Steel ladle trunnion hoisting aligning recognition device and method

A technology for identifying devices and ladles, which is applied in the direction of transportation, packaging, and load-hanging components, can solve problems such as shedding, overturning of ladles, and invisibility, and achieve scientific design, strong practicability, and accurate identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

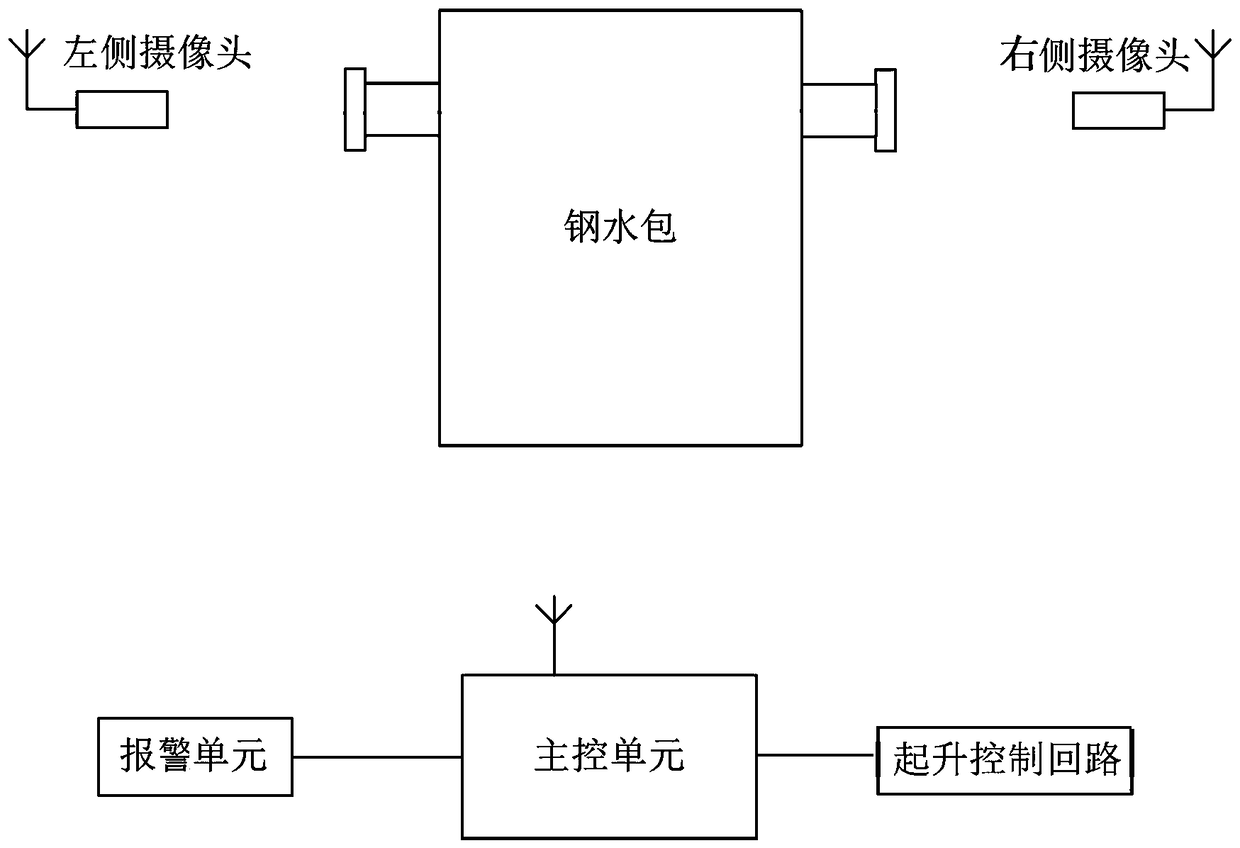

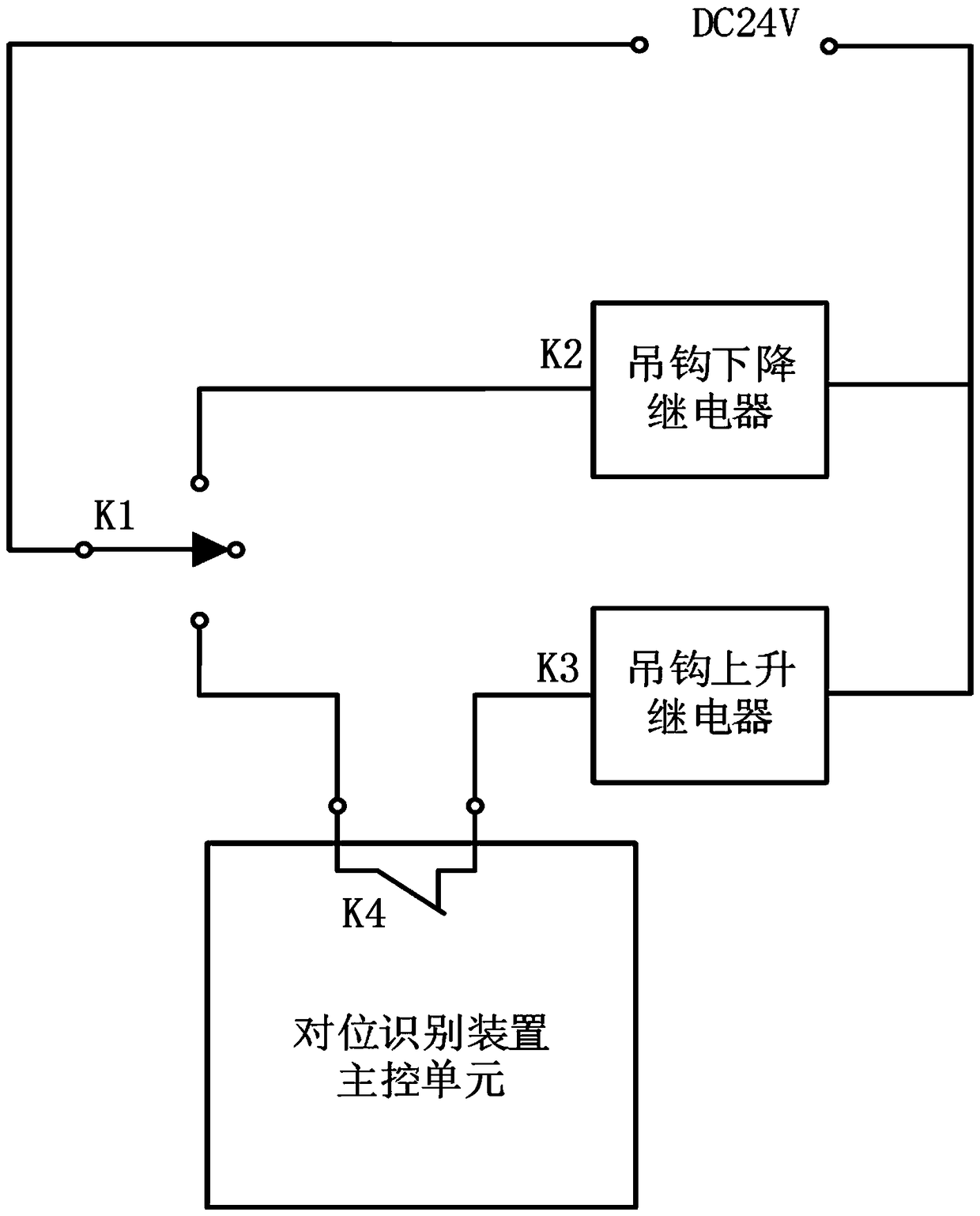

[0062] as attached figure 1 - attached image 3 As shown, a ladle trunnion hoisting alignment identification device, which includes a main control unit, and a first hoisting alignment image acquisition unit, a second hoisting alignment image acquisition unit and a lifting alignment unit respectively connected to the main control unit Lift control loop;

[0063] The ladle trunnion and the hook tip of the crane are painted with white marks;

[0064] The first hoisting alignment image acquisition unit captures in real time the image of the trunnion on one side of the ladle and the white mark of the crane hook tip as the first alignment image information, and transmits it to the main control unit;

[0065] The second hoisting alignment image acquisition unit captures in real time the image of the trunnion on the other side of the ladle and the white mark of the crane hook tip as the second alignment image information, and transmits it to the main control unit;

[0066] The lift...

Embodiment 2

[0073] as attached Figure 4 And attached Figure 5 As shown, a ladle trunnion hoisting alignment identification method, using the alignment identification device described in the above claims, includes the following steps:

[0074] Step 1, paint the end faces of the trunnions on both sides of the ladle to be hoisted and the tip of the crane hook in white;

[0075] Step 2, moving the ladle to be hoisted to a hoisting position, and moving the hook below the trunnion;

[0076] Step 3, the first hoisting alignment image acquisition unit and the second hoisting alignment image acquisition unit collect the alignment image information of the trunnions on both sides of the ladle and the crane hook in real time, and transmit it to the main control unit;

