Patents

Literature

44results about How to "Meet the hoisting requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

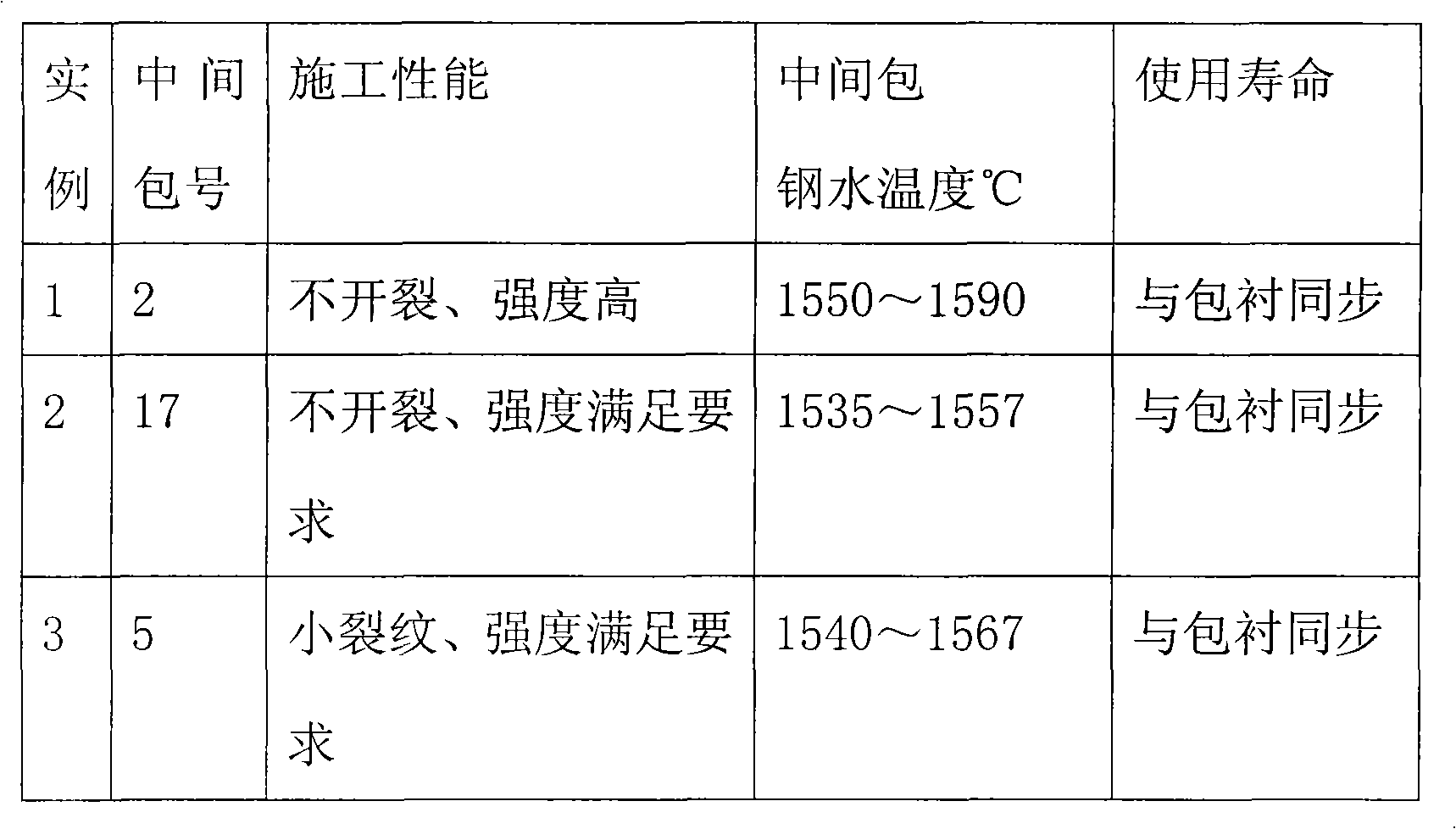

Pouring material for forsterite tundish slag stop wall and production process thereof

The invention discloses a pouring material for a forsterite tundish slag stop wall and a production process thereof. The pouring material is prepared from the following raw materials in part by weight: 5 to 70 parts of forsterite, 15 to 85 parts of magnesium sand, 5 to 15 parts of corundum powder, 3 to 5 parts of composite additive, 0.1 part of organic fiber and 1 part of steel fiber. The production process comprises the following steps of: adding aggregates in the raw materials into a stirrer and mixing and stirring the aggregates uniformly, then adding the fine powder and the composite additive into the mixed aggregates and stirring the mixture for 2 to 3 minutes, adding water into the mixture and stirring the mixture for 2 to 3 minutes when all the materials are mixed and stirred uniformly, and performing discharge, vibration molding, curing, drying and packing. The formula cost of the product is reduced by adopting combined action of the forsterite and the magnesium sand; and the construction performance and the use performance of the product are ensured at the same time of improving the strength of the product by adopting the composite additive, organic fiber, steel fiber andthe like with good performance.

Owner:WUGANG REFRACTORY CO LTD

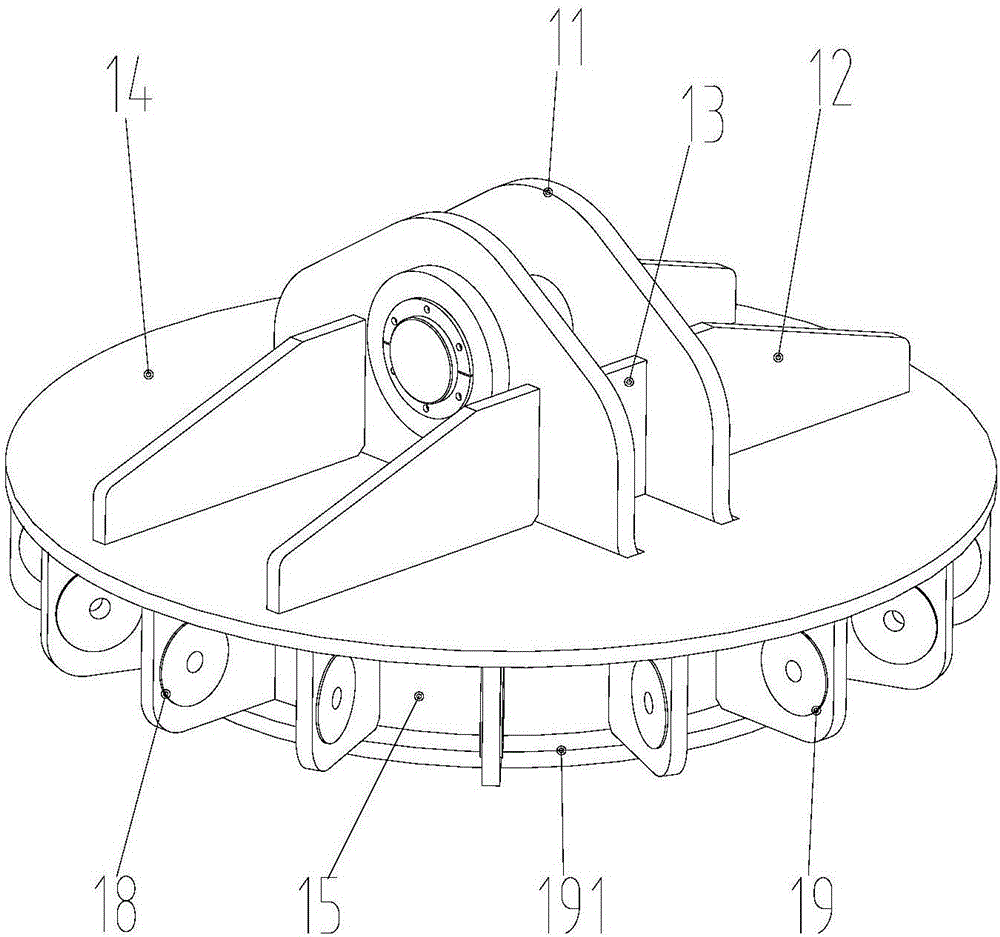

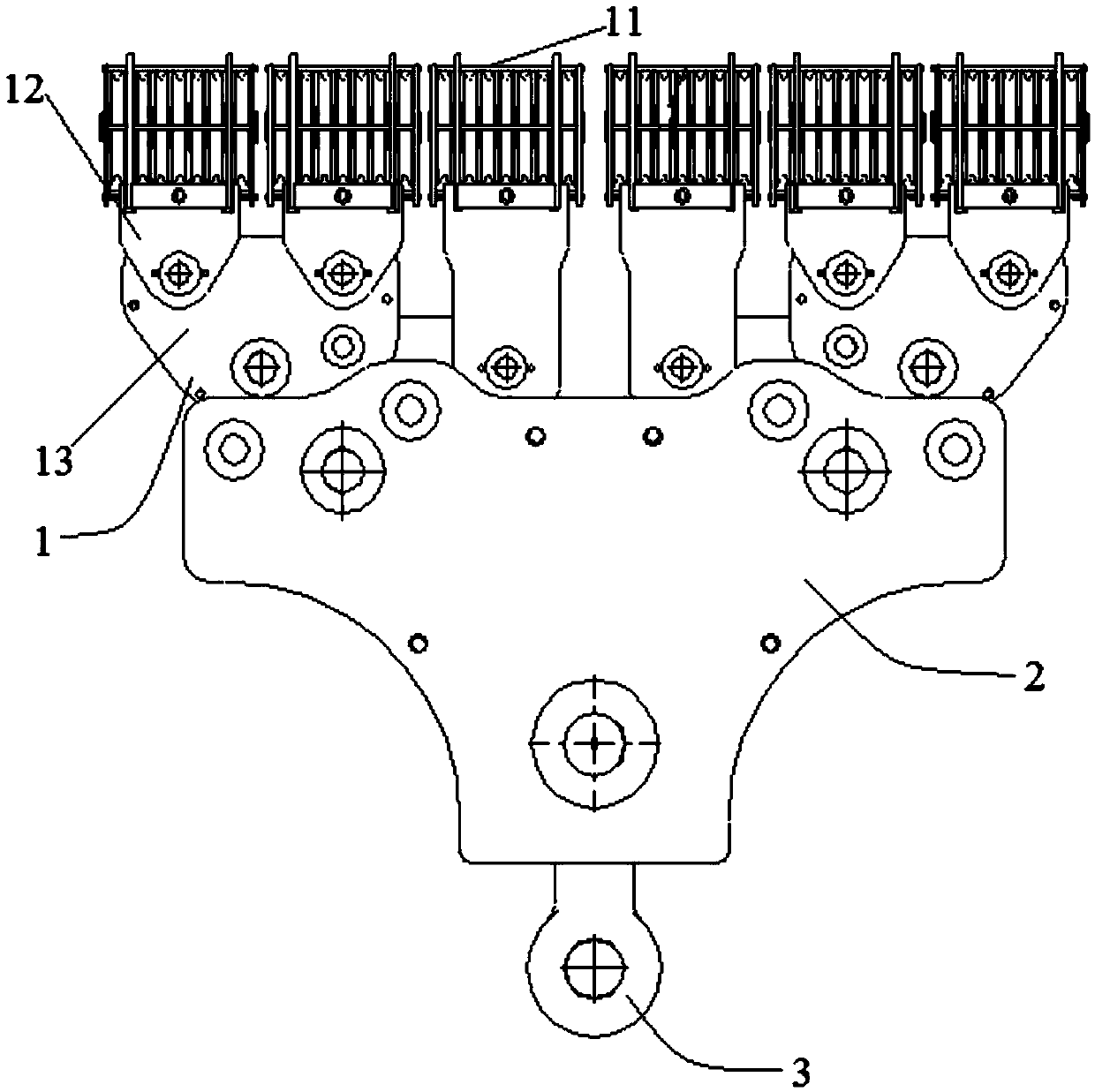

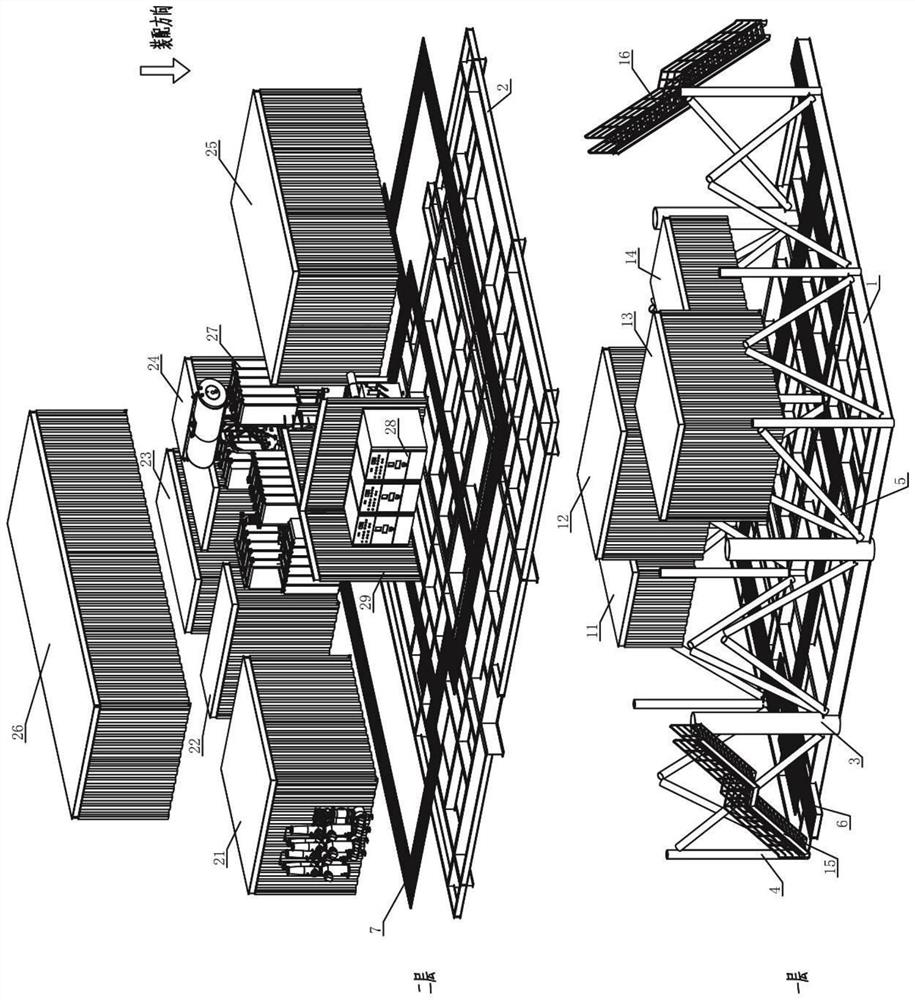

Special hoisting sling and hoisting method for nuclear power station CR10 and reinforcing steel bar composite module

ActiveCN106429791ASimple structureReasonable structureLoad-engaging elementsNuclear powerEngineering

The invention relates to a special hoisting sling and a hoisting method for a nuclear power station CR10 and reinforcing steel bar composite module. The special hoisting sling comprises a transition beam, main slings, sling distributors, outside auxiliary slings, inside auxiliary slings and adjustable pull rods. According to the special hoisting sling and the hoisting method for the nuclear power station CR10 and reinforcing steel bar composite module provided by the invention, the special hoisting sling is adopted as connection between a hoist and the CR10 and reinforcing steel bar composite module, the special hoisting sling is connected before hoisting, the transition beam is connected with the hoist, and the adjustable pull rods are connected with inside and outside lifting lugs on the CR10 and reinforcing steel bar composite module. A center-of-gravity position of the CR10 and reinforcing steel bar composite module is adjusted through applying balance weight and adjusting the adjustable pull rods, so that the level degree of a lower port is ensured. The CR10 and reinforcing steel bar composite module is in position through hook-lifting, rotating, walking and hook-dropping of normal hoisting. According to the special hoisting sling and the hoisting method provided by the invention, the deformation of the CR10 and reinforcing steel bar composite module during a hoisting process can be effectively reduced, the level degree of the lower port of the CR10 and reinforcing steel bar composite module is ensured, and the construction safety is ensured.

Owner:DALIAN YILIY CONSTR MACHINERY

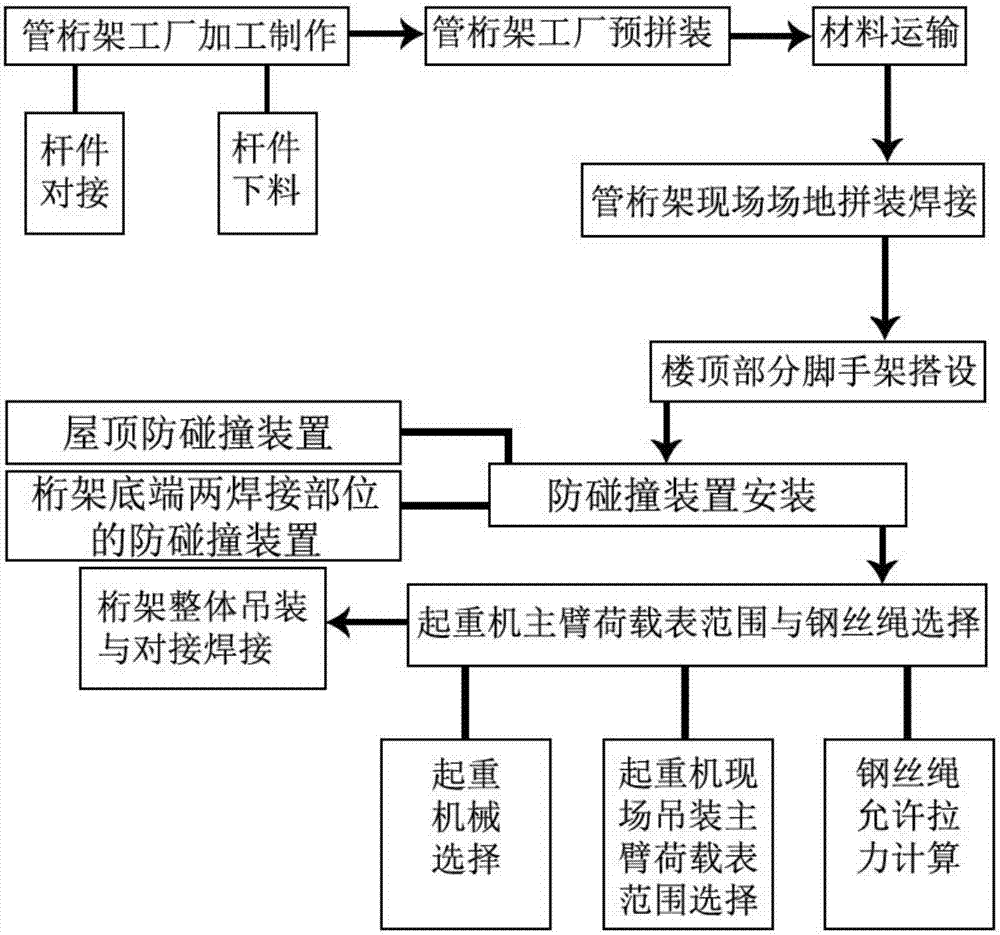

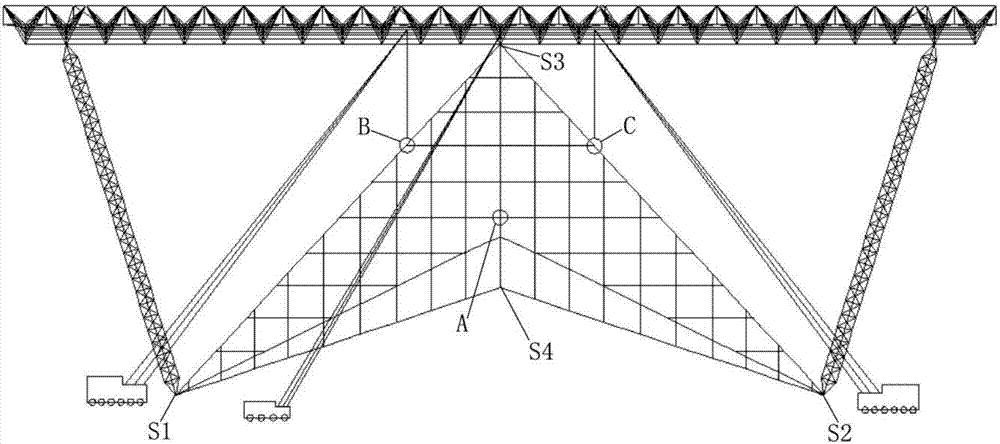

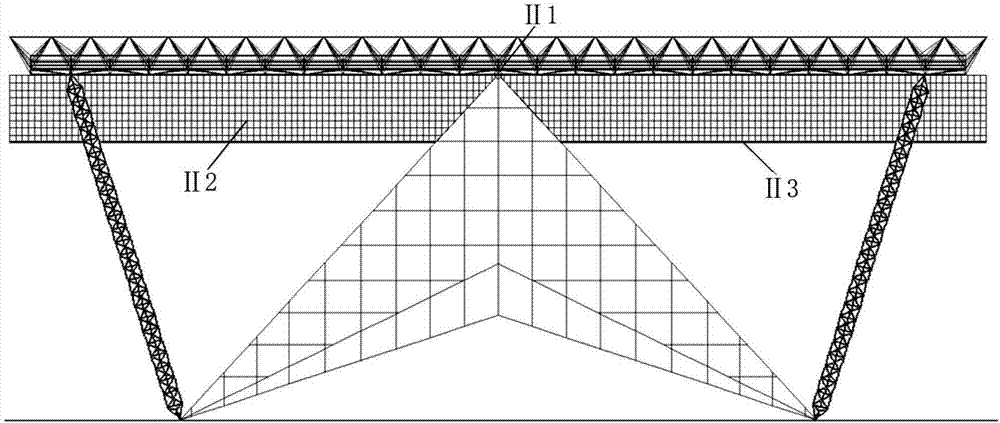

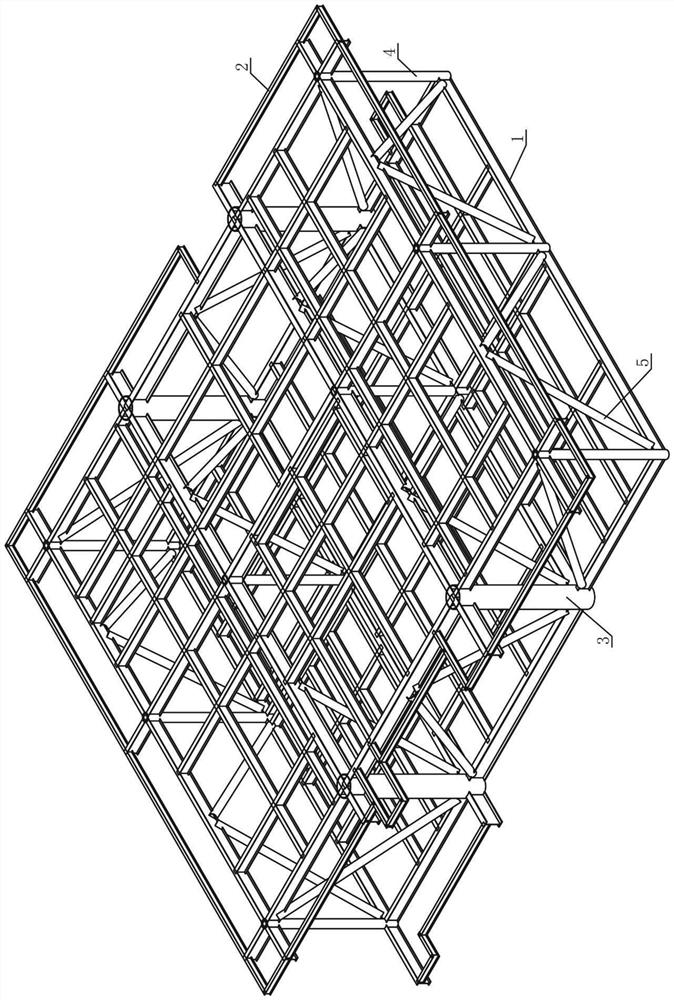

Construction method for integrally hoisting large-size multi-edge-and-corner overhanging truss

ActiveCN107100309AImprove assembly efficiencyEasy constructionBuilding roofsBuilding material handlingTerrainButt welding

A construction method for integrally hoisting a large-size multi-edge-and-corner overhanging truss is disclosed. Integral assembling of a steel pipe truss is conducted on site, and integral hoisting is conducted after assembling is completed; the truss is connected with three welding positions in a butt-joint mode and then is welded firmly; two 500 t all-terrain cranes and a 350 t all-terrain crane are adopted to hoist the whole truss simultaneously, and step-by-step hoisting is conducted from south to north; the truss is totally provided with three main stress support joints which are all fixed by adopting butt welding, a third calibration point support is located at the top of the truss, a welded ball joint at the position of the third calibration point is a support point of a steel rainshed grid frame actually, a first calibration point support and a second calibration point support are located on both the left and right sides of the bottom of the truss correspondingly, and the first calibration point support and the second calibration point support are global stress supporting points of the truss. The construction method for integrally hoisting the large-size multi-edge-and-corner overhanging truss has the characteristics that the construction safety is high, the construction period is short, the engineering quality is easy to guarantee, the ground integral assembling efficiency is high, and the construction cost is reduced greatly.

