Induction motor slot type design and calculation method based on slot type element combination

A technology of induction motor and design method, applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problems of difficult motor design, long time consumption, neglect of iron core reluctance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

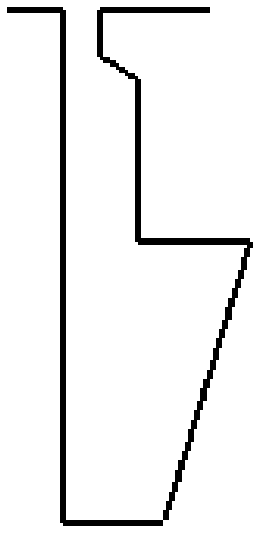

[0094] This embodiment uses the groove element method to calculate the original fixed groove type, the groove type round bottom groove. like Figure 7 shown.

[0095] Specific steps are as follows:

[0096] First analyze the groove shape, make a horizontal line for the node along the endpoint of the line segment forming the groove shape and the widest point in the transverse direction of the arc, decompose the groove shape into groove element diagrams, and name them: segment 1, segment 2, and segment 3, respectively as follows Semicircle, trapezoid, trapezoid, such as Figure 8 shown. According to the principle of calculating from the bottom of the tank upwards, the calculation sequence of the slot elements is from segment 1 to segment 3. (Because the notch part in the induction motor is a small rectangle, and considering the magnetic circuit saturation problem of the notch part, a special algorithm is used in the calculation, and the leakage reactance of the slot is not i...

Embodiment 2

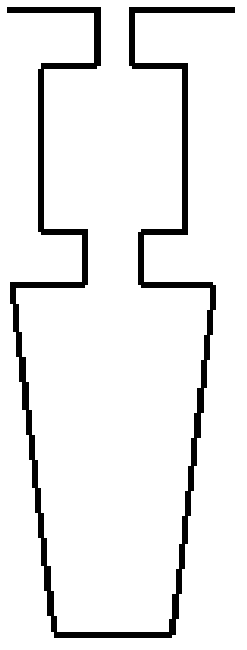

[0124] In this embodiment, the groove type element method is used to calculate the custom groove type. The custom groove type is as follows Figure 9 shown.

[0125] Specific steps are as follows:

[0126]First analyze the groove shape, along the end points of the line segments that make up the groove shape, it is easy to decompose the groove shape into groove element diagrams, named: Segment 1, Segment 2, Segment 3, Segment 4, Segment 5, Segment 6, and Segment 7, respectively rectangle, lower semicircle, upper semicircle, trapezoid, trapezoid, rectangle, trapezoid, such as Figure 10 shown. According to the principle of calculating from the bottom of the tank upwards, the calculation sequence of the slot elements is from segment 1 to segment 7. (Because the notch part in the induction motor is a small rectangle, and considering the magnetic circuit saturation problem of the notch part, a special algorithm is used in the calculation, and the leakage reactance of the slot is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com