Welding installation equipment and construction method of hot-melt welded pipe

A construction method and technology for installing equipment are applied in the field of welding installation equipment and construction of hot-melt welded pipes, which can solve problems such as high cost and poor construction quality, and achieve the effects of convenient operation, simple construction method, and simple and easy-to-operate construction method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: A welding and installation equipment for hot-melt welded pipes.

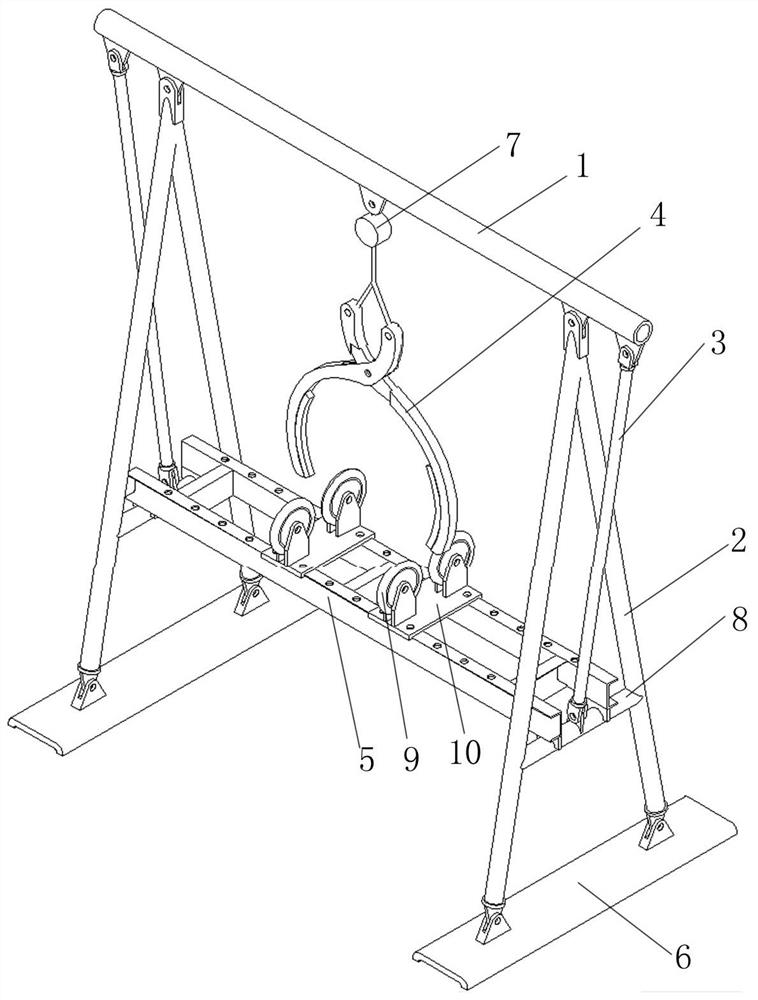

[0030] Such as figure 1 As shown, the welding and installation equipment for hot-melt welded pipes of the present invention includes a hanger 11 and an axially guided tire frame.

[0031] The hanger 11 includes a hanging beam 1, two outriggers 2, an oblique support 3, a chain hoist 7, a hanging clip 4 and a supporting base 6, wherein the outrigger 2 is A-shaped, and the bottom end of the outrigger 2 is fixed with The support base 6 is provided with a support beam 8 in the middle of the outrigger 2 , and the top of the outrigger 2 is fixed on the end of the suspension beam 1 . The suspension beam 1 is horizontally arranged above the ground, and its two ends are respectively fixed above the outrigger 2 . The lower ends of the two oblique supports 3 are fixed on the support beam 8 of the outrigger 2, and the upper ends of the oblique supports 3 are fixed on the suspension beam 1. The oblique...

Embodiment 2

[0034] Embodiment 2: A construction method for welding installation of hot-melt welded pipes.

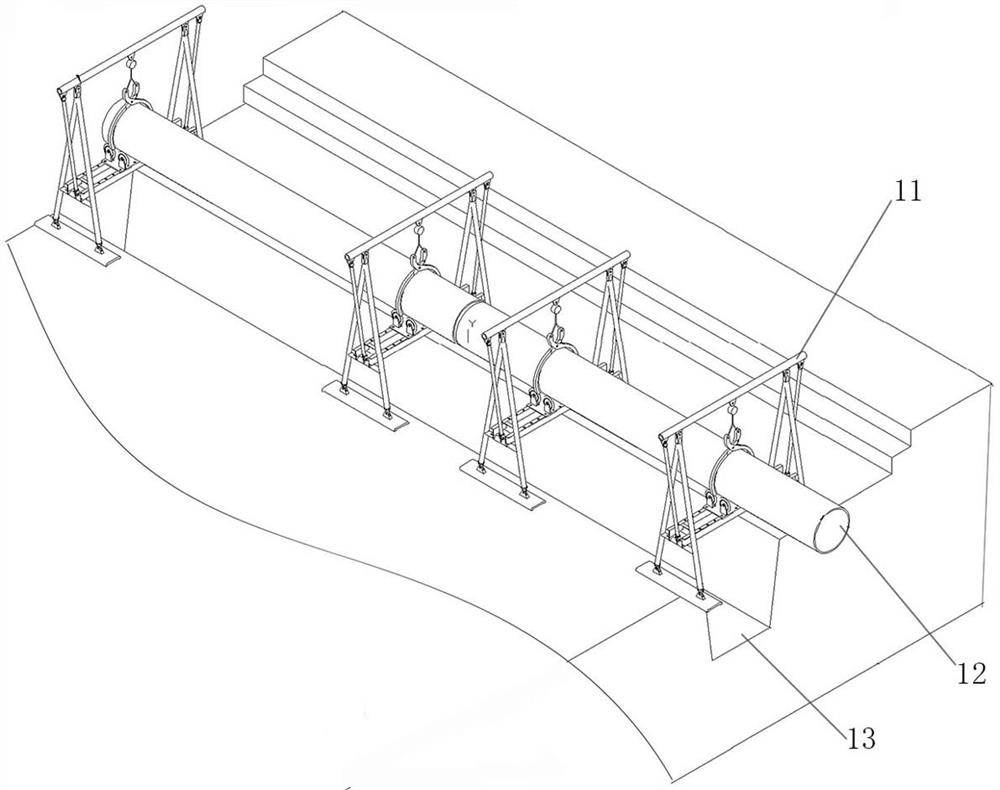

[0035] Such as figure 2 As shown, the installation method of the hot-melt welded pipe 12 of the present invention comprises the following steps:

[0036] A welding installation construction method for hot-melt welded pipes, comprising the following steps:

[0037] a. Apply for temporary road occupation application, use the staggered construction time, use the truck crane to open a number of hot-melt welded pipes 12 to be welded and installed in a row according to the form that the adjacent nozzles are the sub-mouths and the female mouths are opposite, and place the hot-melt pipes for laying In the pipe groove 13;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com