Owner:FUJIAN MINNAN CONSTR ENG

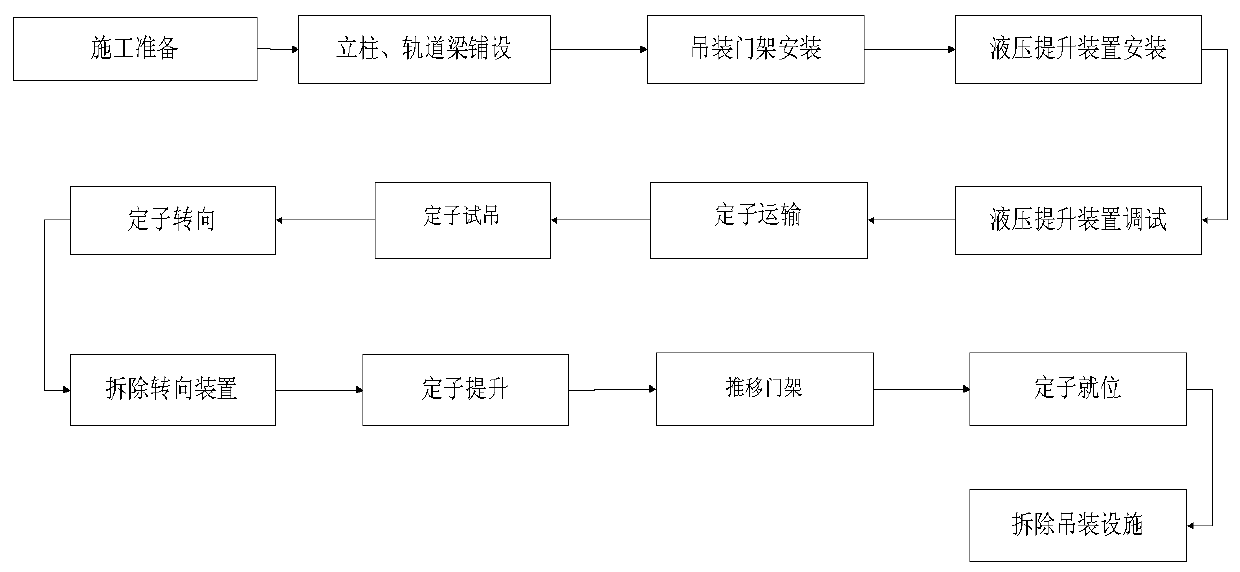

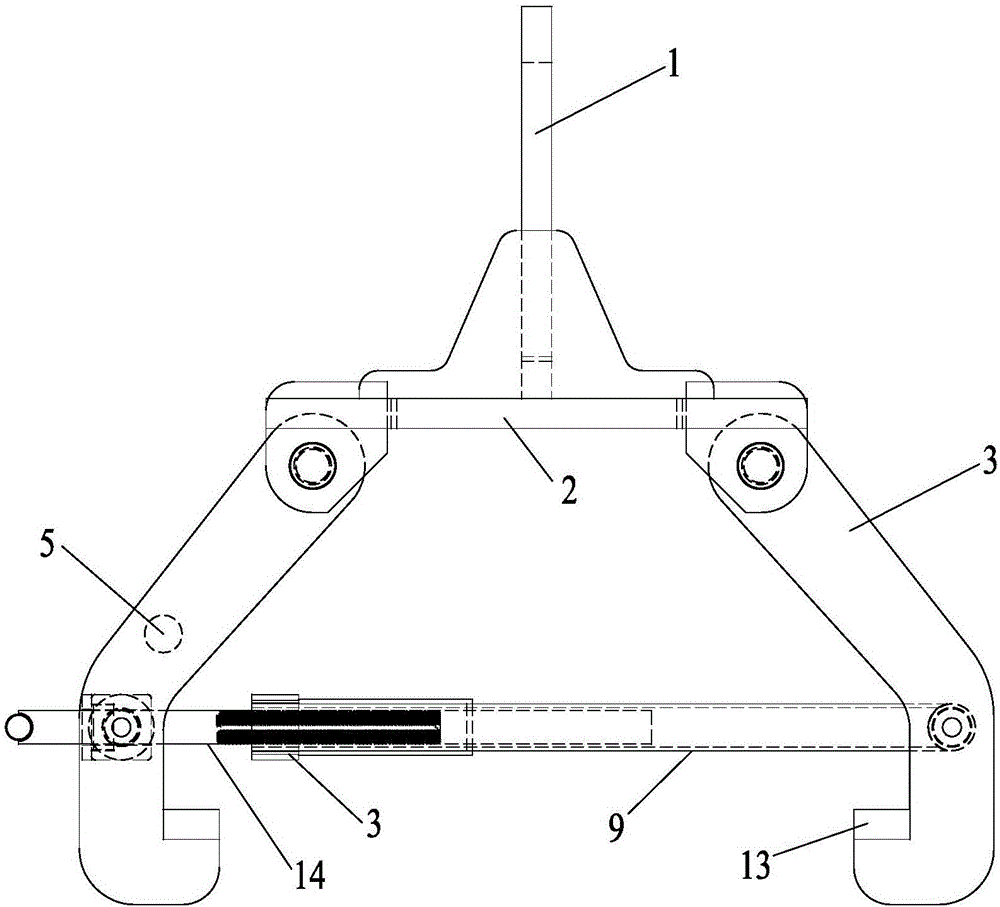

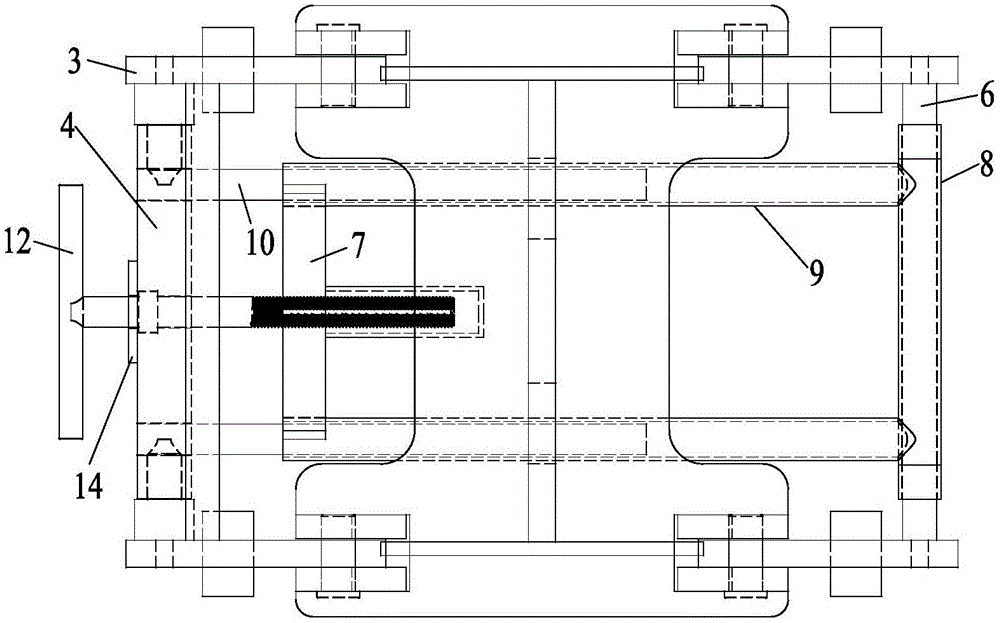

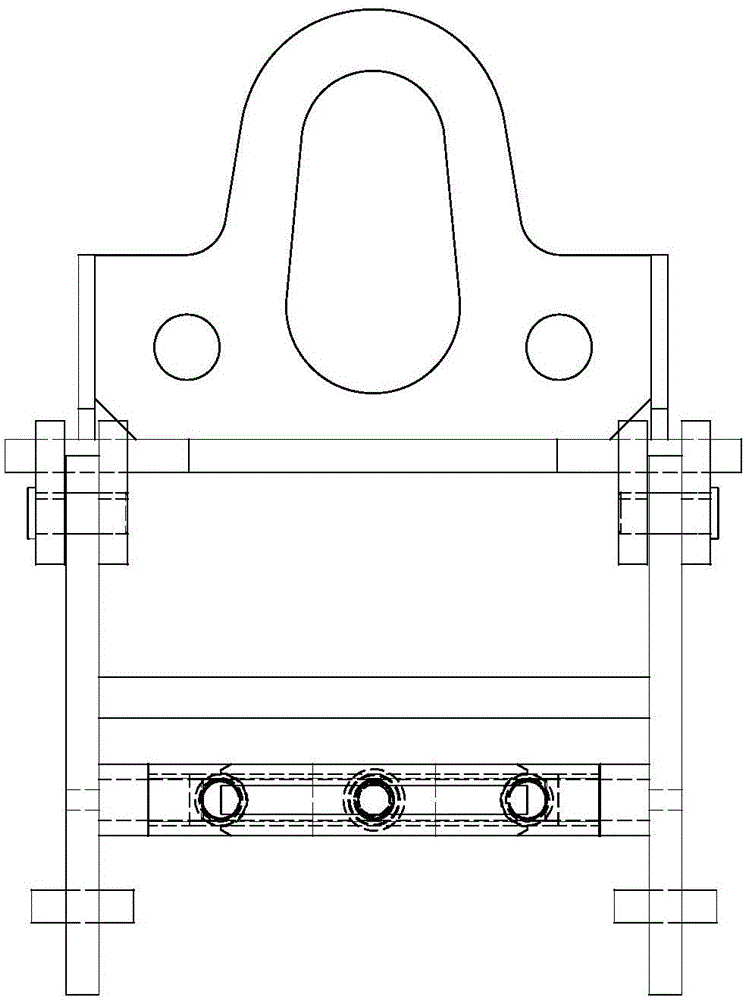

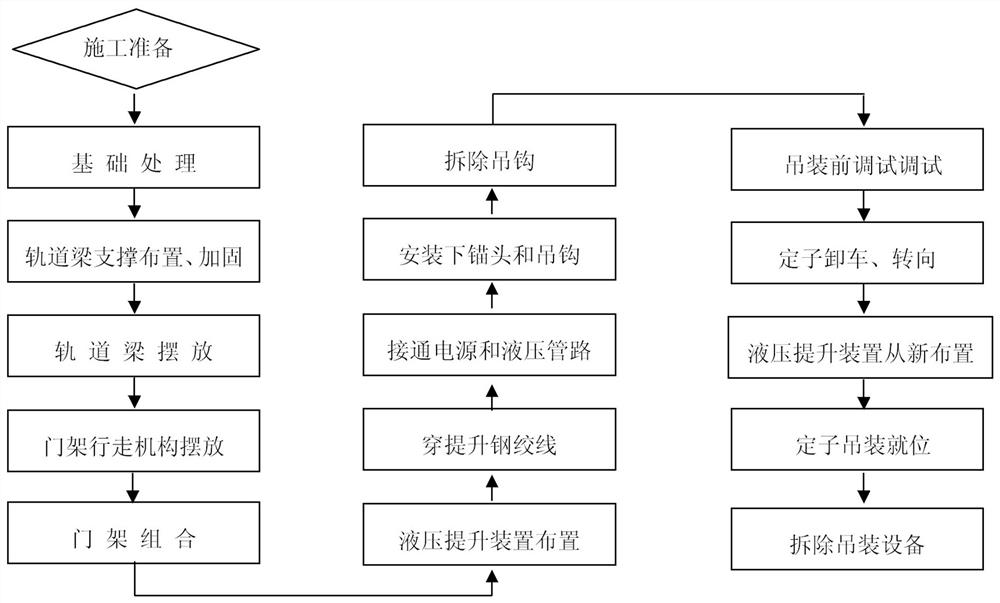

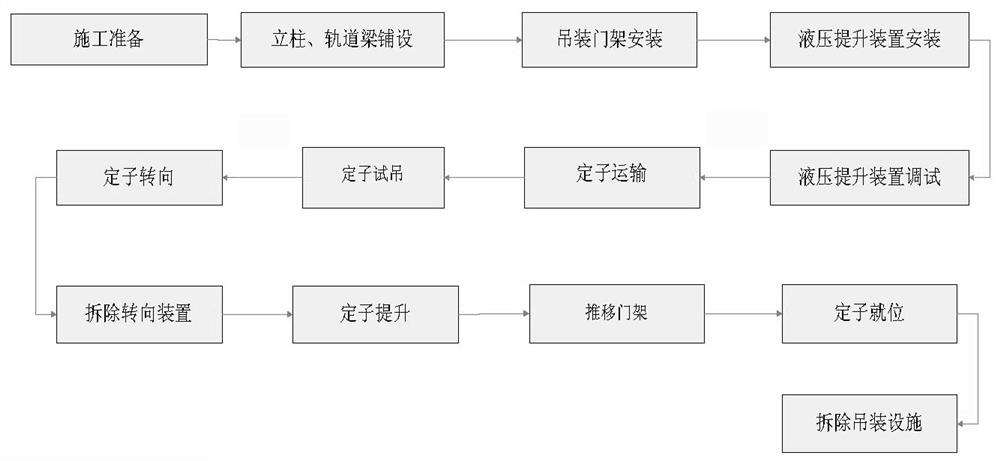

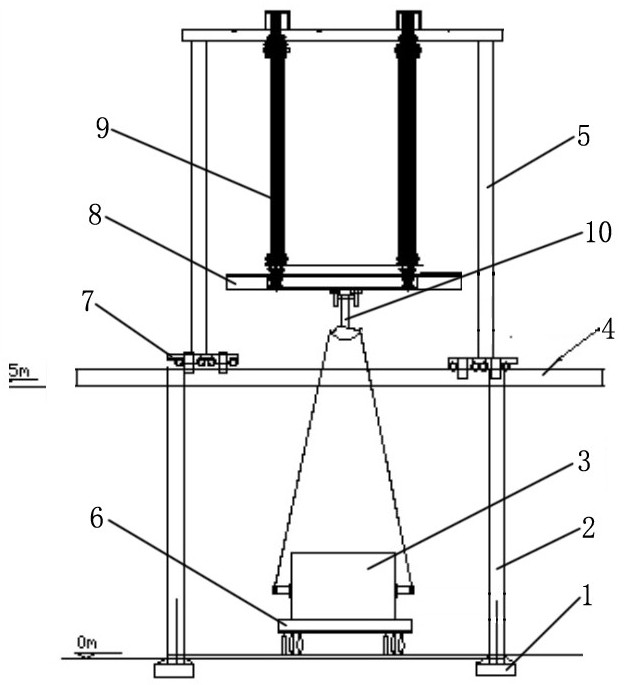

Construction method for hoisting novel phase modifier based on portal frame and Laoxinge device

ActiveCN110407097AChange widthAchieve migrationManufacturing dynamo-electric machinesLoad-engaging elementsButtressEngineering

The invention discloses a construction method for hoisting a novel phase modifier based on a portal frame and a Laoxinge device. Construction preparation and basic treatment are conducted; track beamsupports are arranged and reinforced; track beams are placed; the track beams are arranged in two columns on steel buttresses and fixed through bolts; a portal frame traveling mechanism is placed, anda portal frame is mounted; a hydraulic hoisting device is mounted and arranged; a hoisting device is perfected and debugged; a stator is unloaded and steered; the hydraulic hoisting device is arranged again; the stator is hoisted in position; and hoisting equipment is dismounted. The track beams are laid between a phase modifier base platform and a hoisted object, the Laoxinge device are matchedwith the portal frame to travel on the track beams, the effect that heavy objects are hoisted in position in factories without heavy hoisting equipment in a narrow space is achieved, vertical lifting,lowering, back-and-forth movement and rotation operation of the heavy objects can be completed, and the problems that in the prior art, assembled operation equipment is adopted for operation, the operation steps are cumbersome and complicated, the workload and labor intensity of personnel are increased, and the burden on enterprises is increased are solved.

Owner:POWER CHINA HENAN ENG CO LTD

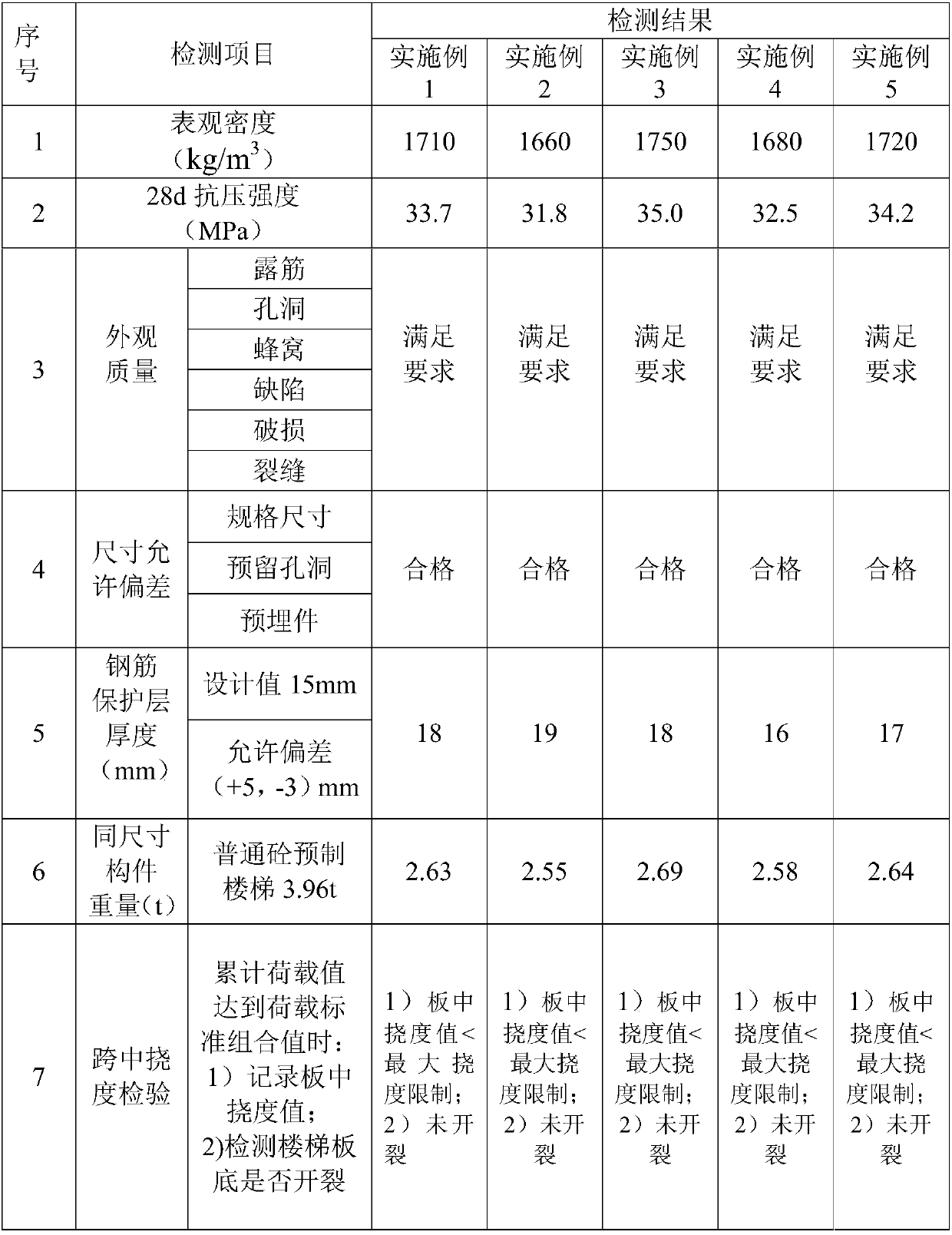

Lightweight ceramsite concrete assembly type prefabricated hollow staircase and preparation method thereof

InactiveCN107759170AConserve non-renewable resourcesSolve the shortage of production resourcesTread-and-riser unitsRebarRenewable resource

The invention discloses a lightweight ceramsite concrete assembly type prefabricated hollow staircase and a preparation method thereof. The hollow staircase is molded by pouring lightweight ceramsiteconcrete, and comprises hollow-column steps, steel bars and hoisting rings, wherein the insides of the hollow-column steps are poured into circular hollow holes; the steel bars are pre-embedded in thelightweight ceramsite concrete; the hoisting rings are arranged on the steps; the lightweight ceramsite concrete is prepared from cement, mineral powder, fly ash, fly ash ceramsite, water-quenched slag, pearlite sand, water and an admixture. According to the lightweight ceramsite concrete assembly type prefabricated hollow staircase, the fly ash ceramsite is taken as aggregate of concrete insteadof natural stones, so that non-renewable resources are saved; the lightweight ceramsite concrete assembly type prefabricated hollow staircase is a green, ecological and environment-friendly buildingmaterial, and has significant significance for solving of the problem of shortage of building material production resources and environmental protection.

Owner:TIANJIN INDZATION CONSTR CO LTD

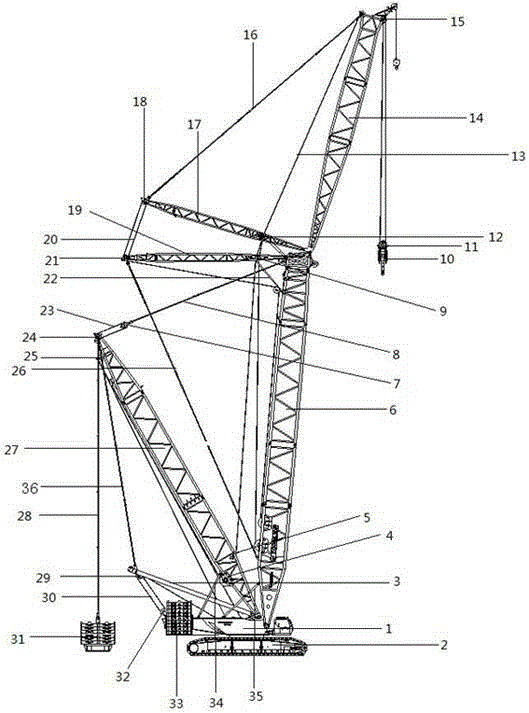

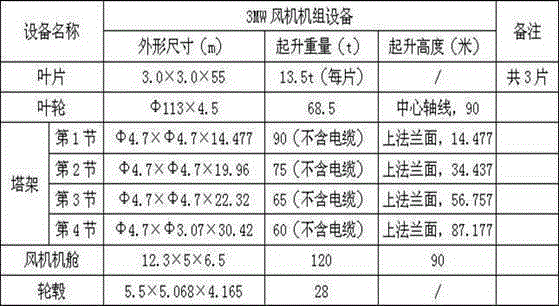

Method for installation of 3 MW wind generating set

The invention discloses a method for installation of a 3 MW wind generating set. The method includes the steps that a main crane is selected; a tower is installed; a cabin is installed; an impeller is installed; vane bolts are tightened through torque; the tower, the cabin and impeller bolts are fastened through torque; and cables are laid and installed. Main crane selection includes the steps that a 630 t crawler belt crane is adopted as the main crane, a working condition of tower type superlift with a 72m main arm and a 36m auxiliary arm is adopted, the auxiliary arm is hinged to the top end of the main arm, and an arm rod of the main crane is formed in a combined mode; and when the cabin is lifted, the main arm, the auxiliary arm and the cabin ascend in a trapezoid shape, and therefore the smallest distance between the cabin and the arm rod is larger than or equal to 5m. By means of the method, the cabin can be prevented from colliding with the arm rod, the impeller and the cabin are in stable butt joint, and the vane bolts are tightened. Construction safety is better guaranteed, the construction progress is accelerated, and construction cost is reduced.

Owner:HUNAN THERMAL POWER CONSTR CO LTD OF CHINA ENERGY ENG GRP

Hoisting equipment for large welding workpiece

ActiveCN103303847AImprove stabilityGuaranteed positioning accuracyLifting devicesProduction lineFixed frame

The invention discloses hoisting equipment for a large welding workpiece, which is used for realizing safe transport of large welding workpiece among different work stations. The hoisting equipment comprises a fixed frame, a driving mechanism, an actuating mechanism, a machine locking mechanism, a guiding mechanism and a location monitoring mechanism, wherein the fixed frame is mounted on two sides of the trolley transporting rail of the welding production line; a locating pin hole matched with the element of the actuating mechanism is formed in the top of the fixed frame; the driving mechanism and the machine locking mechanism are both mounted on the fixed frame, and are matched with the actuating mechanism; the actuating mechanism is assembled with the guiding mechanism; the guiding mechanism and the location monitoring mechanism are fixed on the horizontal ground. The hoisting equipment has the characteristics of high hoisting weight, accuracy in location and good stability; not only is the purpose of hoisting large welding workpiece achieved, but also the safety of nearby operating personnel and equipment is ensured.

