Plate-free tray type offshore substation upper module

A substation and pallet-type technology, which is applied in the direction of closed substations, substations, electrical components, etc., can solve the problems of not considering the structure of outdoor equipment such as firewalls, fewer options for hoisting marine machines, and long operating hours, so as to save construction time and cost , fast and convenient construction, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] 7) Two basically symmetrical ladders are set between the two decks to meet the needs of escape and operation and maintenance; ladders or straight ladders are set to reach the top of the prefabricated cabin to meet the requirements for maintenance.

[0039] In order to describe the present invention more specifically, the present invention will be further described below in conjunction with the accompanying drawings.

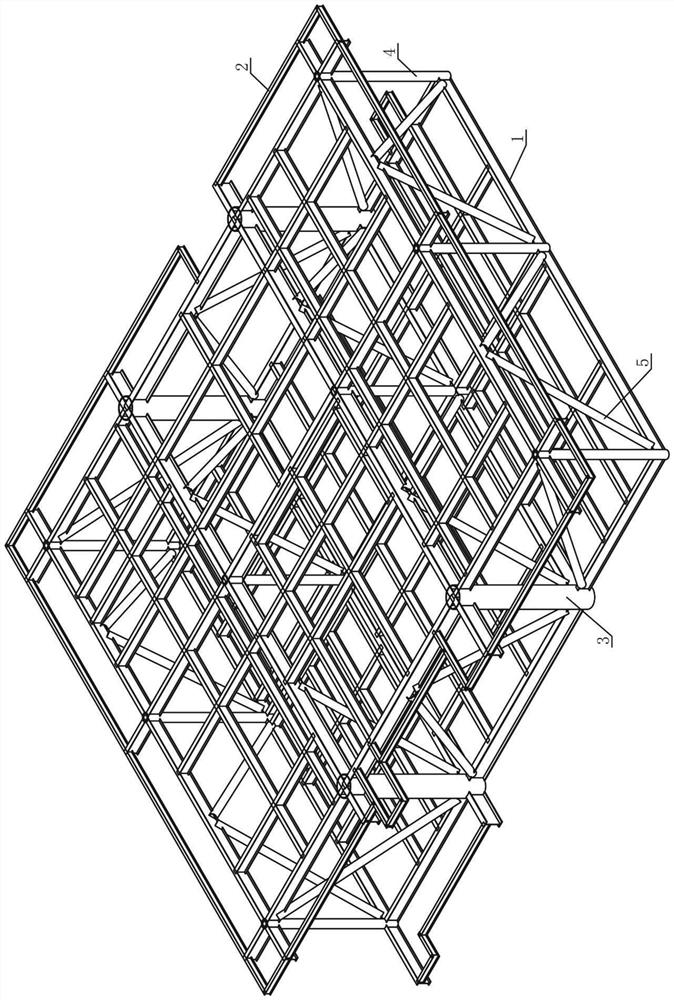

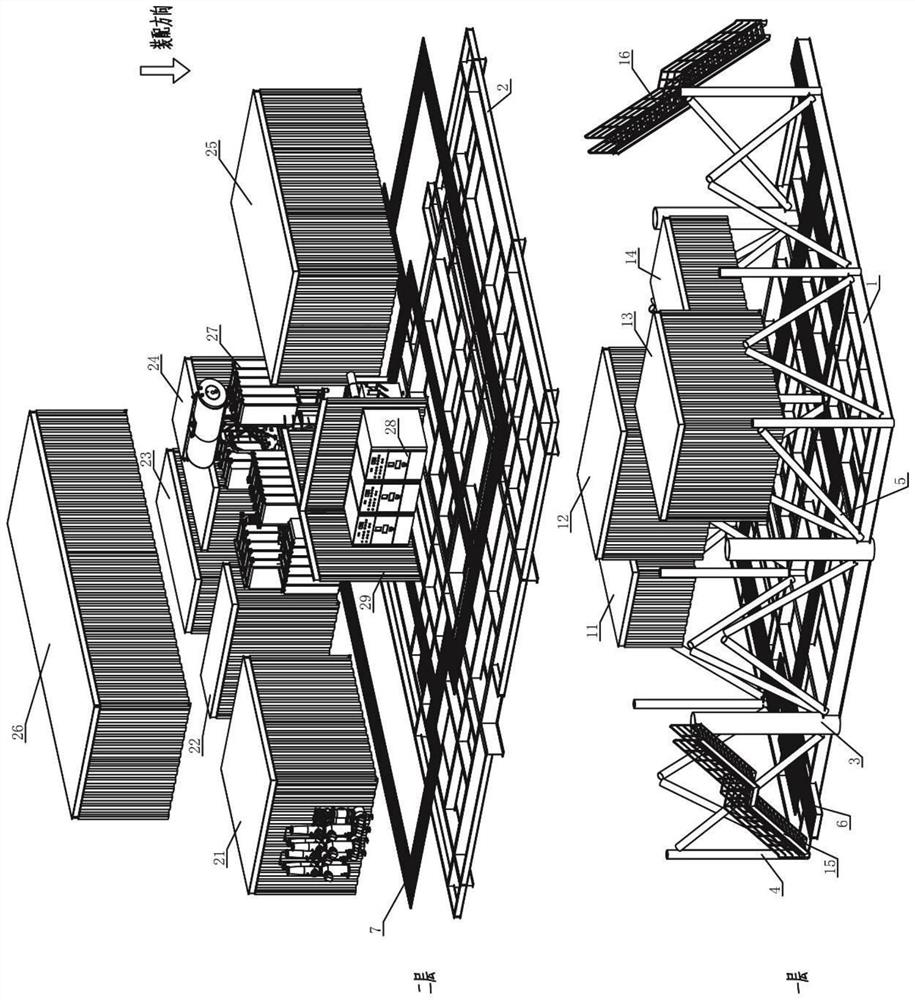

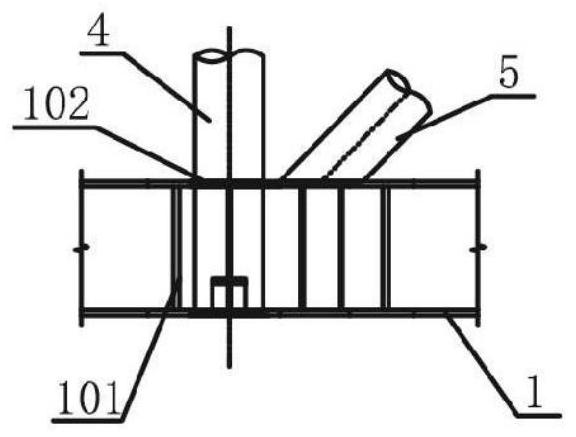

[0040] as attached Figure 1~4 As shown, the upper block of a pallet-less offshore substation has a double-layer frame steel structure as a whole. Several finished prefabricated cabins and outdoor equipment are placed on the two-layer "pallet" according to different functions. Only the two-layer "pallet" Steel gratings are laid in the passage area, equipment maintenance area and boarding assembly area on the road. No ribs and steel decking are installed in all areas, and firewalls are installed between outdoor equipment, which realizes light structure, com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com