Construction method of hoisting stator with hydraulic lifting device and gantry frame

A technology for hydraulically lifting and hoisting the stator, which is applied in the direction of the lifting device, etc., can solve the problems of increasing the strength of the track foundation, narrowness, and increasing strength requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

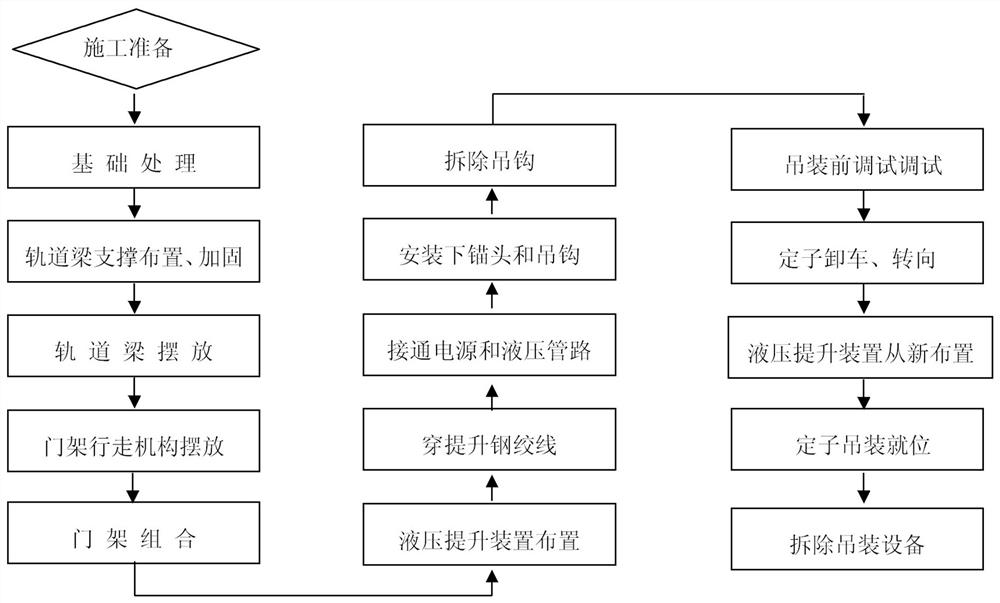

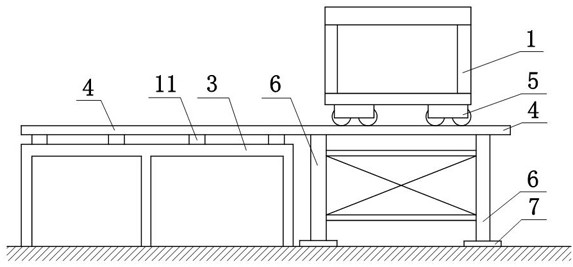

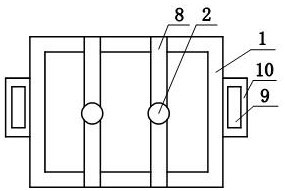

[0048] Example: see figure 1 , figure 2 , image 3 and Figure 4 .

[0049] In the figure: 1-gantry (gantry), 2-hydraulic lifting device, 3-stator platform, 4-track beam, 5-traveling mechanism, 6-column, 7-way base plate, 8-steel beam, 9-hydraulic Pumping station, 10-platform, 11-steel buttress.

[0050] A hydraulic lifting device combined with a gantry frame hoisting stator construction method, which firstly installs the hoisting equipment formed by the GYT-200 type steel cable hydraulic lifting device and the gantry frame, and then uses the installed hoisting equipment to hoist and install the equipment; the hoisting The equipment is installed from bottom to top. The track beam is laid between the stator platform and the hoisting room (maintenance room). If the track beam is used overhead, the support of the track beam must have sufficient strength and stability; Beam, finally install the end beam of the gantry frame; after the gantry combination is completed, add a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com