Owner:精诚工科汽车系统有限公司

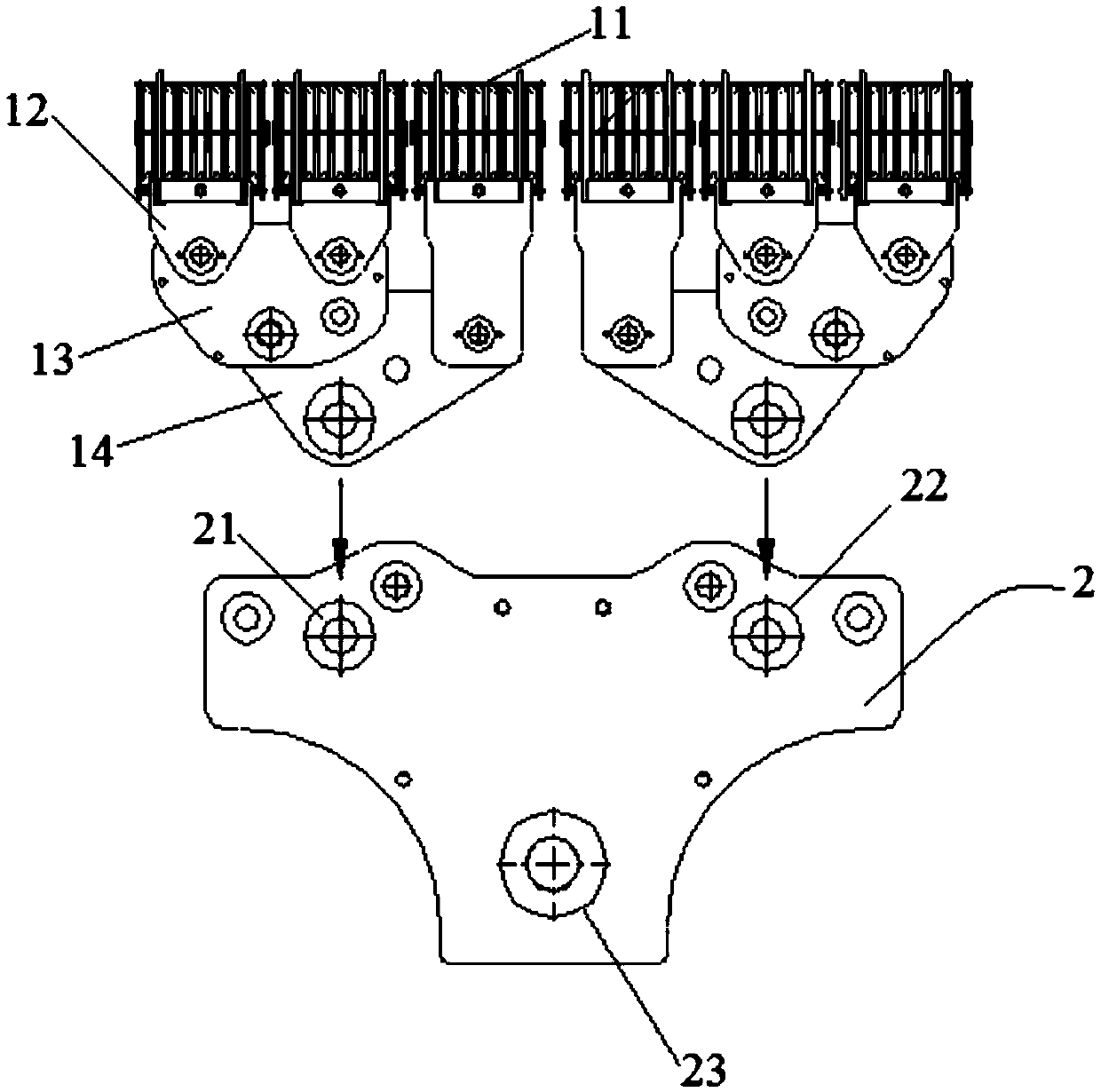

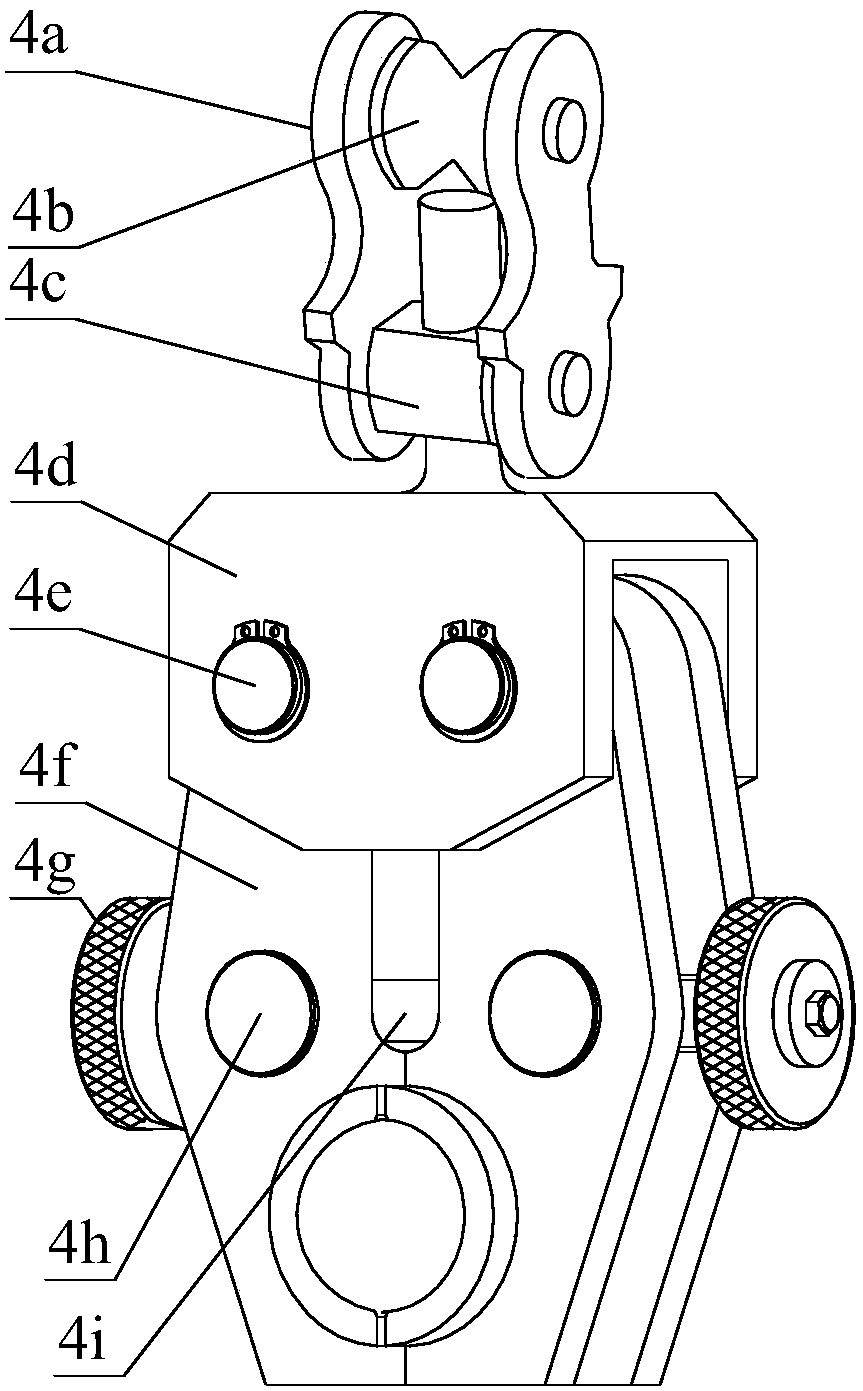

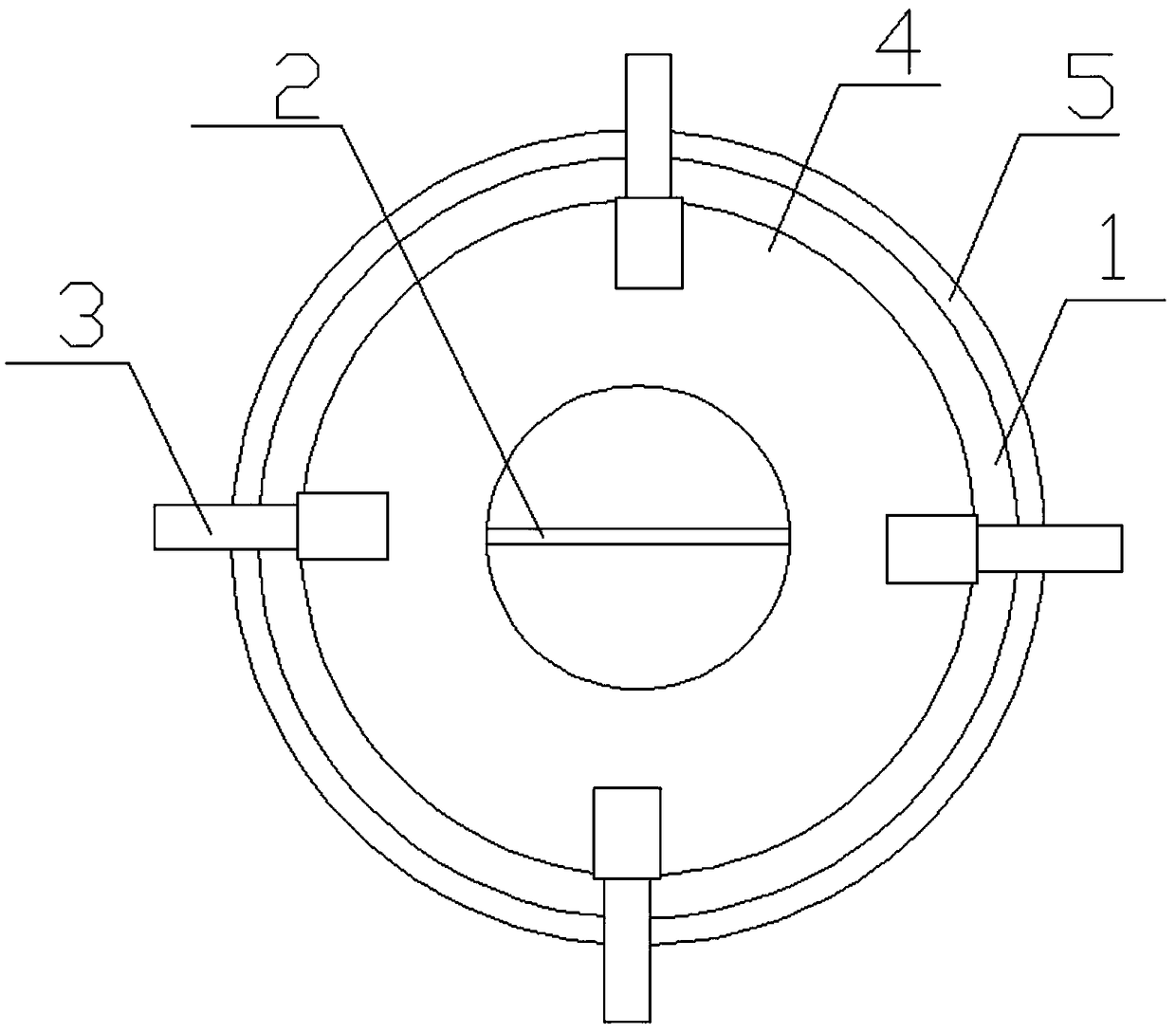

Pulley block combining structure, lifting hook and lifting device

The invention discloses a pulley block combining structure, a lifting hook and a lifting device. The pulley block combining structure comprises a connecting balance beam, a first pulley block assembly and a second pulley block assembly. The number of pulley blocks of the first pulley block assembly and the number of pulley blocks of the second pulley block assembly are different; the connecting balance beam comprises a plurality of connecting parts, and the multiple connecting parts include the first connecting part, the second connecting part and the third connecting part; in the horizontal direction, the first connecting part and the second connecting part are arranged on the two sides of the third connecting part respectively, the first pulley block assembly is connected with the first connecting part, the second pulley block assembly is connected with the second connecting part, and the horizontal distance from the first connecting part to the third connecting part is not equal to the horizontal distance from the second connecting part to the third connecting part so that the moment borne by the first connecting part relative to the third connecting part and the moment borne by the second connecting part relative to the third connecting part can be equal. By means of the pulley block combining structure, as the connecting balance beam is arranged, the balance of more pulley blocks with different numbers can be achieved through the lifting hook.

Owner:XCMG CONSTR MACHINERY

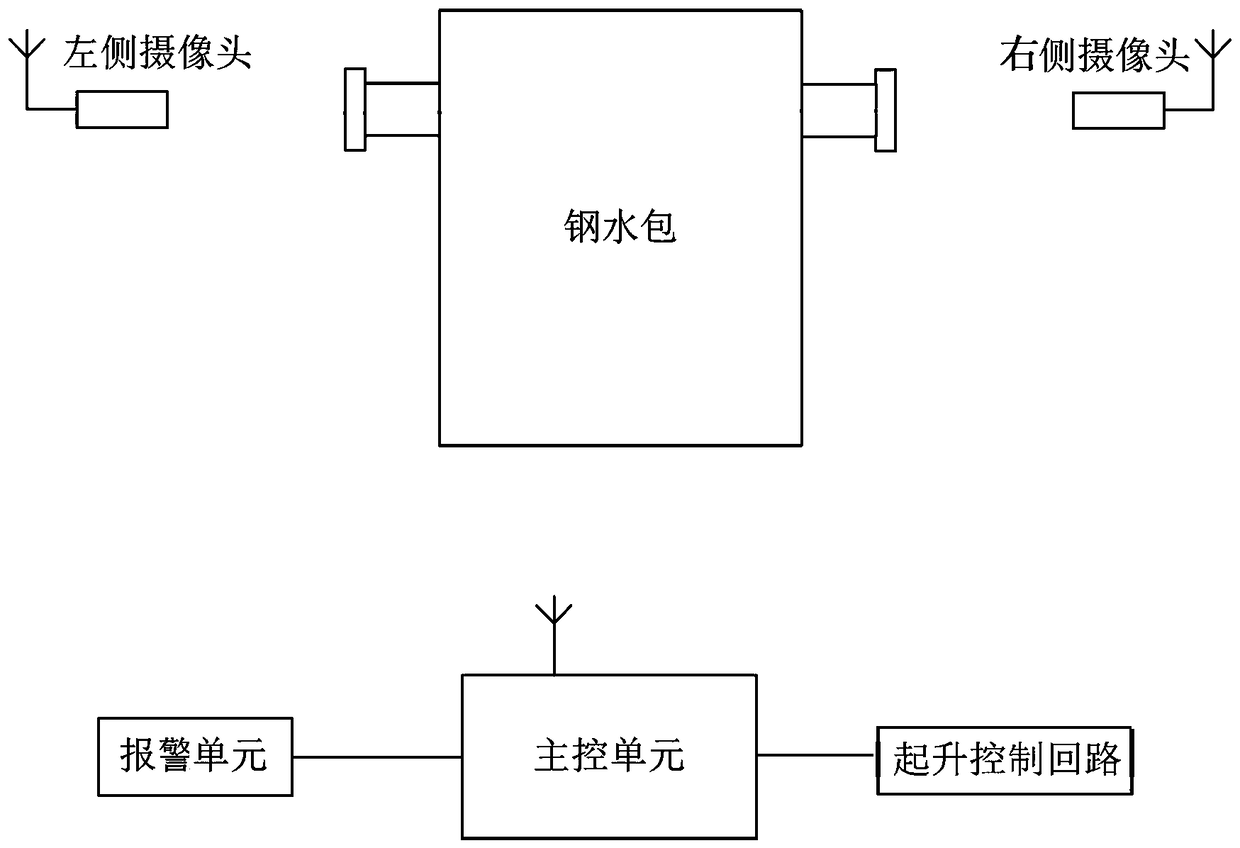

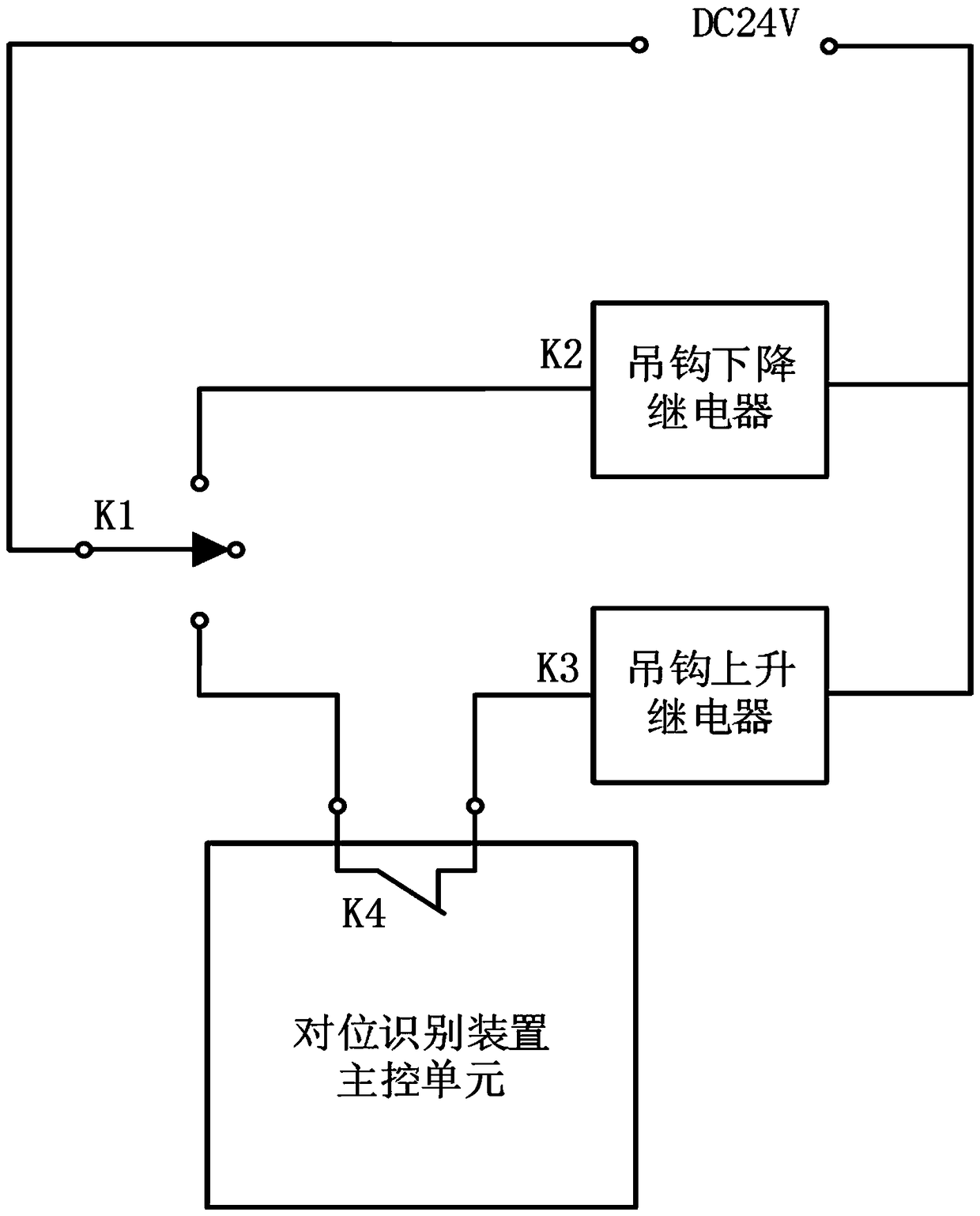

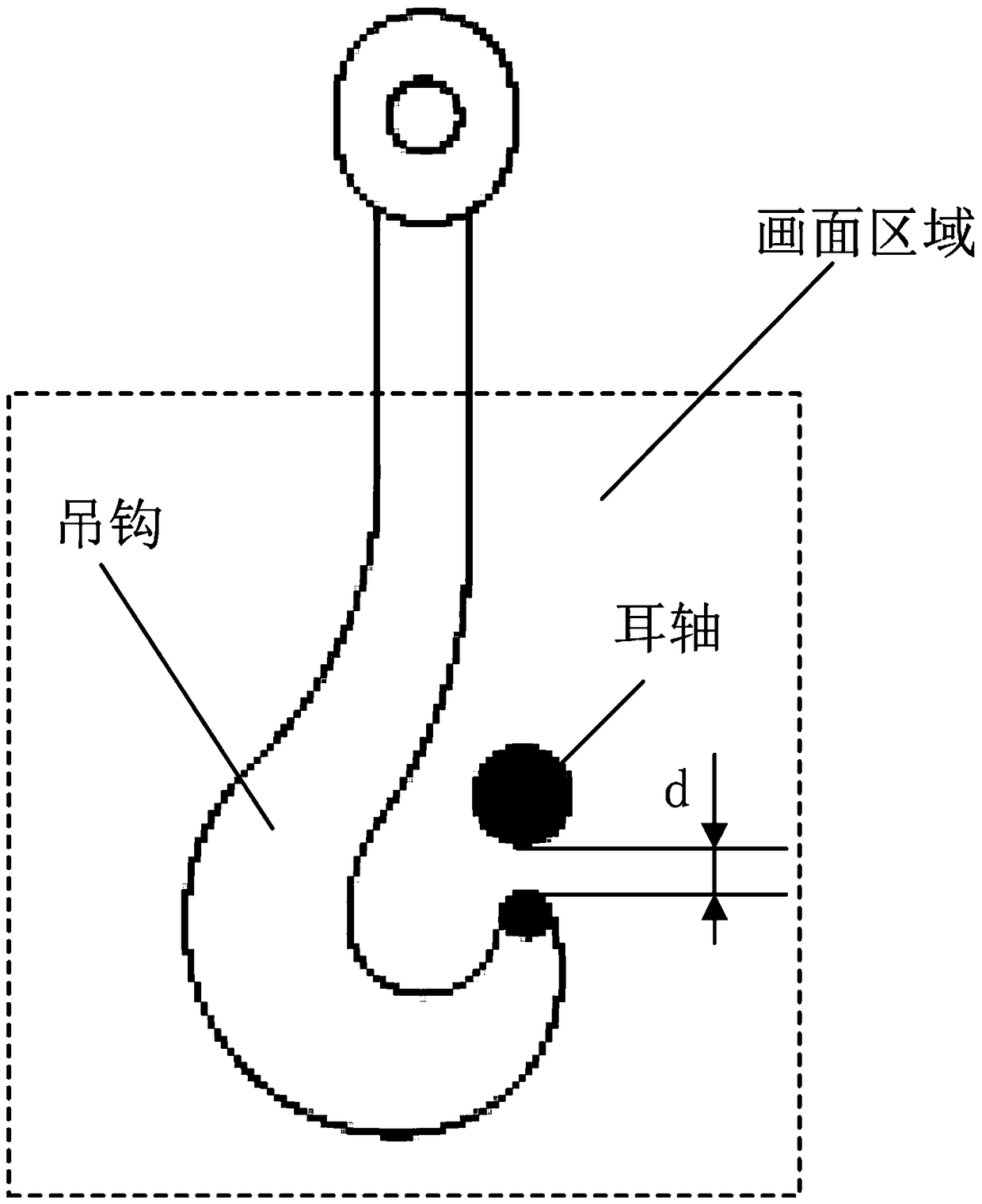

Steel ladle trunnion hoisting aligning recognition device and method

PendingCN108892042AHighlight substantive featuresSignificant progressLoad-engaging elementsIdentification deviceEngineering

The invention provides a steel ladle trunnion hoisting aligning recognition device and method. The recognition device comprises a first hoisting alignment image collecting unit, a second hoisting alignment image collecting unit and a lifting control loop, wherein a trunnion on one side of a steel ladle and a white identification of a lifting hook tip of a crane are shot by the first hoisting alignment image collecting unit in real time and taken as first alignment image information, and the first alignment image information is transmitted to a main control unit; a trunnion on the other side ofthe steel ladle and the white identification of the lifting hook tip of the crane are shot by the second hoisting alignment image collecting unit and taken as second alignment image information, andthe second alignment image information is transmitted to the main control unit; a lifting control loop is connected with the main control unit, which is used for controlling the lifting and lowering of the lifting hook of the crane; the main control unit drives the lifting control loop to work according to the information returned by the first hoisting alignment image collecting unit and the second hoisting alignment image collecting unit. The steel ladle trunnion hoisting aligning recognition device and method are scientific in design, high in practicability, simple in structure and accuratein identification.

Owner:ZHENGZHOU UNIV +1

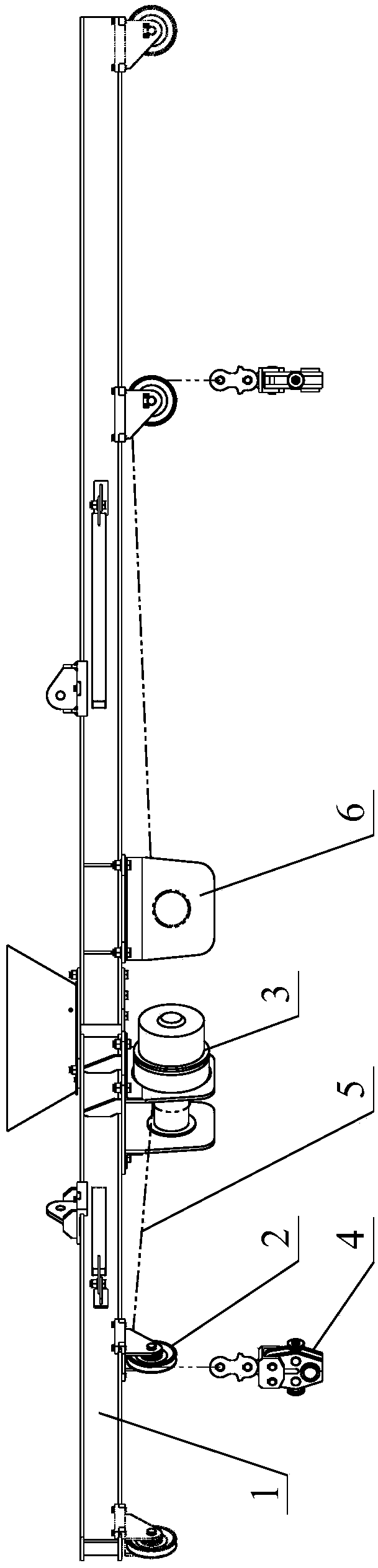

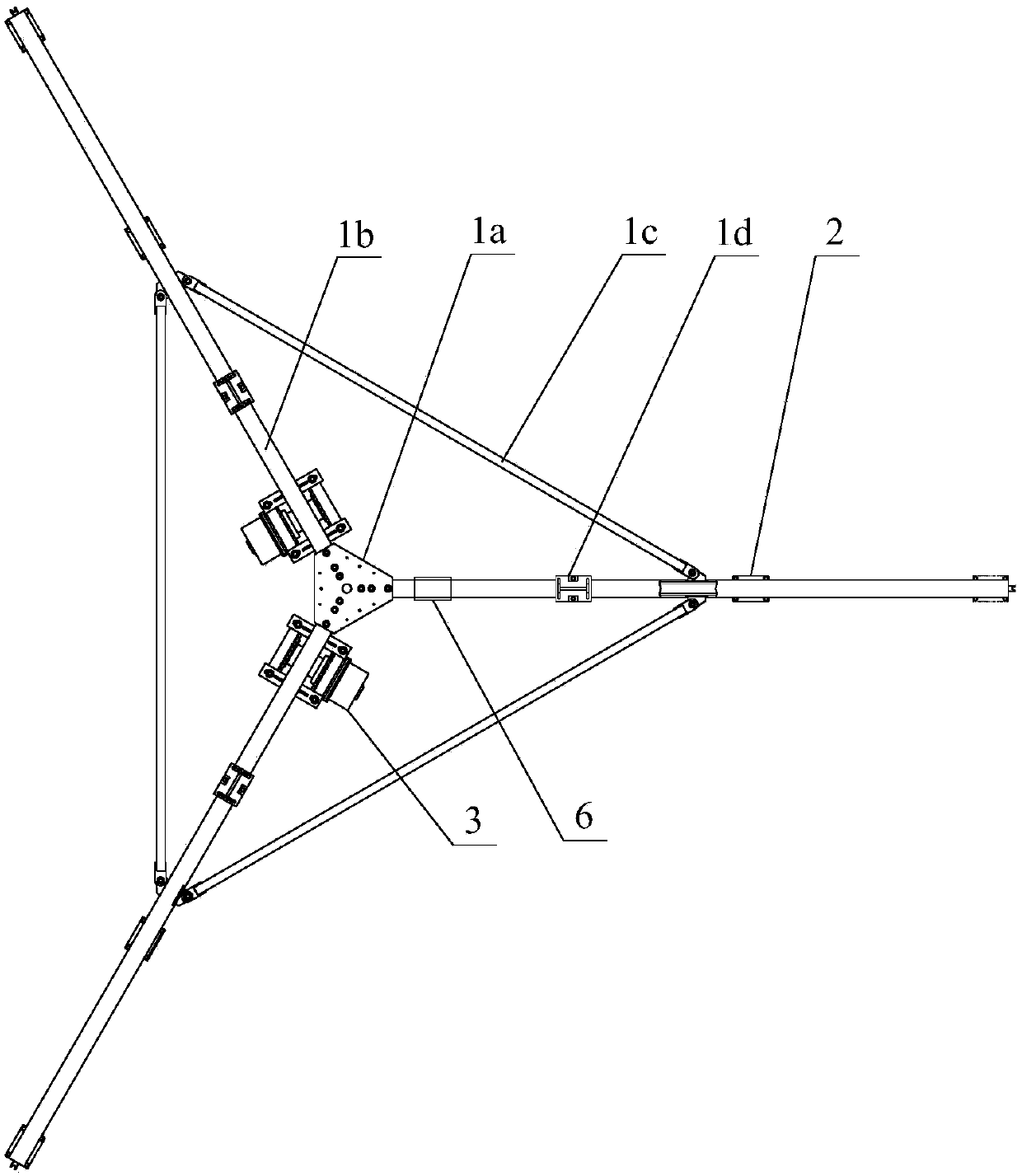

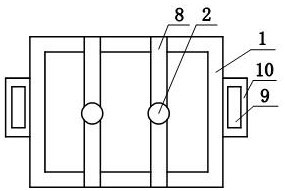

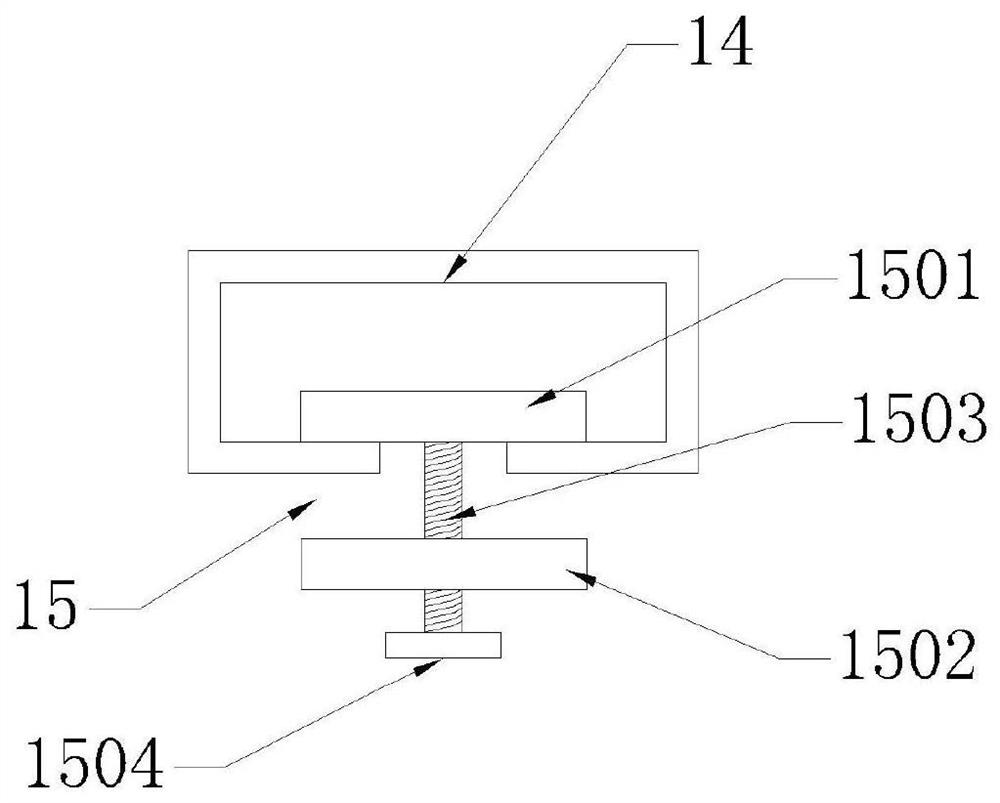

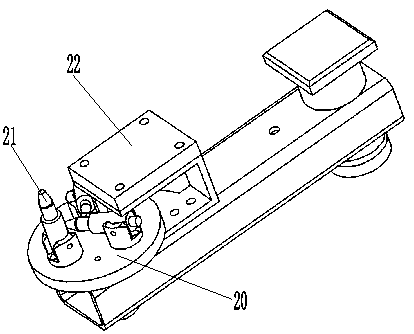

Mass center adjustable single-beam horizontal lifting tool

InactiveCN108046115AAdjustable center of massSimple structureLoad-engaging elementsMechanical engineeringSingle beam

