Lightweight ceramsite concrete assembly type prefabricated hollow staircase and preparation method thereof

A lightweight ceramsite and concrete technology, which can be applied to stairs, treads and vertical plate units, etc., can solve problems such as aggravating the deterioration of the ecological environment, human harm, and occupation of cultivated land, and achieve environmental protection, regular size, and reliable technical support. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

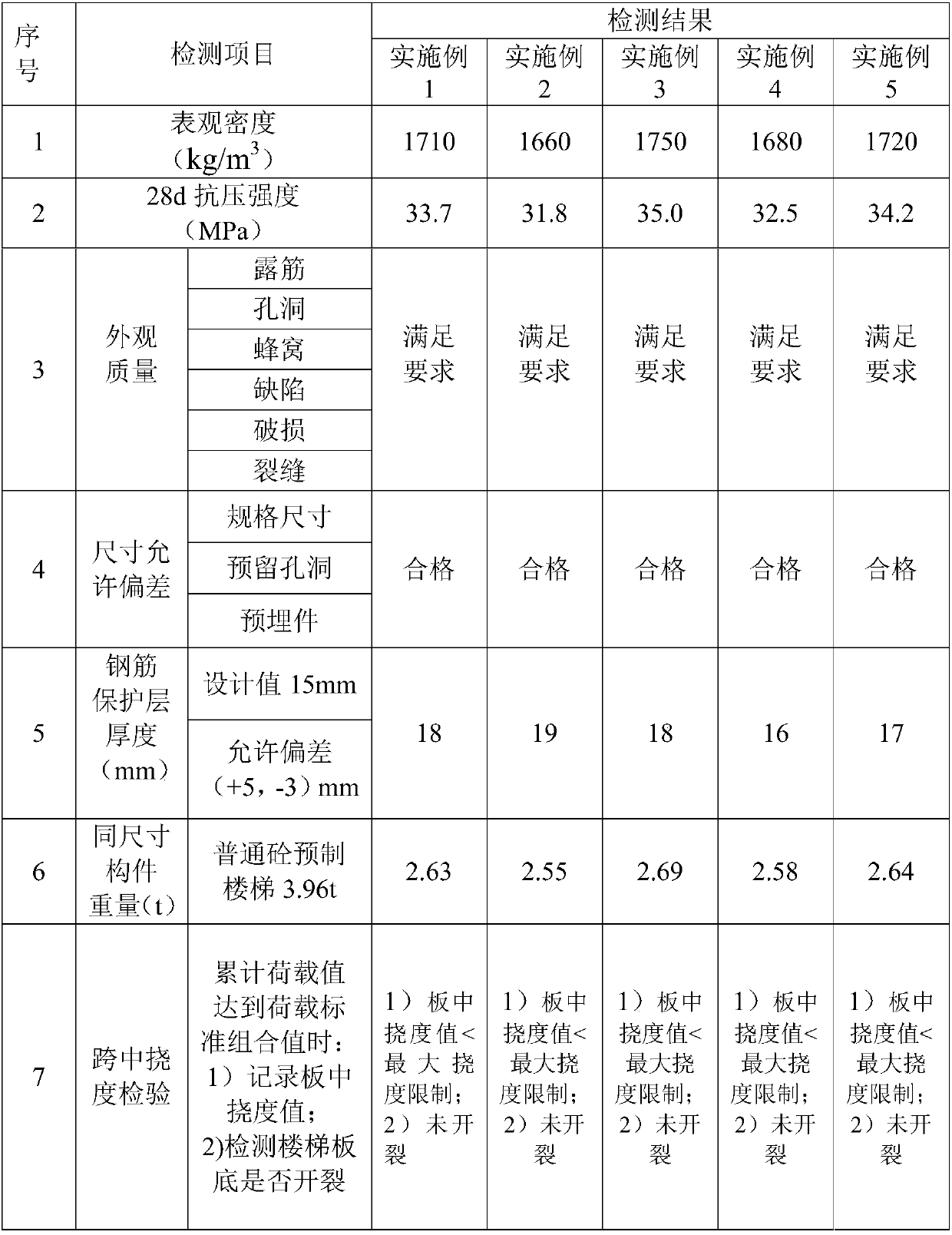

Embodiment 1

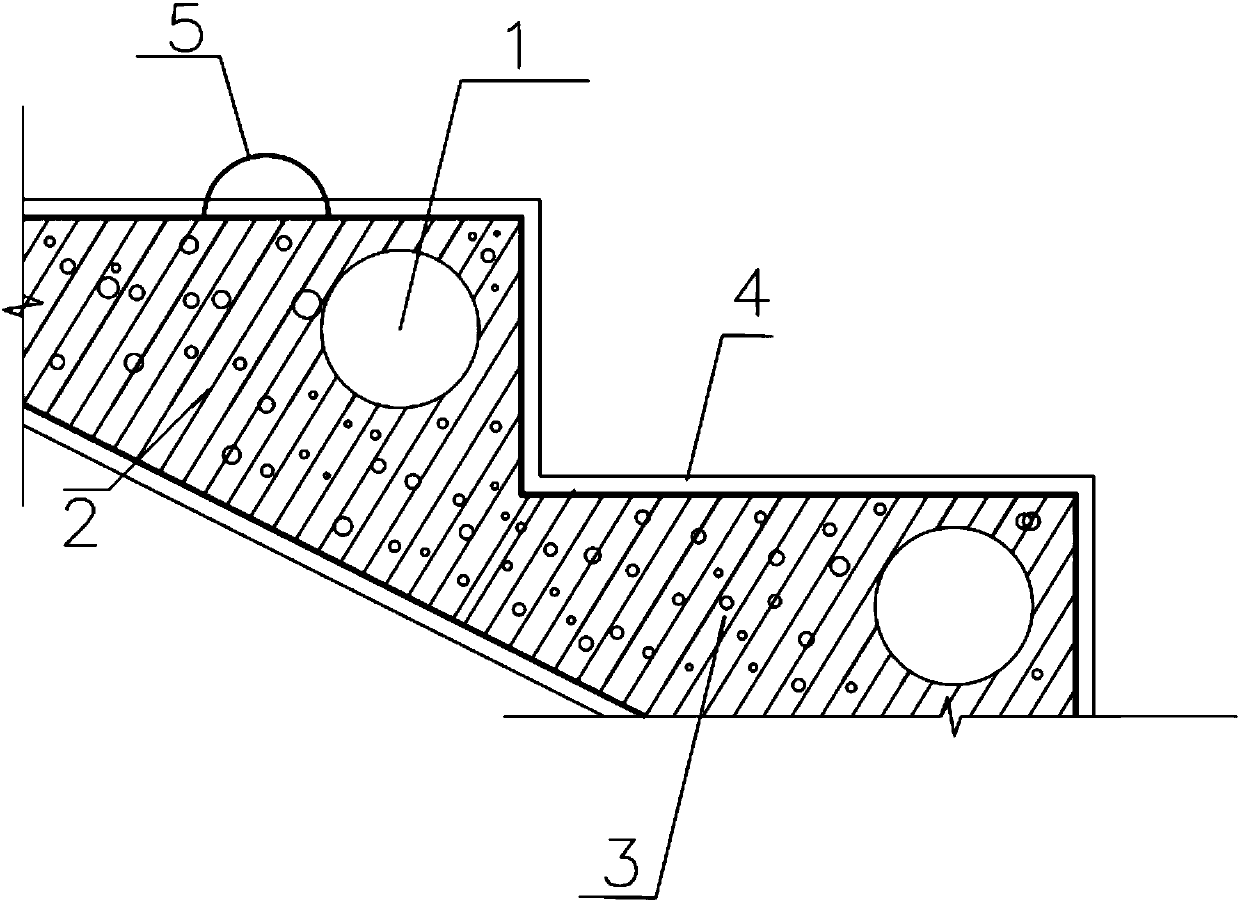

[0034] Such as figure 1 As shown, in this embodiment, the lightweight ceramsite concrete assembled prefabricated hollow staircase includes step holes 1, steel bars 2, lightweight ceramsite concrete 3, steps 4, and hoisting rings 5, and each step is prefabricated with at least one step hole , the step hole is a circular structure, so that the step forms a hollow column step.

[0035] The raw material components and weight ratio of lightweight ceramsite concrete are: cement: mineral powder: fly ash: fly ash ceramsite: water-quenched slag: pearl sand: water: admixture = 280:210:55:600: 520:16:150:14. Among them, the cement is 42.5 grade ordinary Portland cement, which can be Zhengtong 42.5 grade ordinary Portland cement produced by Tianjin Zhenxing Cement Co., Ltd.; the mineral powder is S95 grade mineral powder, which can be used by Tangshan Ruifeng Iron and Steel (Group) Co., Ltd. The S95 grade granulated blast furnace slag powder produced by the company; the fly ash is the s...

Embodiment 2

[0044] In this embodiment, the lightweight ceramsite concrete assembled prefabricated hollow staircase includes step holes, steel bars, lightweight ceramsite concrete, steps, and hoisting rings.

