Double-casing zero-friction static load detection construction method based on uplift pile

A technology of static load detection and construction method, which is applied in the direction of foundation structure engineering, foundation structure test, sheet pile wall, etc., can solve the problems such as the impact of the main construction period, reduce secondary unlucky transportation, speed up construction efficiency, and reduce hoisting safety risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

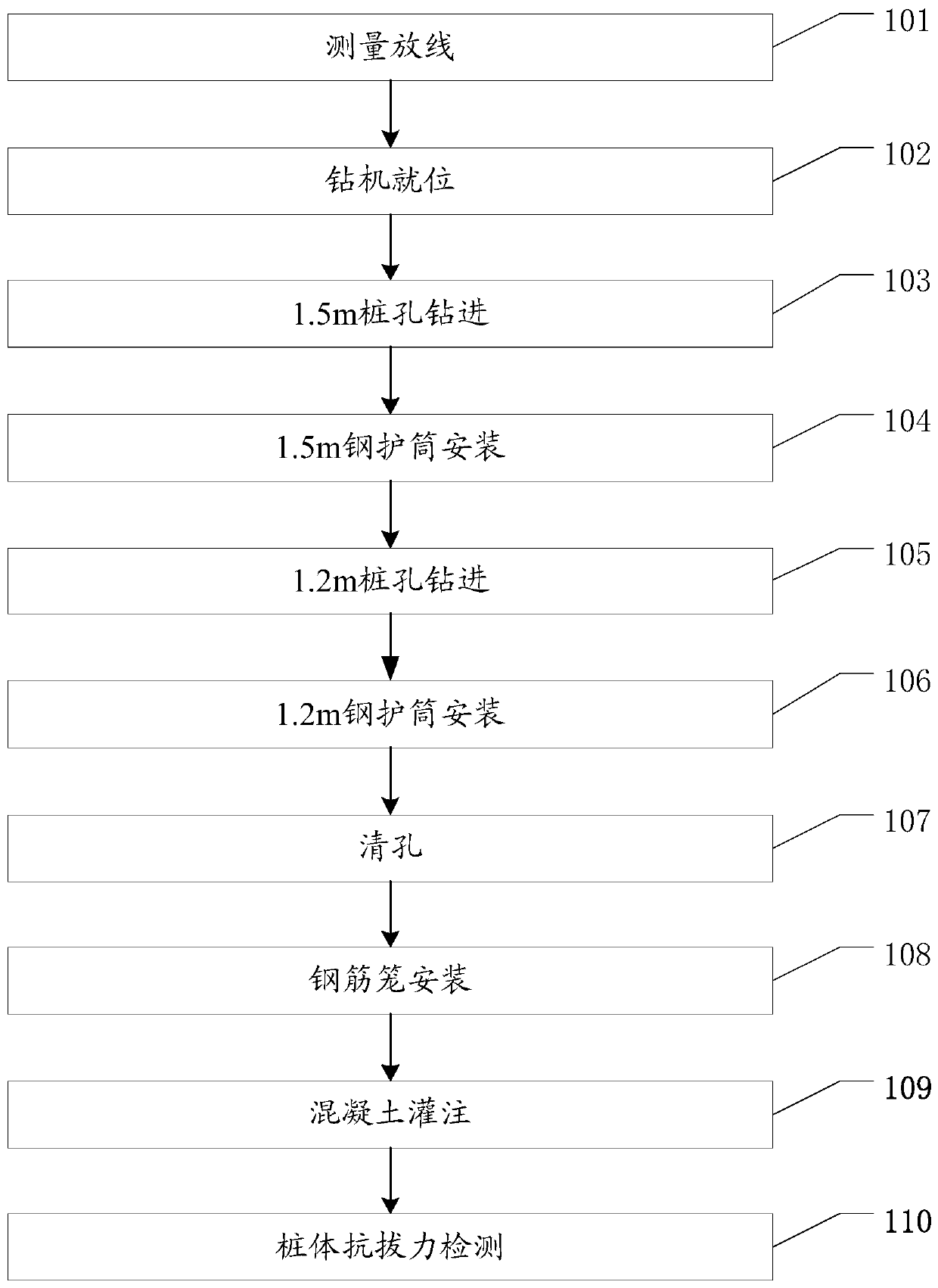

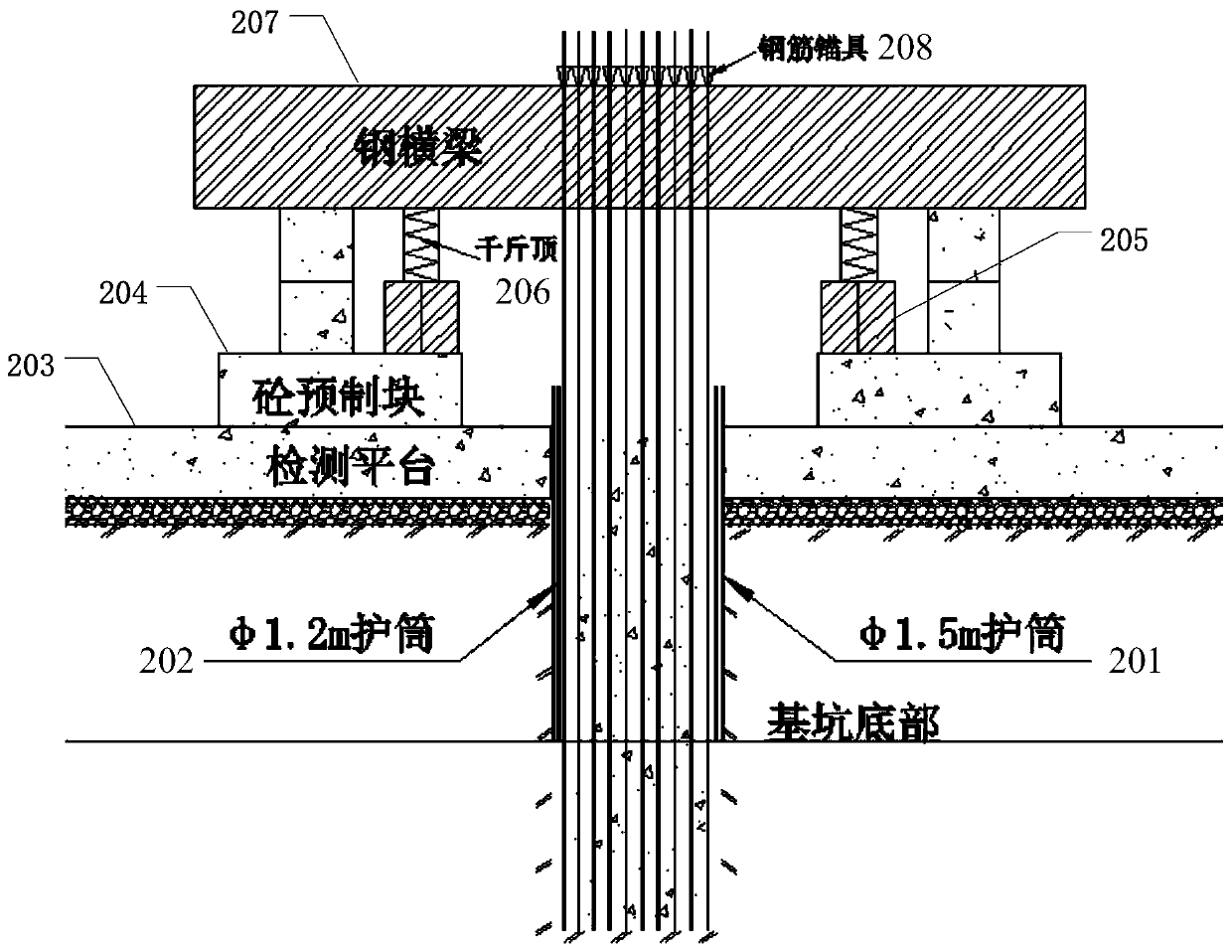

[0040] The embodiment of the present invention provides a construction method for zero-friction static load detection of double casings based on uplift piles. The static load test of uplift piles is carried out on the top of the foundation pit, and the measured data is no different from the data detected at the bottom of the foundation pit. Reinforcement welding and inspection equipment installation are carried out on the top of the foundation pit, and a 25t crane is used for hoisting, which can meet the hoisting requirements, reduce the secondary transportation of materials and equipment, and speed up the construction efficiency. At the same time, all hoisting is carried out on the surface of the foundation pit before excavation, and the safety risk of hoisting has been effectively reduced. .

[0041]The terms "first", "second", "third", "fourth", etc. (if any) in the description and claims of the present invention and the above drawings are used to distinguish similar object...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com