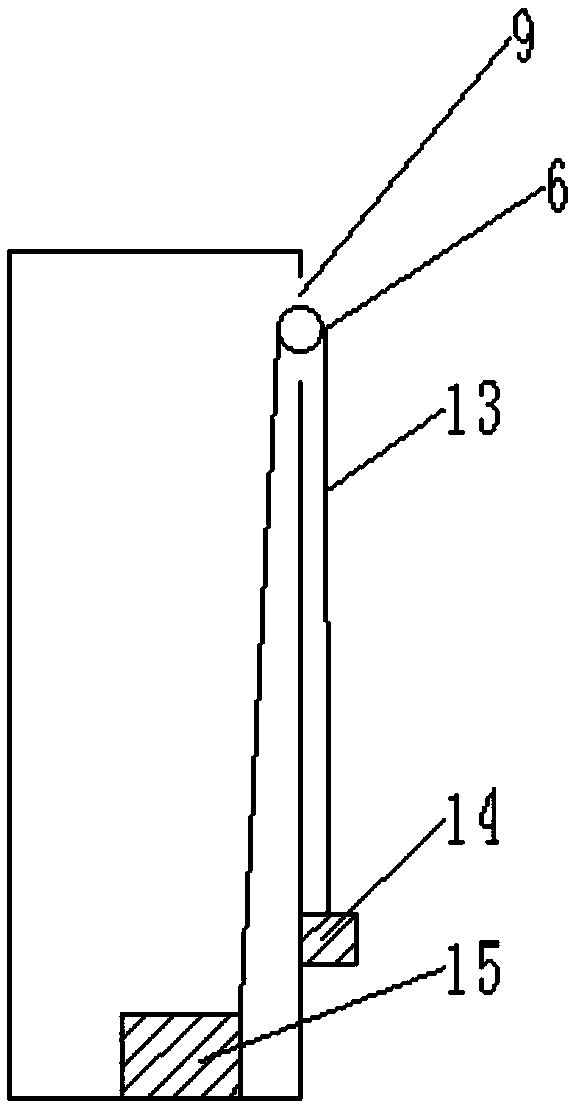

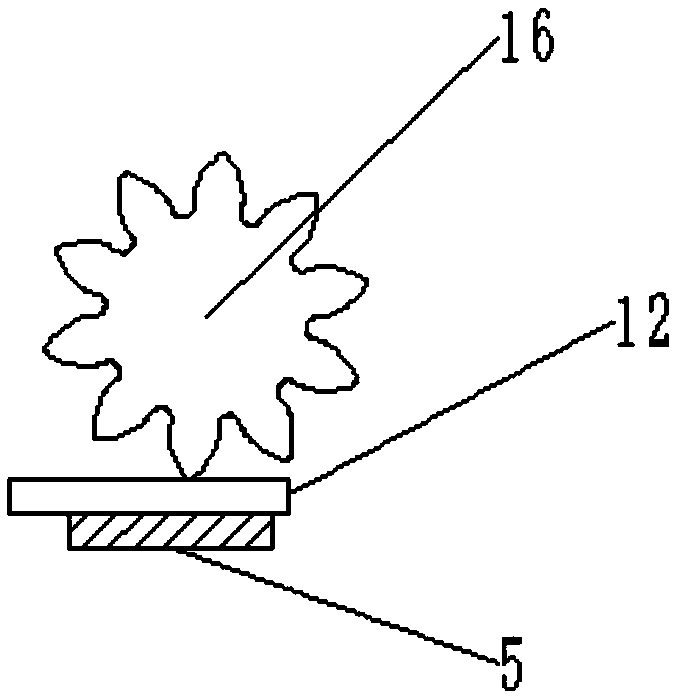

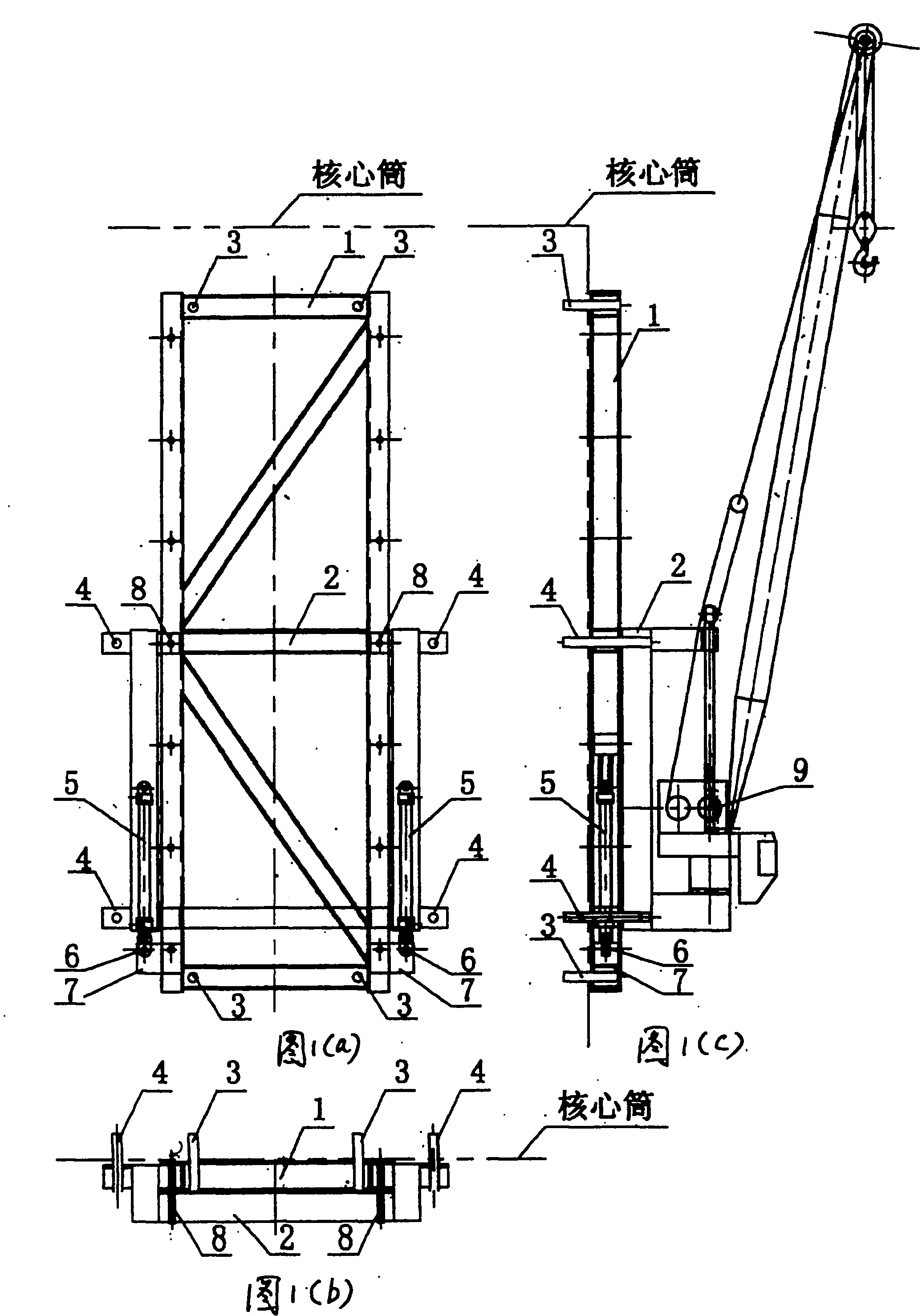

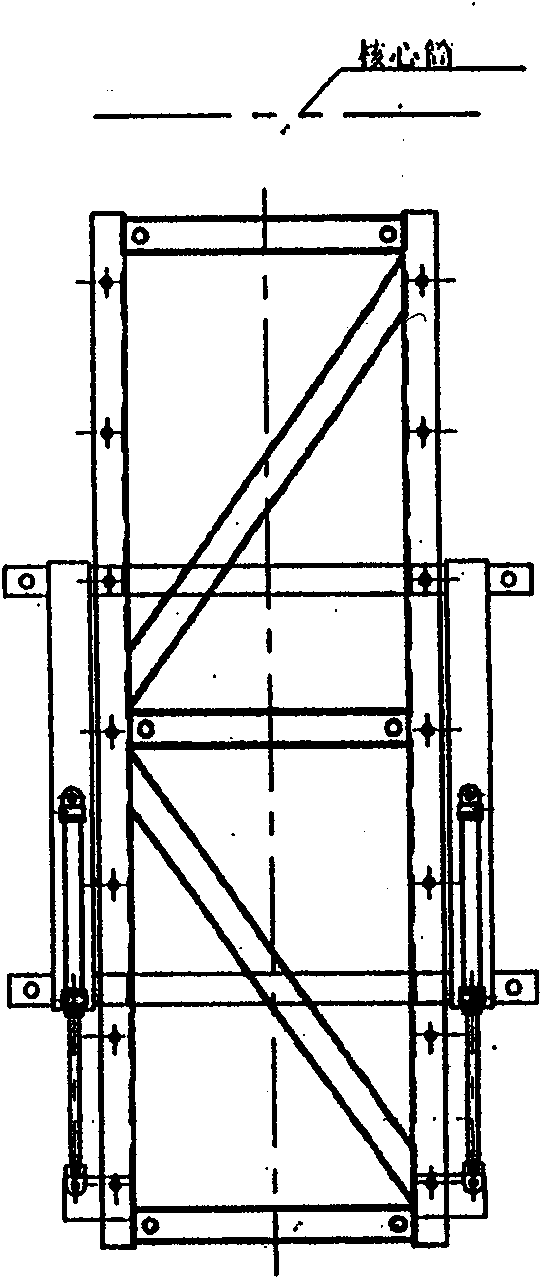

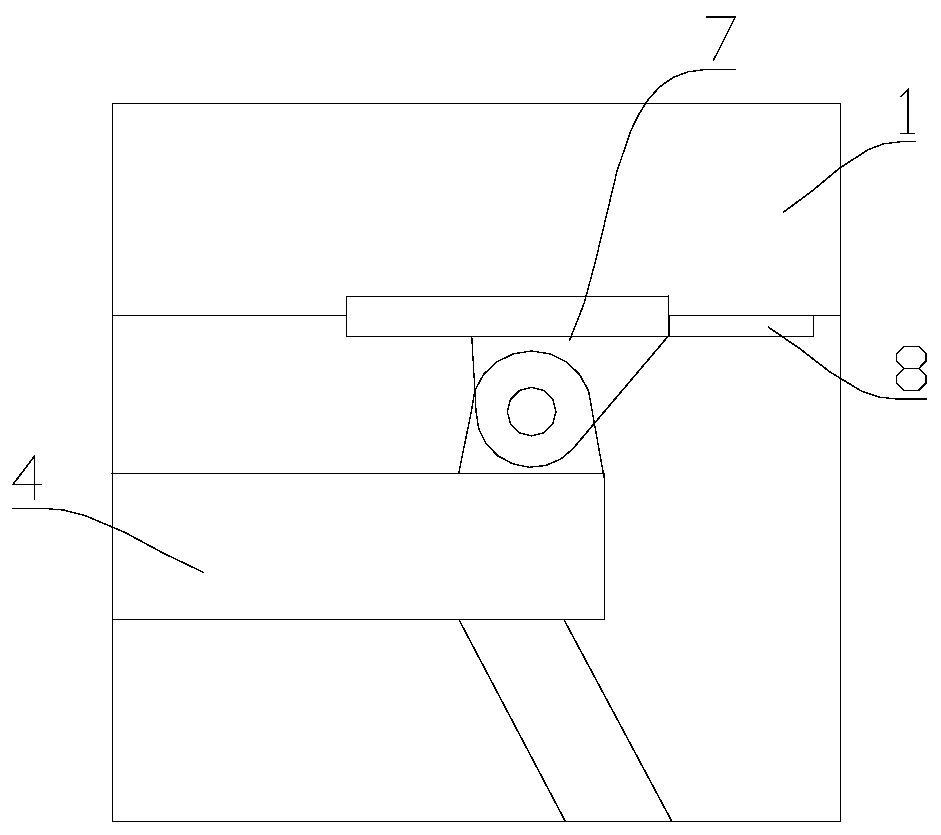

Self-lifting wall-attaching crane for superhigh-rise building construction with core drum

InactiveCN1935622AOvercome the inadequacies that cannot climb on their ownReduced lifting requirementsCranesTower craneAnchor bolt

The invention relates to a wall attachment crane, especially a self-elevating wall attachment crane, comprising attachment self-elevating mechanism and hoisting equipment, where extension of hydraulic oil cylinder of the attachment self-elevating mechanism makes wall attachment crane frame and runner frame slide on the outer wall of a kernel cylinder in turn, so as to support attachment in turn of wall attachment crane frame anchor bolt and runner frame anchor bolt on the outer wall of the kernel cylinder, thus meeting the requirements of self-elevating on the outer wall of the kernel cylinder. And it has functions of self-elevating attached to the outer wall of the kernel cylinder according to the given requirements and performing hoisting operation; and it largely improves economy; it adopts a combined structure, simplifies assembly and disassembly and the wall attachment crane frame can be equipped with the hoisting equipment and other matching construction equipment.

Owner:SHANGHAI MECHANIZED CONSTR GRP

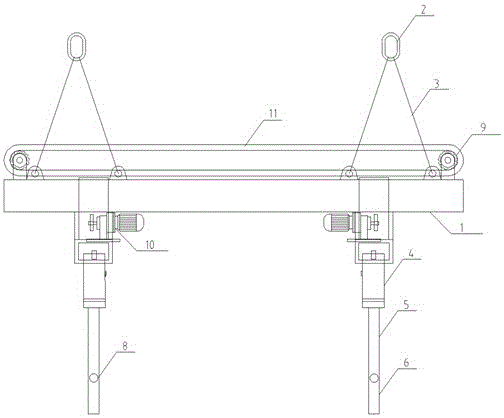

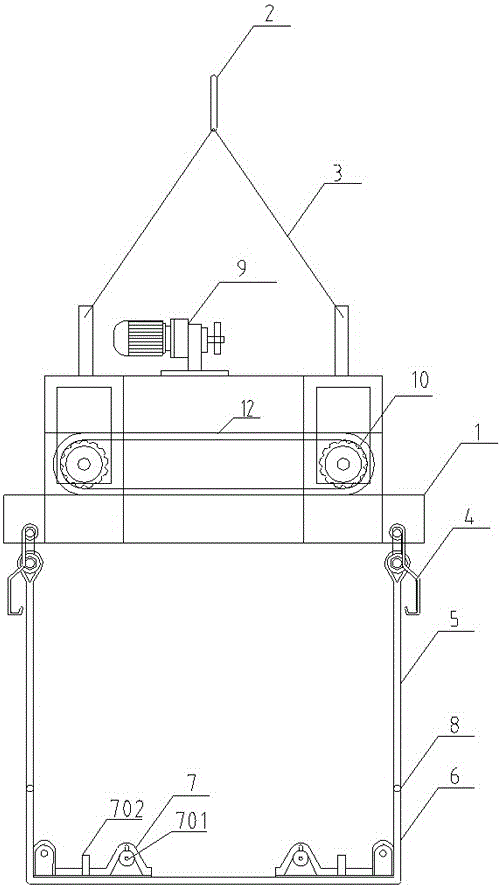

Hoisting equipment

ActiveCN107324233AIncrease resistanceReduced lifting requirementsPortable liftingLoad-engaging elementsSpecific functionEngineering

