Crane lifting adjusting device

An adjustment device and crane technology, which is applied in the direction of cranes, mechanical equipment, load blocks, etc., can solve problems such as prone to topping, large operating range, and lack of vibration reduction, so as to improve work efficiency, prevent excessive swing, and improve practicality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

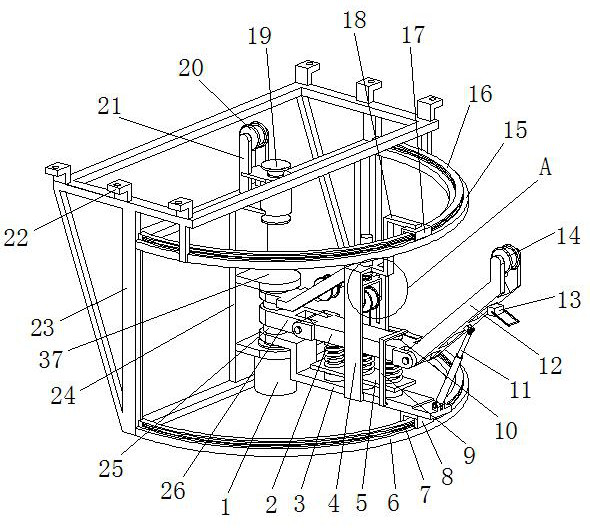

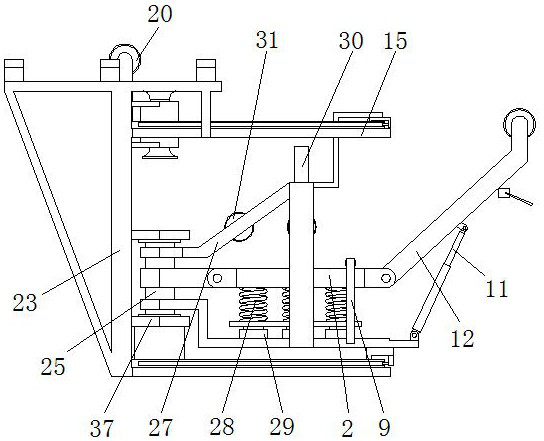

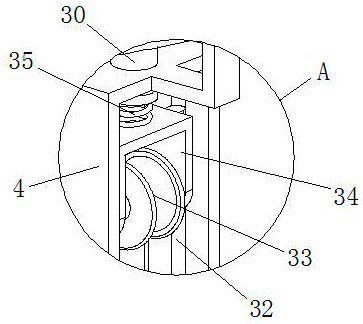

[0026] see Figure 1-5, the present invention provides a technical solution: a hoisting adjustment device for a crane, including a vibration damping arm 2, a rotating support arm 3, a hoisting adjustment arm 12, a lifting rope limit sleeve 19, a mounting frame 23 and a rotating fixed frame 24, rotating Fixing frame 24 is arranged on mounting frame 23, and the front and rear sides of mounting frame 23 tops are all provided with installation suspension plate 22, and installation suspension plate 22 is provided with installation hole, facilitates this device to be installed on the trolley by installing suspension plate 22 Below, the rotating fixed frame 24 is provided with a rotating shaft 25, and the right side of the rotating fixed frame 24 is provided with an ear plate 37. There are two ear plates 37, and the rotating shaft 25 is arranged between the ear plates 37. The lower ear plate The plate 37 is provided with a motor 1, the output shaft of the motor 1 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com