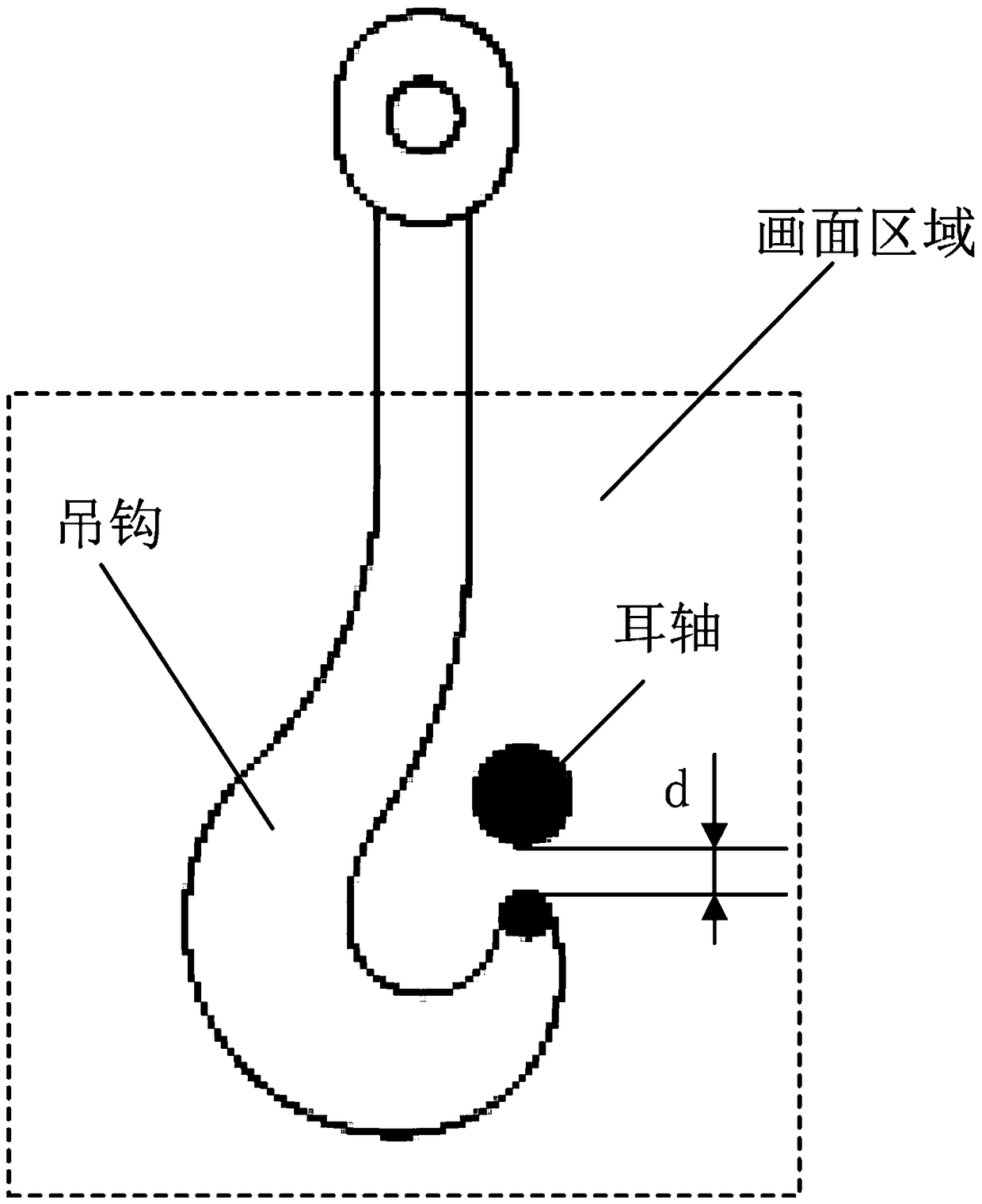

[0077] Step 4, the main control unit recognizes two types of outline rectangles according to the alignment image information, and determines whether it is a trunnion outline rectangle or a hook outline rectangle according to the a...

Embodiment 3

[0097] The difference between this embodiment and embodiment 2 is: as attached Image 6 As shown, in the step 4, the main control unit recognizes the first white area representing the outline rectangle of the steel ladle trunnion according to the alignment image information, and the specific steps are:

[0098] Step 4.1, set the leftmost pixel position of the first white area as Left1=0, the uppermost pixel position Top1=0, the rightmost pixel position Right1=0, the lowermost pixel position Bottom1=0; white pixels Number N(i)=0;

[0099] Step 4.2, progressively scan the alignment image information; set i=0;

[0100] Step 4.3, set j=0;

[0101] Step 4.4, set k=0;

[0102] Step 4.5, if the (i, j+k)th pixel is white, then the number of white pixels in row i is N(i)=N(i)+1;

[0103] Record the first white pixel position F(i)=j of the i-th line, and the last white pixel position L(i)=j+N(i) of the i-th line, and then go to step 4.6; otherwise Go directly to step 4.8;

[0104]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com