Rotary lifting appliance suitable for double-crane lifting

A rotary, double-machine technology, applied in the direction of cranes, trolley cranes, load hanging components, etc., can solve the problems of large investment costs and achieve the effect of improving the degree of generalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

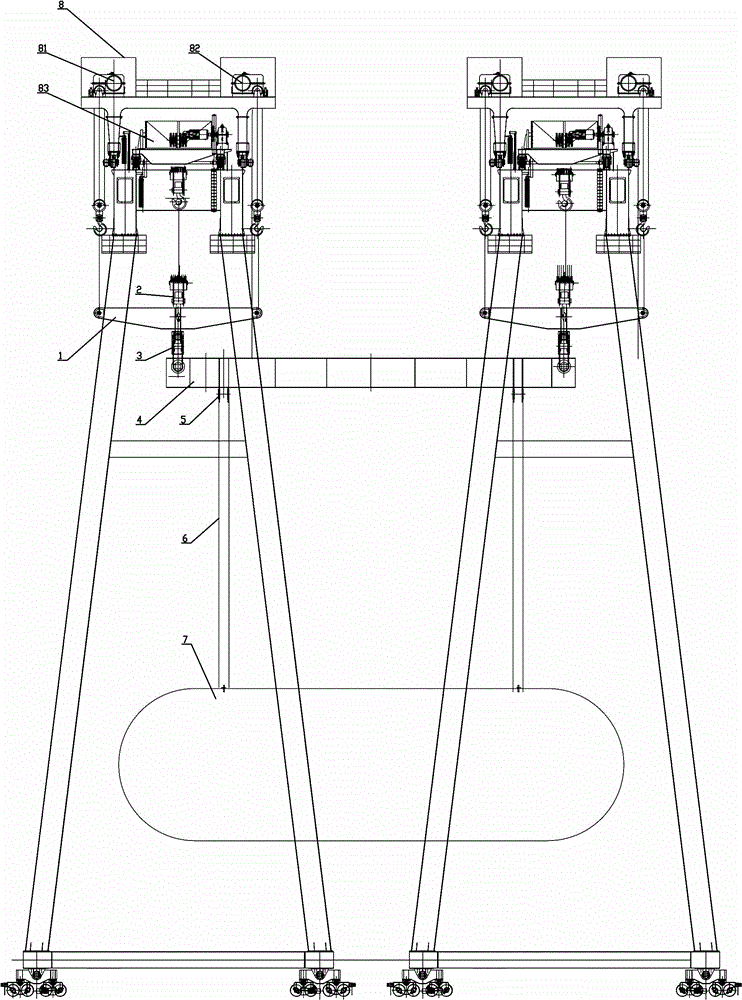

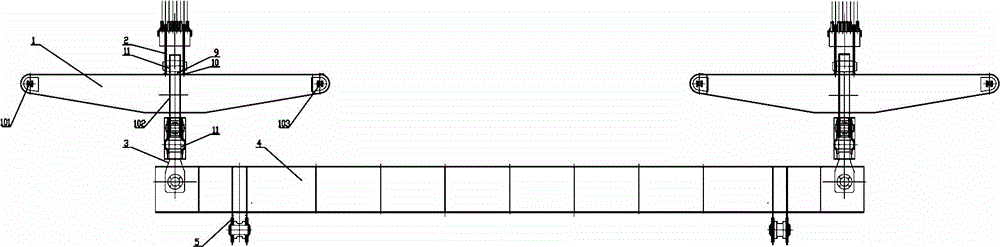

[0015] Such as figure 1 , 2 Among them, a rotary spreader suitable for double-machine cranes, including a balance beam 4, at least two lifting points 5 are arranged under the balance beam 4, and the feature is that a distribution beam is also arranged above the two ends of the balance beam 4 1. There is a distribution beam vertical hole 102 in the middle of the distribution beam 1. The vertical shaft 12 passes through the distribution beam vertical hole 102. One end of the vertical shaft 12 is provided with the first spreader 2, and the other end of the vertical shaft 12 passes through the second spreader 3. Connect with the balance beam 4;

[0016] The two ends of the distribution beam 1 are respectively provided with a distribution beam first suspension point 101 and a distribution beam second suspension point 103 . The weight of the hoisting member 7 below the balance beam 4 is reasonably distributed to the first traveling trolley 81 , the second traveling trolley 82 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com