The invention discloses a mass center adjustable single-beam horizontal lifting tool which comprises a lifting beam assembly, two front lifting bands and two rear lifting bands. The lifting beam assembly comprises two parallel main beams, the middles of the two main beams are fixedly connected through a connecting beam, and a lifting lug is arranged in the middle of the connecting beam. Two frontlifting holes are formed in the front end of each of the two main beams, and two rear lifting holes are formed in the rear end of each of the two main beams. The lower ends of the two front lifting bands are correspondingly connected with front connecting plates, the upper ends of the two front lifting bands are correspondingly connected with front connecting forks, and the two front connecting forks are connected with the front lifting holes in the two main beams correspondingly. The lower ends of the two rear lifting bands are correspondingly connected with basket bolts, the two basket boltsare correspondingly connected with rear connecting plates, the upper ends of the two rear lifting bands are correspondingly connected with rear connecting forks, and the two rear connecting forks areconnected with the rear lifting holes in the two main beams correspondingly. The mass center adjustable single-beam horizontal lifting tool has the advantages of being simple in structure, convenientto adjust and high in adaptability, stepless adjustment of the mass center position of a lifted product can be achieved, and safety and efficiency of product lifting are improved.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

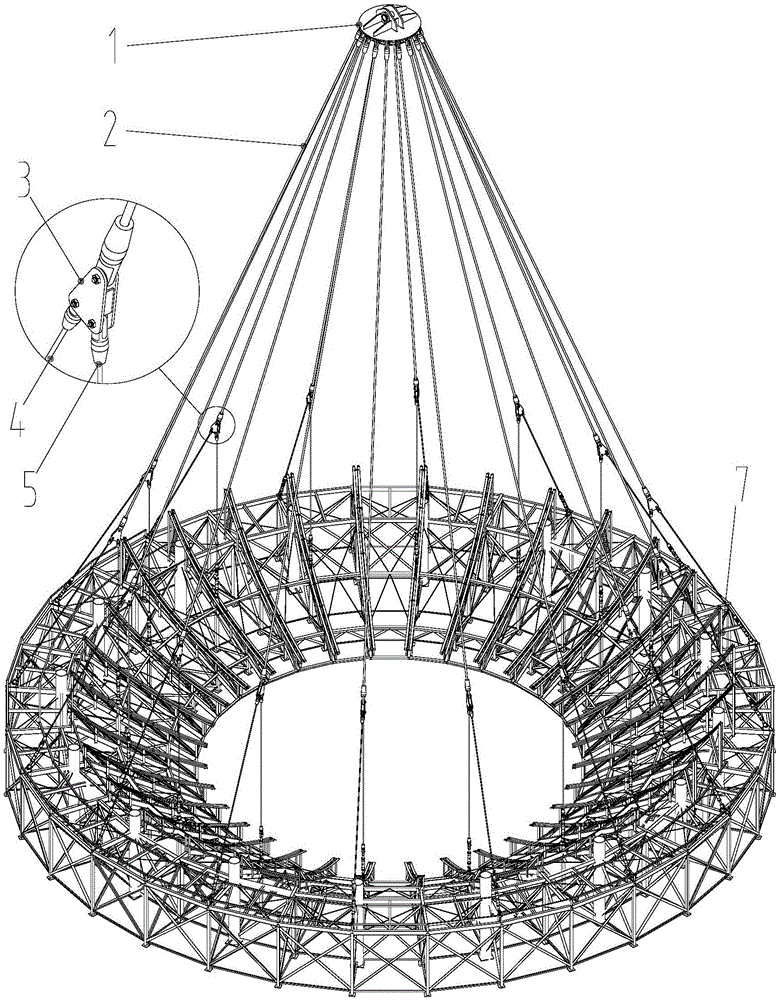

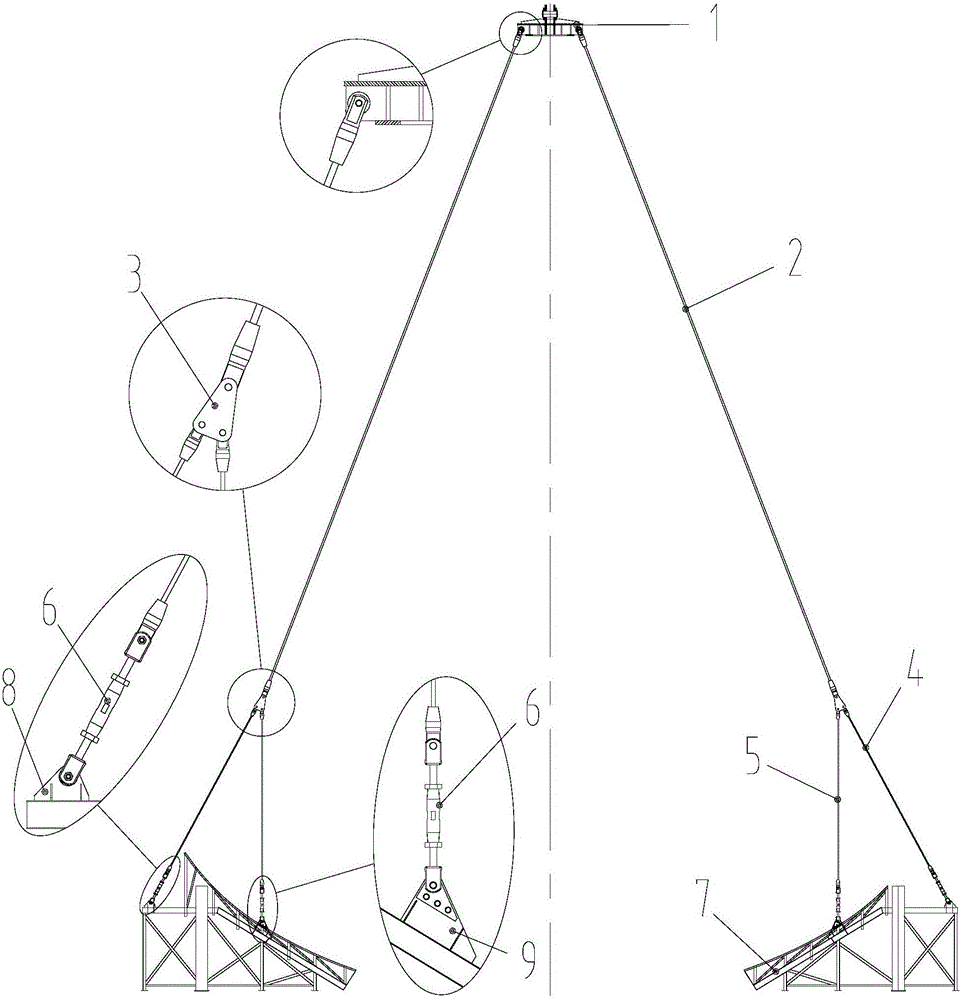

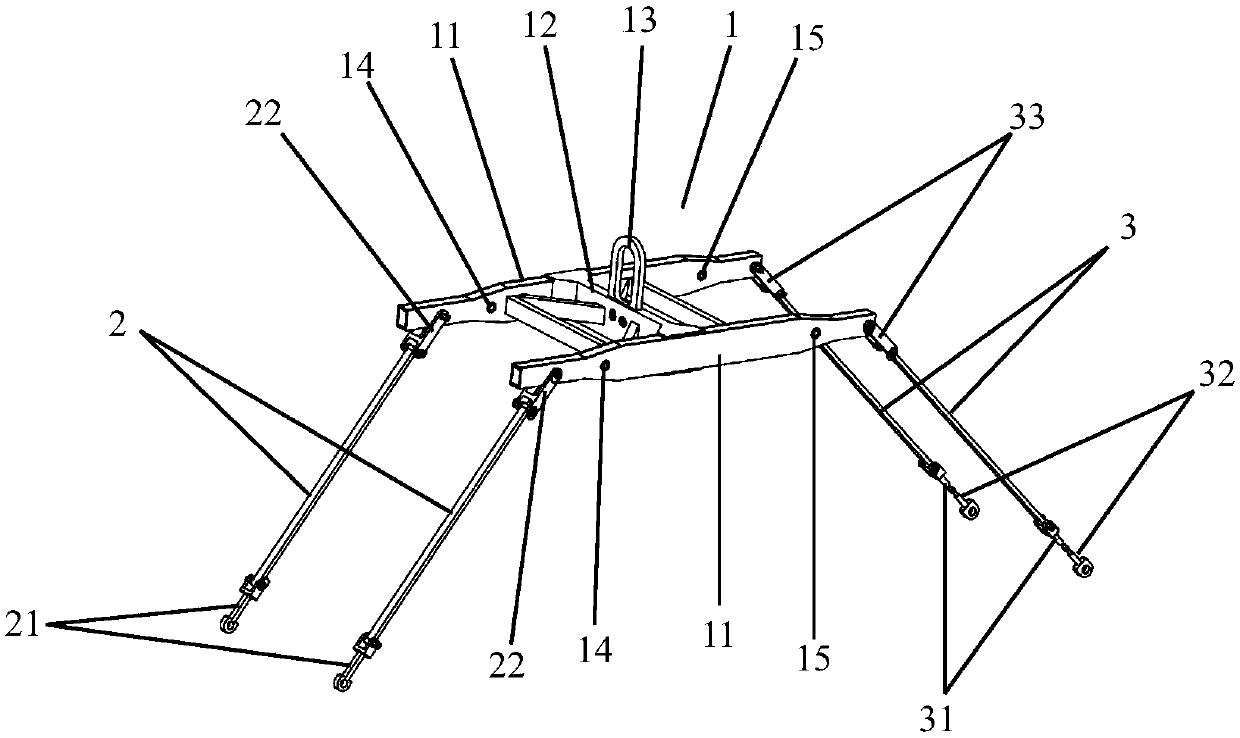

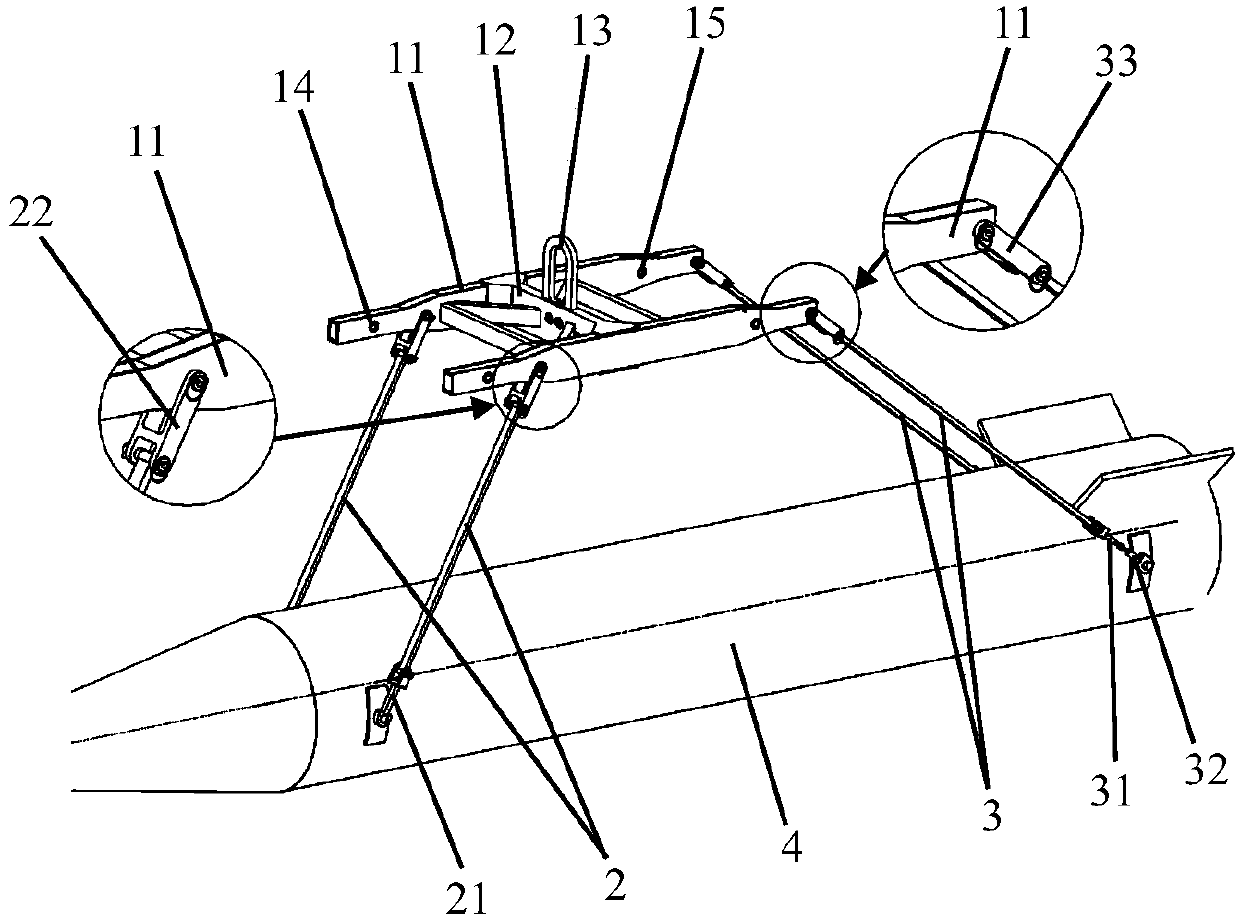

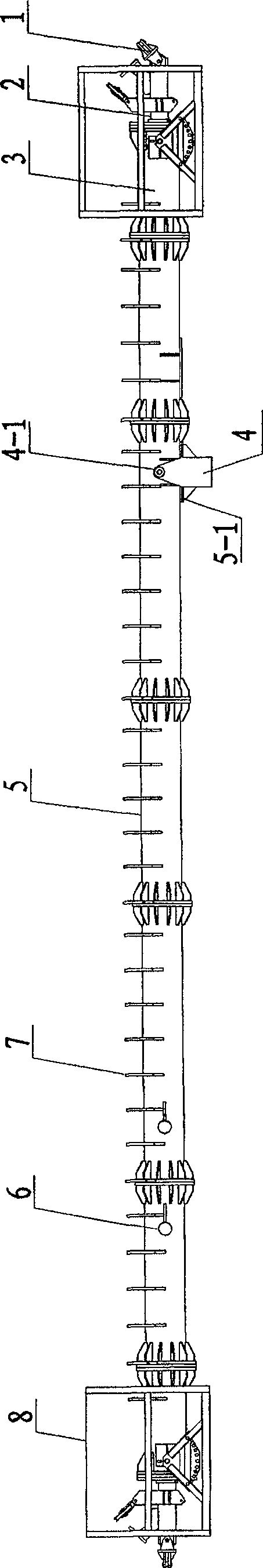

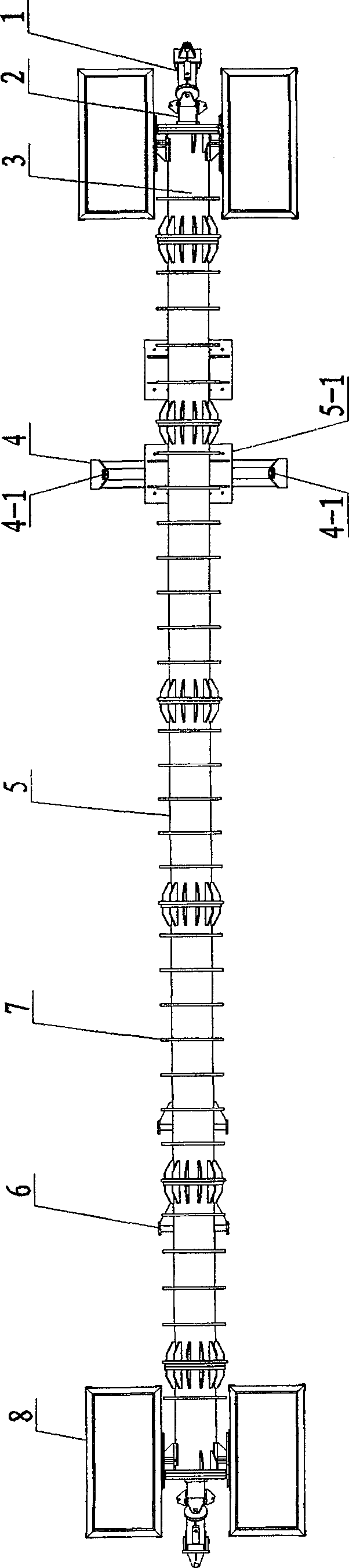

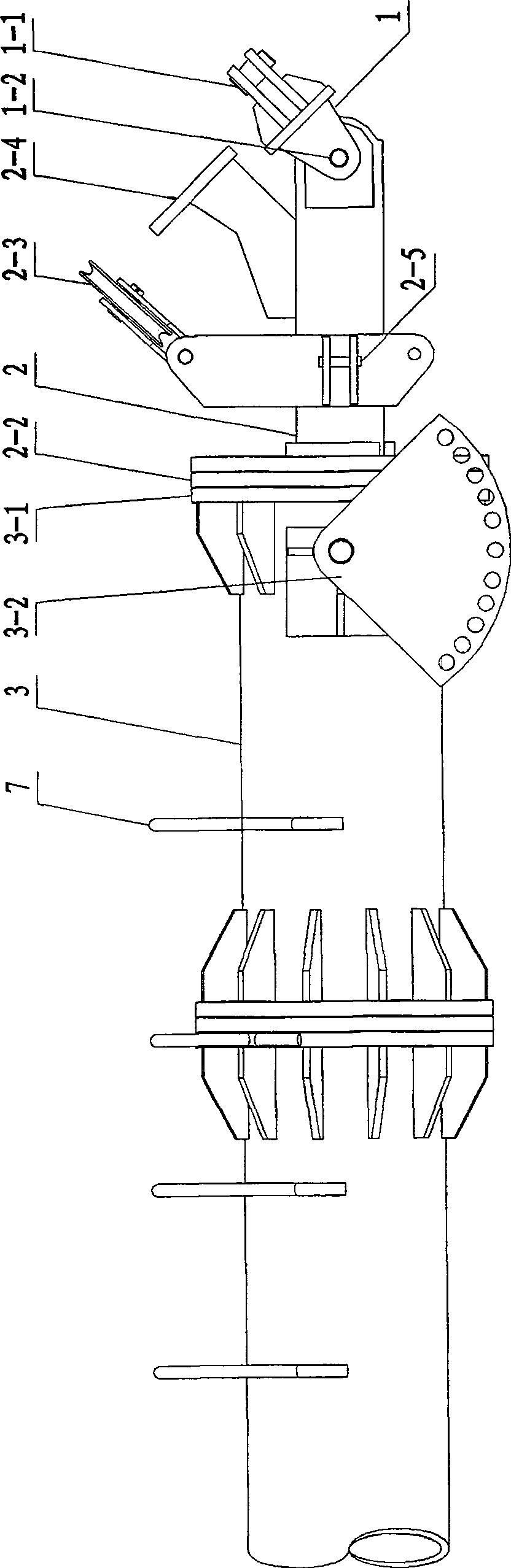

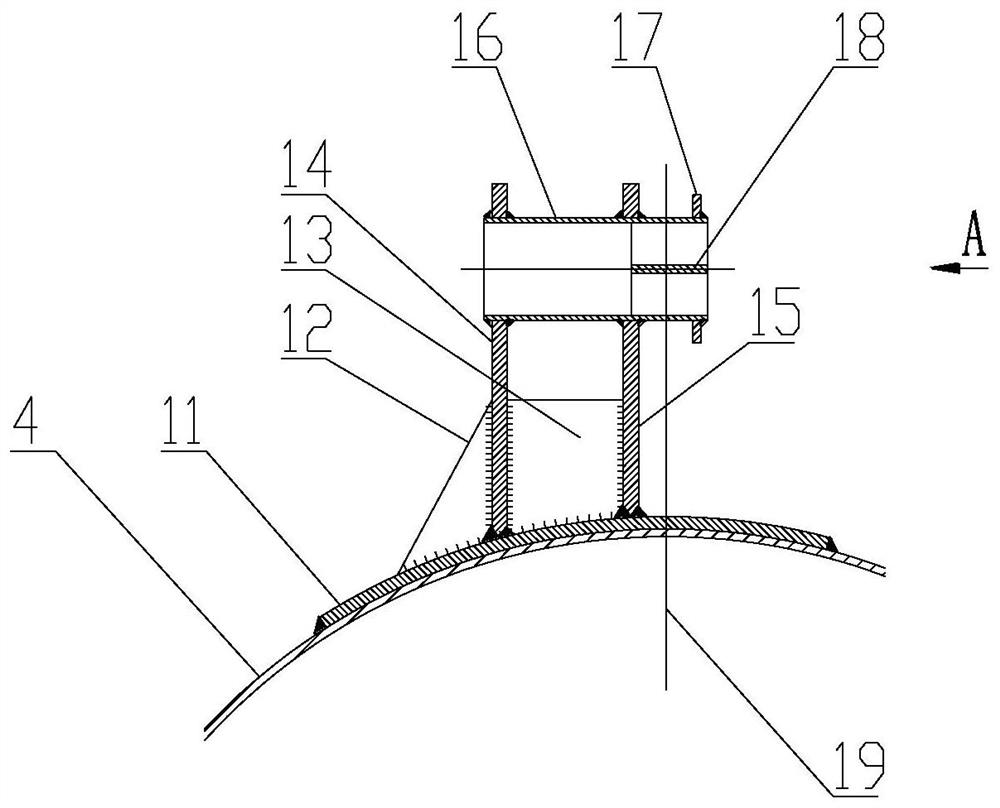

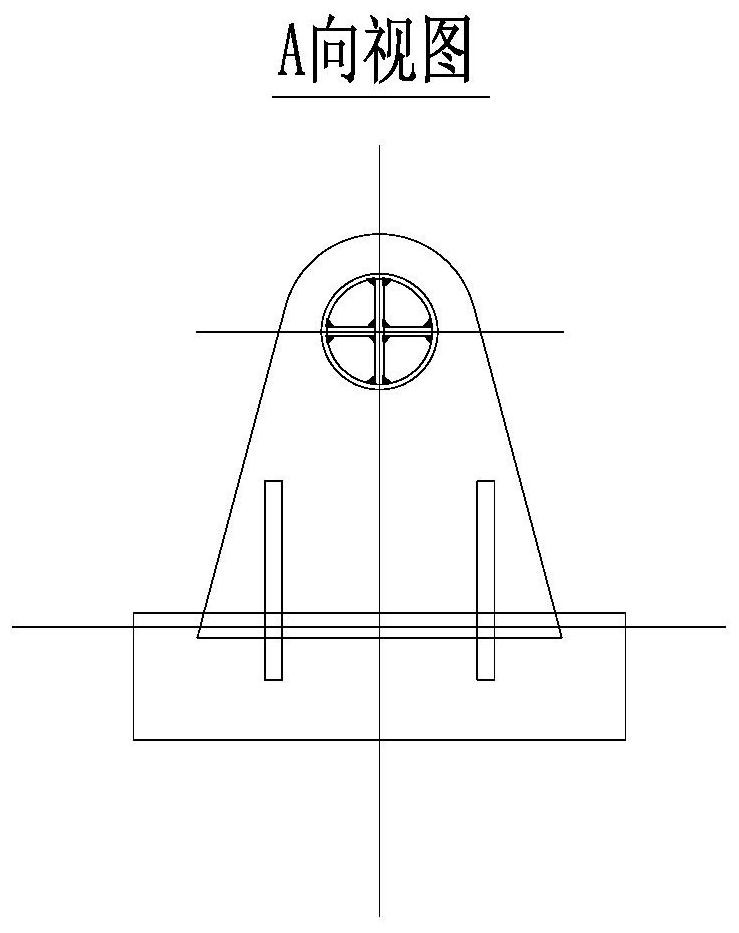

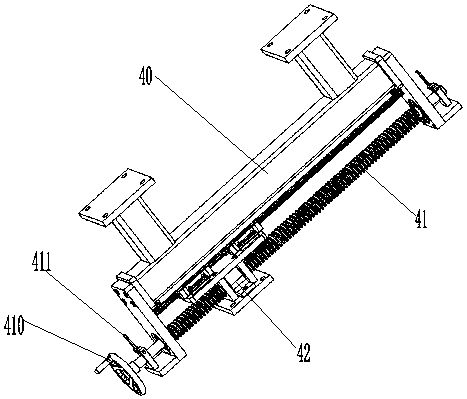

Special lifting device and lifting method for lifting reflector unit of radiotelescope

ActiveCN105152001ANo frequent replacementImprove construction efficiencyLoad-engaging elementsRemote controlRadio telescope

The invention discloses a special lifting device and a lifting method for lifting a reflector unit of a radiotelescope and relates to the technical field of installation of reflector units of radiotelescopes. The special lifting device adopts the structure that a position-adjustable guiding pulley is arranged on each lifting arm, one end of each of two wire cables is connected with a remote-control windlass, and the other end of each of the two wire cables bypasses the corresponding guiding pulley; and one end of the third wire cable is connected with a hanging bracket, the other end of the third wire cable bypasses the corresponding guiding pulley, and a universal lifting claw is tied to each wire cable. The special lifting device and the lifting method can adapt to the lifting requirements of reflector units of different sizes to improve the construction efficiency.

