A prefabricated concrete staircase mold and its manufacturing method

A technology of prefabricated concrete and prefabricated assembly, applied in the direction of molds, stairs, manufacturing tools, etc., to meet the requirements of production and hoisting, reduce the amount of concrete, and reduce the effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

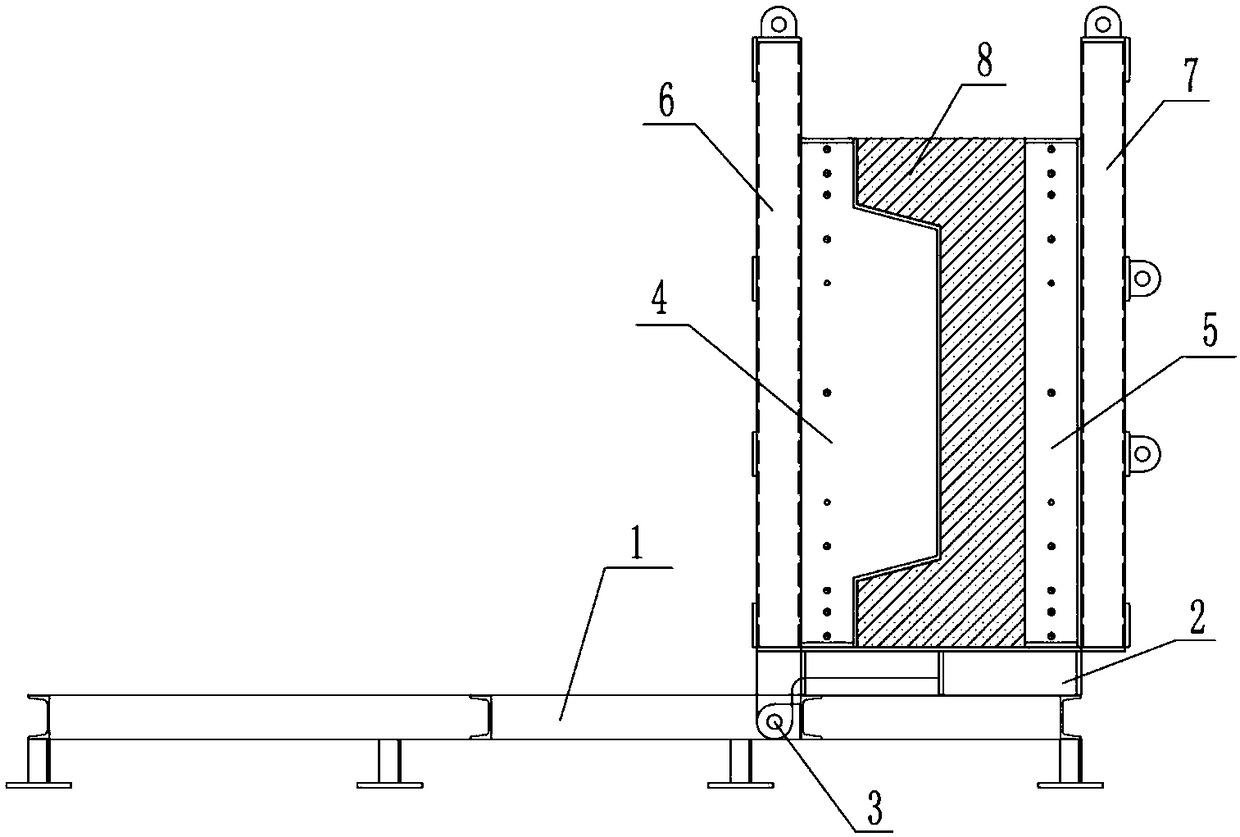

[0031] Embodiment 1 prefabricated assembled concrete staircase mold

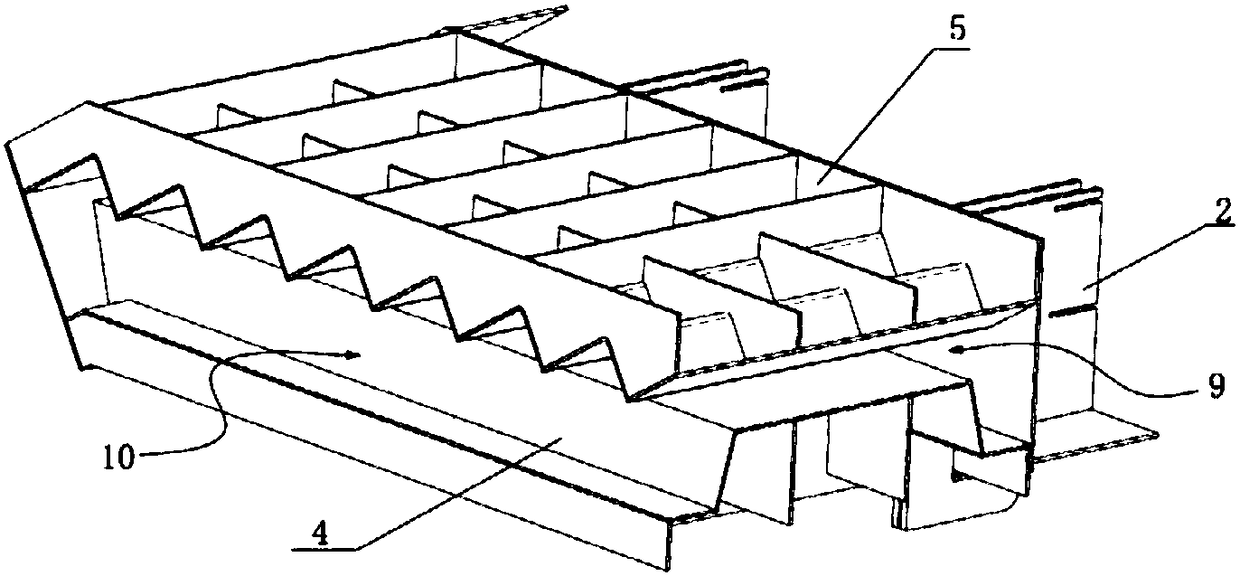

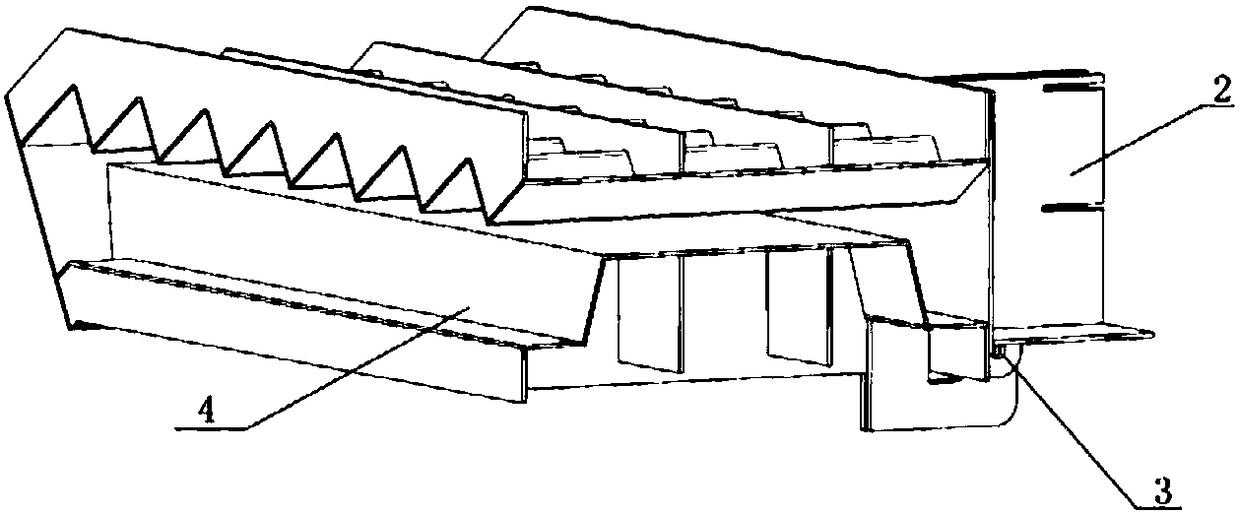

[0032] Referring to the accompanying drawings, the prefabricated concrete staircase mold includes a detachably connected backboard template 4 and a step surface template 5; the mold forms a cavity 9 for pouring precast concrete stairs through the combination of the backboard template and the step surface template, and travels along the stairs One side of the direction forms an opening 10 for pouring concrete;

[0033] The mold also includes a support base 1, the combined back plate formwork and step surface formwork are rotatably connected on the support base 1, the mold has a horizontal state on the support base and a vertical state with the opening facing upwards after being turned around the rotating joint .

[0034] Wherein, as shown in the figure, the inner wall surface of the step surface template is a step surface structure forming a stair step.

[0035] During specific implementation, the mold also...

Embodiment 2

[0039] A kind of method utilizing embodiment 1 mold to manufacture stairs, the method steps are as follows:

[0040] A. Place the reinforced mesh cage of the prefabricated concrete stairs on the backboard template; Figure 4a shown.

[0041] B. Install the combined step surface template; Figure 4b shown.

[0042] C. Turn the combined backboard formwork and step surface formwork into a vertical state on the support base through the overturn mechanism; as Figure 4c shown.

[0043] D. Pouring concrete from the side opening of the mold; Figure 4d shown.

[0044] E. After the precast concrete stairs are formed and meet the strength requirements, turn the combined back plate formwork and step surface formwork into a horizontal state on the supporting base through the overturning mechanism; Figure 4e , as shown in 4f.

[0045] F. Remove the step surface template of the mold; Figure 4g shown.

[0046] G. Take out the precast concrete stairs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com