Transition beam for sling suitable for hoisting large objects

A technology for large objects and slings, which is applied in the field of transition beams, and can solve problems such as unsatisfactory hoisting of large weights, extremely high requirements for welding technology, and broken solder joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

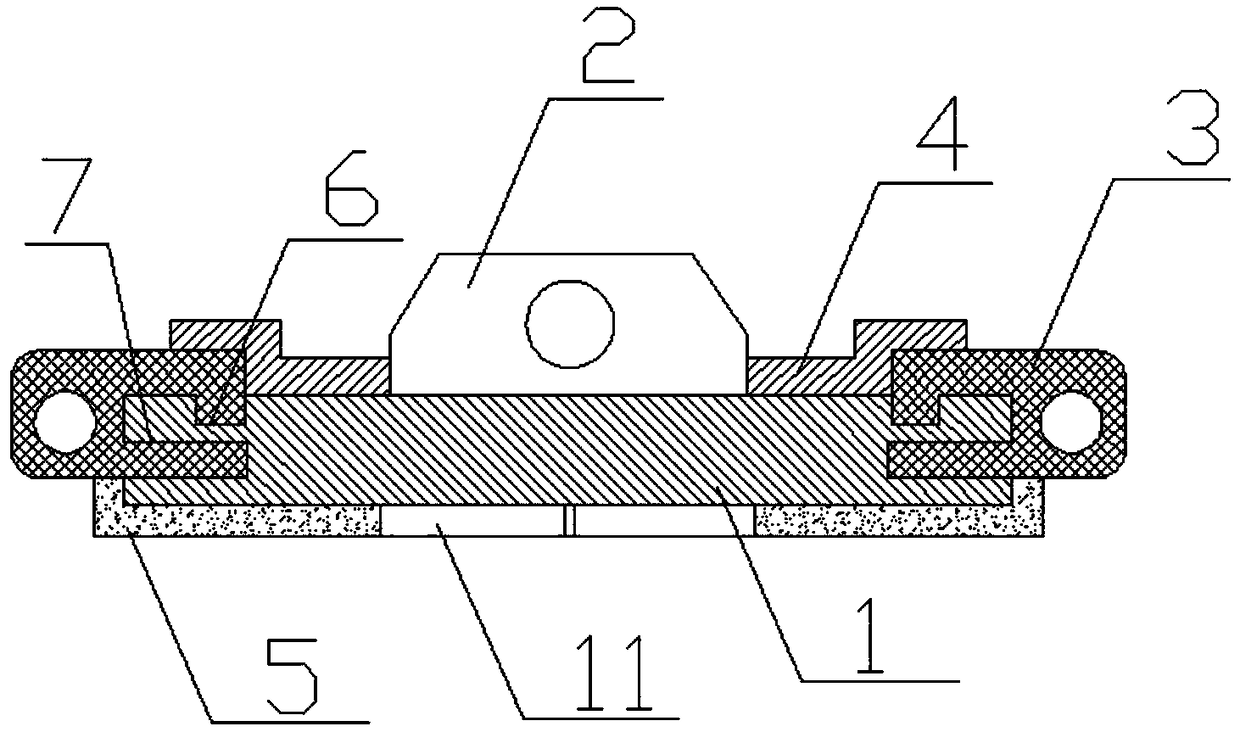

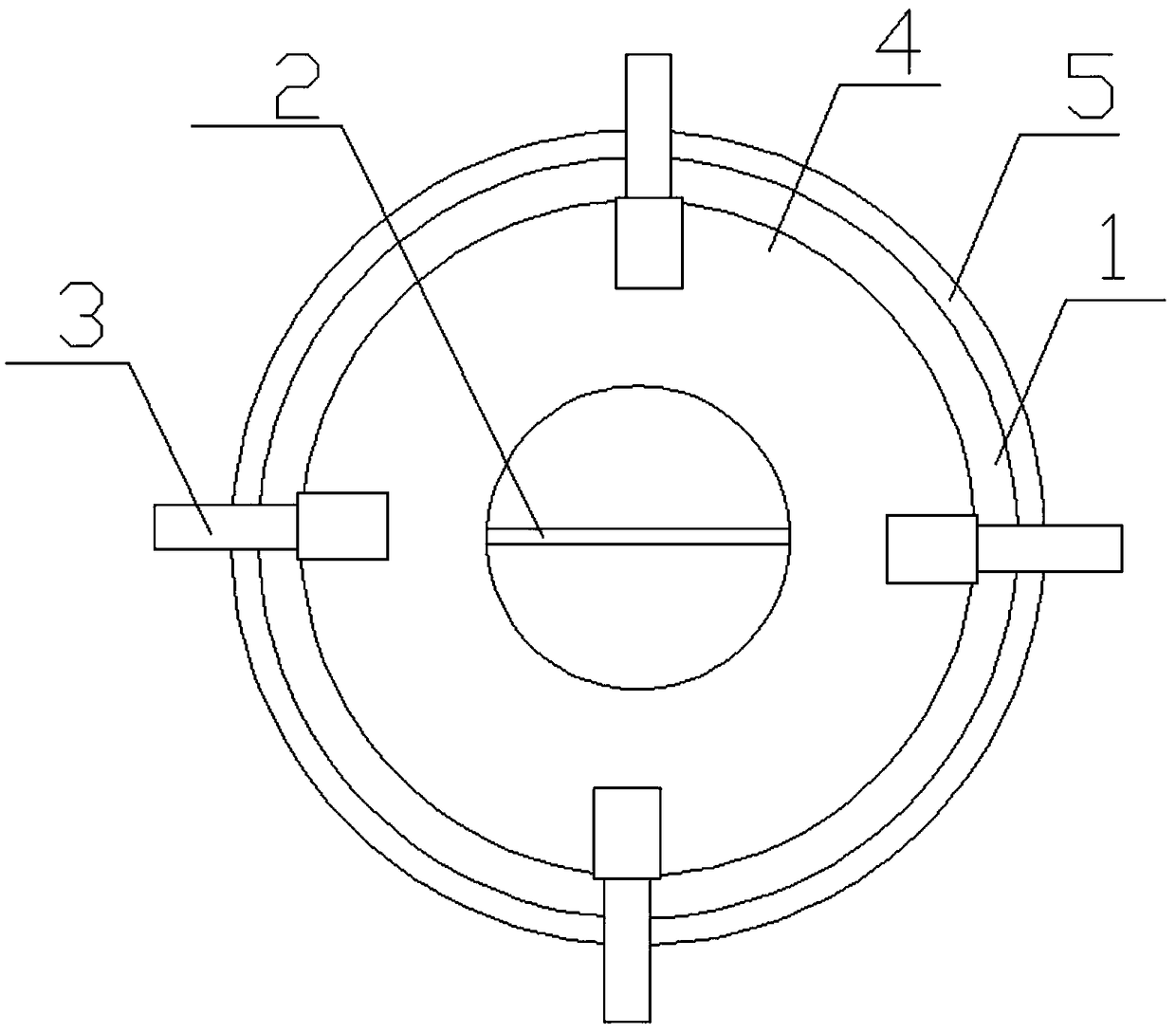

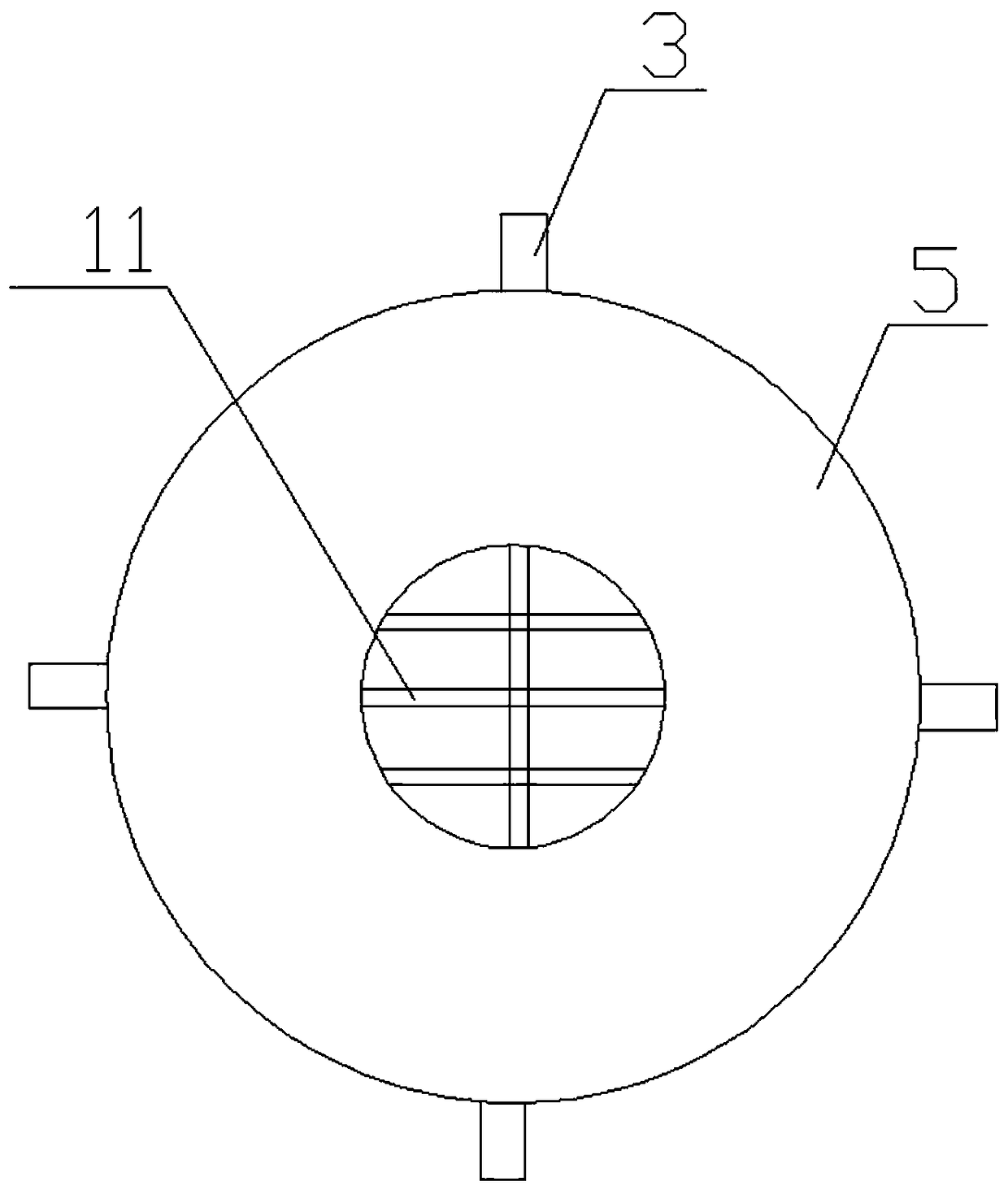

[0021] Such as Figure 1 to Figure 4 As shown, a transition beam suitable for hoisting large objects with a sling includes a circular support plate 1, an upper lug 2, a side lug 3, an upper reinforcement plate 4, and a lower reinforcement plate 5, wherein the The upper surface of the circular support plate 1 is provided with four limit holes 6 along the peripheral circumferential direction, and the side of the circular support plate 1 is provided with four sockets 7 transversely along the circumferential direction, and each of the limit holes 6 corresponds to One socket 7 and the two are located in the same longitudinal section, each of the limiting holes 6 and the corresponding socket 7 is provided with a side lug 3, and the side lug 3 includes a lifting hole 8, an upper Connecting piece 9 and lower connecting piece 10, described lifting hole 8 is positioned at the side of circular support plate 1, and described upper connecting piece 9 is positioned at the upper end of lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com