Owner:HEAVY EQUIP ENG CO LTD OF WUCHANG SHIPBUILDING IND

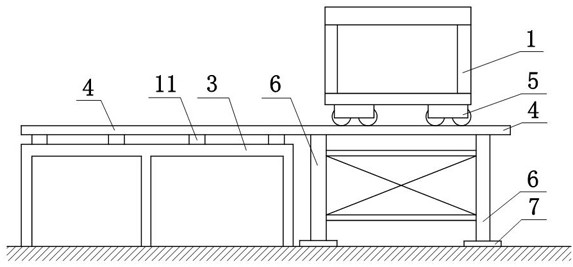

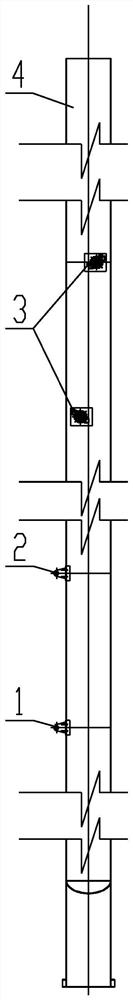

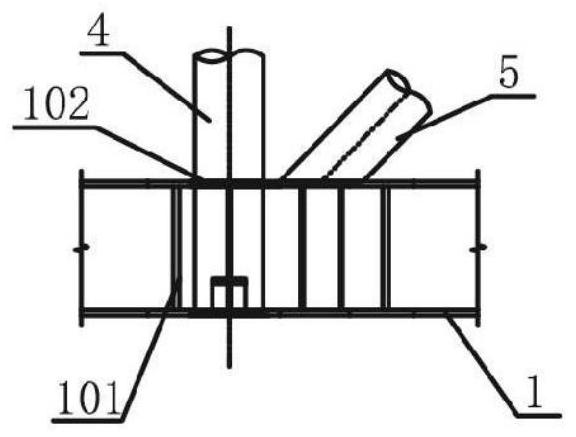

Mobile lifting bracket for building bridge

InactiveCN102797225AMeet the hoisting requirementsSolve high-altitude installationBridge erection/assemblyArchitectural engineeringWinch

The invention discloses a mobile lifting bracket for building a bridge. The mobile lifting bracket is characterized by comprising a truss structure (1), a beret piece (2), a walking device (3) and a winch (4) and is characterized in that the beret piece (2) is mounted on the top surface of the truss structure (1); the walking device (3) is mounted at the bottom of the truss structure (1); and the winch (4) is mounted at the tail part of the truss structure (1). The mobile lifting bracket for building the bridge, disclosed by the invention, has finite operation positions on the surface of the bridge when being mainly used for building the bridge, can be assembled and disassembled on the bridge surface and can freely move in a lifting position; the lifting position of the lifting bracket can be changed according to construction needs; and the length of a lifting arm of the lifting bracket can be also changed to satisfy various lifting requirements.

Owner:GUIZHOU BRIDGE CONSTR GROUP

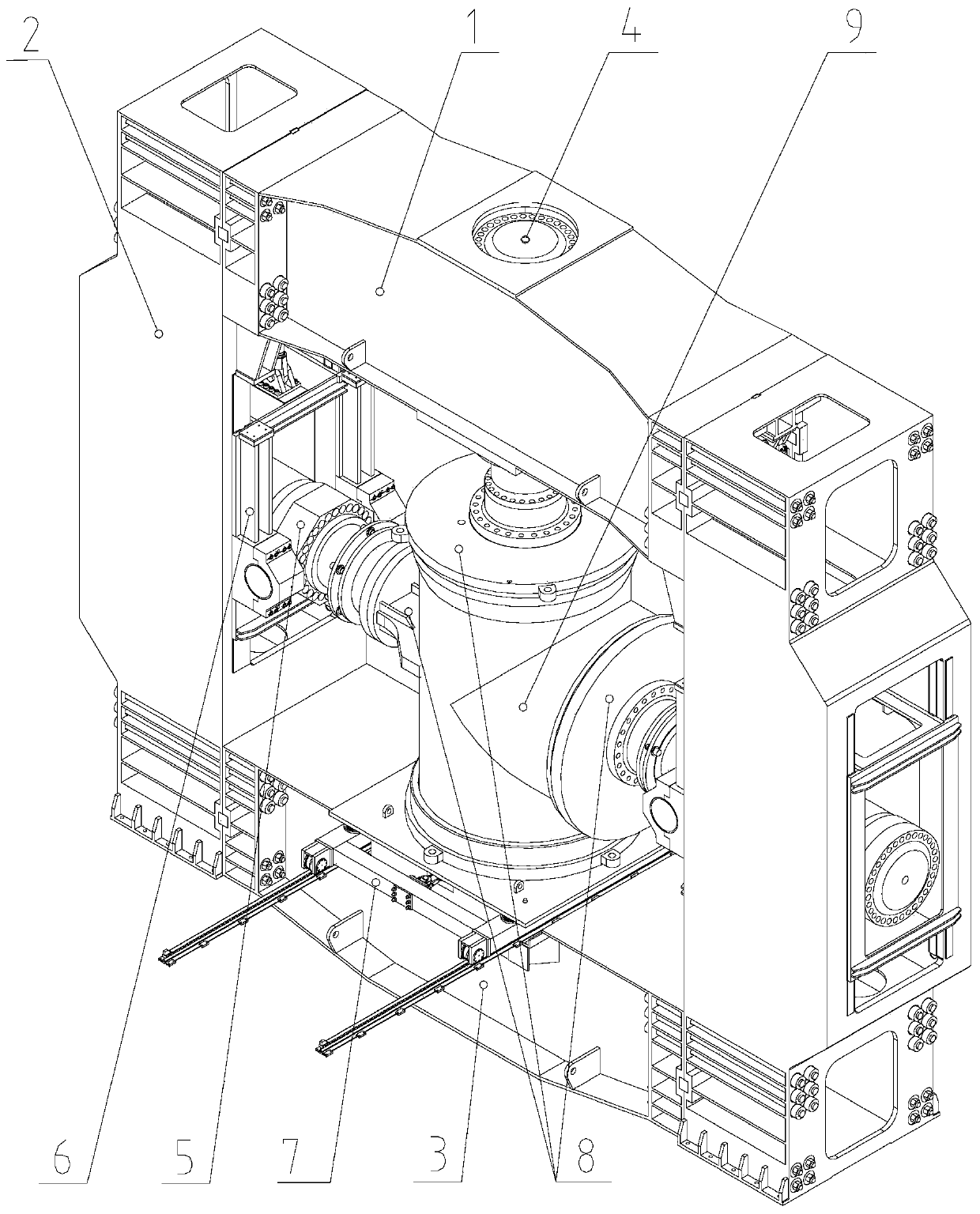

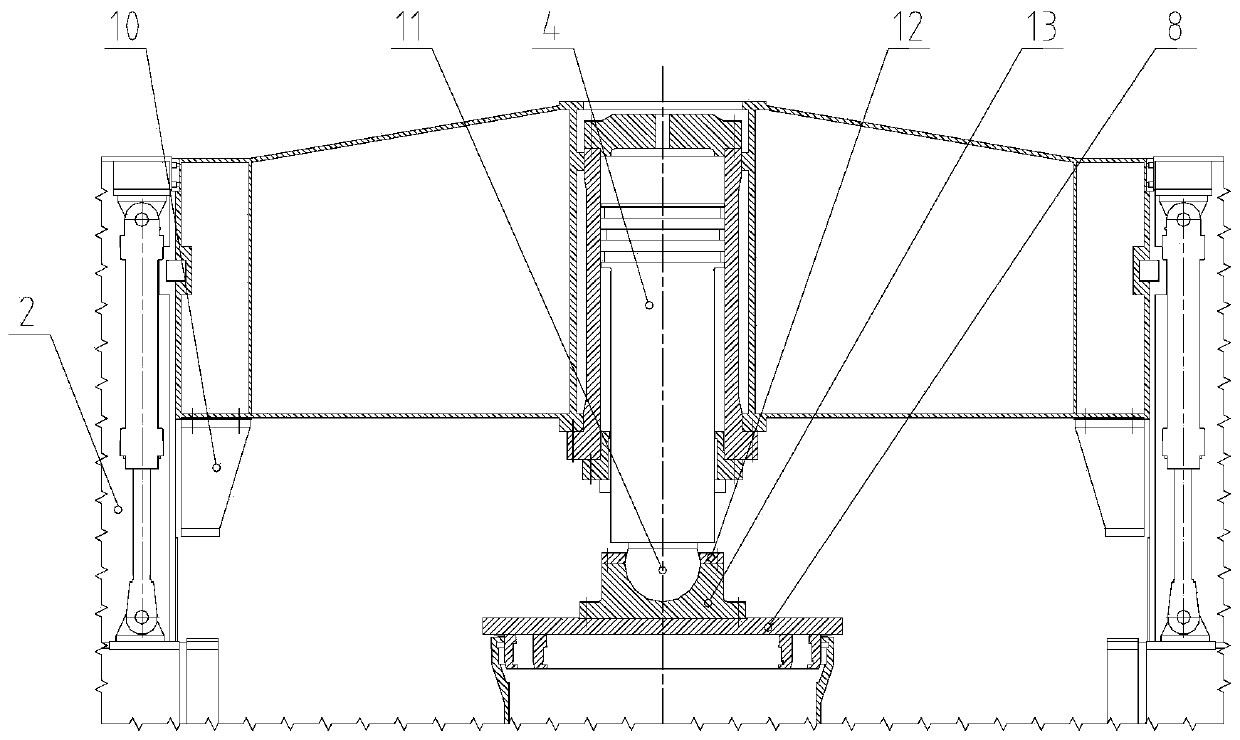

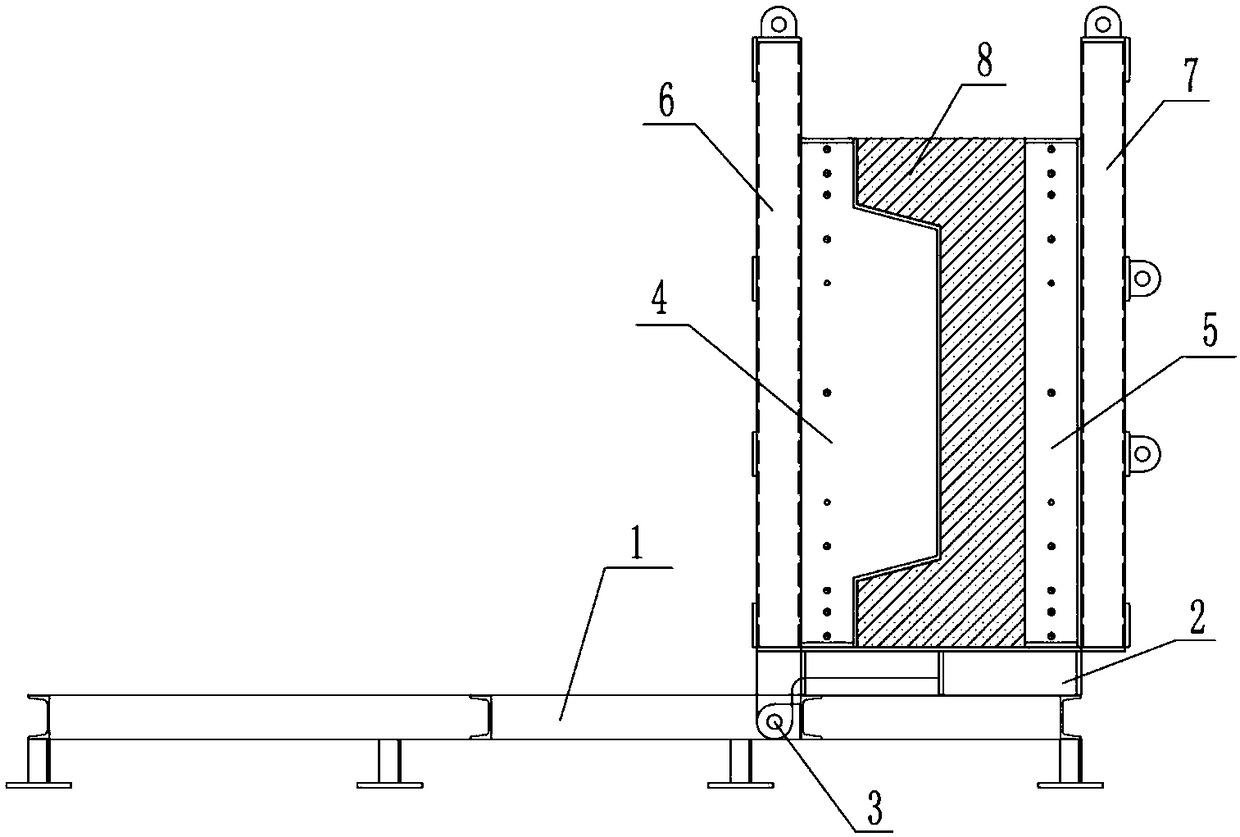

Hydrostatic testing machine for ultra-large drift diameter cast pipe

PendingCN109855980AAvoid lateral forcesExtended service lifeMaterial strength using tensile/compressive forcesMaster cylinderPipe fitting

The invention relates to the technical field of the hydrostatic test device of the cast pipe, specifically hydrostatic testing equipment for an ultra-large drift diameter cast pipe, and relates to hydrostatic test devices in different structural forms and with drift diameters at DN1600-2200 pipe fitting. The hydrostatic testing equipment comprises a mounting support frame, a main cylinder, side cylinders, side cylinder driving mechanisms, a moving trolley and tools, wherein the mounting support frame is a hollow-square shaped frame structure; the main cylinder is arranged at a middle locationof an upper part of the mounting support frame; the side cylinder is arranged at a side cylinder driving mechanism; the side cylinder driving mechanism can move along an upright under the driving of alifting cylinder; the moving trolley is arranged at a lower part of the mounting support frame; a tee pipe fitting is arranged on the moving trolley and moved to the center of the mounting support frame; an upper part port of the tee pipe fitting is blocked by the tool on the main cylinder, the middle port is blocked by the tool on the side cylinder at the left side (or right side), and the otherside cylinder provides support force balance, and the lower part is blocked by the tool on the moving trolley.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

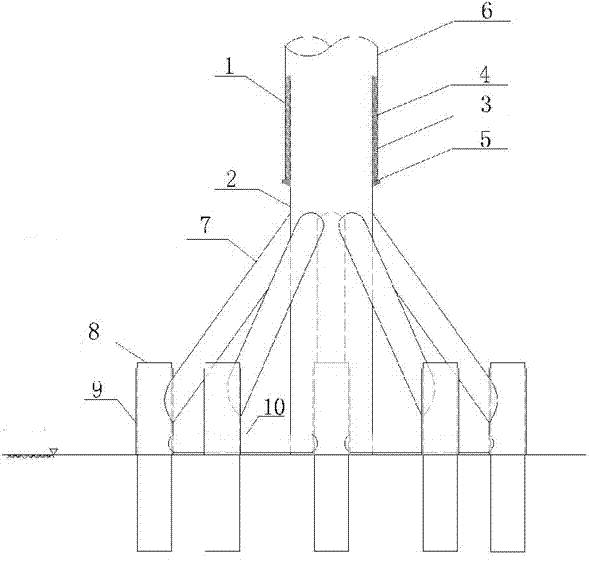

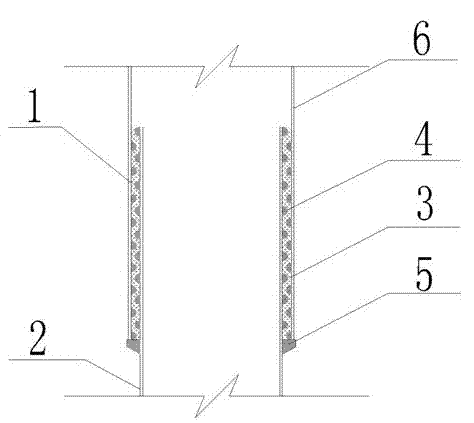

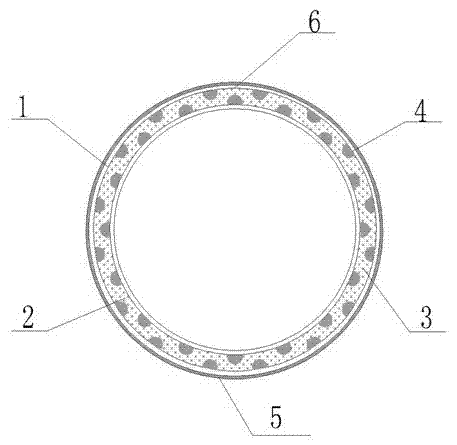

Jacket wind turbine foundation connecting piece

The invention discloses a jacket wind turbine foundation connecting piece which comprises a jacket, wherein a connecting piece steel pipe is sheathed outside a jacket top steel pipe, a steel block is fixed on the outer wall of the jacket top steel pipe and / or the inner wall of the connecting piece steel pipe, and a grouting material is filled in a clearance between the jacket top steel pipe and the connecting piece steel pipe; and a sealing ring is arranged at the lower end of the connecting piece steel pipe, and a wind turbine tower drum is sheathed outside the connecting piece steel pipe. By adopting the jacket wind turbine foundation connecting piece, accurate leveling of the top of the connecting piece steel pipe is ensured, the hoisting requirement of the upper wind turbine high-rise structure is achieved, and the jacket wind turbine foundation can be popularized and applied in the offshore wind farm field.

Owner:POWERCHINA ZHONGNAN ENG

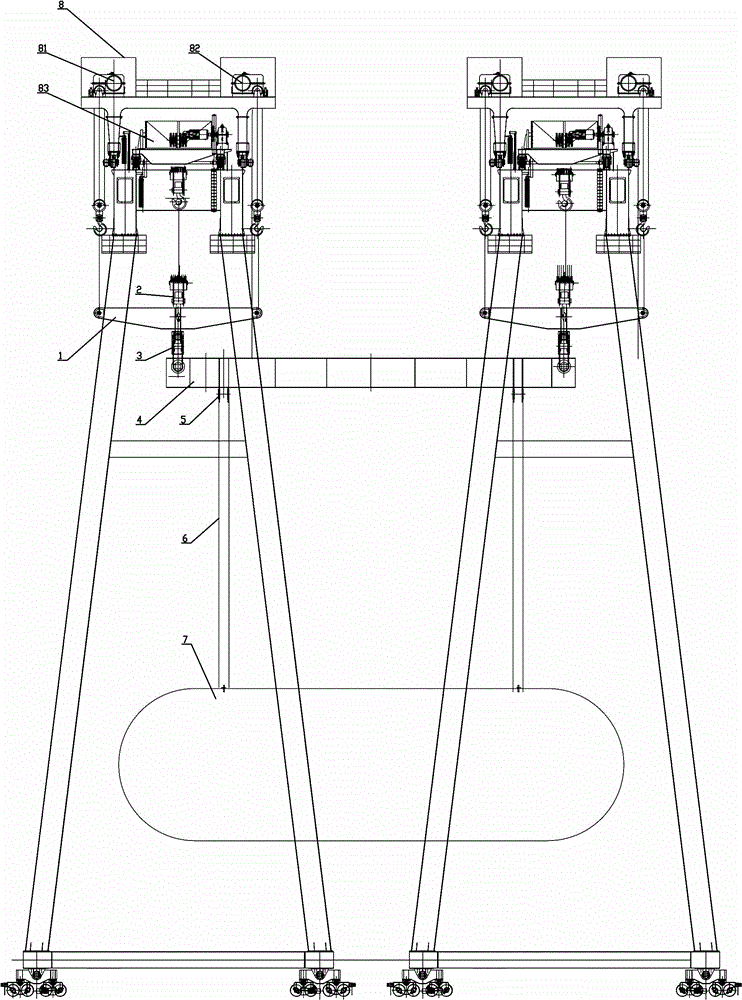

Rotary lifting appliance suitable for double-crane lifting

InactiveCN105084219AMeet the hoisting requirementsMeet the needs of hoistingTrolley cranesLoad-engaging elementsEngineeringLifting weight

The invention provides a rotary lifting appliance suitable for double-crane lifting. The rotary lifting appliance comprises a balance beam. At least two lifting points are formed below the balance beam. The rotary lifting appliance is characterized in that distribution beams are further arranged above the two ends of the balance beam, the middles of the distribution beams are provided with vertical distribution beam through holes, and vertical shafts penetrate through the vertical distribution beam through holes; one end of each vertical shaft is provided with a first lifting appliance body, and the other end of each vertical shaft is connected with the balance beam through a second lifting appliance body; the two ends of each distribution beam are provided with a first distribution beam lifting point and a second distribution beam lifting point. According to the rotary lifting appliance, the distribution beams are arranged and connected through the vertical shafts, so that the lifting weight is reasonably distributed to first walking trolleys, second walking trolleys and third walking trolleys of two portal cranes through the distribution beams; and besides, the vertical shafts and the distribution beams are in clearance fit, the distribution beams can rotate freely, and the lifting requirements of the positions of the walking trolleys and hooks of various portal cranes are met.

Owner:CHINA GEZHOUBA GROUP MACHINERY & SHIP

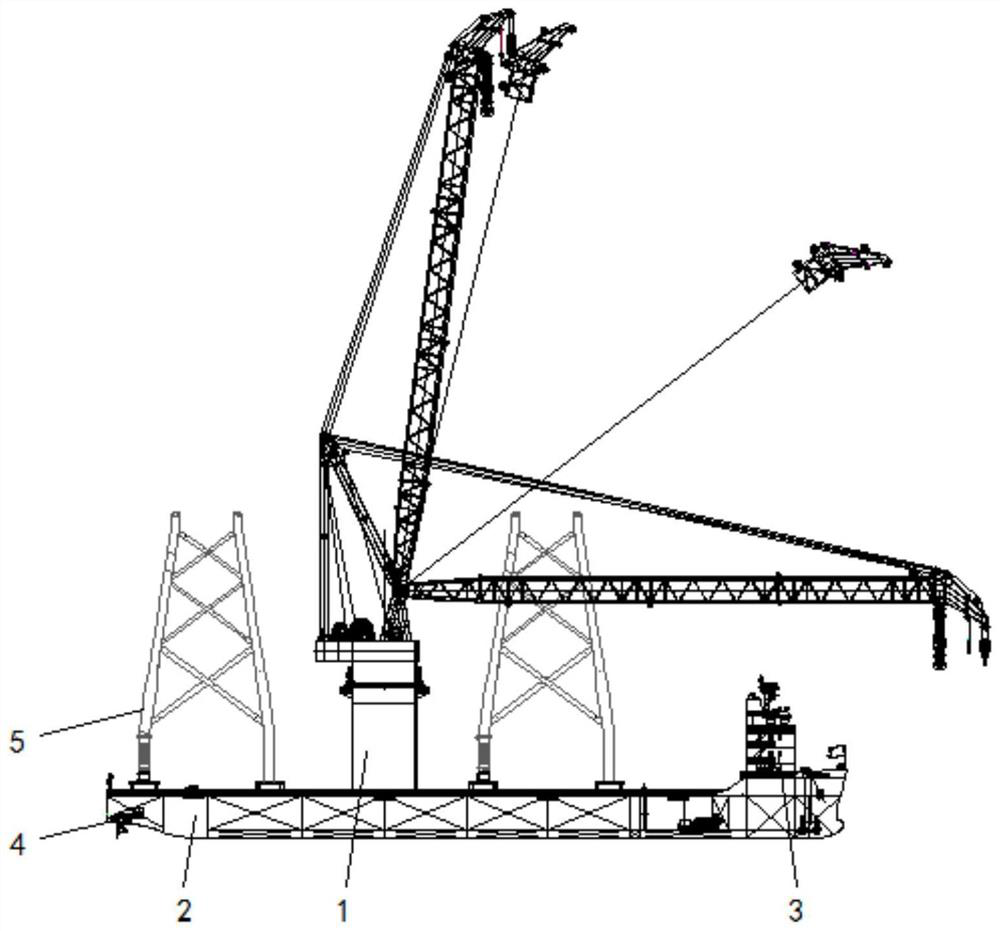

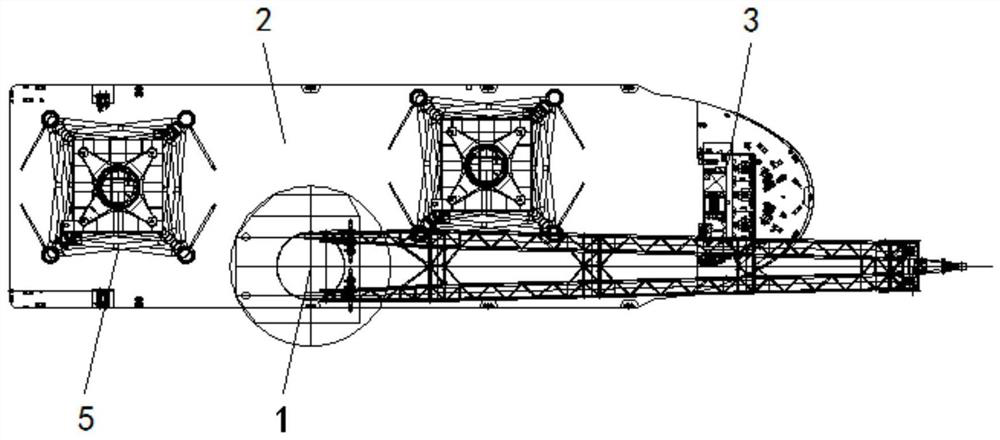

Multifunctional wind power supporting ship

PendingCN112158303AEfficient transportEffective installationArtificial islandsCargo handling apparatusClassical mechanicsPropeller

The invention relates to the technical field of offshore wind power generation, and discloses a multifunctional wind power supporting ship which comprises a ship body, a crane is fixedly connected tothe top of the ship body, and a propelling device is fixedly connected to the left side wall in the ship body. According to the professional wind power construction work ship, the transport ship workdeck in the ship body serves as the flight main deck, on the basis of 32 meters of the main ship body, the main deck flies towards the two sides by 2 meters, the width of the work deck reaches 36 meters, the loading area is effectively increased, and meanwhile the influence of the main ship body on sailing resistance is reduced; the 360-degree full-rotation propeller in the propelling device enables the work ship to have good advancing and retreating capacity, the requirement of the ship for a marine power positioning system can be met, rapid positioning of the work ship can be achieved through a DP positioning system in the propelling device, the DP positioning system assists a wave compensation system. And the requirement of rapid offshore unloading of the fan can be met.

