Horizontal connecting structure and connecting method of laminated slab type edge component and solid shear wall

An edge component, horizontal connection technology, applied in building structure, construction, etc., can solve the problems of different economic and social benefits, difficult to guarantee the quality of grouting connection, and imperfect assembly technology, so as to shorten the time of key lines, reduce The effect of woodworking workload and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

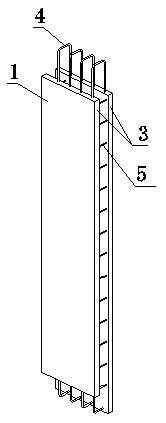

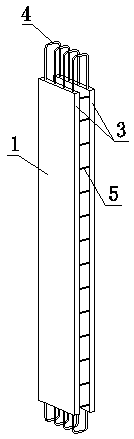

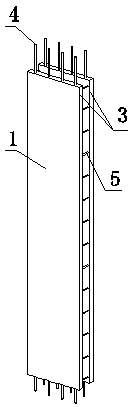

[0060] A horizontal connection structure between a laminated slab edge member and a solid shear wall, which comprises: a prefabricated laminated slab edge member 1 and a solid shear wall 2, and the prefabricated laminated slab edge member is an inline edge member or T-shaped or L-shaped or Z-shaped or U-shaped composed of in-line edge components, the in-line edge components are composed of two layers of prefabricated concrete slabs 3, and there is a cavity between the two layers of precast concrete slabs, The longitudinal steel bars 4 and stirrups 5 of the edge members are pre-embedded in the two-layer prefabricated concrete slab, and the stirrups are in a closed ring shape, and the ends of the prefabricated laminated plate edge members are the same as the solid shear wall Connection, the horizontal steel bar 6 of the solid shear wall is ring-shaped or straight strip or L-shaped, and the straight strip or L-shaped steel bar extends into the edge member of the laminated plate I...

Embodiment 2

[0062] According to the horizontal connection structure between the laminated slab edge member and the solid shear wall described in Embodiment 1, the horizontal annular steel bar protruding from the solid shear wall extends into the cavity of the laminated slab edge member and connects with the prefabricated laminated slab edge The closed annular stirrups of the components are handed over to form a handover gap, and the pinned longitudinal rib 7 is inserted into the said handover gap to form a pinned structure.

Embodiment 3

[0064] According to the horizontal connection structure between the laminated slab edge member and the solid shear wall described in embodiment 1 or 2, the horizontal annular reinforcement of the solid shear wall is connected to the prefabricated laminated slab edge member annular stirrup through the additional reinforcement ring 8 Connection, the additional reinforcing bar ring is handed over to the horizontal annular steel bar of the solid shear wall and the annular stirrup of the laminated plate edge member respectively to form a handover gap, and the pinned longitudinal reinforcement is respectively inserted in the two gaps to form a pinned structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com