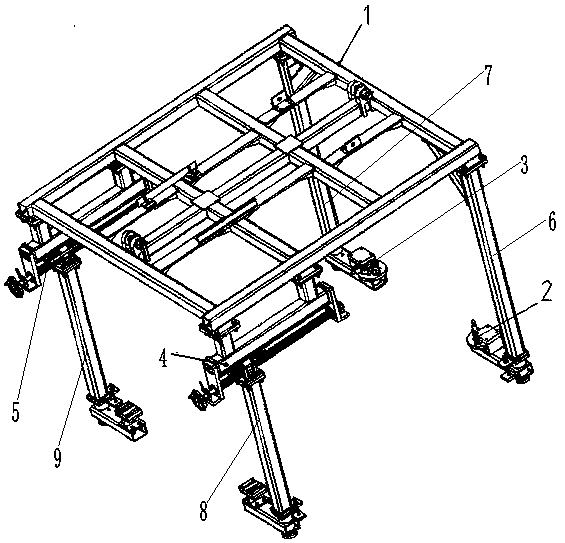

Catenary flexible lifting appliance

A flexible and spreader technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of time-consuming and laborious, poor adaptability and occupied area, and achieve improved adaptability, smaller occupied area and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

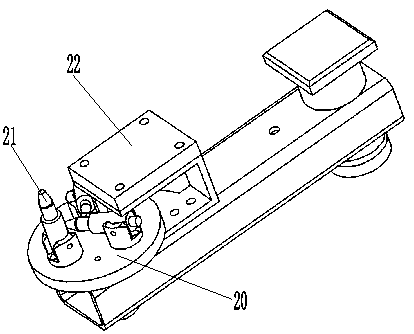

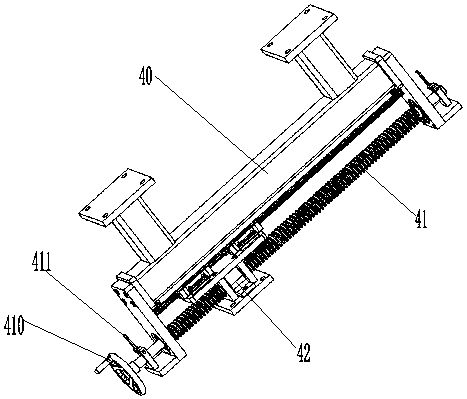

[0026] When hoisting the M1 platform body, first adjust the spiral turntable 20 on the first support leg 6 and the second support leg 7, erect the M1 platform positioning pin 21 on the spiral turntable 20, and put the rest of the vehicle body positioning pins 21 down, Another positioning pin is used to fix the spiral turntable 20 on the base 22, adjust the first adjustment mechanism 4 and the second adjustment mechanism 5 of the third leg 8 and the fourth leg 9, and adjust the third leg 8 and the fourth leg. Outrigger 9 is adjusted to correct position, and vehicle body is hoisted on the spreader.

Embodiment 2

[0028] When hoisting the M2 platform body, first adjust the spiral turntable 20 on the first support leg 6 and the second support leg 7, erect the M2 platform positioning pin 21 on the spiral turntable 20, put down the rest of the vehicle body positioning pins 21, Another positioning pin is used to fix the spiral turntable 20 on the base 22, adjust the first adjustment mechanism 4 and the second adjustment mechanism 5 of the third leg 8 and the fourth leg 9, and adjust the third leg 8 and the fourth leg. Outrigger 9 is adjusted to correct position, and vehicle body is hoisted on the spreader.

Embodiment 3

[0030] When hoisting the M3 platform body, first adjust the spiral turntable 20 on the first support leg 6 and the second support leg 7, erect the M3 platform alignment pin 21 on the spiral turntable 20, and put down the rest of the body alignment pins 21, Another positioning pin is used to fix the spiral turntable 20 on the base 22, adjust the first adjustment mechanism 4 and the second adjustment mechanism 5 of the third leg 8 and the fourth leg 9, and adjust the third leg 8 and the fourth leg. Outrigger 9 is adjusted to correct position, and vehicle body is hoisted on the spreader.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com