Owner:CHINA NAT CHEM ENG HEAVY MECHANIZED CORP

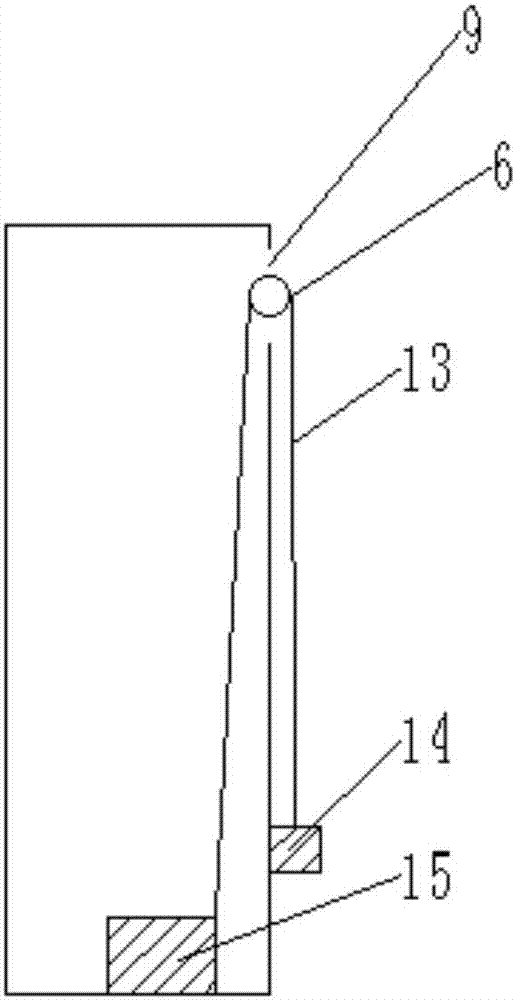

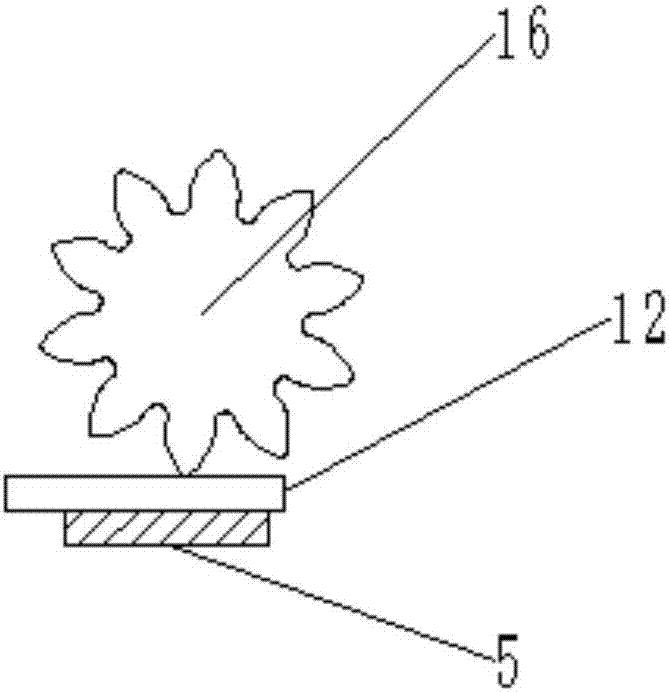

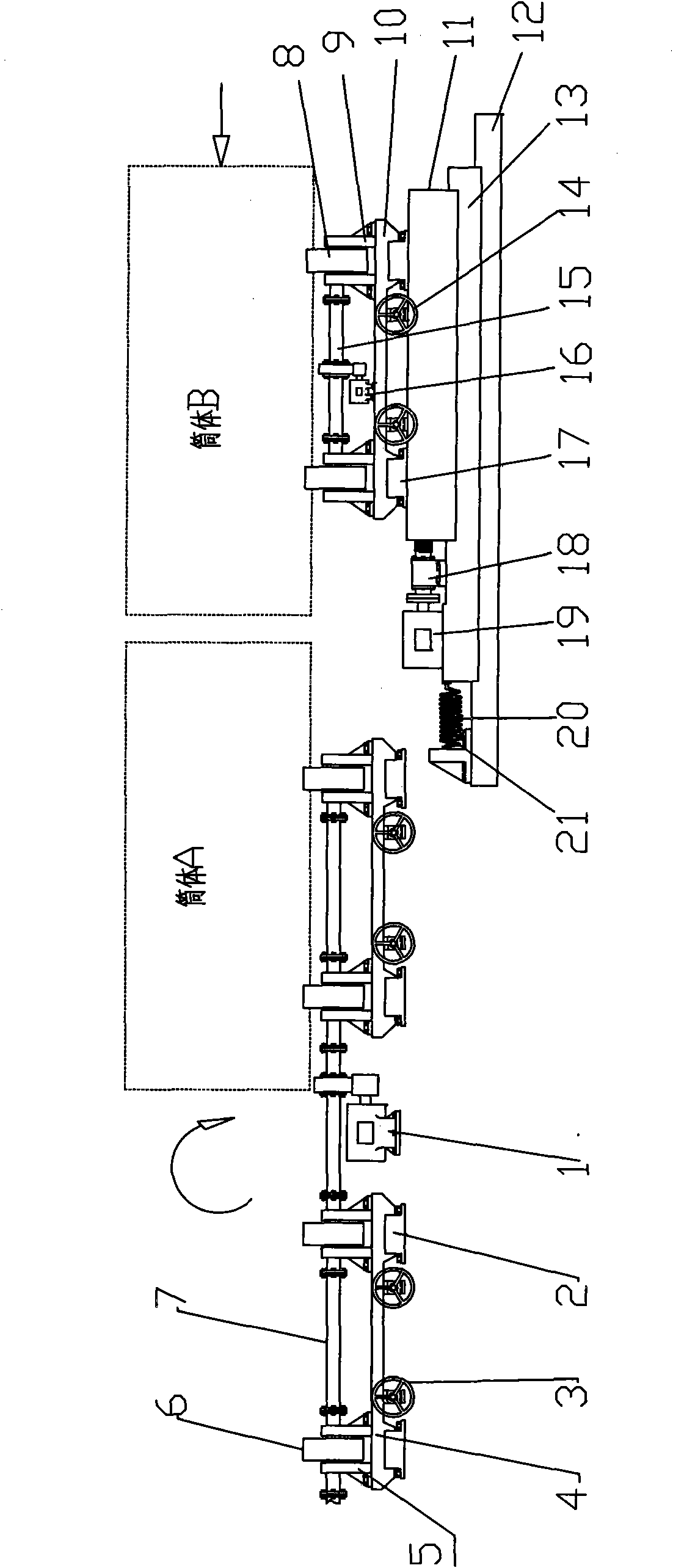

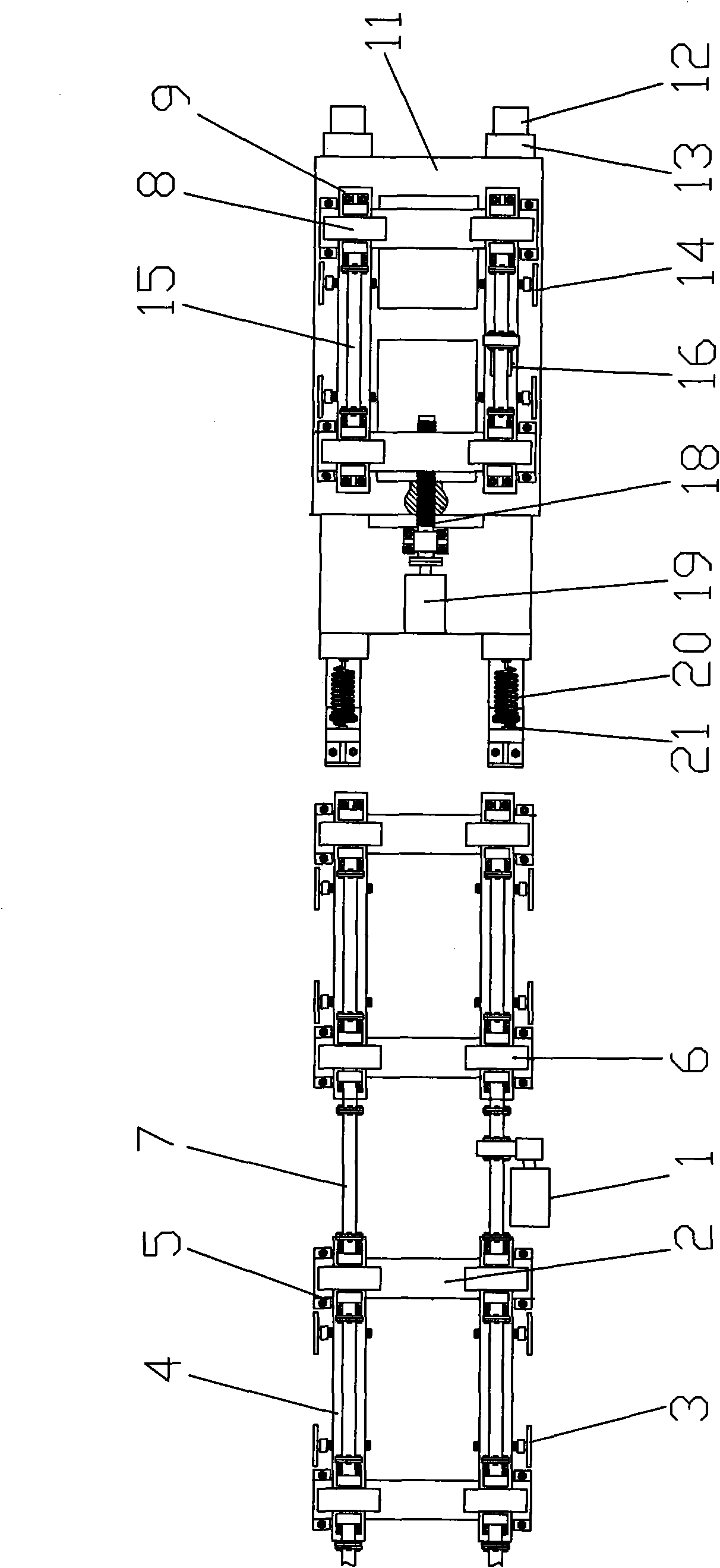

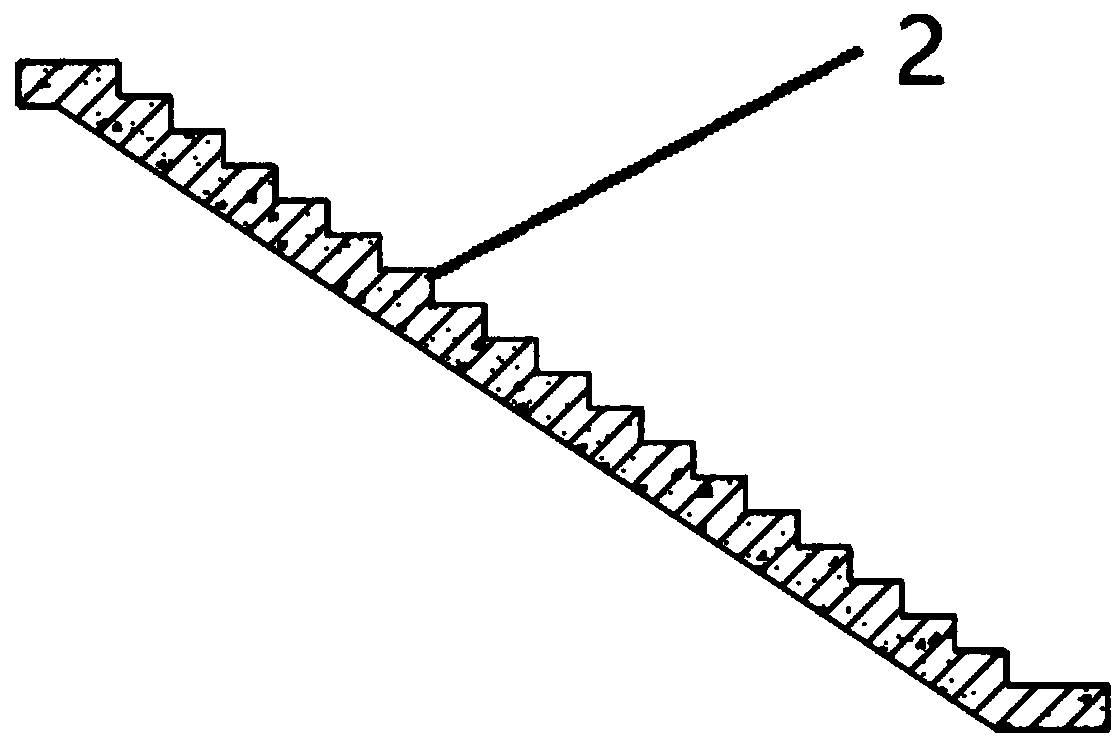

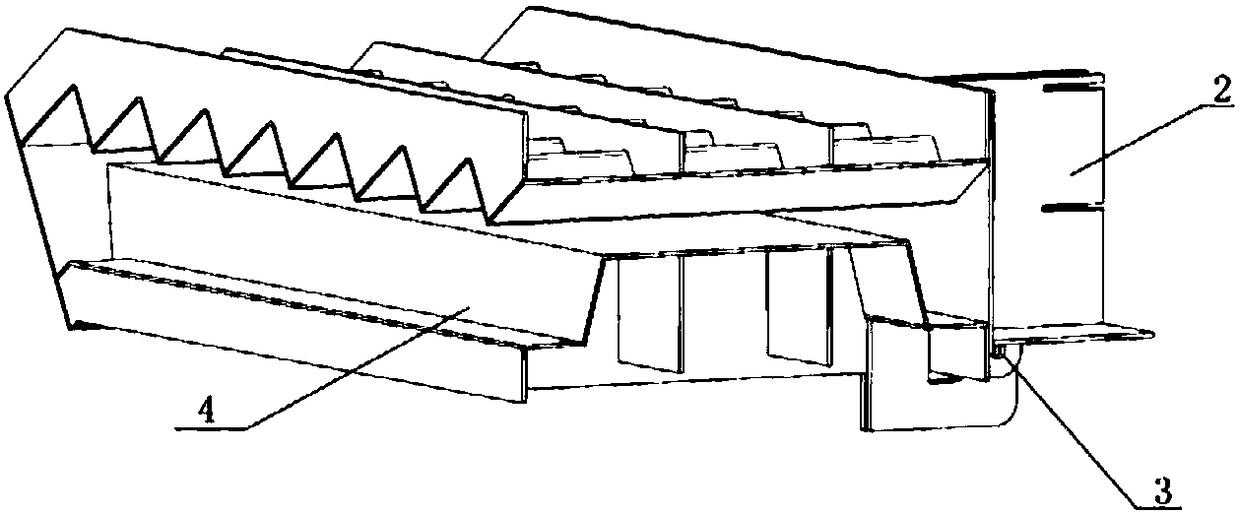

Automatic butt joint and grinding-in tooling equipment of large barrel

InactiveCN101992370AMaintain always elastic contactReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftButt joint

The invention discloses automatic butt joint and grinding-in tooling equipment of a large barrel, which is mainly composed of a barrel rolling rack and a barrel moving rack, wherein the axis of two rows of transmission shafts on the barrel rolling rack and the axis of two rows of transmission shafts on the barrel moving rack are on the same horizontal plane, and the axis of two rows of transmission shafts of two types of racks at the same side is collinear so as to ensure that the butt joint barrels are on the same axis; the barrel on the moving rack carries out linear displacement under the transmission action of a moving rack lead screw so as to realize automatic butt joint; under the axial pressure maintained by spring extension, circumference grinding is carried out to enhance the butt joint precision of two barrels; the transmission of the moving rack lead screw drives the butt joint barrel to carry out the linear displacement; and the butt join barrel on the rolling rack carriesout circumference rolling to form an opposite spiral butt join-grinding movement with the linear displacement barrel on the moving rack. The tooling equipment of the invention improves equipment service life, reduces energy consumption, improves precision, has simple structure, strong reliability, high butt join precision and speed, time and labor saving, safety and high efficiency and lowers equipment investment.

