Tail lifting lug structure and construction method suitable for thin-wall slender equipment

A lifting lug and equipment technology, which is applied in the tail lifting lug structure and the construction field of thin-walled and slender equipment. It can solve the problems of large equipment specifications and sizes, which cannot meet the hoisting requirements of thin-walled and slender equipment, and reduce stress concentration. , The hoisting process is coherent and smooth, and the hoisting process is safe and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

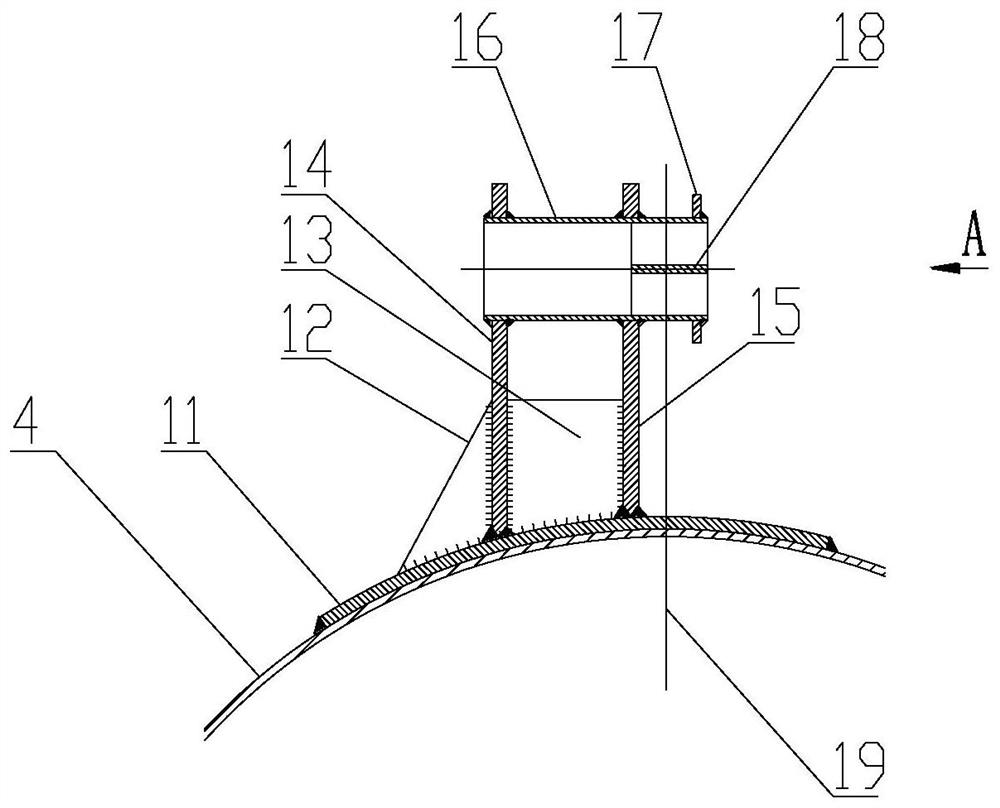

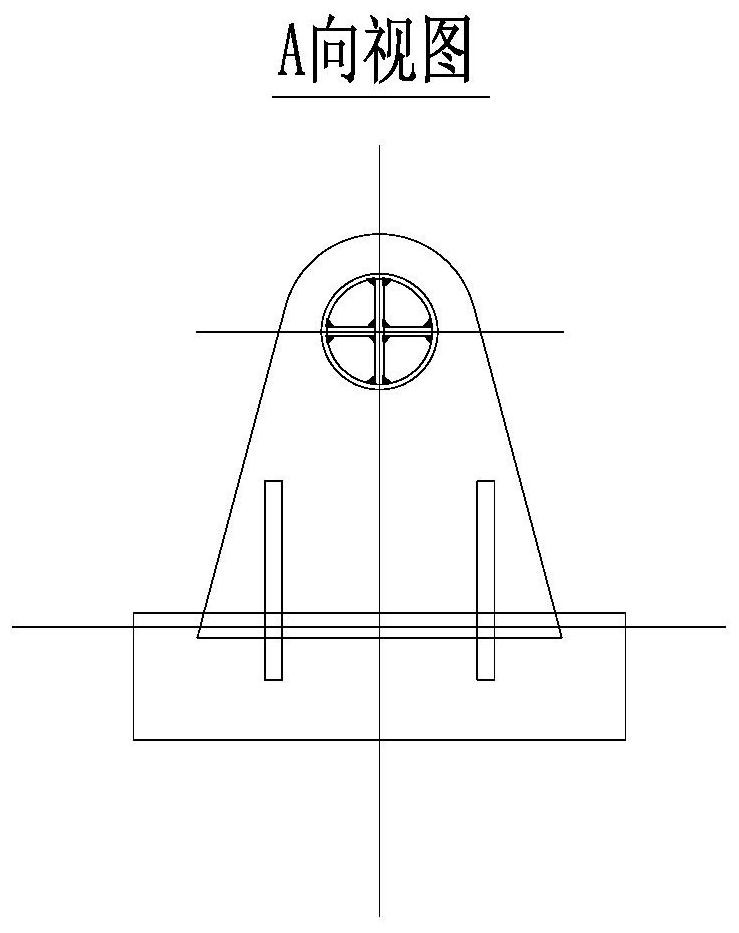

[0034] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0035] In a certain project, the tail gas vent tube in the purification and CO separation device has a weight of about 46 tons, a diameter of 1.6m, and a height of 97.5m. It is a thin-walled and slender device. After analysis, if the existing technology is used for hoisting, the overall hoisting equipment will produce plastic deformation, that is, the equipment will be deformed and bent after standing upright, and the quality cannot be guaranteed. Selecting four pipe-type main lugs 3 and the tail lug structure of this embodiment can solve the problem of overall hoisting of the equipment, so that the exhaust gas venting cylinder can be hoisted in place smoothly.

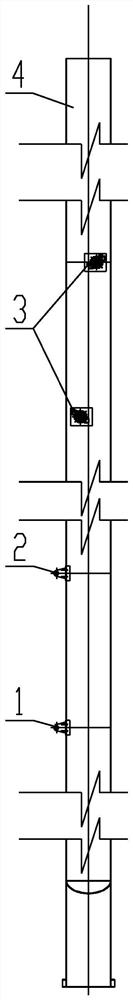

[0036] Such as figure 1 As shown, this embodiment provides a tail lug structure suitable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com