Owner:南通润吉尼海洋装备有限公司

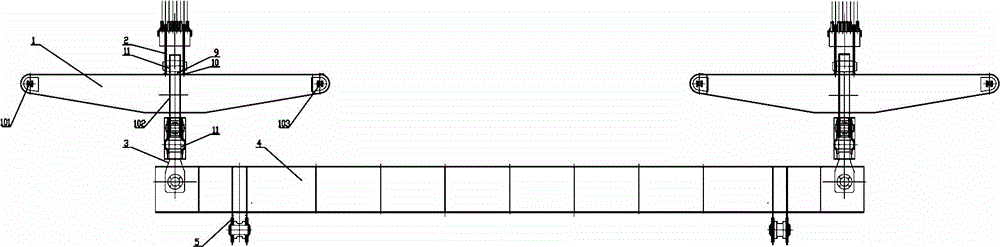

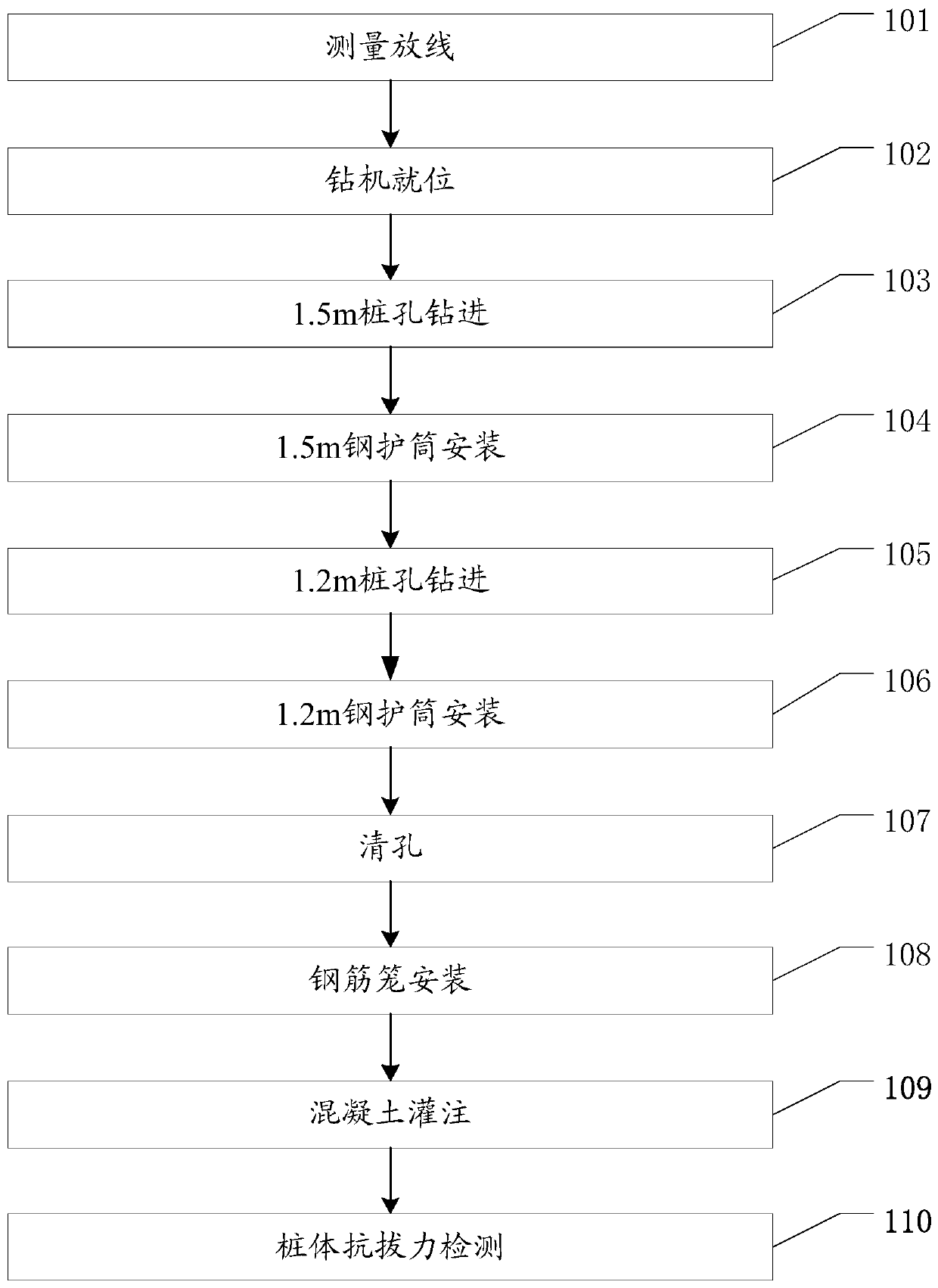

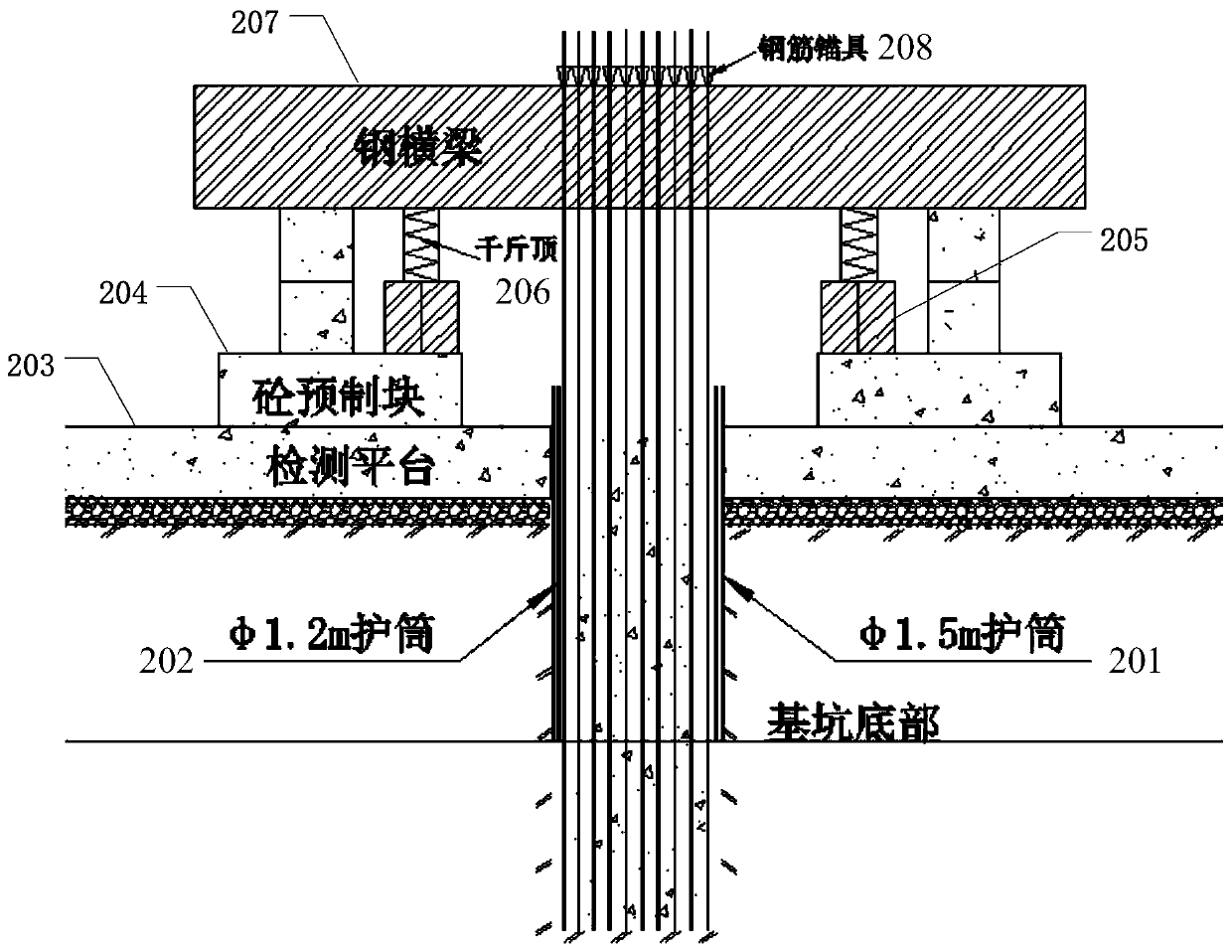

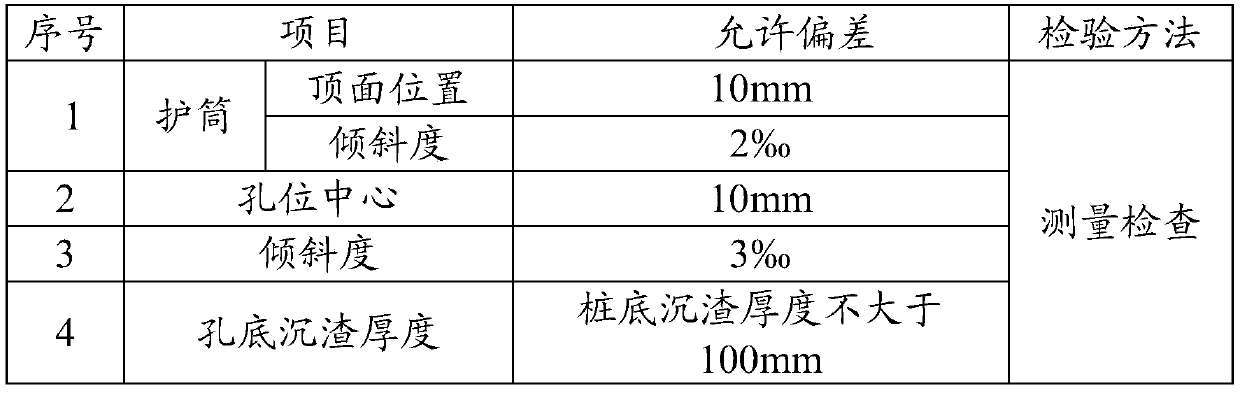

Double-casing zero-friction static load detection construction method based on uplift pile

InactiveCN111335305AReduce secondary bad luckMeet the hoisting requirementsFoundation testingBulkheads/pilesSlurryTotal station

The invention discloses a double-casing zero-friction static load detection construction method based on an uplift pile. The double-casing zero-friction static load detection construction method is used for welding steel bars at the top of a foundation pit and installing detection equipment, secondary transportation of material equipment is reduced, and the construction efficiency is improved. Thedouble-casing zero-friction static load detection construction method specifically comprises the steps that (1) surveying and setting out are conducted, specifically, before the uplift pile is drilled, a total station is used for placing pile position points, and the pile position setting-out error is within the range required by the specification; (2) a drilling machine is in place, specifically, the drilling machine is moved in place, sole timber is laid under a base, the drilling machine is kept stable, and a drill rod is vertical; (3) a 1.5m pile hole is drilled; (4) a 1.5m steel casing is installed; (5) a 1.2m pile hole is drilled; (6) a 1.2m steel casing is installed; (7) hole cleaning is conducted, specifically, after the 1.2m steel casing is installed, hole bottom cleaning is conducted on the uplift pile formed hole, diluted slurry meeting the requirements is injected from the hole bottom through a guide pipe, and circulation is conducted; (8) a steel reinforcement cage is installed; (9) concrete is poured; and (10) the uplift resistance of a pile body is detected.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

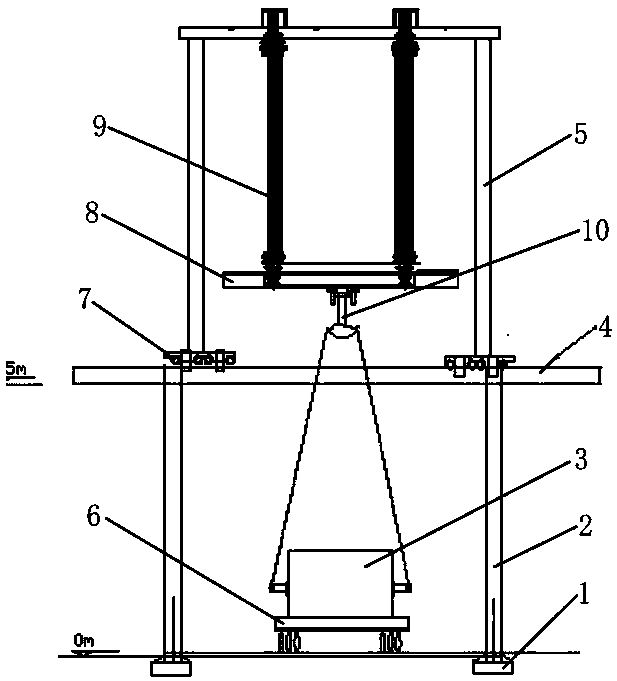

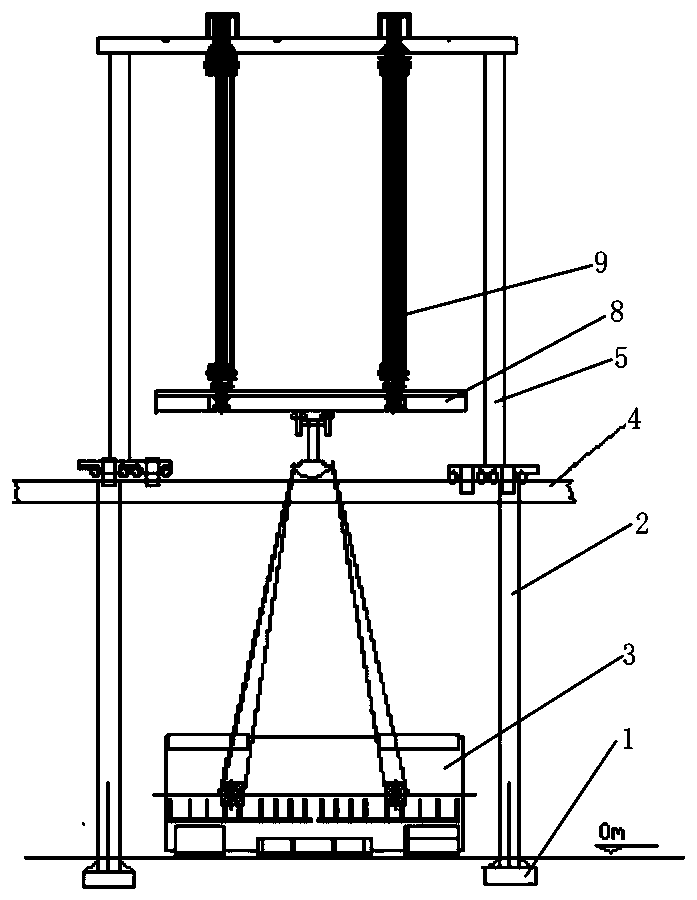

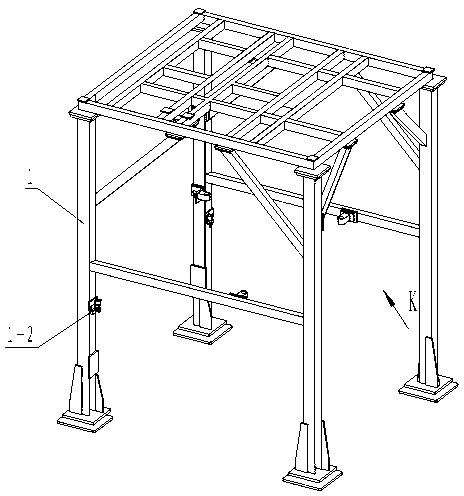

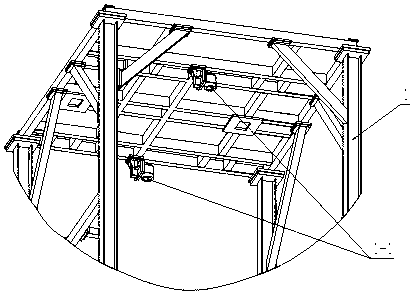

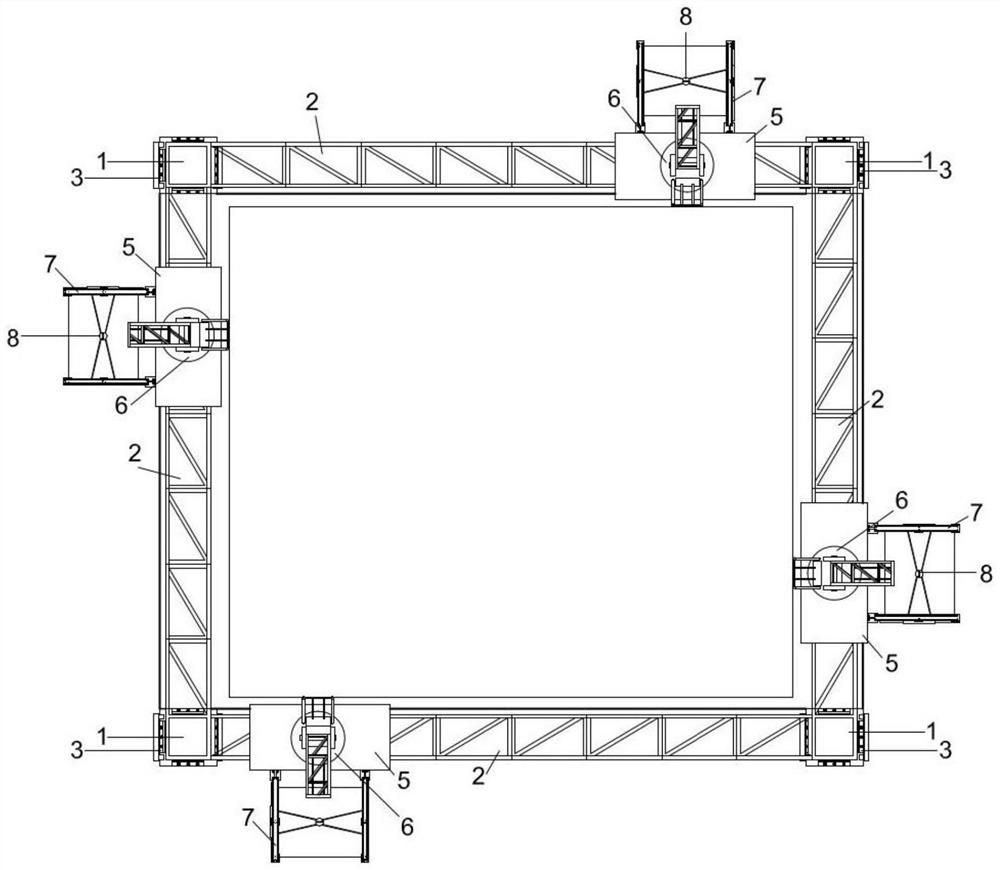

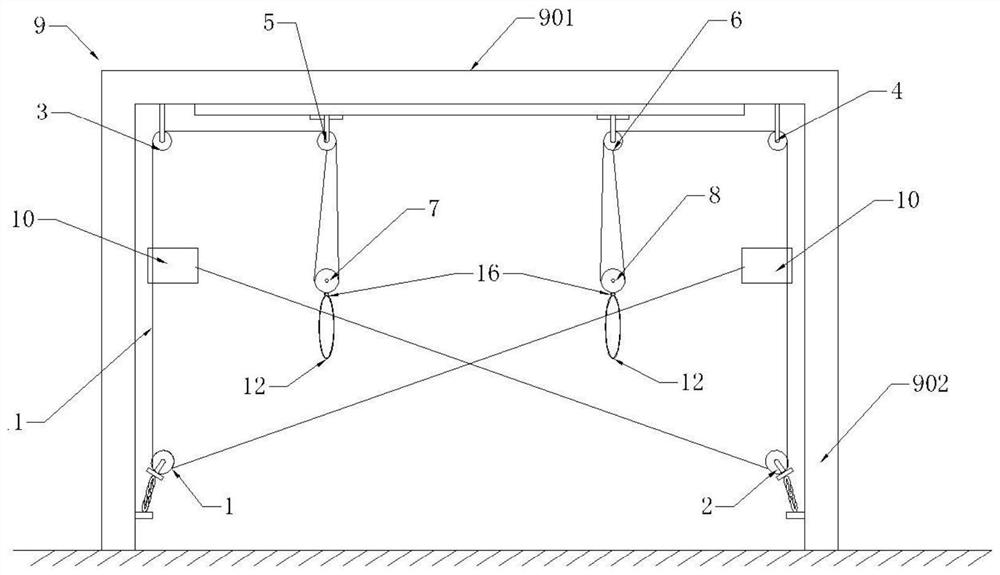

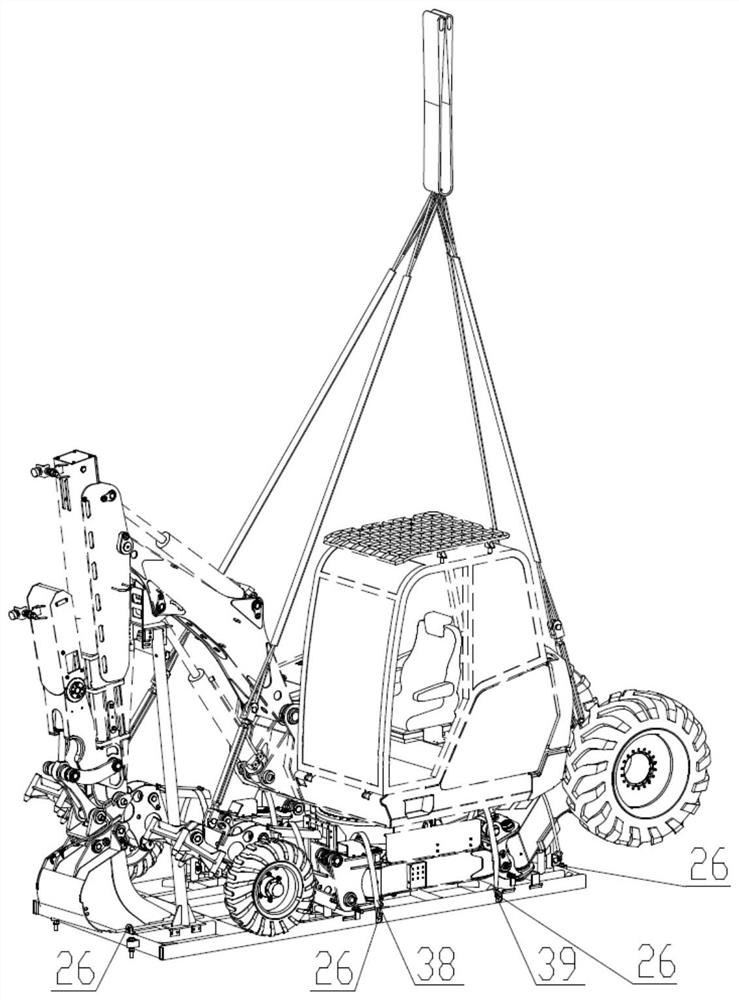

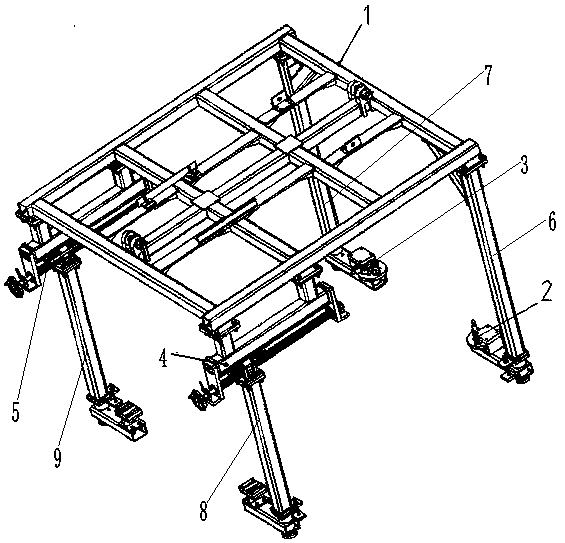

Integrated hoisting system applied to prefabricated components and hoisting method thereof

ActiveCN112938774AEasy to installSmall footprintCargo handling apparatusPassenger handling apparatusEngineeringStructural engineering

The invention discloses an integrated hoisting system applied to prefabricated components and a hoisting method thereof. The integrated hoisting system comprises a fixing mechanism and more than four vertical stand columns, wherein the four vertical stand columns are located at the four corners of a building; the building is located in an area defined by the vertical stand columns; a transverse track beam is arranged between every two vertical stand columns; one end of the transverse track beam is mounted at the top of one vertical stand column, and the other end of the transverse track beam is mounted at the top of the other vertical stand column; the transverse track beam is provided with a travelling trolley; a movable arm crane is arranged on the upper surface of the travelling trolley; a hoisting mechanical arm is arranged on the outer side of the travelling trolley; and a hydraulic jacking mechanism is arranged at the bottom of each vertical stand column. The integrated hoisting system is convenient to mount and construct, good in safety, large in hoisting capacity and stable in hoisting, and is applied to hoisting of various specifications of prefabricated components; and and the construction efficiency is improved.