Owner:SINOMA TECH (XUZHOU) HEAVY MASCH CO LTD +1

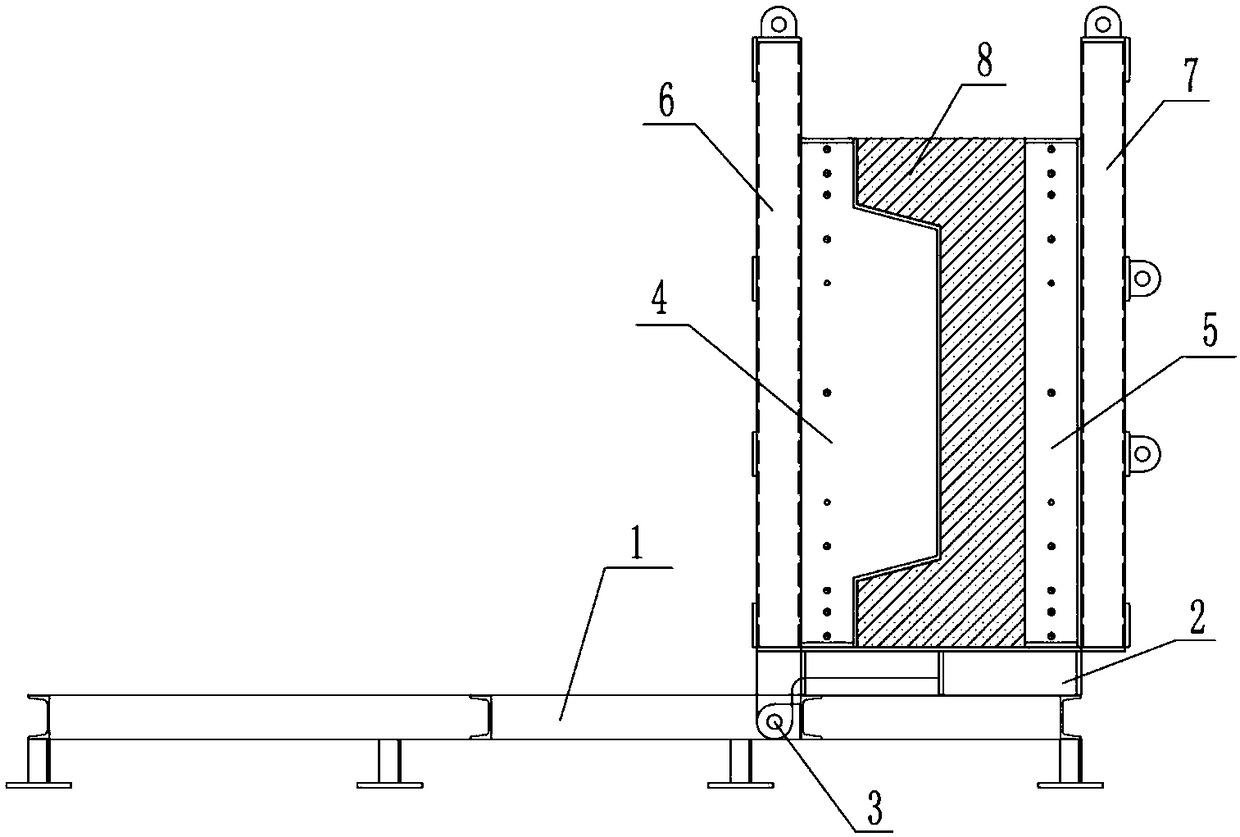

Reaction frame and method for adopting reaction frame for performing static testing

PendingCN108398255AAvoid stress concentrationEasy to transportMachine part testingStress concentrationEngineering

The invention discloses a reaction frame and a method for adopting the reaction frame for performing static testing. The reaction frame comprises a supporting unit, a loading unit and a load uniform unit, wherein the supporting unit comprises at least two supporting columns, and the loading unit is arranged on the supporting unit and applies loads to a piece to be loaded; the load uniform unit isarranged between the loading unit and the piece to be loaded and used for uniforming the loads applied to the piece to be loaded by the loading unit; the supporting unit can rotate around the axis ofat least one supporting column. By arranging the load uniform unit, the phenomenon that stress concentration is caused due to the fact that the loads are applied to the piece to be loaded by the loading unit can be effectively avoided; meanwhile, the supporting unit is rotatable, the supporting unit is rotated so that a testing region below an electric hoist hook is not blocked, the piece to be loaded is convenient to transport, and the hoisting requirement for the piece to be loaded is lowered.

Owner:ZHANJIANG JIANKE ENG QUALITY TESTING CENT CO LTD

Method for rapidly installing steelmaking diffusing tower in narrow area

The invention discloses a method for rapidly installing a steelmaking diffusing tower in a narrow area. The method includes the steps of dividing a main pipe into three branch pipes, arranging an operating platform at the upper end of each branch pipe, and independently installing the three branch pipes. The method has the advantages that the main pipe of the diffusion tower is divided into the three branch pipes to be respectively lifted, the lifting requirement for a crane is reduced, the length of the main pipe is shortened in a converted mode, and therefore the diffusion tower can be installed in the narrow area; the operating platforms are arranged below the connecting positions of the three branches, and therefore convenience is brought to welding fixation between the branch pipes.

Owner:CHINA MCC5 GROUP CORP

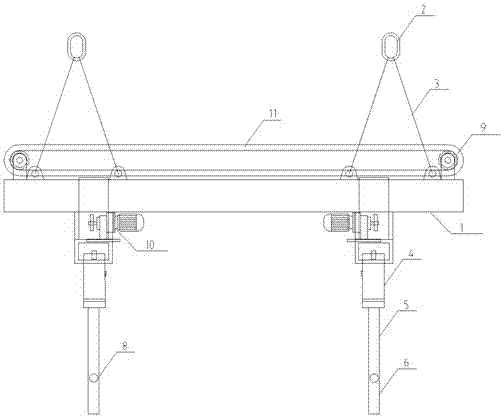

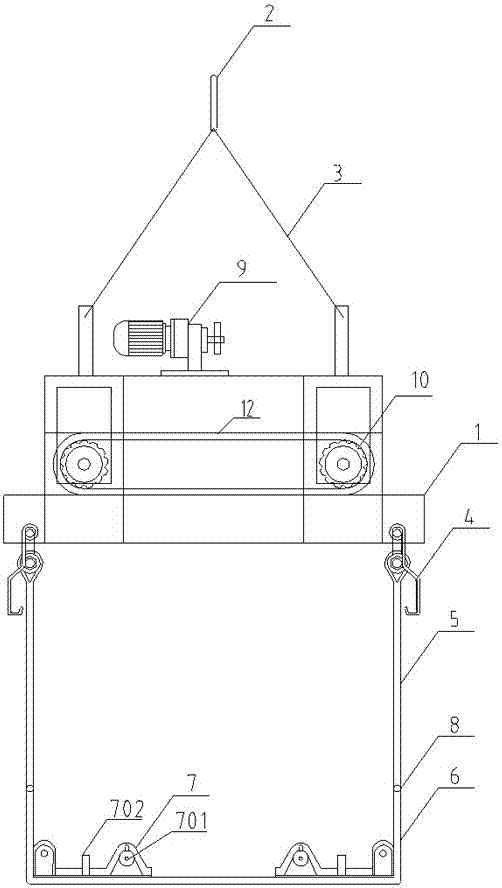

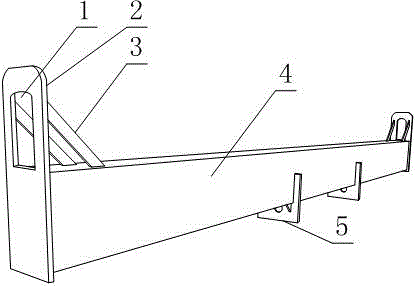

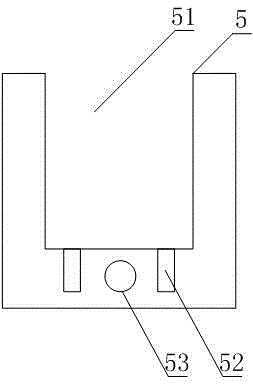

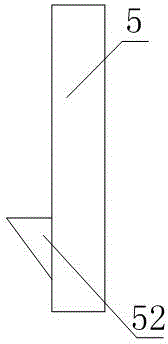

Novel lifting appliance for transporting passenger car body

ActiveCN105110166AReduced lifting requirementsMeet the lifting requirementsLoad-engaging elementsCar passengerControl theory

The invention provides a novel lifting appliance for transporting a passenger car body. The novel lifting appliance comprises a lifting appliance body and a lifting eye device, wherein the lifting appliance body comprises a main framework and a lifting ring connected with the main framework through a lifting chain; the main framework comprises four lifting points; the lifting eye device comprises lifting claws arranged on the lifting points respectively; lifting point slings are also arranged on the lifting points; each lifting point sling is connected with a U-shaped support through a connecting ring. The novel lifting appliance has the advantages that complete dependence on the upper part side window structure of the passenger car body is avoided; the strength pressure on the upper part side window structure is reduced; the novel lifting appliance is suitable for passenger car bodies with arc side windows, and convertible and semi-convertible sightseeing buses; the lifting requirements of passenger car bodies of almost all structures can be met approximately. Moreover, due to the arrangement of the U-shaped support device, the stability of the passenger car body when the passenger car body is lifted up is enhanced; friction between the lifting belts and the skin of the passenger car body is avoided. Furthermore, manual moving is avoided during the lifting process, so that the labor efficiency is greatly improved, and the potential safety hazard is reduced.

Owner:ANHUI ANKAI AUTOMOBILE

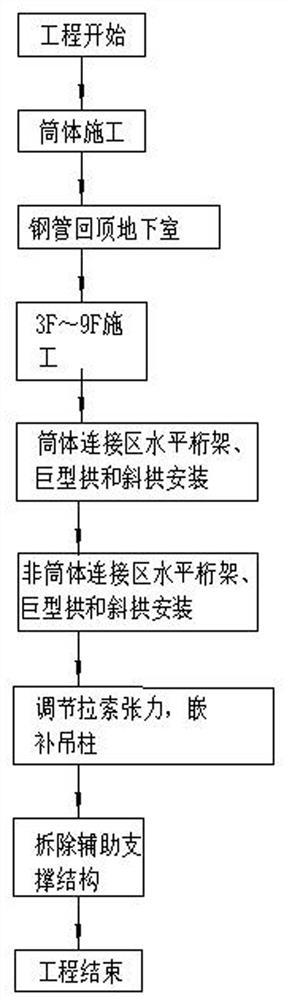

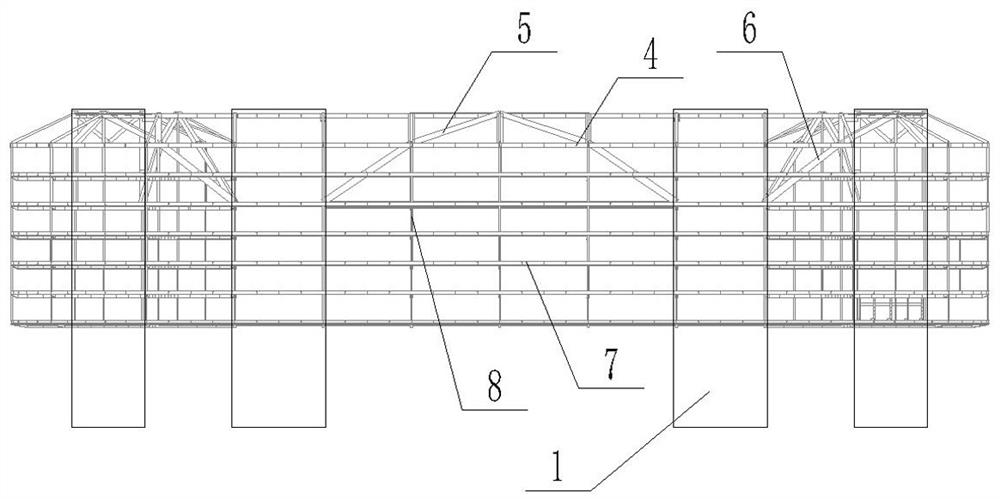

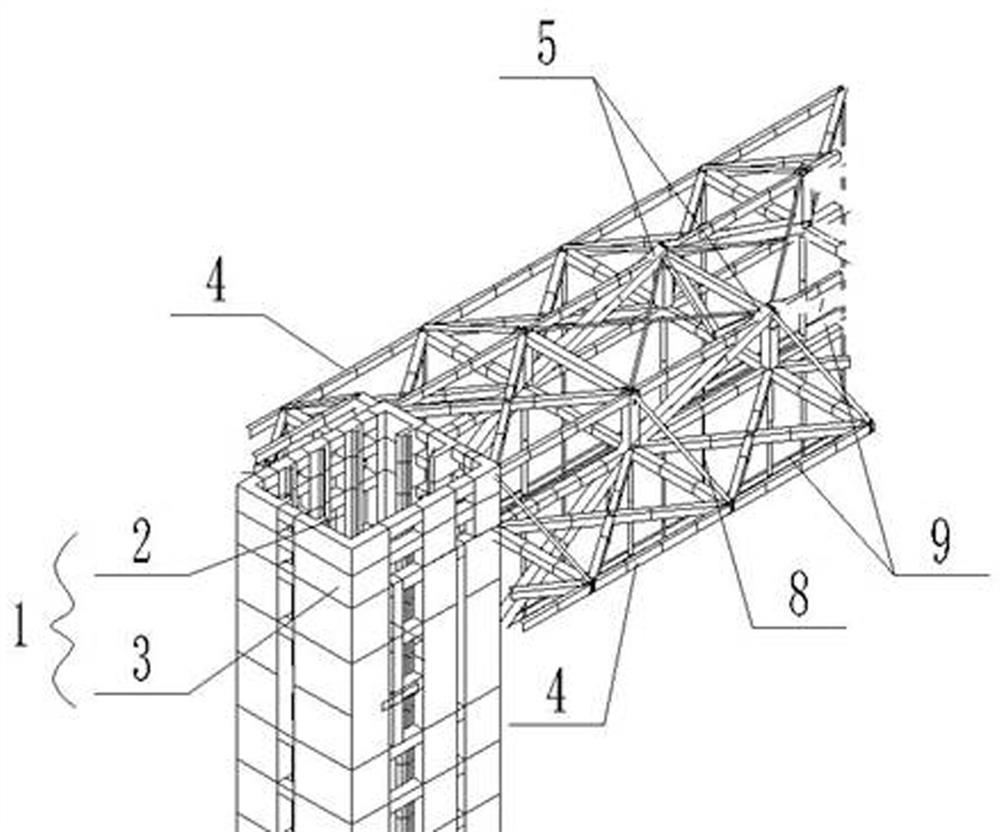

Horizontal truss system containing giant arch and construction method of horizontal truss system

PendingCN113882507AEven by forceDoes not affect the usable areaFloorsBuilding material handlingReinforced concreteArchitectural engineering

The invention discloses a horizontal truss system containing a giant arch and a construction method of the horizontal truss system. The horizontal truss system is arranged on the upper portions of a plurality of barrels and comprises a horizontal truss structure, the whole horizontal truss structure is in a rectangular-ambulatory-plane shape, each barrel is of a reinforced concrete structure and comprises a core barrel and a steel framework, the upper end of the core barrel penetrates through the horizontal truss structure, the pair of giant arches is arranged on each edge of the horizontal truss structure and located between the barrels on the two sides, a pair of inclined arches is arranged between the barrels on the two sides of each corner, and the structure forms a stress self-balancing system and has few supporting structures; the construction method of the structure mainly comprises the steps of steel structure installation of the barrel, concrete structure construction, supporting structure building, steel bar truss floor support plate laying, giant arch and horizontal truss structure installation and supporting structure dismantling, a stress self-balancing system is built through an auxiliary supporting structure, the construction process of the structure is simplified, and the construction period and cost are reduced.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Lifting equipment

ActiveCN107324233BIncrease resistanceReduced lifting requirementsPortable liftingLoad-engaging elementsSpecific functionEngineering

