B-pillar plaque strengthening structure and vehicle

A technology for strengthening structures and decorative panels, which is applied to superstructures, vehicle components, superstructure subassemblies, etc., can solve the problems of B-pillar decorative panels being easily blown away by air curtains and low reliability, and achieve multiple Power point, prevent the air curtain from flying, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

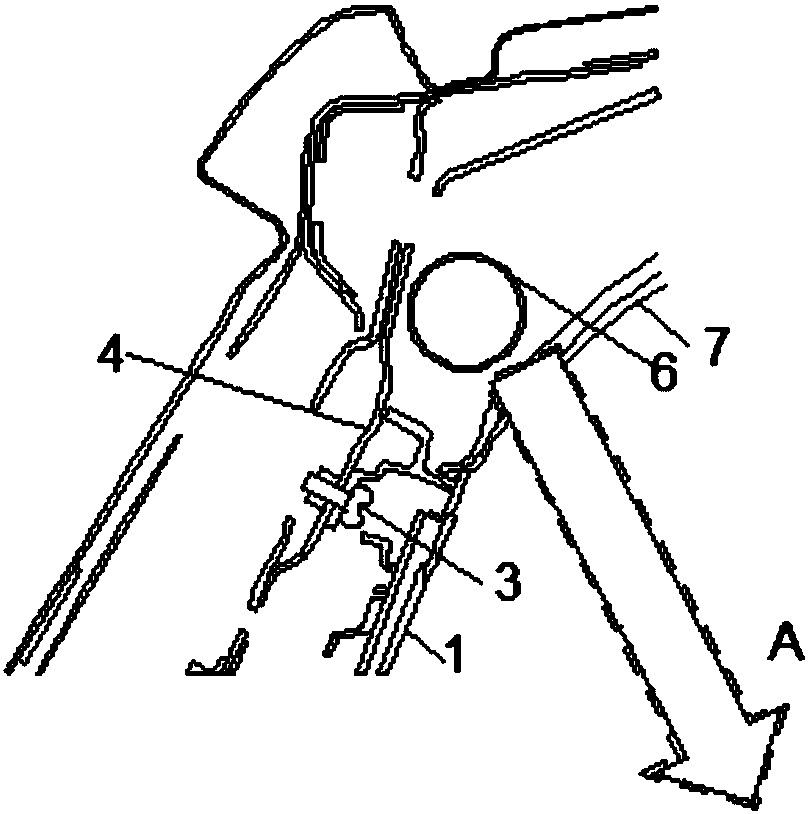

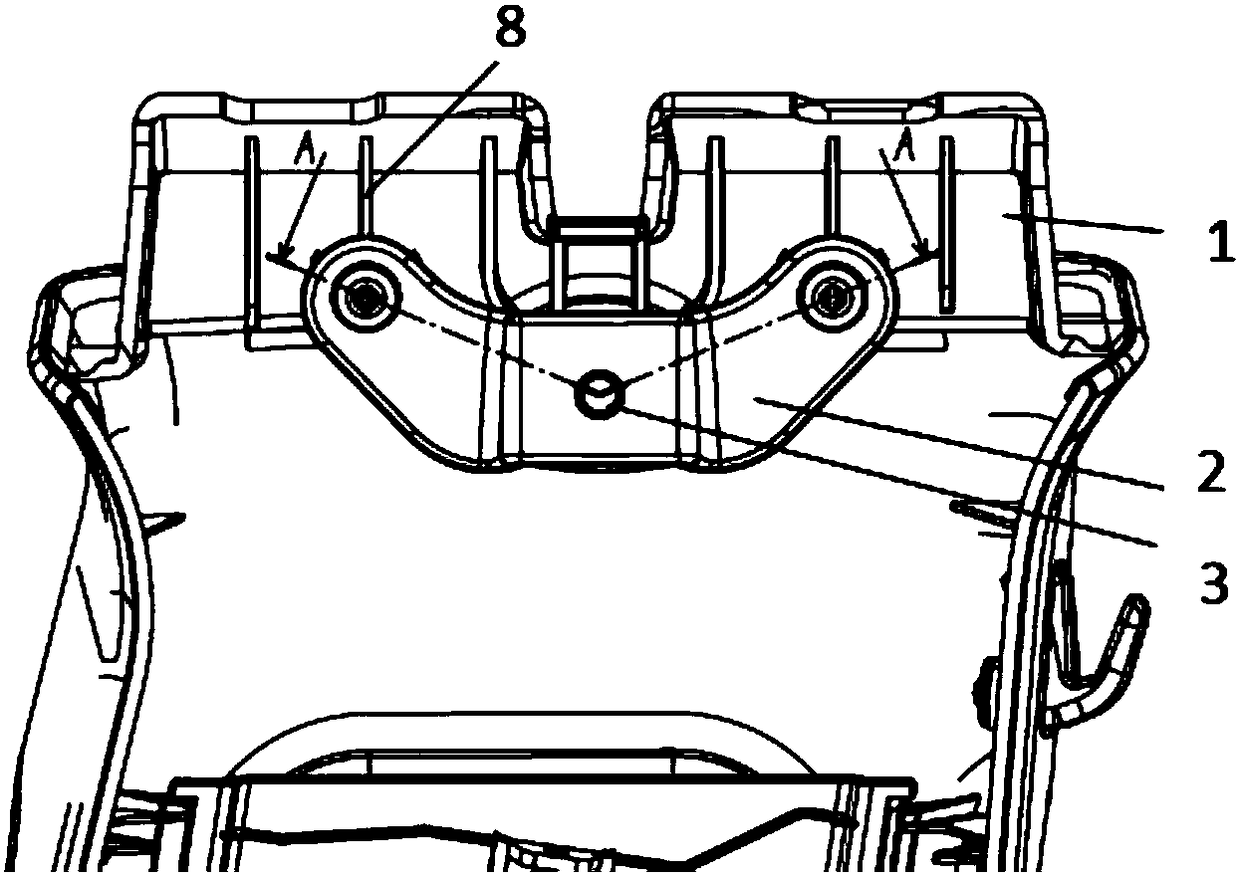

[0041] image 3 A schematic front view of the reinforcement structure of the B-pillar trim provided in Embodiment 1 of the present invention; Figure 4 A top view of the B-pillar trim reinforcement structure provided in Embodiment 1 of the present invention.

[0042] Such as image 3 with Figure 4 As shown, the B-pillar trim reinforcement structure provided by the first aspect of the present invention includes a B-pillar trim 1 and a bracket 2, the B-pillar trim 1 is connected to the vehicle body sheet metal 4 through the bracket 2, and the The B-pillar trim 1 is connected to the bracket 2 through a connecting piece, and the bracket 2 is connected to the body sheet metal 4 through bolts 3 .