Owner:SOUTHEAST UNIV

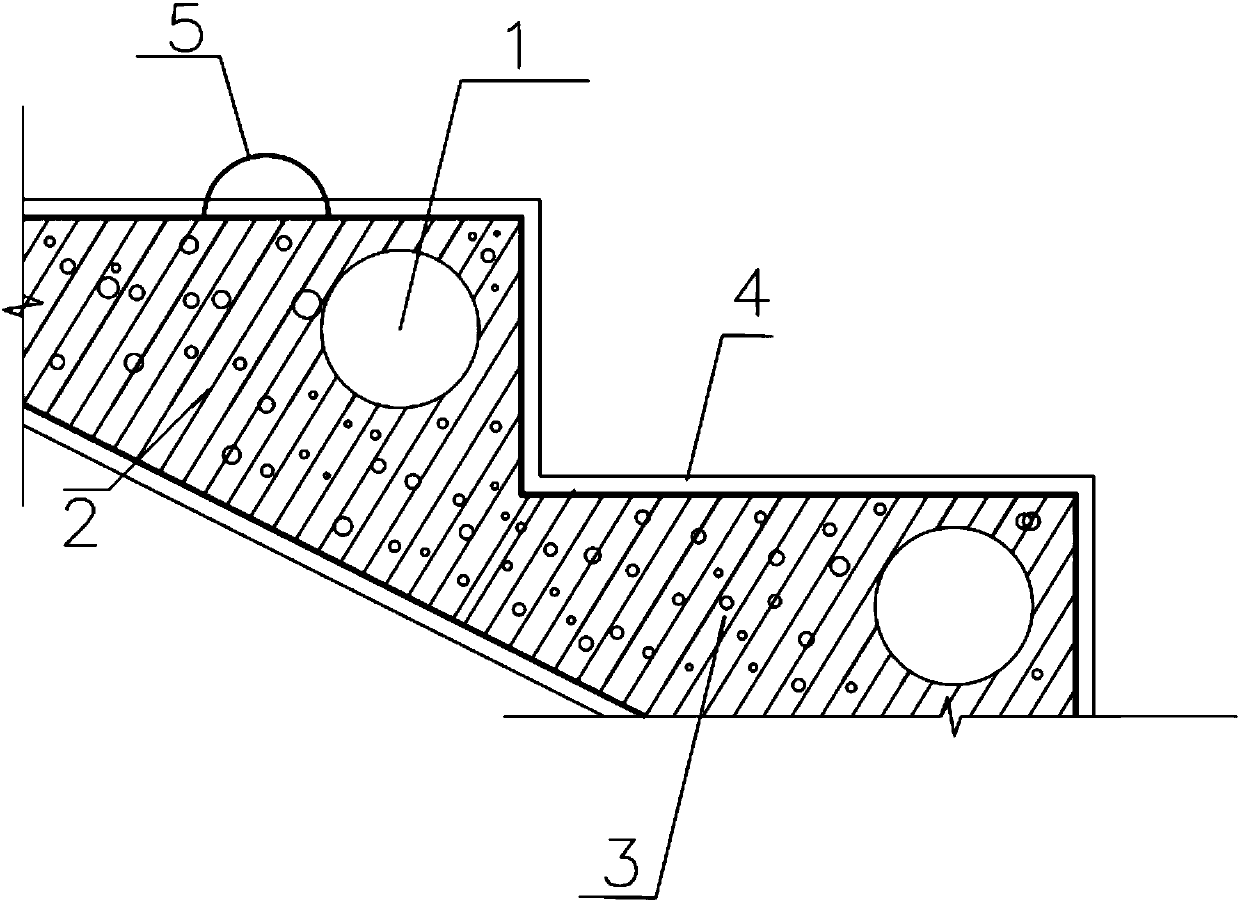

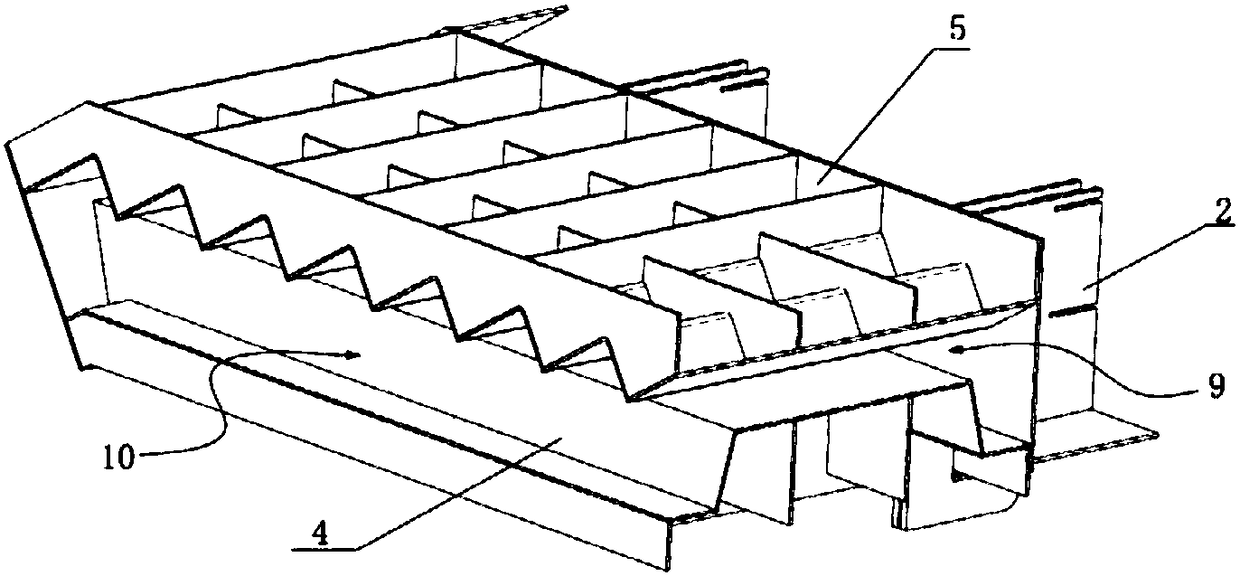

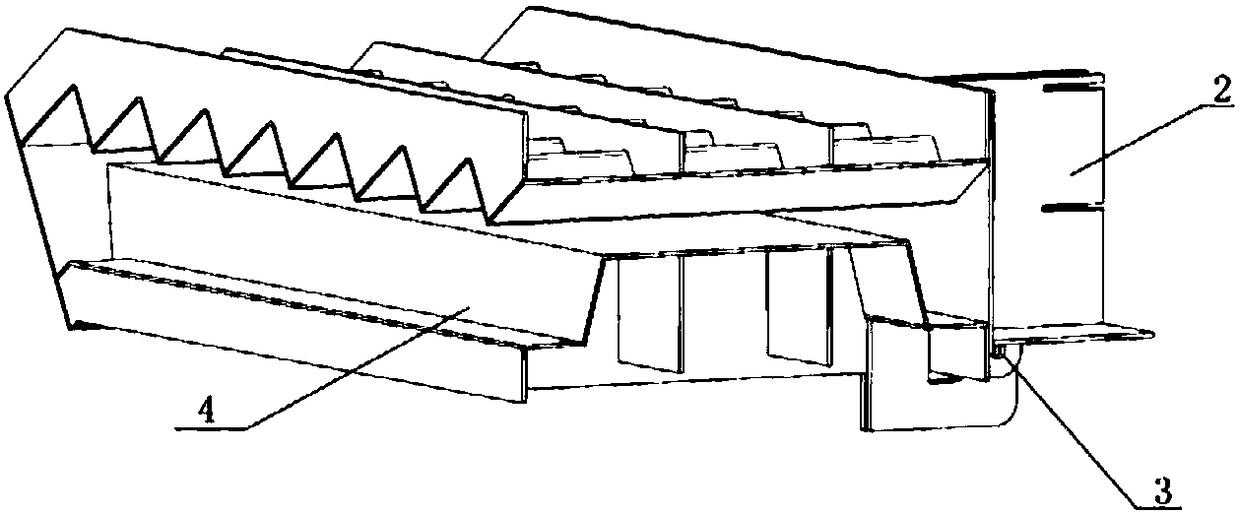

A prefabricated concrete staircase mold and its manufacturing method

ActiveCN106378861BAvoid destructionReduce the construction of the receiving surfaceMouldsMould auxillary partsPrecast concreteBy-product

The invention discloses a prefabricated type concrete stair mould and a stair manufacturing method. The mould comprises a back board molding board and a step surface molding board which are detachably connected; the molding boards are combined into a cavity for pouring prefabricated concrete stairs, and are equipped with side openings for pouring concrete; the mould further comprisesa supporting base; the molding boards are rotatably connected on the supporting base; and each molding board has a horizontal state and a perpendicular state for forming an upward opening after being turned over around a rotary connecting part. The manufacturing method comprises the following steps of: suspending a reinforcing mesh cage, assembling a step surface molding board, turning the mould into a perpendicular state, pouring concrete, turning the mould into a horizontal state, disassembling the step surface molding board and the like. According to the mould and a construction method thereof, prefabricated concrete stairs do not needed to be turned over while the horizontal type stair mould is disassembled, damages caused by product turning over are avoided, most important features and least light receiving surface requirements of vertical type stairs are met, forming appearance is good, and product quality is guaranteed.

Owner:湖北科宇智能装备有限公司

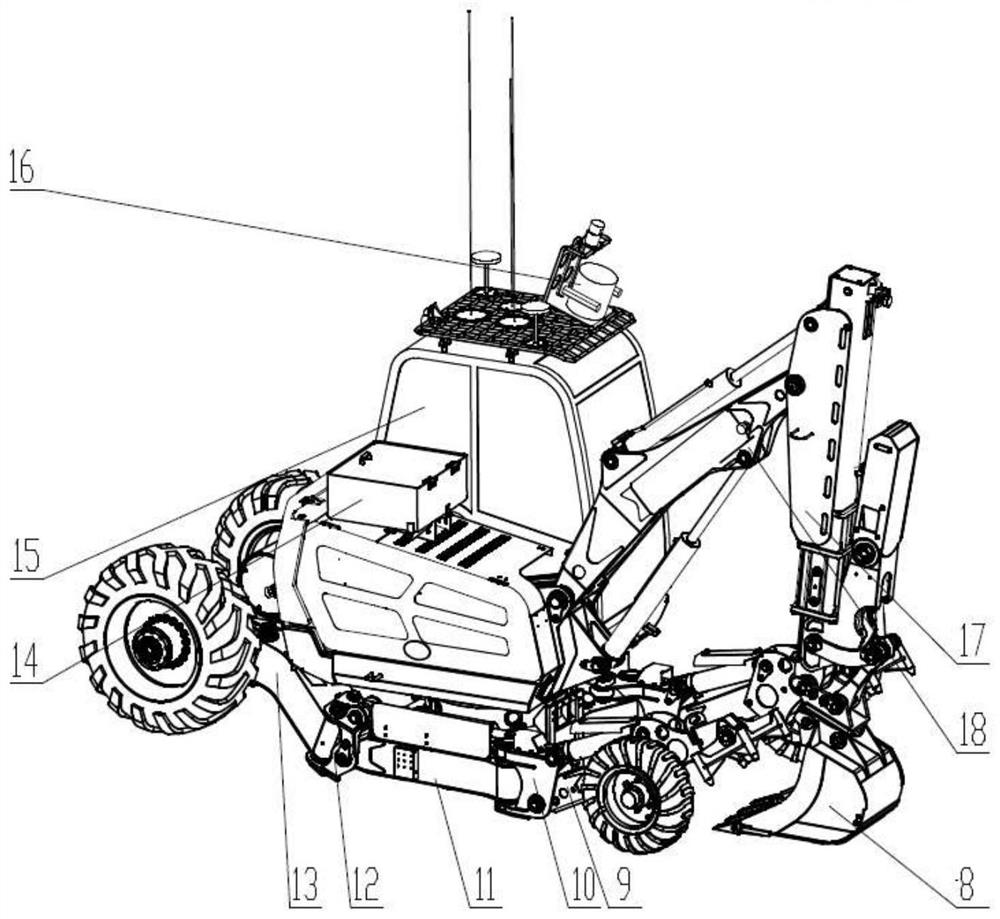

Lifter suitable for excavator bucket rod

InactiveCN106081885AMeet the hoisting requirementsWill not cause scratchesLoad-engaging elementsExcavatorIndustrial engineering

The invention discloses a lifter suitable for an excavator bucket rod. The lifter comprises a lifting frame, multiple lifting arms rotationally arranged on the lifting frame and used for hooking the excavator bucket rod, and a locking device connected with the lifting arms for keeping the lifting arms in a clamping state. The lifter suitable for the excavator bucket rod can satisfy the lifting requirements of the excavator bucket rod, is high in safety, and cannot cause scratch of the excavator bucket rod.

Owner:ANHUI CHANG YONG DE MACHINERY

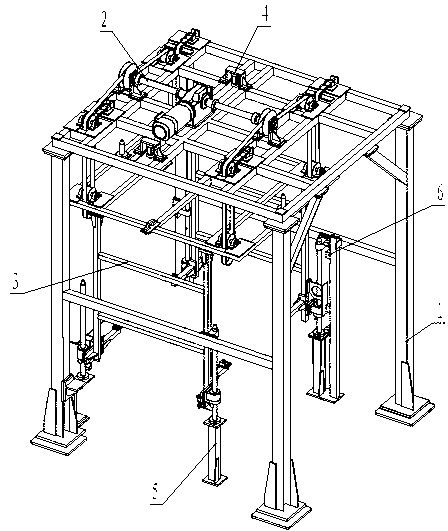

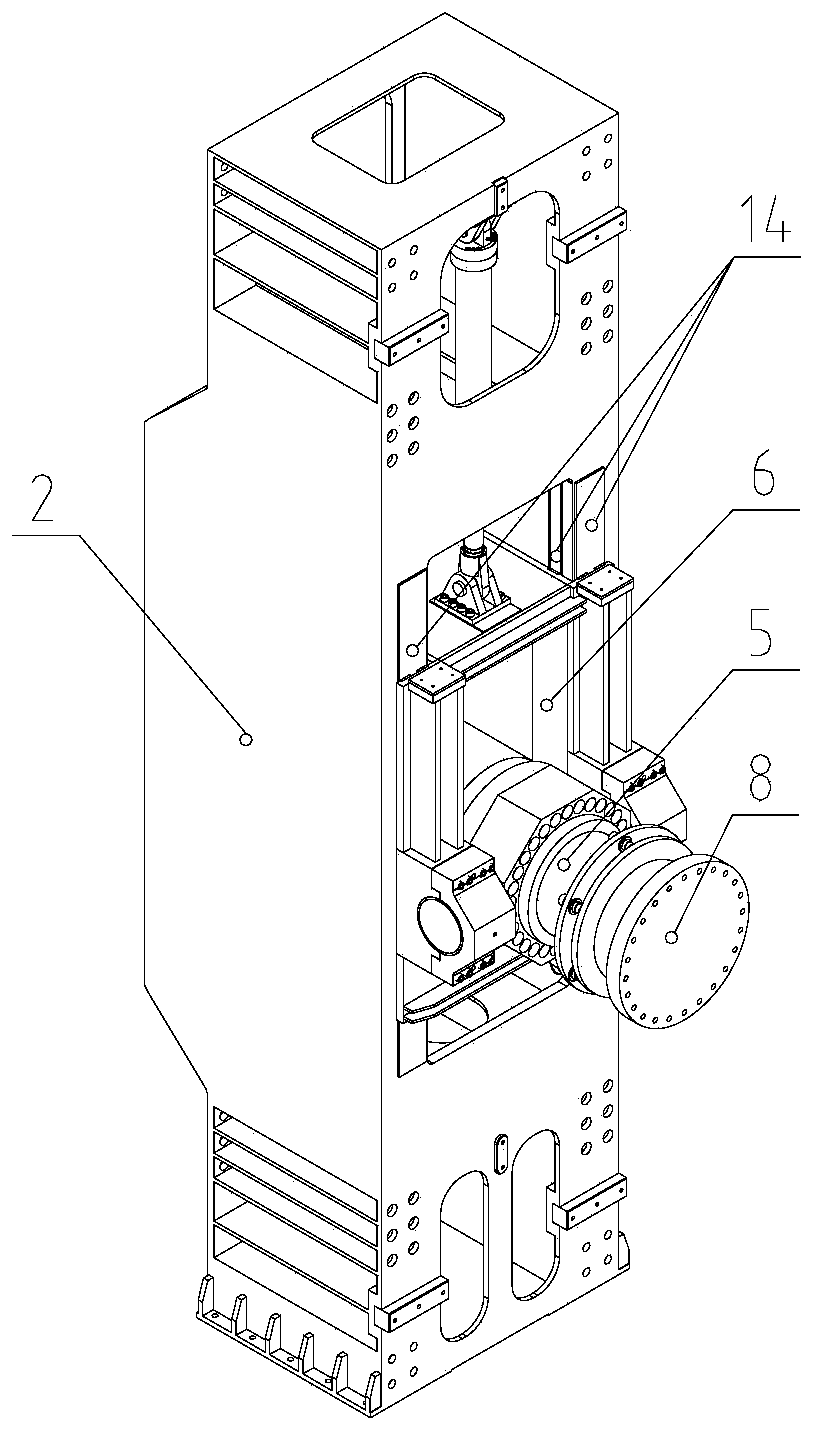

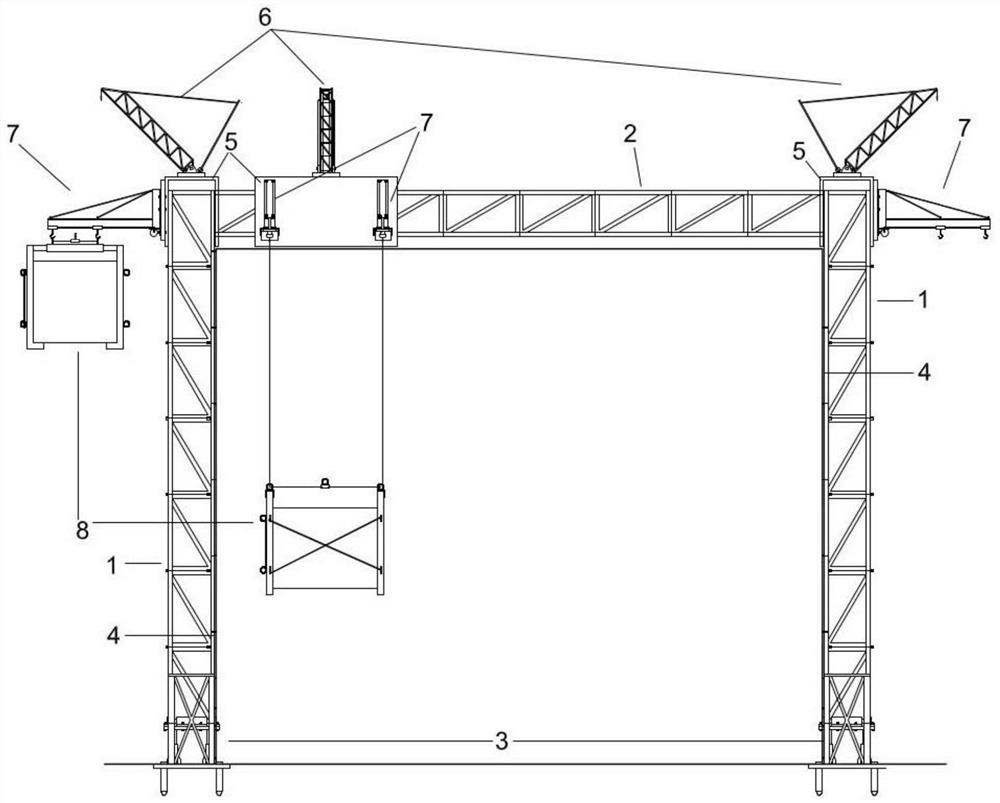

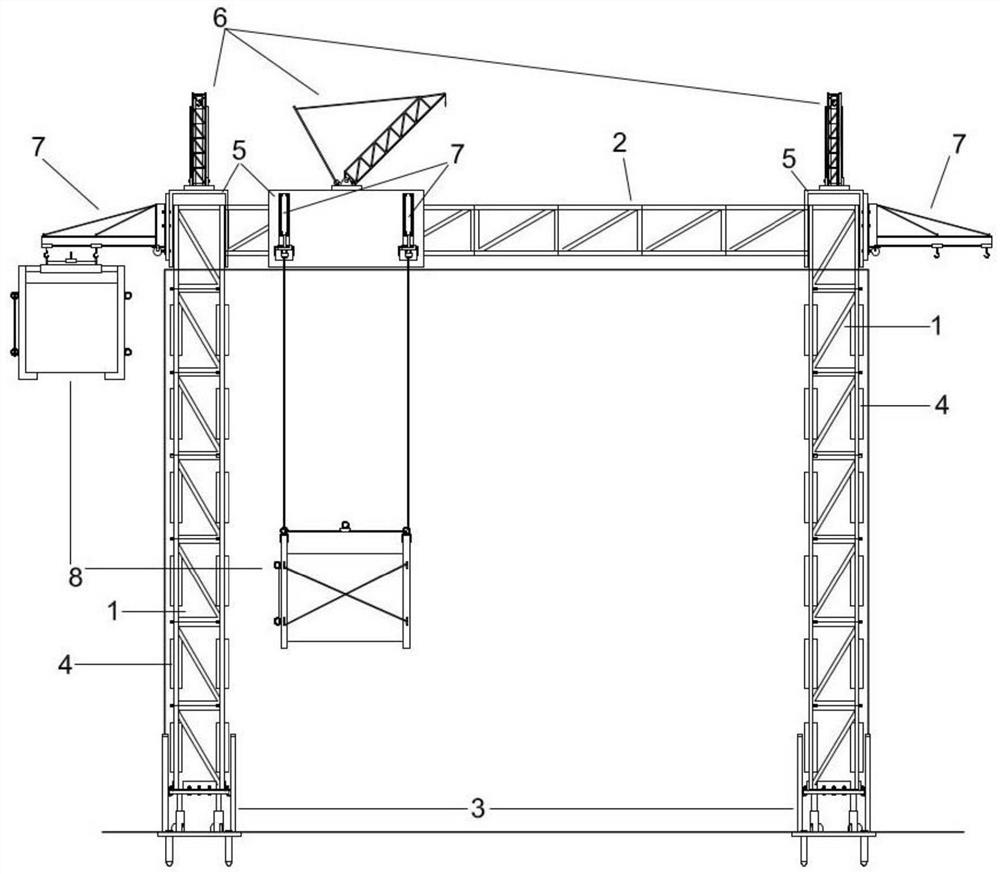

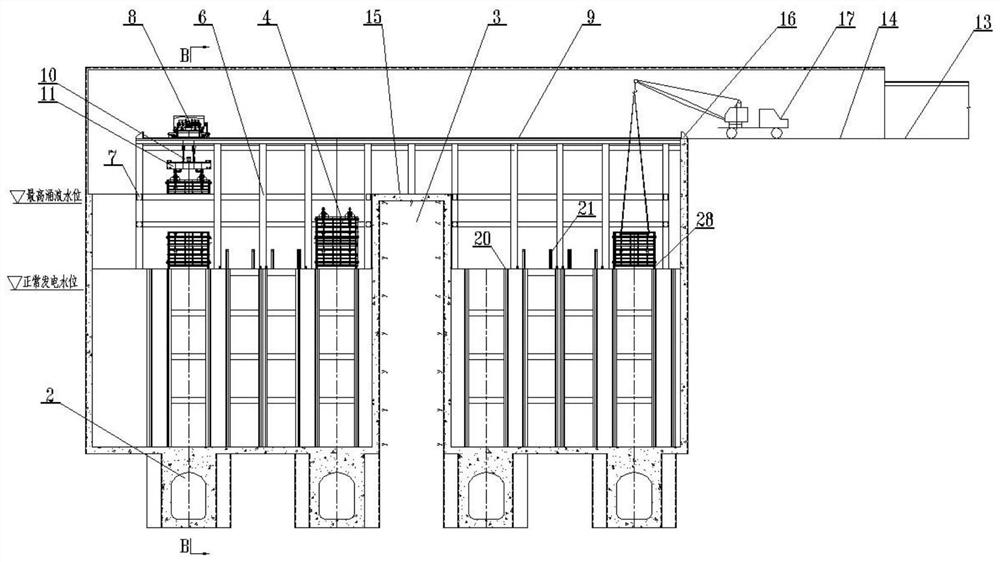

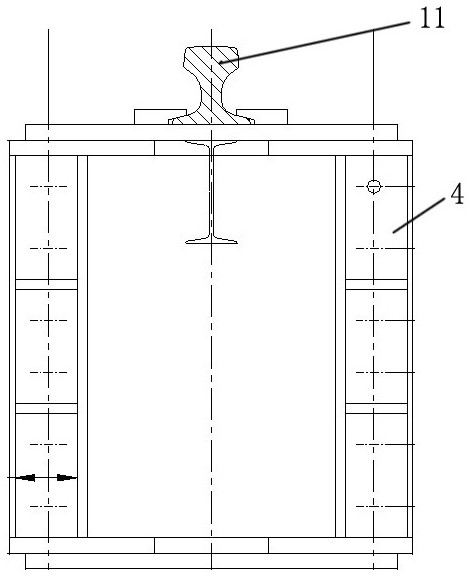

Construction method of hoisting stator with hydraulic lifting device and gantry frame

The invention discloses a construction method for hoisting a stator by cooperation of a hydraulic lifting device and a portal frame. The method comprises the following steps that firstly, a hoisting device formed by the hydraulic lifting device and the portal frame is installed, then the device is hoisted and installed through the installed hoisting device, a track beam is laid between a stator platform and a hoisting object, the portal frame is installed on the track beam, then the hydraulic lifting device is arranged on the portal frame, after the stator is lifted by the hydraulic lifting device, the portal frame moves along the track beam to the position of the stator in place under the action of a thruster, and then the hydraulic lifting device is operated to drop the stator to complete the position. According to the construction method, the space is narrow, so that the heavy objects in factory building can be hoisted in place without a large-tonnage hoisting device; and the vertical lifting, descending, front-back moving and rotating operation of the heavy objects can be completed.

