Three-section combined type mobile warehouse

A combined and warehouse technology, applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of time-consuming and labor-intensive access to materials and equipment, impact on construction progress, large labor costs and time costs, etc., to save material storage Taking time and cost, high safety, and avoiding the effect of casualties of porters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

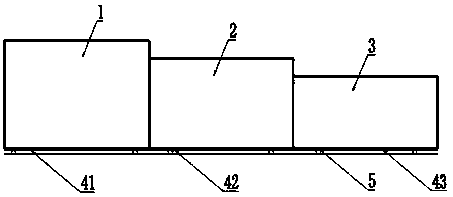

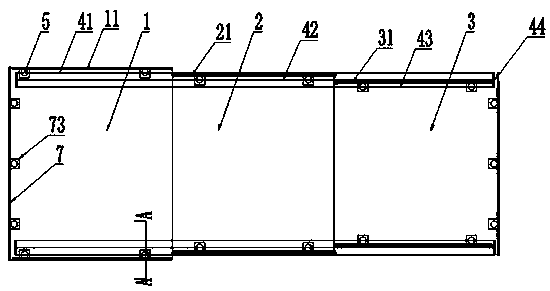

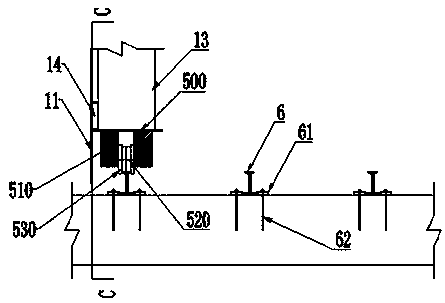

[0046] Such as figure 1 with 2 As shown, a three-section combined mobile warehouse is characterized in that it includes the first, second, and third sections with heights of 6m, 5m, and 4m, widths that gradually decrease by 70cm, lengths of 8m, and top longitudinal slopes of 6.25%. Sliding warehouses 1, 2, 3, and the first, second, and third rails 41, 42, 43 for the first, second, and third sliding warehouses 1, 2, and 3 to slide in turn, and as image 3 with Figure 4 The pulley assembly 5 shown;

[0047] Each sliding warehouse 1, 2, 3 is erected on the rails 41, 42, 43 by two pulley assemblies 5 installed at the lower ends of respective two sides and can slide to the two ends of the rails by manually applied power, and each rail contains two The parallel equal-length rails 6 fixed on the ground, the rails 6 of the second rail 42 and the third rail 43 are sequentially arranged between the rails of the first rail 41 and the second rail 42, and the distance between the three...

Embodiment 2

[0057] Example 1 was repeated, but with the following differences, such as image 3 As shown, a three-section combined mobile warehouse also includes a rail clamp 61 for fixing the rail 6 and a rail clamp fixing bolt 62. The rail clamp 61 is provided with a rail end and a fixed end, and the rail end is fixed on the lower part of the rail 6. On one side, the fixed end is provided with a threaded hole whose diameter matches the diameter of the track clamping bolt 62, and the track clamping bolt 62 is inserted into the threaded hole of the track clamping plate 61 and fixed below the ground, so that the rail 6 can be fixed.

Embodiment 3

[0059] Repeat Example 1, but with the following differences. A three-section combined mobile warehouse also includes steel track baffles 44 arranged at both ends of the track 7 to prevent the sliding warehouses 1, 2, and 3 from sliding out of the two ends of the track.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com