Owner:CHINA NAT CHEM ENG HEAVY MECHANIZED CORP

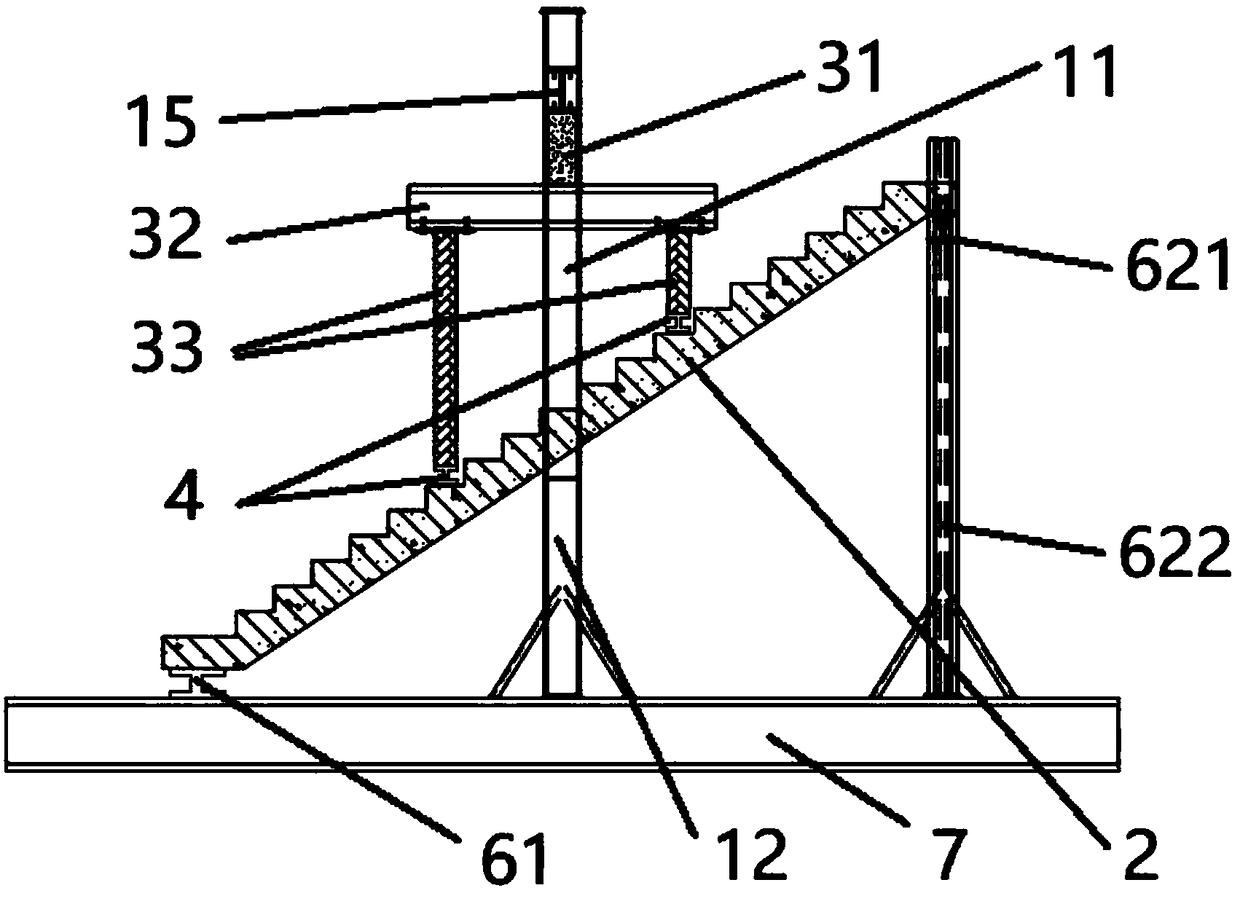

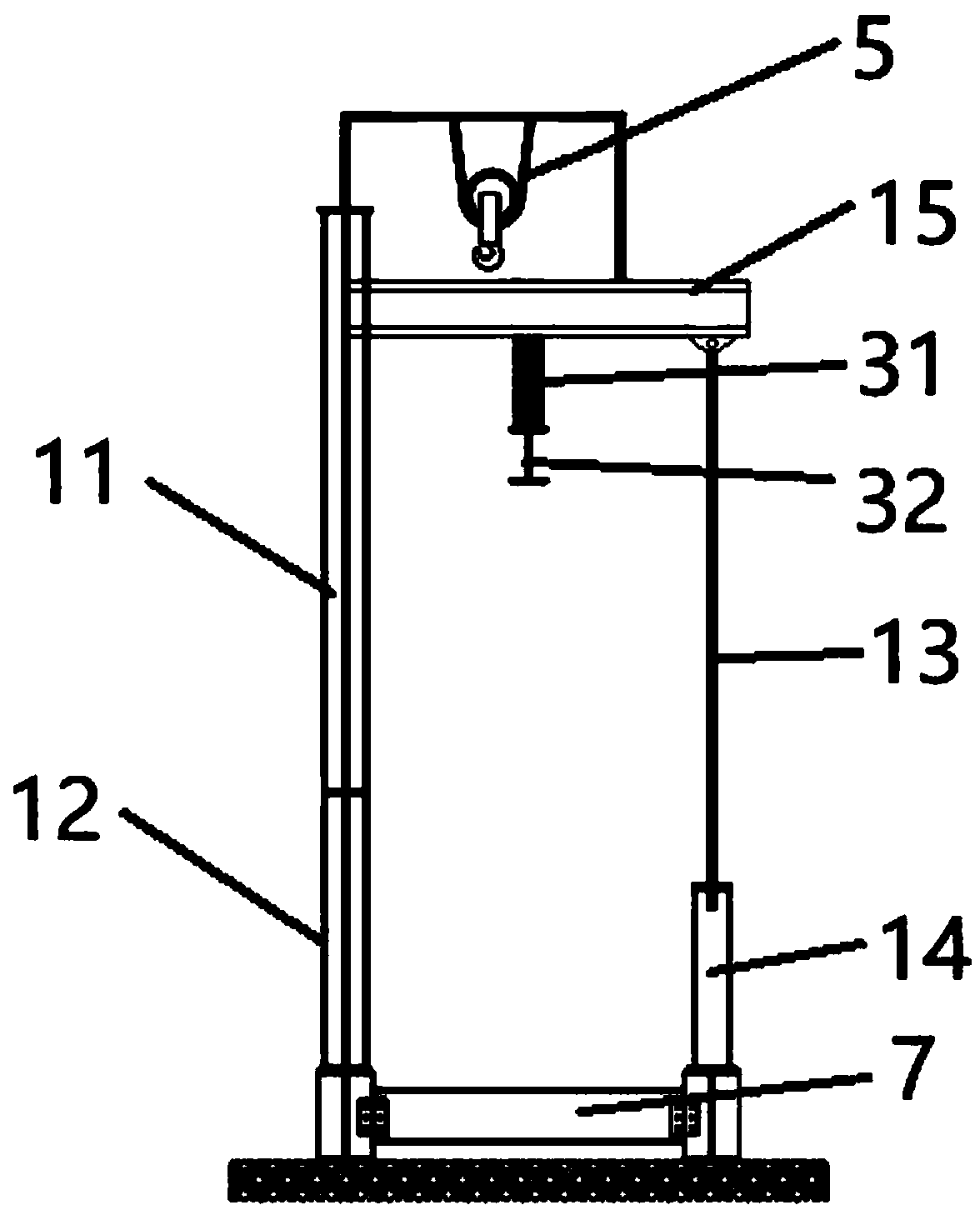

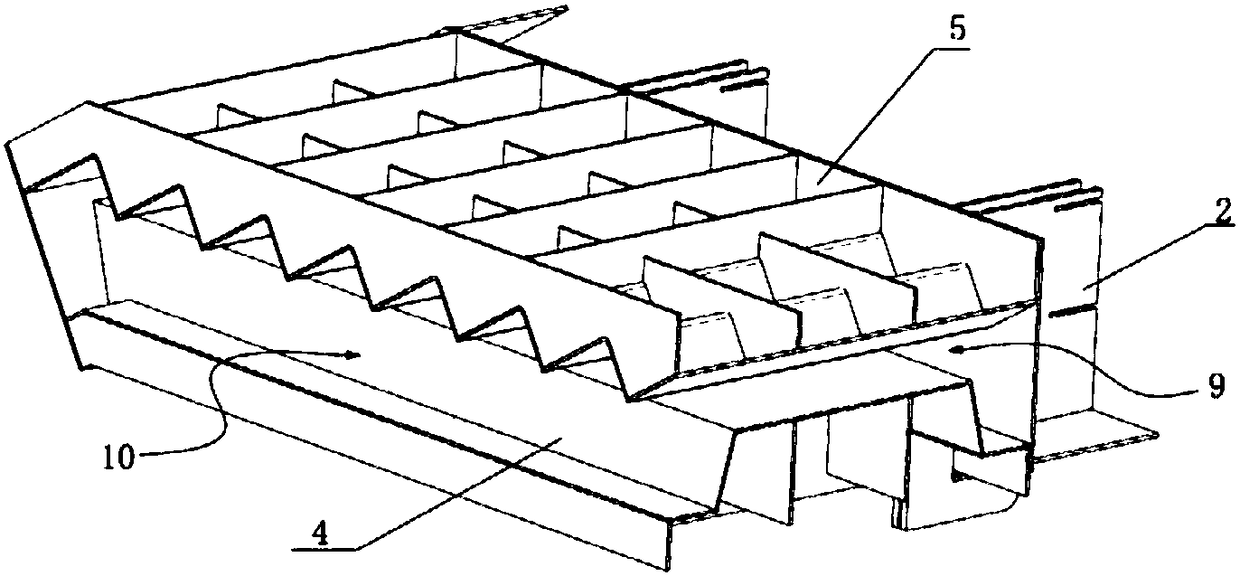

A prefabricated concrete staircase mold and its manufacturing method

ActiveCN106378861BAvoid destructionReduce the construction of the receiving surfaceMouldsMould auxillary partsPrecast concreteBy-product

The invention discloses a prefabricated type concrete stair mould and a stair manufacturing method. The mould comprises a back board molding board and a step surface molding board which are detachably connected; the molding boards are combined into a cavity for pouring prefabricated concrete stairs, and are equipped with side openings for pouring concrete; the mould further comprisesa supporting base; the molding boards are rotatably connected on the supporting base; and each molding board has a horizontal state and a perpendicular state for forming an upward opening after being turned over around a rotary connecting part. The manufacturing method comprises the following steps of: suspending a reinforcing mesh cage, assembling a step surface molding board, turning the mould into a perpendicular state, pouring concrete, turning the mould into a horizontal state, disassembling the step surface molding board and the like. According to the mould and a construction method thereof, prefabricated concrete stairs do not needed to be turned over while the horizontal type stair mould is disassembled, damages caused by product turning over are avoided, most important features and least light receiving surface requirements of vertical type stairs are met, forming appearance is good, and product quality is guaranteed.

Owner:湖北科宇智能装备有限公司

A light-steel keel composite wood wool panel for external hanging wall panel and manufacturing method thereof

The invention relates to an externally-hung wallboard manufactured by compounding light steel keels and wood wool slabs, and a manufacturing method of the externally-hung wallboard. The externally-hung wallboard comprises a light steel keel skeleton, the wood wool slabs and foam concrete, wherein the light steel keel skeleton has a fence structure formed by a plurality of vertical keels and horizontal through keels; the wood wool slabs are respectively connected with the two sides of the surface of the light steel keel skeleton, so that a wallboard structure is formed; the parts between the light steel keel skeleton and the wood wool slabs are filled with the foam concrete, and the externally-hung wallboard is formed after the foam concrete is solidified. Compared with the prior art, the externally-hung wallboard has the advantages that the wallboard is low in manufacturing cost and environmentally-friendly in materials; the wallboard has excellent functions of heat preservation, heat insulation and noise absorption; the externally-hung wallboard is light in structure, high in rigidity, firm and durable; the externally-hung wallboard is simple in construction and low in hoisting requirement; the surface of the wallboard has a waterproof function and is corrosion-resistant.