Owner:POWER CHINA HENAN ENG CO LTD

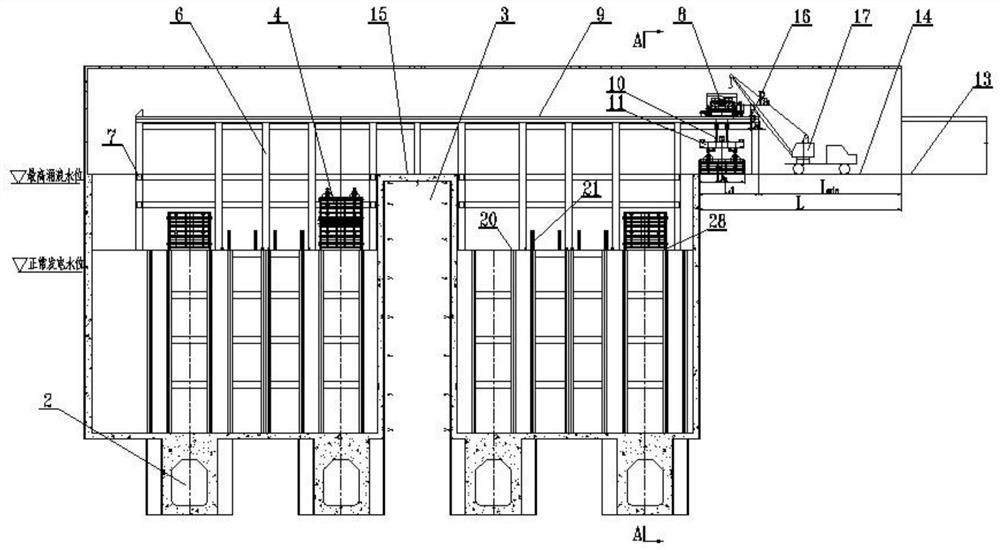

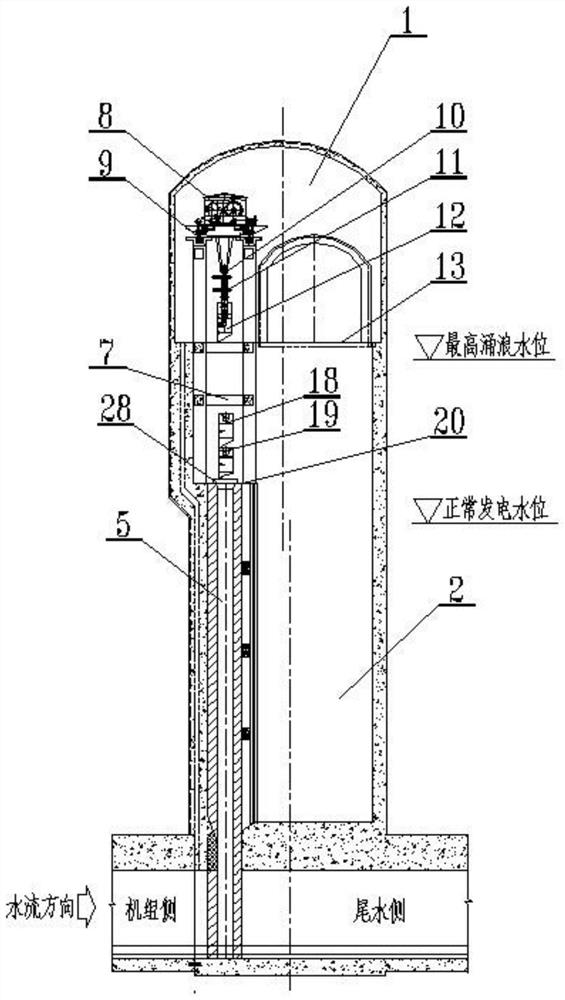

Arrangement and installation method and structure of tail water surge shaft gate and opening and closing equipment

ActiveCN113502790ALess investmentReliable lockingBarrages/weirsWater-power plantsPower stationWater flow

The invention discloses an arrangement and installation method and structure of a tail water surge shaft gate and opening and closing equipment. According to the method, a tail water surge chamber is designed into two or more independent tail water surge shafts, adjacent independent tail water surge shafts are separated by a rock ridge, and the top elevation of the rock ridge is slightly higher than the highest surge water level of the tail water surge shafts; at least one tail water surge shaft gate is arranged on each independent tail water surge shaft, and gate groove center lines of all the tail water surge shaft gates are arranged on the same straight line; a connecting beam in the middle of a framed bent of each independent tail water surge shaft is omitted in the water flow direction; the opening and closing equipment is connected to the gates through grabbing beams; the elevation height from the center of a grabbing beam lower hanging head to the top of the rock ridge is larger than the maximum height of a single-section gate leaf of the gate; and the gate is stored and fixed through a beam column combined type locking device or a gate storage groove arranged on a maintenance platform. According to the arrangement and installation method and structure, the tail water surge shaft gate is operated through the movable opening and closing device, and the overhaul requirement of a power station can be met without the rock ridge.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Construction method of hoisting new condenser based on gantry and Rausinger device

ActiveCN110407097BChange widthAchieve migrationManufacturing dynamo-electric machinesLoad-engaging elementsButtressControl theory

The invention discloses a construction method for hoisting a new type of condenser based on a gantry and a Rausinger device. Construction preparation and foundation treatment are carried out; track beams are supported and reinforced; track beams are placed; track beams are arranged in two rows on steel on the pier and fixed by bolts; placement of the gantry traveling mechanism and installation of the gantry; installation and layout of the hydraulic lifting device; improvement and commissioning of the lifting device; unloading of the stator and steering; re-layout of the hydraulic lifting device; hoisting of the stator in place; dismantling Hoisting equipment; the present invention lays track beams between the foundation platform of the condenser and the hanging objects, and adopts a Rausinger device to cooperate with a gantry to walk on the track beams, so that the space is narrow and heavy in the workshop without large-tonnage lifting equipment. The object is hoisted in place, and the vertical lifting, lowering, forward and backward movement and rotation operations of the heavy object can be completed, which solves the problem of cumbersome and complicated operation steps caused by patchwork of operating equipment in the prior art.

Owner:POWER CHINA HENAN ENG CO LTD

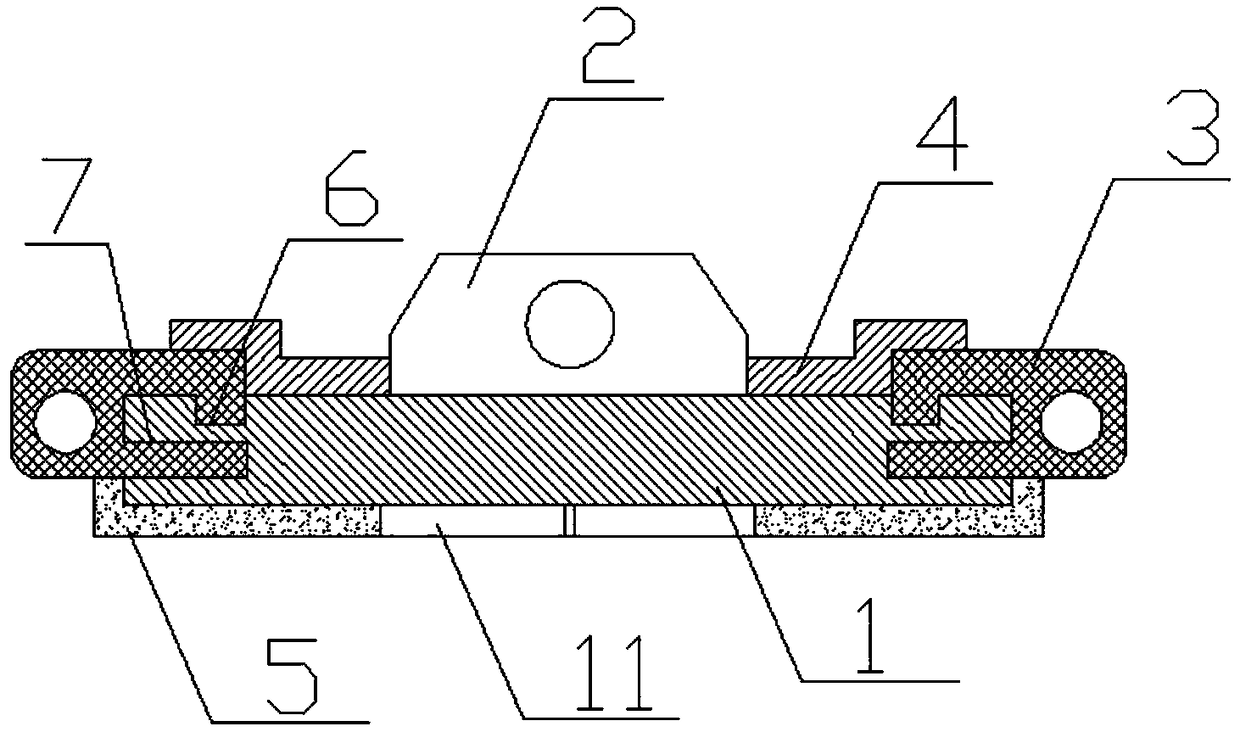

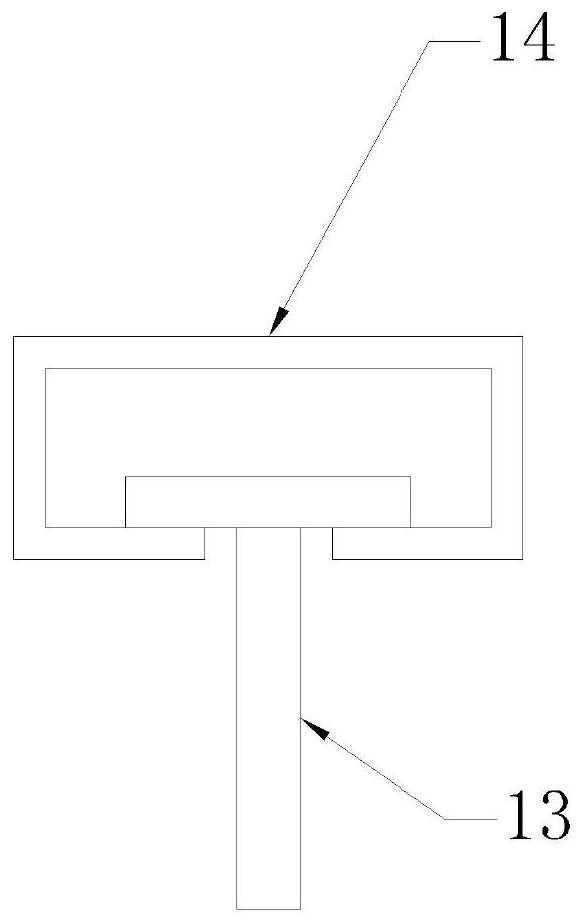

Assembled crane sling

ActiveCN100513289CEasy to transportMeet the hoisting requirementsLoad-engaging elementsEngineeringLifting equipment

The invention discloses a packaged crane hanger, which aims to provide an auxiliary machine of the crane with lifting height longer than the lever of crane and adjustable. The invention belongs to the technology field of lifting equipments and operations and comprises a suspender and hanging head and also a motion bar. The suspender is connected by basic bars on the front end and the rear end and one to five pieces of lengthening bars in the middle in series; the outer ends of the two basic bars are connected with the motion bar and the hanging head in turns; the lengthening bars are provided with balance hanging beams and lifting lugs on both ends; hook hanger shafts are provided on the lengthening bars symmetrical with the balance hanging beams to form three hanging nodes; the hanging head can extend and rotate along the three-dimensional direction. The hanger has adjustable length, convenient assembly and disassembly, convenient transport and saves storage space, which makes full use of the advantages of the mechanical work of the crane, greatly improves the working efficiency and safety of production and personnel and lightens the labor intensity of workers. The invention avoids the limit of the work height and space of the work place and is suitable for using in lifting equipments and components in various complicated environments like tunnels.

Owner:中国水利水电第七工程局有限公司

Transition beam for sling suitable for hoisting large objects

ActiveCN108609478AMeet the hoisting requirementsGuaranteed safe operationLoad-engaging elementsOptimal designEngineering

The invention belongs to the technical field of intelligent hoisting and particularly relates to a transition beam for a sling suitable for hoisting large objects. In the current intelligent hoistingtechnological field, the sling plays an important role, the transition beam serves as a key part of the sling, and safe operation of the current intelligent hoisting technology is guaranteed. The structures of lateral lifting lugs serving as key parts for bearing the sling in the transition beam are subjected to optimal design, and the bearing stability is guaranteed through dual actions of welding and mechanical connection; upper connecting pieces of the lateral lifting lugs can be connected with limiting holes in a clamped manner, an upper reinforcing plate can further play a pressing role on the upper connecting pieces, and the role of secondary fixing is achieved; and lower connecting pieces stretch into inserting holes to play bottom supporting and transverse stabilizing roles, and alower reinforcing plate further plays a supporting role on the lower connecting pieces. Through a series of the above structural optimization, the transition beam for the sling can meet the hoisting requirements for the large objects which are large in weight and size through strict calculation, type selection and load testing.

Owner:QINGDAO HUANGHAI UNIV

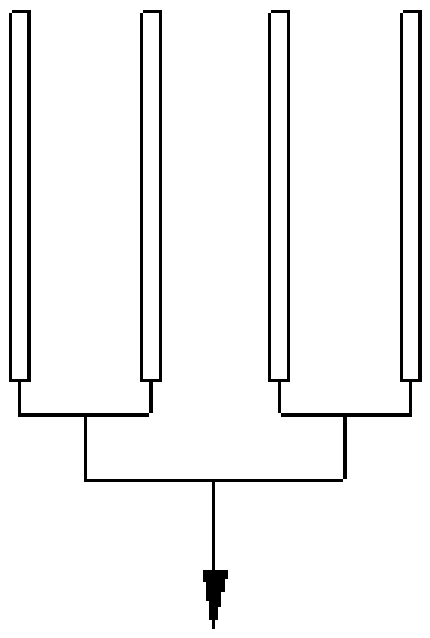

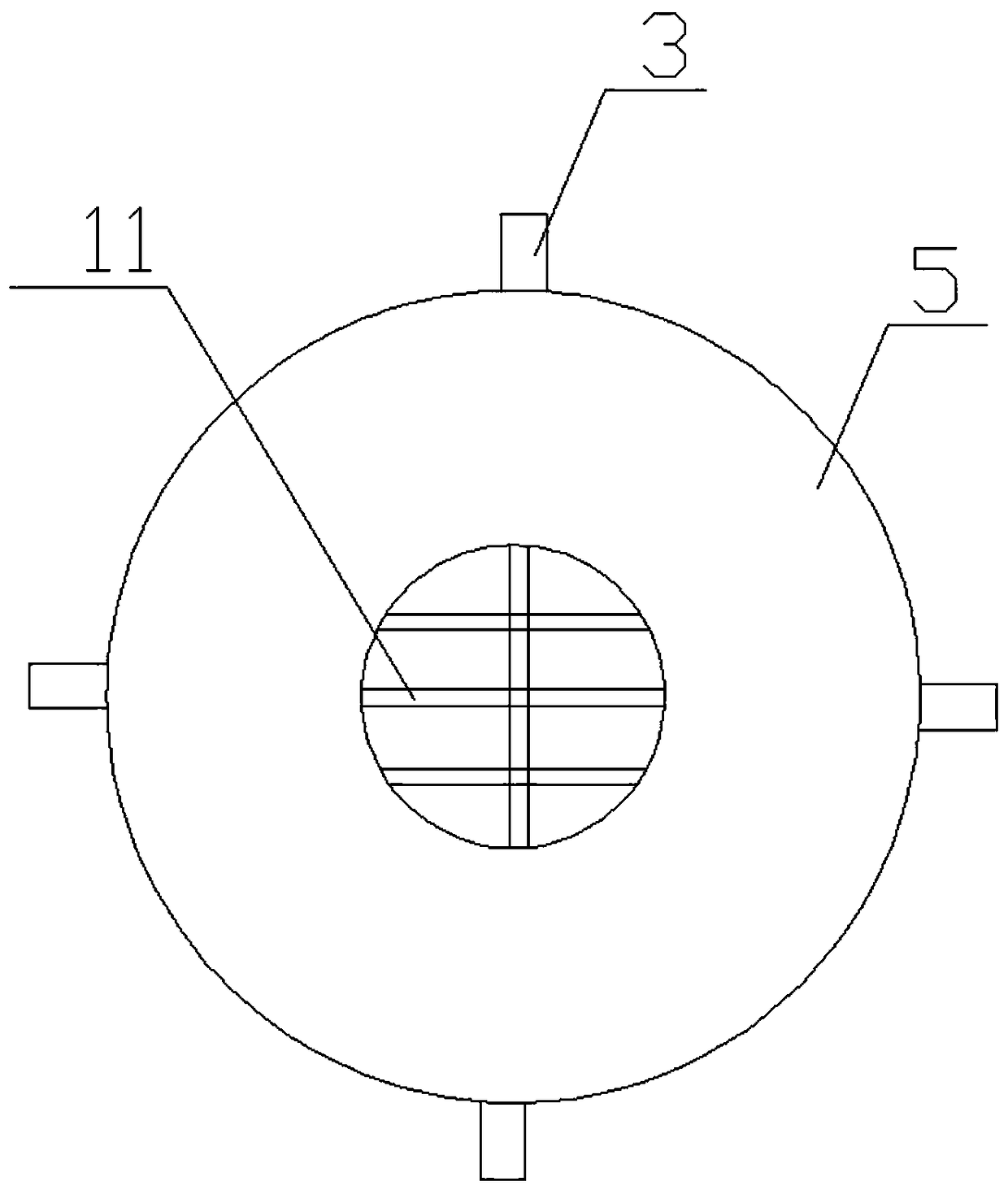

Steam pocket mounting device and using method thereof

PendingCN113788395AHoisting safetyStable hoistingWinding mechanismsTrolleysSteel frameControl theory

The invention discloses a steam pocket mounting device and a using method thereof. The device comprises a steel frame, a left lower fixed pulley and a right lower fixed pulley are installed at the bottom ends of two opposite stand columns on the outermost side of the steel frame respectively, and a left upper fixed pulley and a right upper fixed pulley are correspondingly installed on a cross beam over the left lower fixed pulley and the right lower fixed pulley. A first hoisting fixed pulley and a second hoisting fixed pulley are installed between the left upper fixed pulley and the right upper fixed pulley, a first movable pulley and a second movable pulley are arranged below the first hoisting fixed pulley and the second hoisting fixed pulley respectively, and slings are arranged below the first movable pulley and the second movable pulley. One end of a pull rope is fixedly connected with the first hoisting fixed pulley, and the other end of the pull rope is sequentially connected with the first movable pulley, the first hoisting fixed pulley, the upper left fixed pulley and the lower left fixed pulley and then connected with a winch which is fixedly arranged on the ground and located at one end of the left lower fixed pulley and the right lower fixed pulley. A pull rope on the other side is arranged in a same way. The device is designed according to an actual site, and the problem that an existing boiler drum hoisting device is limited by the site and cannot meet the high-altitude hoisting requirement is solved.

Owner:GUIZHOU ELECTRIC POWER DESIGN INST

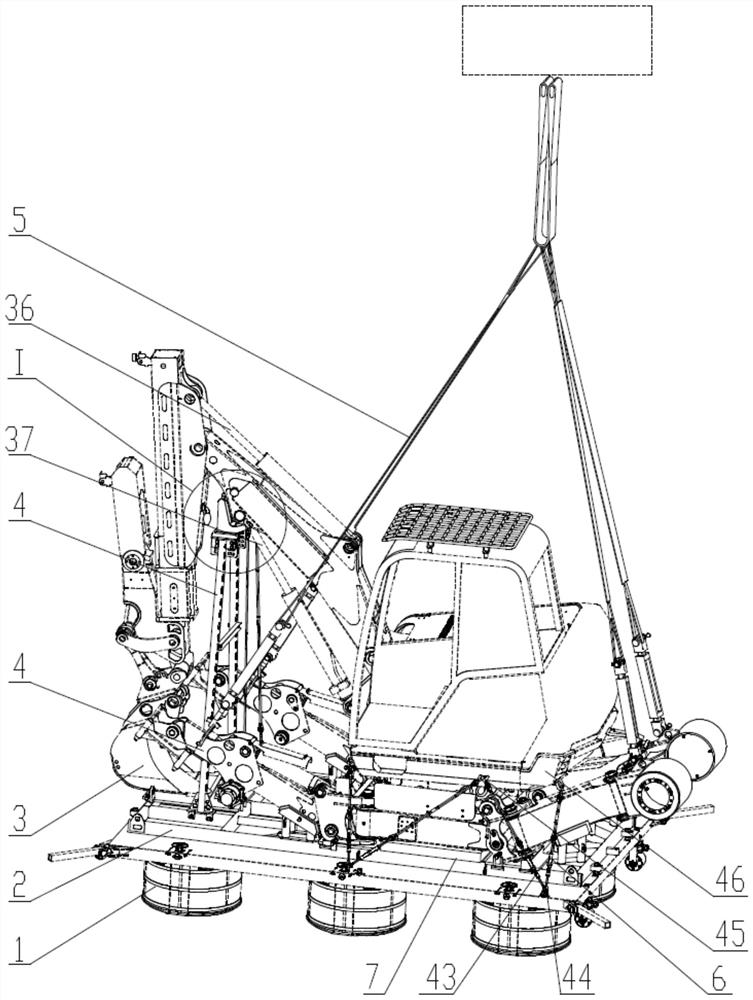

An ultra-low-altitude remote emergency reloading rescue vehicle system

ActiveCN109808888BSo as not to damageGuaranteed lightweightFreight handlingLaunching weaponsMarine engineeringUncrewed vehicle

Owner:XCMG CONSTR MACHINERY

Tail lifting lug structure and construction method suitable for thin-wall slender equipment

PendingCN113023559AIncrease the stress pointUniform force distributionLoad-engaging elementsStress concentrationStress point

The invention belongs to the technical field of lifting lugs, and discloses a tail lifting lug structure and construction method suitable for thin-wall slender equipment. The tail lifting lug structure comprises two tubular shaft type tail-slipping lifting lugs which are arranged in the axial direction of an equipment barrel in an up-down spaced mode, and the two tubular shaft type tail-slipping lifting lugs are symmetrically arranged in the radial direction of the equipment barrel. The two tubular shaft type tail-slipping lifting lugs are the same in structure, lifting lug tubular shafts are welded to a reinforcing plate through a first vertical plate and a second vertical plate, and the reinforcing plate is welded to the equipment barrel. The first vertical plate is arranged at one ends of the lifting lug tubular shafts, outer check rings are arranged at the other ends of the lifting lug tubular shafts, and the second vertical plate is arranged between the first vertical plate and the outer check rings. According to the construction method, the two tubular shaft type tail-slipping lifting lugs are connected with the two ends of a steel wire rope hung on a pulley, and the pulley is connected with a rigging hung on a lifting hook of a tail-slipping crane. According to the tail lifting lug structure and construction method suitable for the thin-wall slender equipment, the stress points of the tail lifting lugs are increased, stress concentration is reduced, so that stress is uniformly distributed when the thin-wall slender equipment is lifted, and the overall lifting requirement is met.

Owner:中石化重型起重运输工程有限责任公司 +1

Catenary flexible lifting appliance

PendingCN110054075AMeet the hoisting requirementsMeet the positioning needsLoad-engaging elementsEngineeringRotating disc

The invention discloses a catenary flexible lifting appliance. The catenary flexible lifting appliance comprises a framework structure, a first rotary positioning mechanism, a second rotary positioning mechanism, a first adjusting mechanism, a second adjusting mechanism, a first supporting leg, a second supporting leg, a third supporting leg and a fourth supporting leg, wherein the front end of the frame structure is connected with the first rotary positioning mechanism and the second rotary positioning mechanism through the first support leg and the second support leg, the rear end of the frame structure is connected with the third supporting leg and the fourth supporting leg through the first adjusting mechanism and the second adjusting mechanism, and a spiral rotating disc is adopted, so that the lifting appliance can be used for meeting the positioning of a plurality of types of automobiles; the position of the third supporting leg and the position of the fourth supporting leg canbe adjusted by using the first adjusting mechanism and the second adjusting mechanism, so that the hoisting requirements of different vehicle lengths can be met, the stability is guaranteed, and the adaptability is improved; and positioning holes in the bottoms of vehicle bodies of different types are different, so that the first rotary positioning mechanism and the second rotary positioning mechanism are additionally arranged on the lifting appliance so as to meet the positioning requirements of the multiple vehicle types.

Owner:FAW CAR CO LTD

Plate-free tray type offshore substation upper module

PendingCN114645532AReduce weightReduce dosageArtificial islandsEnclosed substationsMarine engineeringEngineering

The invention provides a plate-free tray type offshore substation upper module which comprises two layers of frame type steel structures, each frame type steel structure is formed by beams, columns and inclined struts, and main columns, structural columns and inclined struts are arranged between the upper layer of beams and the lower layer of beams; a prefabricated cabin or outdoor equipment is connected to a beam or a column of the frame-type steel structure to form an integral offshore transformer substation upper module. According to the frame type steel structure, a beam system serves as a framework of the plate-free tray structure type, grating channel areas are only arranged on a channel area, an equipment overhaul area and an embarkation gathering area on two layers of trays of an upper module of the plate-free tray structure type offshore transformer substation, and ribs and steel bed boards are not arranged on all the areas. A two-layer steel structure arrangement mode is adopted, original third-layer and fourth-layer beams, columns, ribs, plates and the like are omitted, meanwhile, first-layer and second-layer ribs, steel bed boards and the like are omitted, the using amount of steel can be reduced by about 50%-60%, the weight of an upper module is reduced, and then the choices of construction ship machine equipment are increased.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com