[0043] In the B-pillar trim reinforcement structure provided by the present invention, the B-pillar trim 1 is connected to the bracket 2 through a connecting piece, and the bracket 2 is connected to the vehicle body sheet metal 4 through bolts 3 . The bracket 2 is connected to the bo...

Embodiment 2

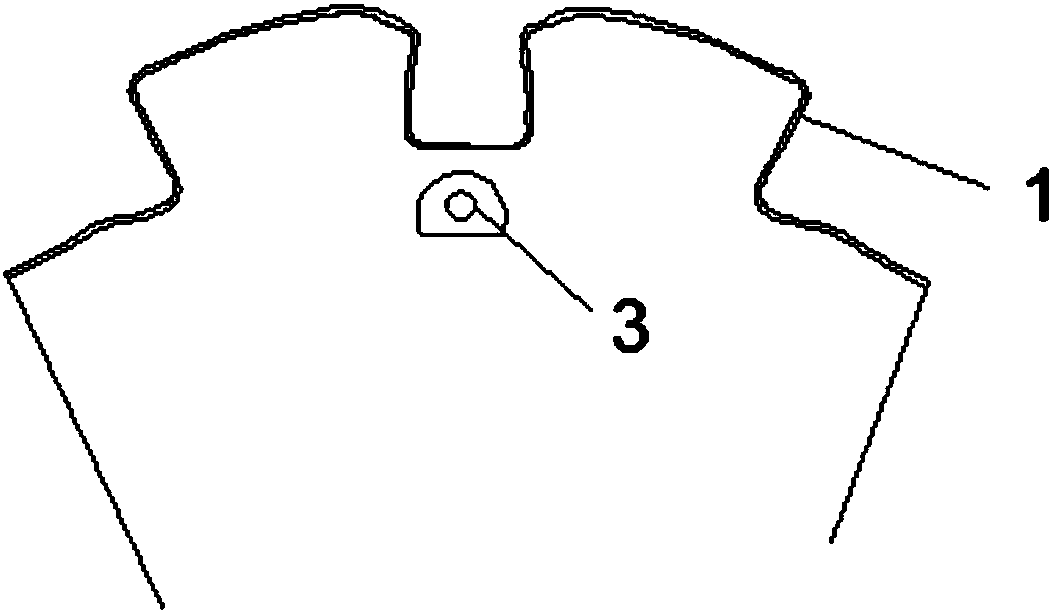

[0055] In order to increase the strength, in any of the above technical solutions, further, the B-pillar trim 1 is provided with protrusions, the bracket 2 is provided with grooves corresponding to the protrusions, and the bolts 3 pass through It is connected with the body sheet metal 4 behind the protrusion and the groove.

[0056] A groove and a raised structure are provided to make the connection between the B-pillar trim 1 and the bracket more firm.

[0057] In order to make the connection more stable, in any of the above technical solutions, further, the bolt 3 is arranged in the groove and located at the centerline of the bracket 2 . All the other are the same as embodiment one.

[0058] In the reinforced structure of the B-pillar trim provided by the present invention, the bolt 3 in the middle of the bracket 2 is connected to the body sheet metal 4, and connected to the B-pillar trim 1 through two self-tapping screws 5, two self-tapping screws 5 and one bolt 3 Compare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com