Owner:TONGJI UNIV

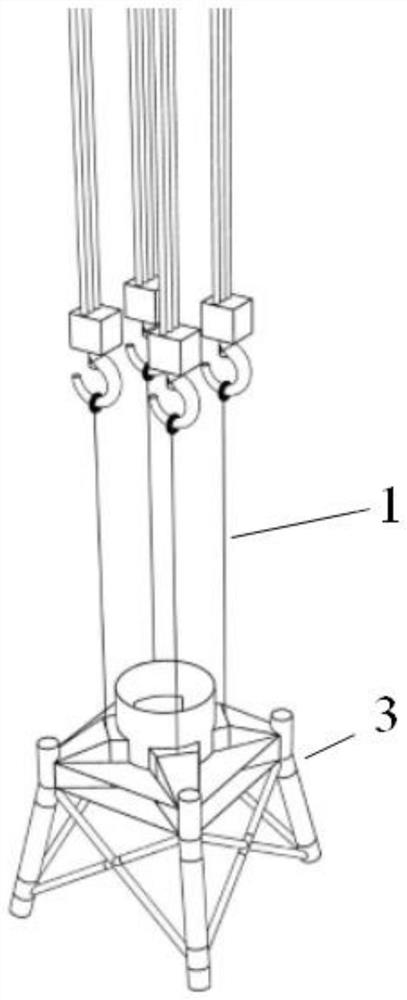

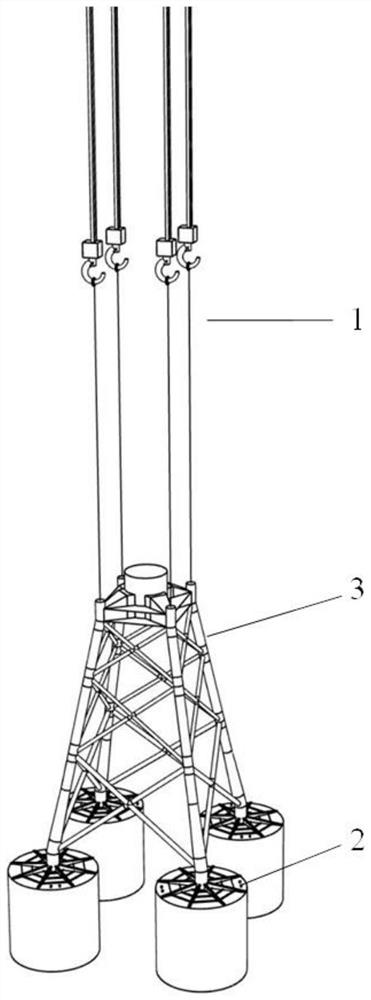

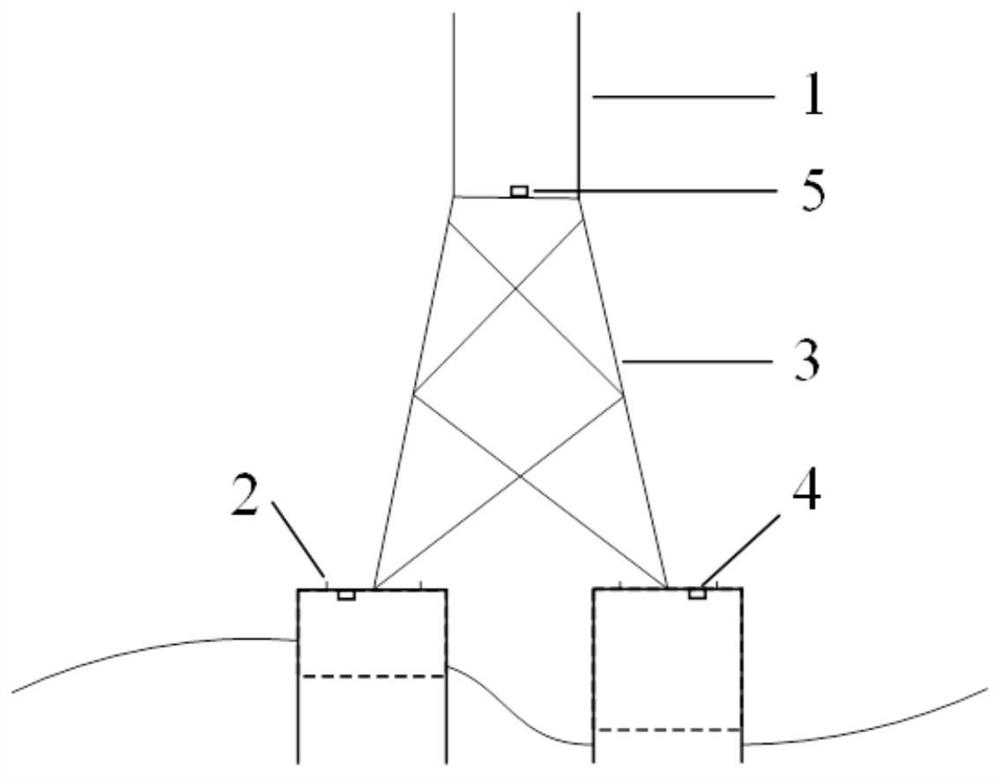

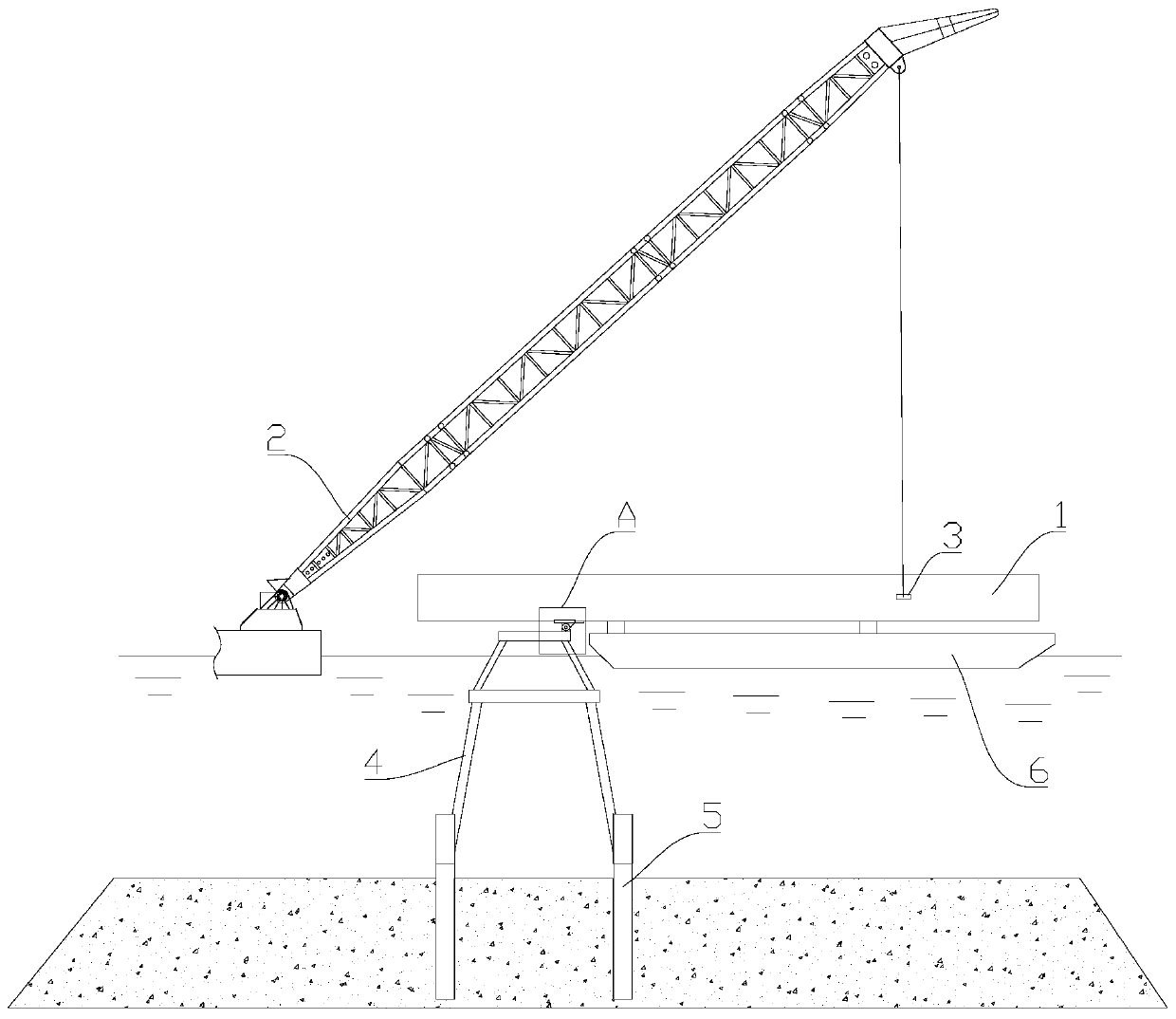

Attitude control method for splash zone of offshore wind power multi-barrel jacket foundation

ActiveCN113415724AImprove posture controlAvoid construction risksFoundation engineeringWind energy generationSuction forceMarine engineering

The invention belongs to the technical field of offshore wind power foundations, and discloses an attitude control method for a splash zone of an offshore wind power multi-barrel jacket foundation; the wave height condition and various existing construction states are systematically considered; each suction barrel of the multi-barrel jacket foundation is equipped with an independent hanging cable; the lowering and / or jacking speed of the multi-barrel jacket foundation is controlled; in the sinking and / or recycling process of the multi-barrel jacket foundation, the suction barrels are kept in the suffocated state; certain buoyancy is provided; furthermore, the buoyancy is adjusted by inflating or deflating the suction barrels; then, the tension of the hanging cables is controlled, so that the hanging force of the hanging cables is effectively reduced in the crossing process of the splash zone; the hoisting requirement for a self-elevating installation ship or a floating crane ship is effectively reduced; the attitude control capability of the lowering process and / or the recovery process of the multi-barrel jacket foundation is obviously enhanced; the construction accuracy is improved; the construction operability is enhanced; and the construction risk when the multi-barrel jacket foundation passes through the splash zone is avoided.

Owner:张浦阳 +1

Quick Installation Method of Steelmaking Diffuser Tower in Narrow Area

The invention discloses a method for rapidly installing a steelmaking diffusing tower in a narrow area. The method includes the steps of dividing a main pipe into three branch pipes, arranging an operating platform at the upper end of each branch pipe, and independently installing the three branch pipes. The method has the advantages that the main pipe of the diffusion tower is divided into the three branch pipes to be respectively lifted, the lifting requirement for a crane is reduced, the length of the main pipe is shortened in a converted mode, and therefore the diffusion tower can be installed in the narrow area; the operating platforms are arranged below the connecting positions of the three branches, and therefore convenience is brought to welding fixation between the branch pipes.

Owner:CHINA MCC5 GROUP CORP

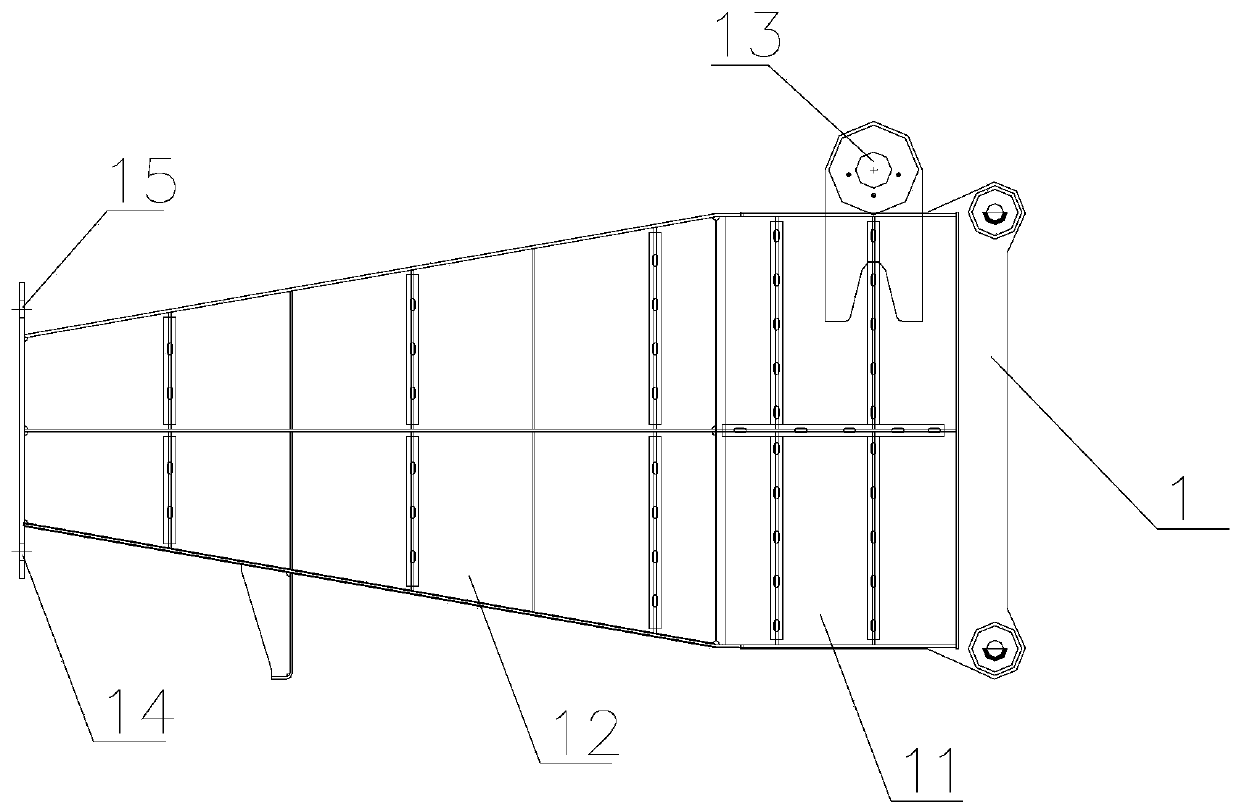

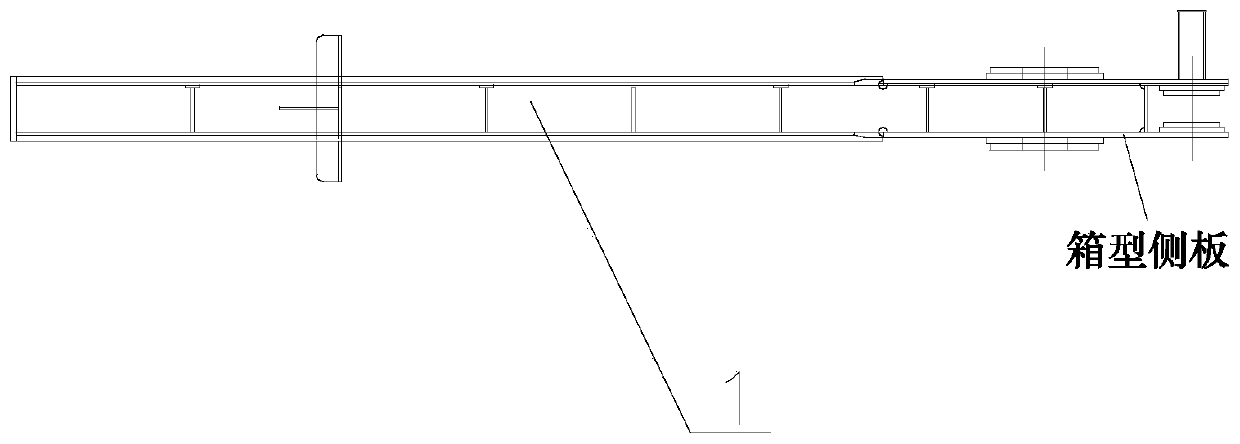

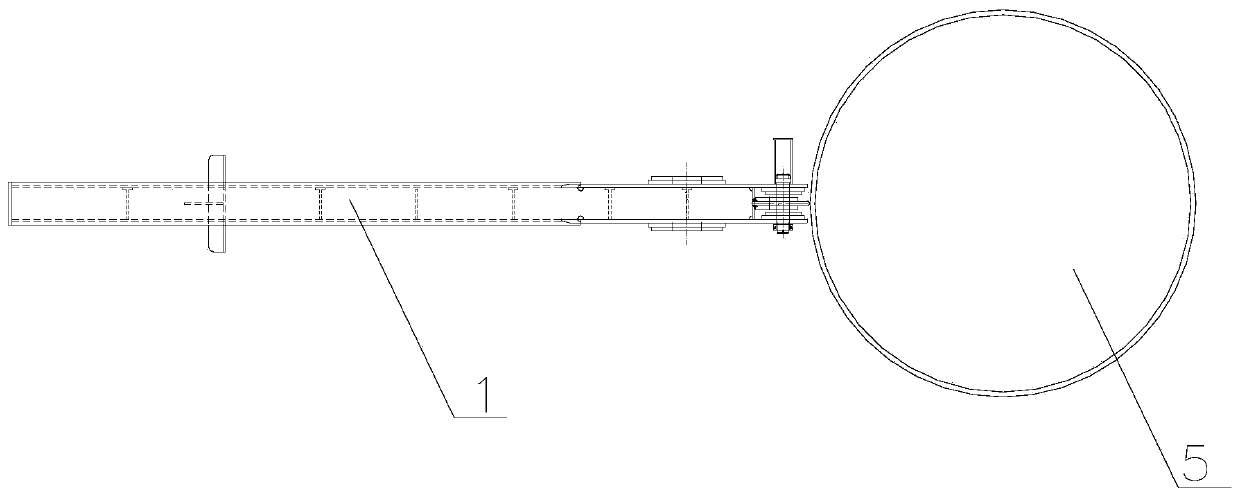

A combined beam beam and hanging beam device and its hoisting method

ActiveCN109230978BLower the altitudeReduced lifting requirementsLoad-engaging elementsEngineeringStructural engineering

The invention discloses a combined weighing rod lifting beam device, comprising two weighing rod lifting beams which separately have a flat box-shaped structure on the whole; each weighing rod liftingbeam comprises an equal width section and a gradual contraction section, wherein the upper end of each equal width section is provided with a lifting lug; the tail end of each weighing rod lifting beam is provided with a counterweight connection hole. The combined weighing rod lifting beam device solves the problem that a crane cannot lift from the upper part of a structure of an object to be lifted due to the insufficient lifting height; after the combined weighing rod lifting beam device is connected and fixed with the object to be lifted, the height required for lifting is lowered, and thelifting requirements are reduced. When the crane cannot lift from the upper part of the object to be lifted due to the insufficient lifting height, a main beam is formed by using a connecting beam torealize bolted fixation between the two weighing rod lifting beams, and the main beam and two side beams are connected and fixed with three apex structures of the triangular section of the object tobe lifted. After the main beam is disassembled, the two weighing rod lifting beams can be independently used for lifting a columnar structure with a circular or rectangular cross section.

Owner:广州黄船海洋工程有限公司

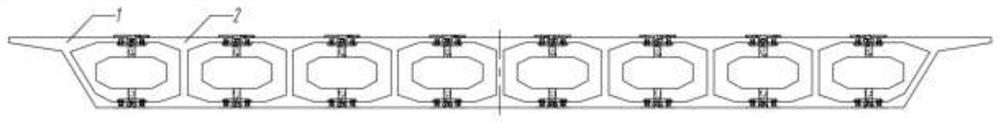

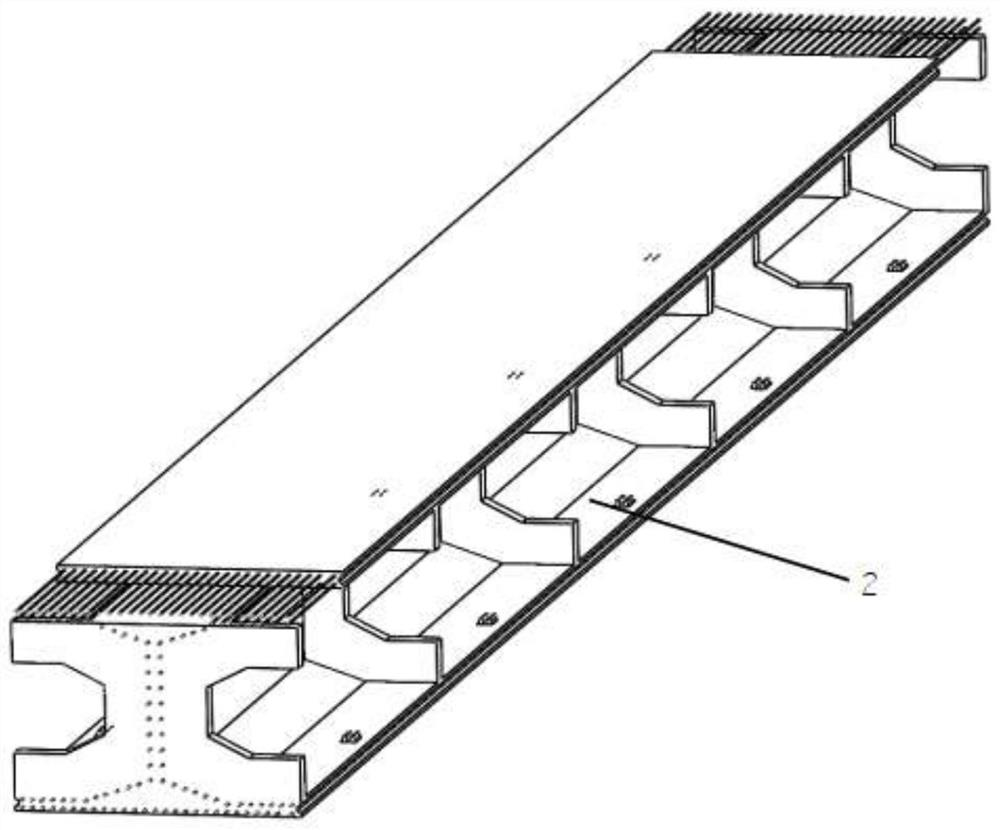

A new construction method for superstructure of multi-chamber continuous uhpc box girder bridge

ActiveCN111877182BReasonable designImprove mechanical performanceBridge erection/assemblyBridge materialsArchitectural engineeringStructural engineering

The invention discloses a novel multi-chamber continuous UHPC box girder bridge superstructure construction method, including UHPC prefabricated longitudinal block beam, UHPC prefabricated longitudinal block side beam, cast-in-place UHPC joint, prefabricated steel connector, shear force Nails, pre-embedded steel backing plates, pre-embedded bolts, temporary supports, permanent supports, stiffened beams, cast-in-place UHPC bottom plates, cast-in-place UHPC webs, cast-in-place UHPC roofs and thickened areas, simply supported system girders, stiffeners Beam floor, main beam web. The beneficial effect of the present invention is: the multi-chamber UHPC box girder is prefabricated in longitudinal blocks, assembled and connected on site through special connectors, and several multi-chamber simply supported box girders are first formed, and then passed on the pier by special The pouring method makes the box girder structure change from simply supported to continuous. The structural quality is excellent, the splicing is reliable, the mechanical performance and durability are good, the construction is convenient, the construction period can be greatly shortened, and the space under the bridge can be saved, which is very suitable for the needs of construction and development.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

Automatic butt joint and grinding-in tooling equipment of large barrel

InactiveCN101992370BMaintain always elastic contactReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesButt jointDrive shaft

The invention discloses automatic butt joint and grinding-in tooling equipment of a large barrel, which is mainly composed of a barrel rolling rack and a barrel moving rack, wherein the axis of two rows of transmission shafts on the barrel rolling rack and the axis of two rows of transmission shafts on the barrel moving rack are on the same horizontal plane, and the axis of two rows of transmission shafts of two types of racks at the same side is collinear so as to ensure that the butt joint barrels are on the same axis; the barrel on the moving rack carries out linear displacement under the transmission action of a moving rack lead screw so as to realize automatic butt joint; under the axial pressure maintained by spring extension, circumference grinding is carried out to enhance the butt joint precision of two barrels; the transmission of the moving rack lead screw drives the butt joint barrel to carry out the linear displacement; and the butt join barrel on the rolling rack carries out circumference rolling to form an opposite spiral butt join-grinding movement with the linear displacement barrel on the moving rack. The tooling equipment of the invention improves equipment service life, reduces energy consumption, improves precision, has simple structure, strong reliability, high butt join precision and speed, time and labor saving, safety and high efficiency and lowers equipment investment.