[0045] The raw material components and weight ratio of lightweight ceramsite concrete are: cement: mineral powder: fly ash: fly ash ceramsite: water quenching slag: pearl sand: water: admixture = 260:185:50:610: 510:18:155:13. Among them, the cement is 42.5 grade ordinary Portland cement, which can be Zhengtong 42.5 grade ordinary Portland cement produced by Tianjin Zhenxing Cement Co., Ltd.; the mineral powder is S95 grade mineral powder, which can be used by Tangshan Ruifeng Iron and Steel (Group) Co., Ltd. The S95 grade granulated blast furnace slag powder produced by the company; the fly ash is the second grade fly ash, and the second grade fly ash produced by Tianjin Beijiang Environmental Protection Building Materials Co., Ltd. can be used; the fly ash ceramsite has a density o...

Embodiment 3

[0054] In this embodiment, the lightweight ceramsite concrete assembled prefabricated hollow staircase includes step holes, steel bars, lightweight ceramsite concrete, steps, and hoisting rings.

[0055] The raw material components and weight ratio of lightweight ceramsite concrete are: cement: mineral powder: fly ash: fly ash ceramsite: water-quenched slag: pearl sand: water: admixture = 300:215:60:590: 530:15:160:15. Among them, the cement is 42.5 grade ordinary Portland cement, which can be Zhengtong 42.5 grade ordinary Portland cement produced by Tianjin Zhenxing Cement Co., Ltd.; the mineral powder is S95 grade mineral powder, which can be used by Tangshan Ruifeng Iron and Steel (Group) Co., Ltd. The S95 grade granulated blast furnace slag powder produced by the company; the fly ash is the second grade fly ash, and the second grade fly ash produced by Tianjin Beijiang Environmental Protection Building Materials Co., Ltd. can be used; the fly ash ceramsite has a density of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com