Owner:SINOMA TECH (XUZHOU) HEAVY MASCH CO LTD +1

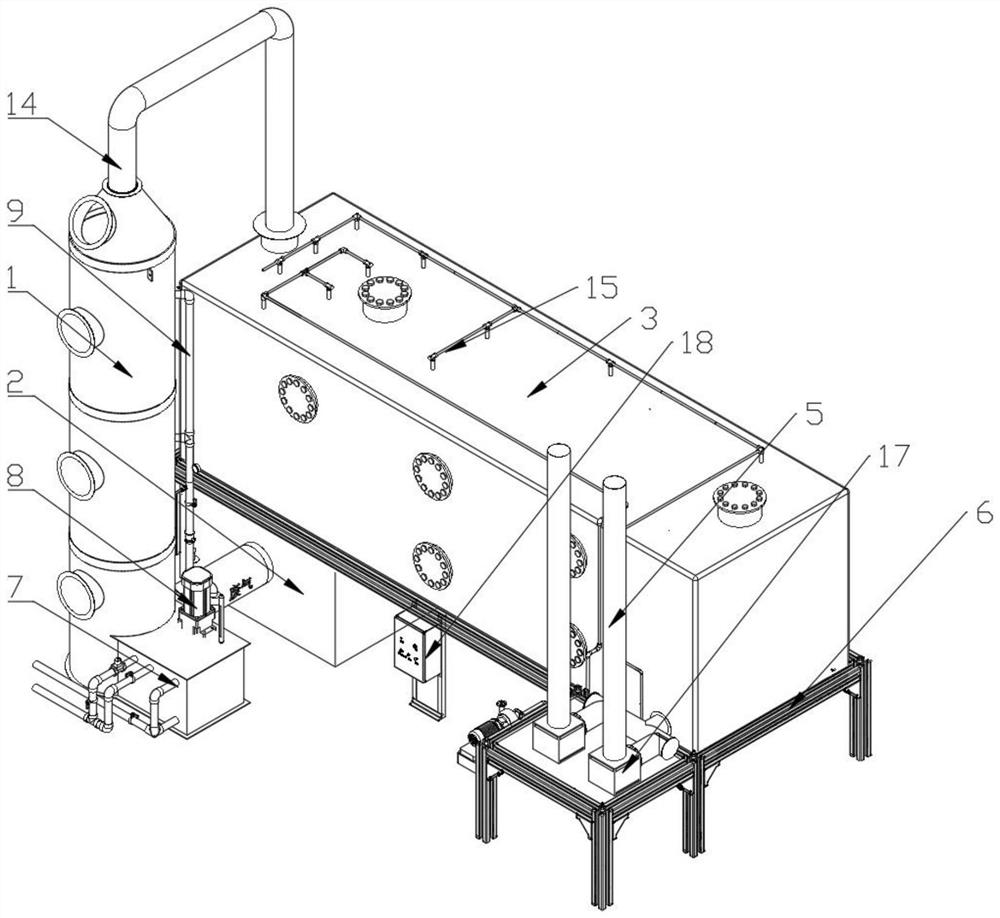

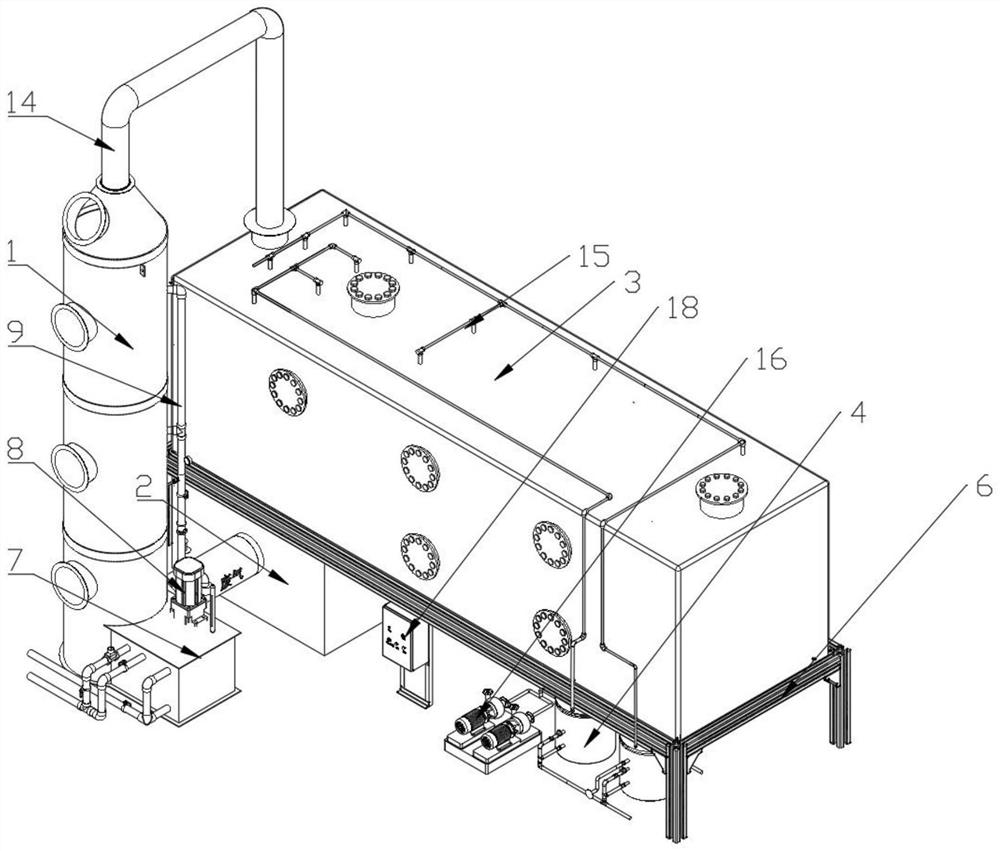

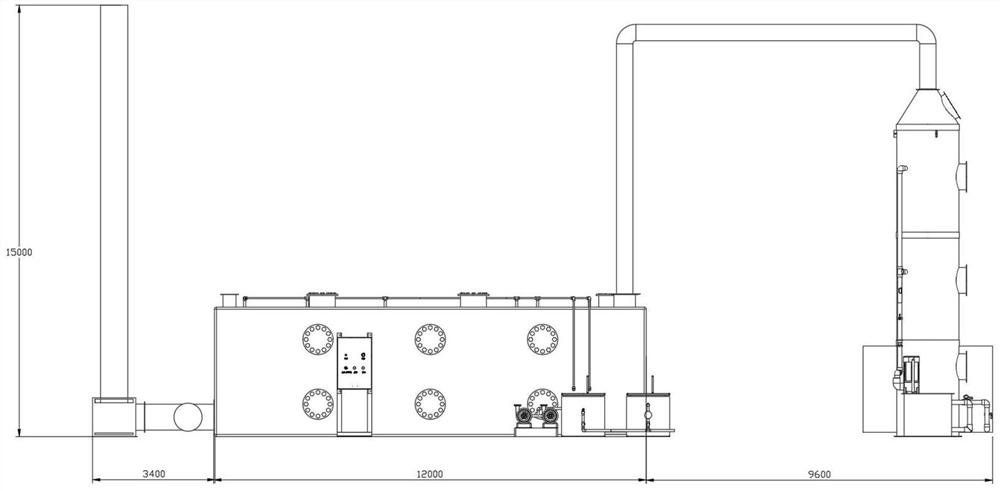

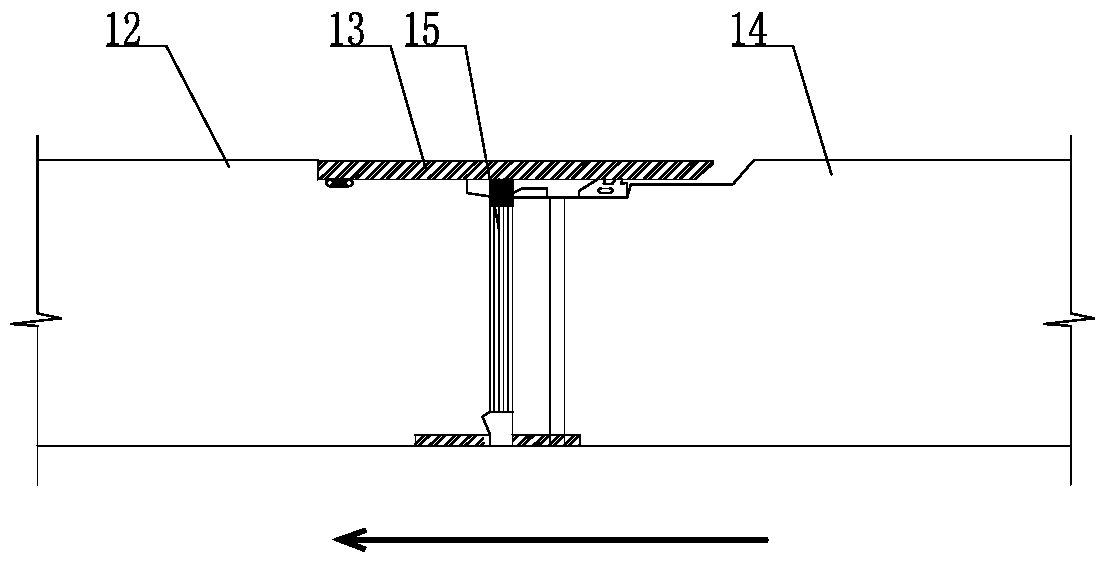

Novel apron conveyor slag removal device

PendingCN114288846AReduce lifting requirementsReduce power consumptionDispersed particle separationAir quality improvementAir pumpProcess engineering

A novel apron conveyor slag removal device comprises a washing tower, an air pump box, a filter box, a feeding barrel and an exhaust pipe, the air pump box, the washing tower, the filter box and the exhaust pipe are sequentially connected, the feeding barrel is connected with the filter box, the filter box and the exhaust pipe are both carried on a base frame, the air pump box and the feeding barrel are both located in the base frame, and the filter box is connected with the exhaust pipe. The exhaust pipe and the washing tower are located on the same side of the filter box, the filter box comprises a gas inlet box, an alkaline box, a biological box and a gas outlet box, and the gas inlet box, the alkaline box, the biological box and the gas outlet box are sequentially connected from the head end to the tail end. The air power device has the advantages that the positions of the washing tower, the exhaust pipe and the filter box are rearranged, the requirement for an equipment building site is lowered, the air lifting requirement is lowered by raising the filter box, meanwhile, the feeding box and the air pump box are arranged below the filter box, the space structure is further optimized, power consumption of the air power device is lowered, and noise is lowered.

Owner:德州众和环保装备制造有限公司

New passenger car body transfer spreader

ActiveCN105110166BReduced lifting requirementsMeet the lifting requirementsLoad-engaging elementsEngineering

The invention provides a novel passenger car body transfer spreader, which includes a spreader body and a lifting lug device, the spreader body includes a main frame and a lifting ring connected to the main frame through a lifting chain; four lifting points are arranged on the main frame , the lifting lug device includes lifting claws respectively arranged on each lifting point; the lifting point is also provided with a lifting point sling, and the lifting point sling is connected to a U-shaped lifting device through a connecting ring. The present invention avoids all dependence on the upper side window structure of the passenger car body, reduces the structural strength pressure of the upper side window, and is suitable for the body with curved side windows, as well as open-top and semi-open-top sightseeing cars, and basically meets all requirements. Structural bus body lifting requirements. At the same time, the setting of the U-shaped lifting device strengthens the stability when lifting the vehicle body and avoids friction between the suspenders and the skin of the vehicle body. In addition, manual movement is avoided during the lifting process, which greatly improves labor efficiency and reduces potential safety hazards.

Owner:ANHUI ANKAI AUTOMOBILE

Self-lifting wall-attaching crane for superhigh-rise building construction with core drum

InactiveCN1935622BOvercome the inadequacies that cannot climb on their ownReduced lifting requirementsCranesTower craneAnchor bolt

The invention relates to a wall attachment crane, especially a self-elevating wall attachment crane, comprising attachment self-elevating mechanism and hoisting equipment, where extension of hydraulic oil cylinder of the attachment self-elevating mechanism makes wall attachment crane frame and runner frame slide on the outer wall of a kernel cylinder in turn, so as to support attachment in turn of wall attachment crane frame anchor bolt and runner frame anchor bolt on the outer wall of the kernel cylinder, thus meeting the requirements of self-elevating on the outer wall of the kernel cylinder. And it has functions of self-elevating attached to the outer wall of the kernel cylinder according to the given requirements and performing hoisting operation; and it largely improves economy; it adopts a combined structure, simplifies assembly and disassembly and the wall attachment crane frame can be equipped with the hoisting equipment and other matching construction equipment.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Lifting tool and lifting method applying tool

InactiveCN104891321AReduced lifting requirementsReduce dependenceLoad-engaging elementsGravitationRollover

The invention discloses a lifting tool and a lifting method applying the tool. The method is realized in dependence on the tool; the tool structure, serving as a middle transition piece, is used as a middle piece in a lifting process of such weights as a leveler frame; the lifting force to the weights can be transferred to different unbuckling plates through a cross beam, so that the lifting requirement on a single crane can be reduced, and the reduction of the dependency on the workshop crane lifting capacity is facilitated; the lifting of the weights with different shapes or volumes can be satisfied through adjusting the positions of the unbuckling plates; and the provided lifting tool can obtain multiple lifting points on the weights conveniently, facilitates prevention or reduction of the generation possibility of such dangerous conditions as rollover of the weights caused by the problem that the gravity centers are not on a lifting ascending line in the lifting process of the weights, and facilitates improvement of the lifting stability.

Owner:CHINA MCC5 GROUP CORP

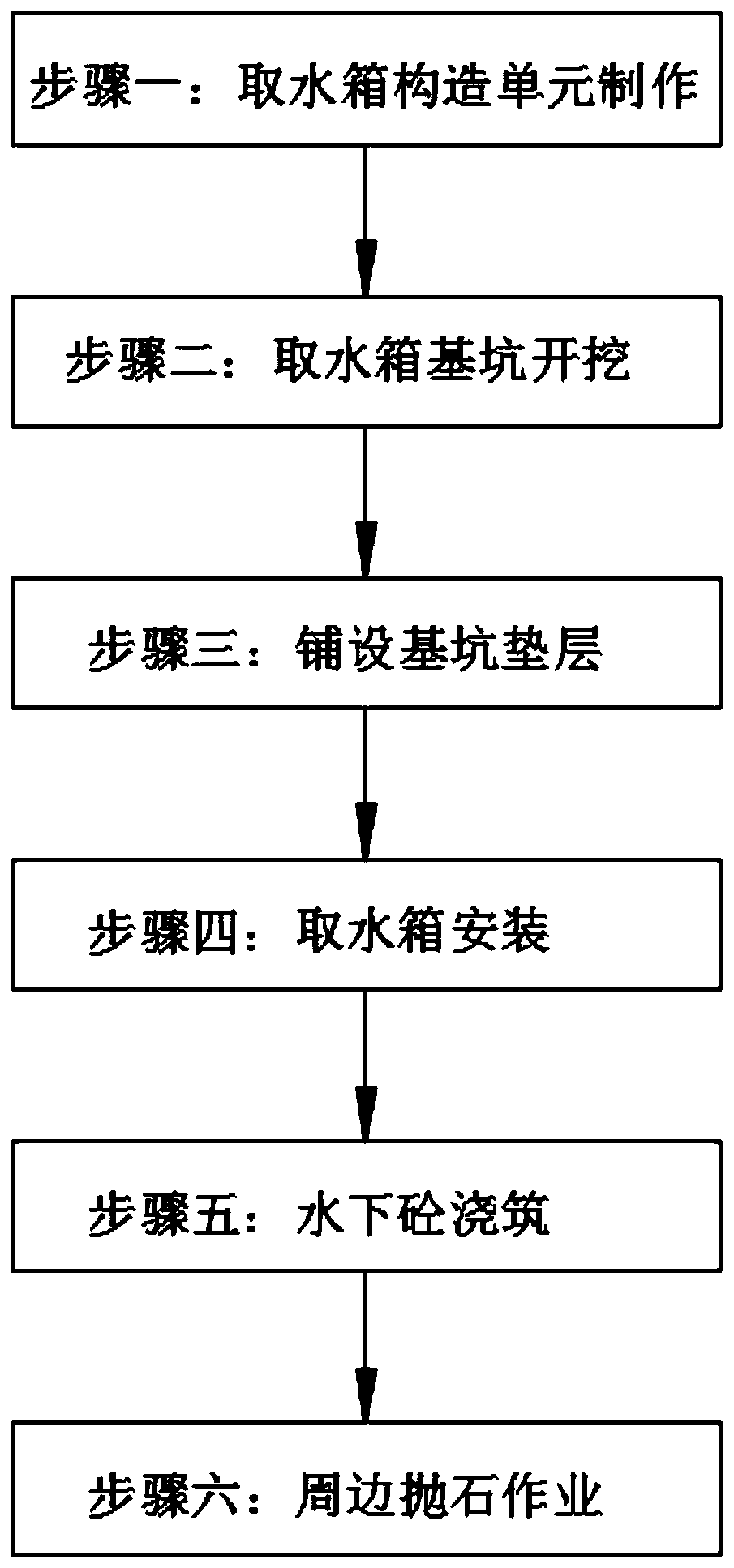

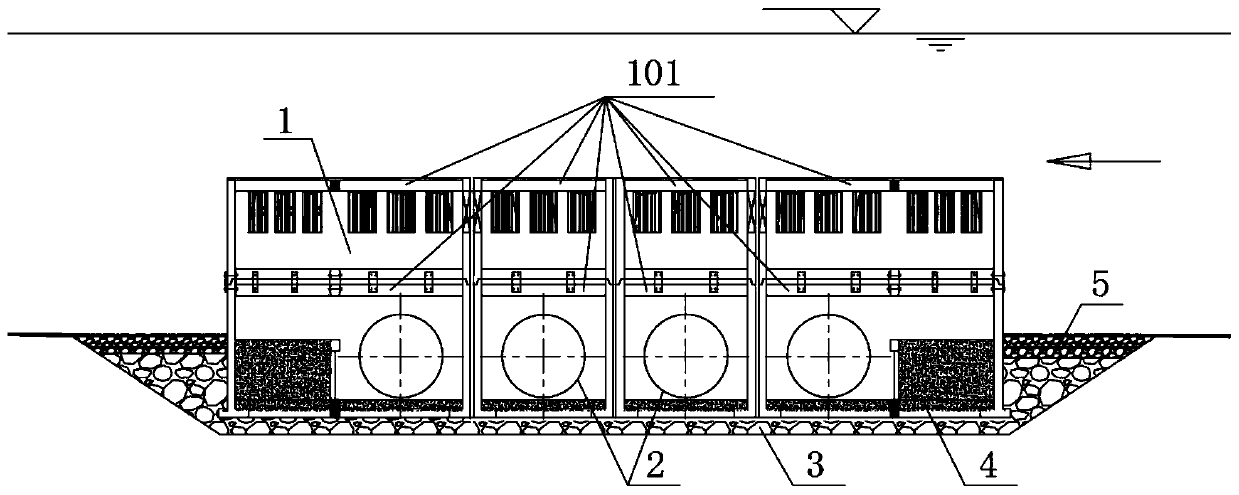

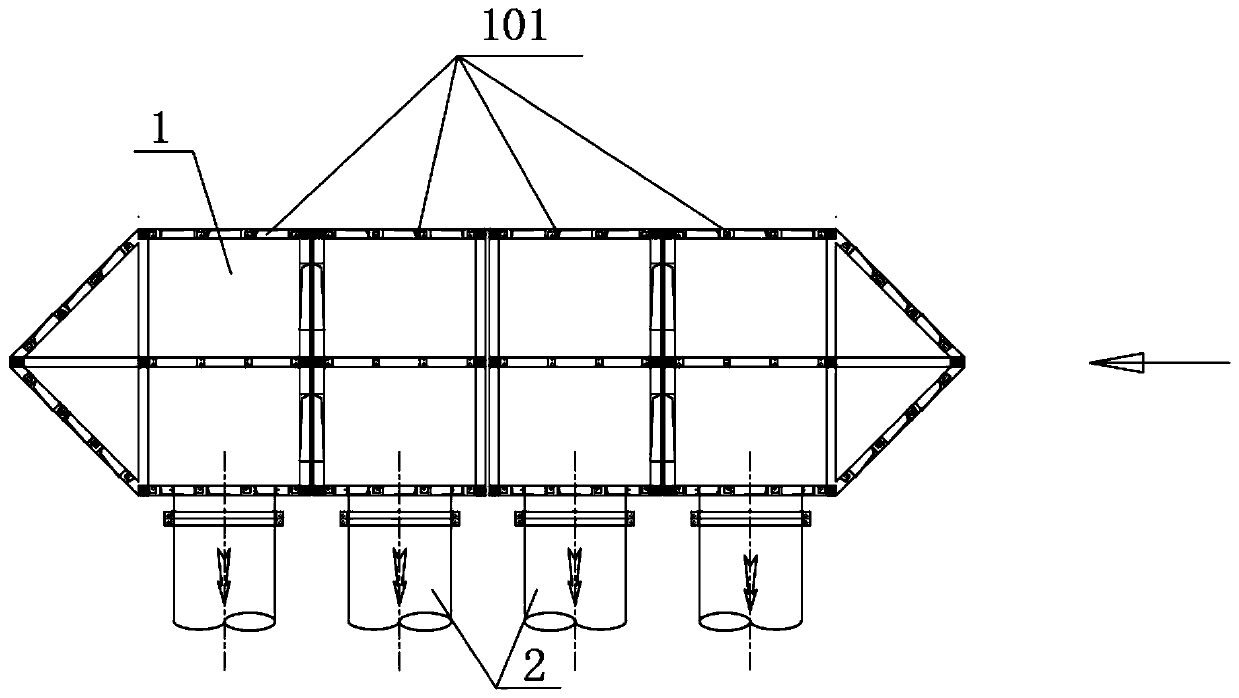

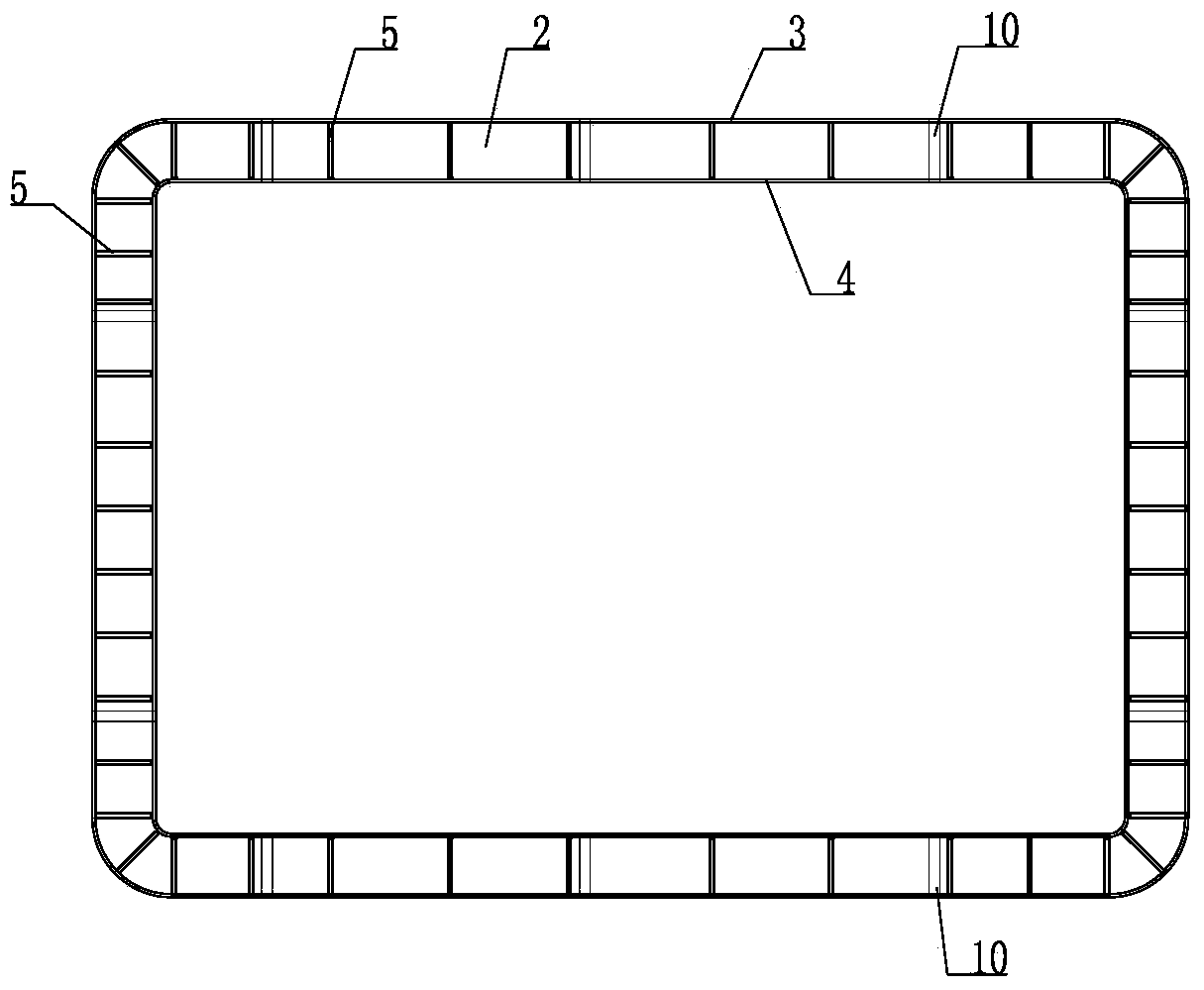

Method for manufacturing and mounting water taking tank for drinking water project

InactiveCN110258725AReduced lifting requirementsShorten construction timeWater supply tanksCofferdamEngineering

The invention belongs to the technical field of construction of drinking water projects, and discloses a method for manufacturing and mounting a water taking tank for a drinking water project. The method comprises the five steps that 1, construction units of the water taking tank are manufactured; 2, a foundation pit of the water taking tank is excavated; 3, a foundation pit cushion layer is laid; 4, the water taking tank is mounted; and 5, underwater concrete pouring is conducted. The method that water clean mud and the water taking tank are divided into a plurality of construction units to be prefabricated on a shore, then the construction units are transported to the water face position of a water taking point for sinking in place and assembling is adopted, a cofferdam does not need to be arranged, the construction time is saved, and the construction cost is reduced; and the water taking tank is prefabricated in blocks and then is hoisted into water for assembling, the single-time hoisting weight is decreased, and the lifting requirements for a floating crane are reduced.

Owner:CHINA HUAYE GROUP +1

Steel-concrete-ultrahigh performance concrete combined segment and construction method thereof

ActiveCN113217018AUniform and dense microstructureImprove impermeabilityUnderground chambersWind energy generationArchitectural engineeringStructural engineering

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL +1

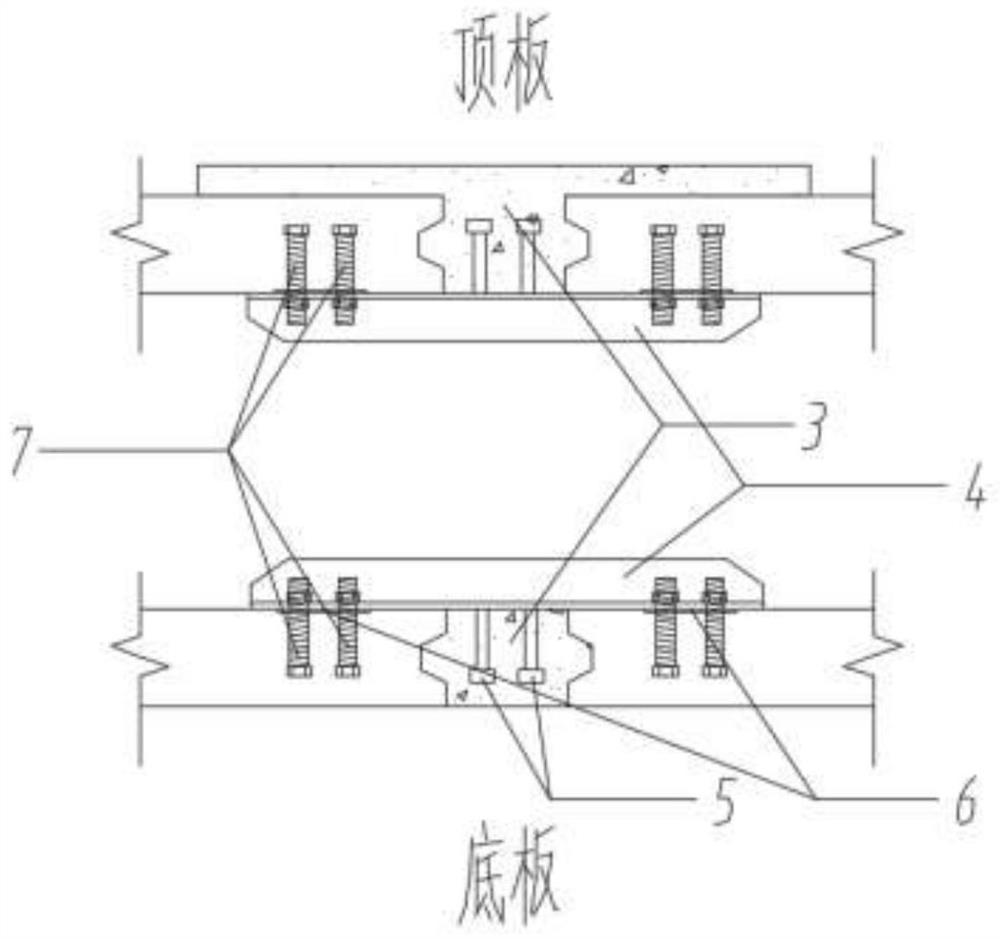

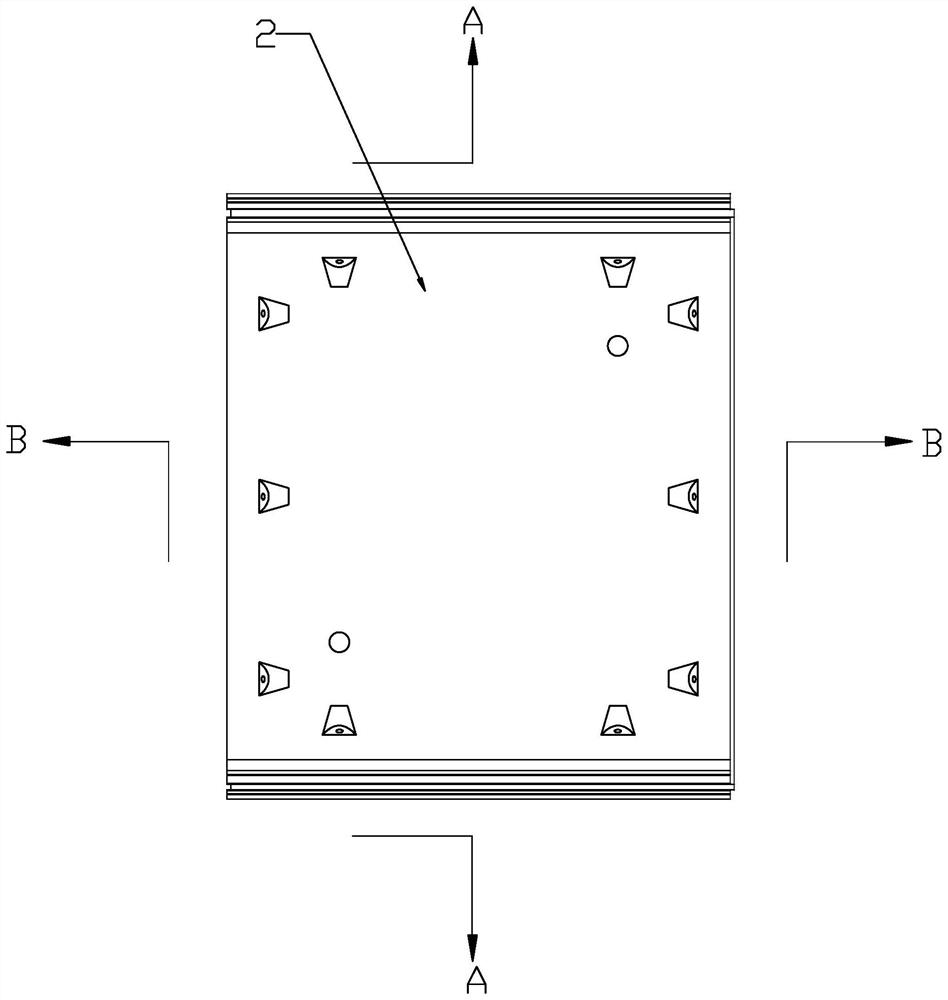

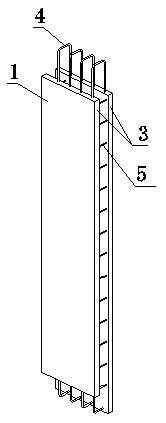

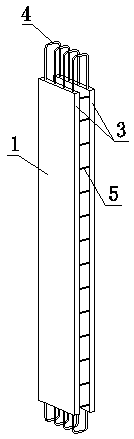

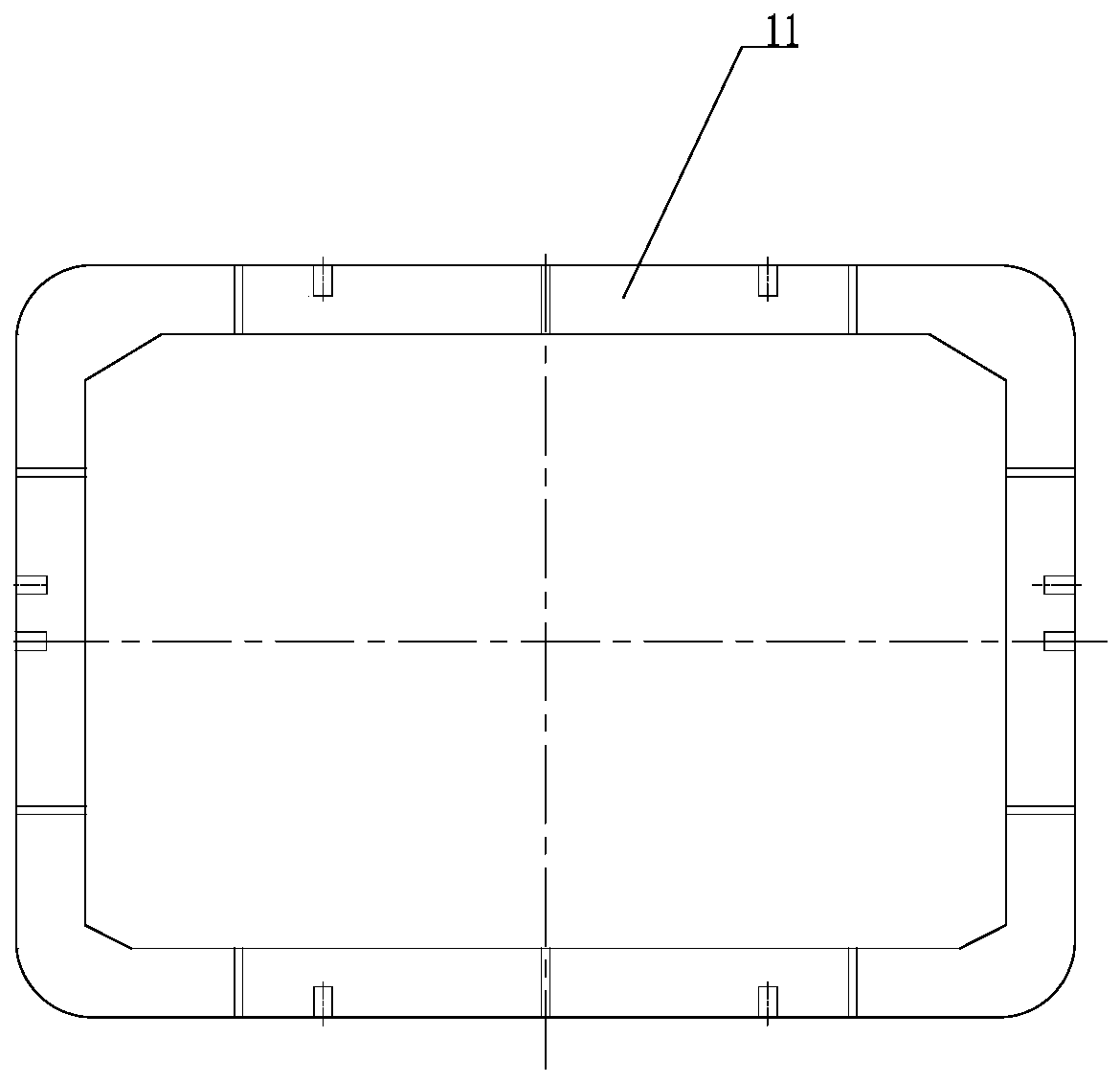

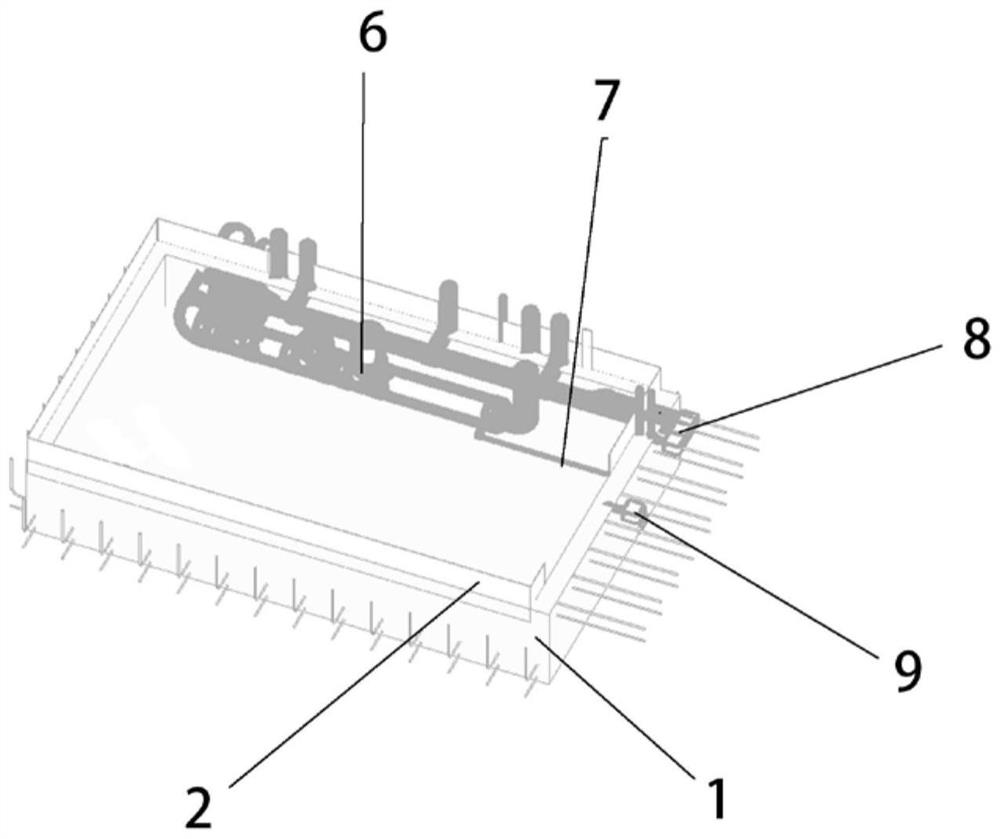

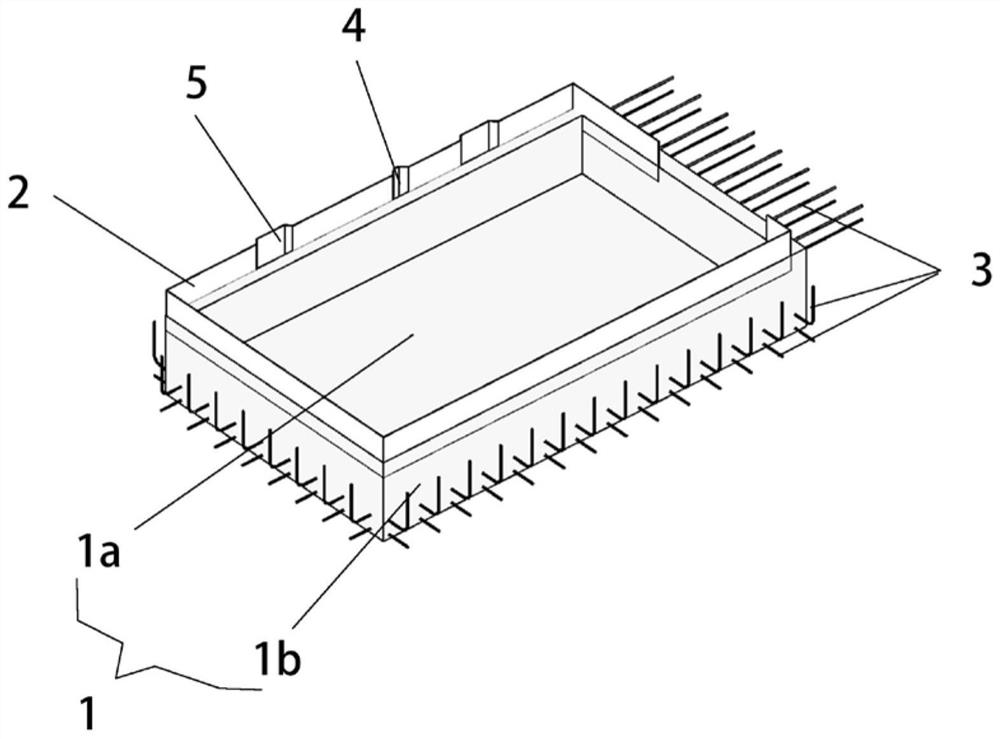

Horizontal connecting structure and connecting method of laminated slab type edge component and solid shear wall

PendingCN110616812ASimple connection structureEasy to installBuilding constructionsSocial benefitsReinforced concrete

The invention provides a horizontal connecting structure and connecting method of a laminated slab type edge component and a solid shear wall. At present, for different assembled building constructionmodes, generated economical benefits and social benefits are different. An edge component of a reinforced concrete shear wall structure at a current stage uses a cast-in-place form, and the filed cast-in-place amount is great. The horizontal connecting structure of the laminated slab type edge component and the solid shear wall comprises the prefabricated laminated slab type edge component (1) and the solid shear wall (2), wherein the prefabricated laminated slab type edge component is a 1-shaped edge component or a T-shaped or L-shaped or Z-shaped or U-shaped component formed by the 1-shapededge components; the 1-shaped edge component consists of two layers of prefabricated concrete thin slabs (3); a cavity is formed between the two layers of prefabricated concrete thin slabs; edge component longitudinal steel bars (4) and hoop bars (5) are embedded in the two layers of prefabricated concrete thin slabs; the hoop bars are in a sealed annular shape; and the end parts of the prefabricated laminated slab type edge component are connected with the solid shear wall. The horizontal connecting structure and connecting method are used in the field of building construction.

Owner:HUBEI YUHUI NEW BUILDING MATERIAL

Hydraulic drive gyrorotor automatic butting tooling equipment

InactiveCN101992369BImprove docking accuracyReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderDrive shaft

The invention discloses hydraulic drive automatic gyrorotor butting tooling equipment, which mainly comprises a cylinder rolling rack and a cylinder moving rack. Axes of two rows of transmission shafts on the cylinder rolling rack and axes of two rows of transmission shafts on the cylinder moving rack are positioned on the same plane, and the axes of the transmission shafts on the same side of the two racks are collinear, so that cylinders are butted in the same axis; under the hydraulic driving of the moving rack, the cylinders on the moving rack are displaced linearly, automatically butted,and subjected to circumferential grinding-in, and the butting accuracy of two cylinders is improved; and under the transmission of the hydraulic cylinder of the moving rack, the butted cylinders are driven to displace linearly, circumferentially roll on the rolling rack, and form relative spiral butting-grinding-in motion with the cylinders linearly displacing on the moving rack. The service lifeof the equipment is prolonged, the energy consumption is reduced, and the accuracy is improved; and the equipment has a simple structure, high reliability, high butting accuracy and high speed, is time-saving, labor-saving, safe and high-efficiency, and reduces equipment investment.

Owner:SINOMA TECH (XUZHOU) HEAVY MASCH CO LTD +1

The method of making large lateral opening of large section pipe jacking

ActiveCN105484762BSmall sizeGuaranteed structural strengthUnderground chambersTunnel liningReinforced concreteRebar

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

Single-point hoisting type pile erecting system and construction method for pile erecting

ActiveCN111532983AOvercome horizontal forcesEasy constructionWind motor assemblyWind motor supports/mountsArchitectural engineeringStructural engineering

The invention provides a single-point hoisting type pile erecting system and a construction method for pile erecting, and belongs to the technical field of offshore wind power pile foundation construction. The single-point hoisting type pile erecting system and the construction method for pile erecting realize single-point hoisting type pile erecting of an offshore wind power pile. The single-point hoisting type pile erecting system involves a crane, a guide frame, a pile turning device, a clamping block and a hoisting point, wherein the clamping block and the hoisting point are arranged on apile body; the clamping block and the hoisting point are arranged close to the two axial ends of the pile body, and the clamping block is located on the lower side surface of the pile body when the pile body is horizontally placed; a hoisting cable of the crane is connected with the hoisting point; the guide frame is fixedly supported on the seabed at the position of the pile to be erected, the guide frame is located below the end, provided with the clamping block, of the pile body when the pile body is horizontally placed, and a U-shaped opening for allowing the pile body to be turned thereinand limiting the position of the erected pile body is formed in the side, away from the hoisting point, of the guide frame; the pile turning device is arranged on the side, away from the U-shaped opening, of the top of the guide frame, the pile turning device turns towards the direction of the U-shaped opening, the pile turning device supports the lower side surface of the pile body when the pilebody is horizontally placed, and the side, close to the hoisting point, of the pile turning device is abutted against the side, away from the hoisting point, of the clamping block.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG +1

Precast concrete toilet base plate, manufacturing method and mounting method

PendingCN113931495AReduced lifting requirementsIncrease budgetConstruction materialFloorsRebarPrecast concrete

The invention discloses a prefabricated concrete toilet base plate, a manufacturing method and a mounting method. The prefabricated concrete toilet base plate comprises a concrete caisson and a water stop steel plate reverse ridge. Exposed steel bars in the horizontal direction are reserved at the upper ends of the side walls of the concrete caisson; a circle of water stop steel plate reverse ridge is arranged at the upper end of the concrete caisson; and a prefabricated water supply and drainage system and a prefabricated power supply system are arranged in the concrete caisson, a reserved water supply and drainage connector and a reserved electric wire connector are reserved from the concrete caisson, and a decorative surface layer is laid. Compared with a traditional integral prefabricated toilet, the overall weight is greatly reduced, the requirement for the hoisting weight of a tower crane is reduced, emerging assembly meets the market requirement, the working procedures such as part manufacturing, water testing, water and electricity reserving and embedding, waterproofing and surface layer decorating are completed in a factory, the on-site wet operation and decorating working procedures are reduced, and only connection is needed; and meanwhile, production inspection and batch production are carried out in the factory, the project progress can be accelerated, and industrial quality control is achieved.

Owner:中国建筑工程(澳门)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com