Arrangement and installation method and structure of tail water surge shaft gate and opening and closing equipment

A water surge well and installation structure technology, applied in hydropower, water conservancy projects, hydropower stations, etc., can solve the problems of increased investment, overflow, damage, etc., and achieve the effect of saving investment and locking the gate firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

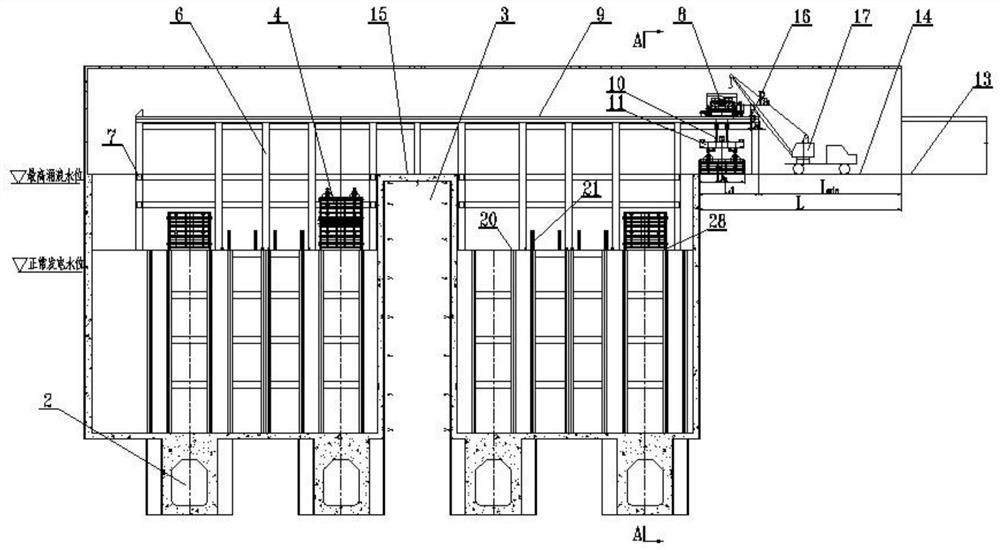

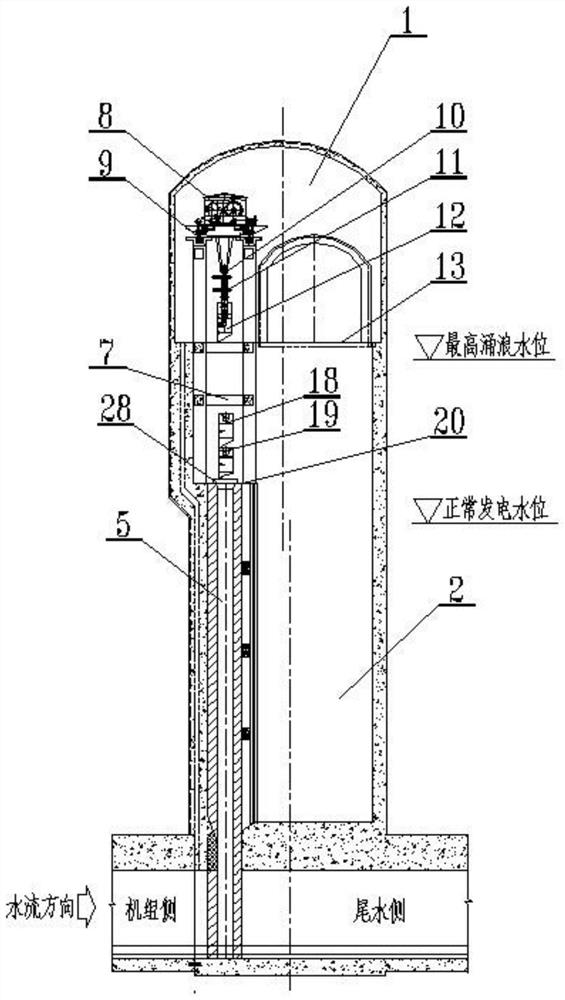

[0050] as attached figure 1 , figure 2 , Figure 7-10 As shown, in this embodiment, the tail water surge chamber 1 is composed of two independent tail water surge wells 2, and adjacent independent tail water surge wells 2 are separated by rock ridges 3 . Each independent tail water surge well 2 is provided with two tail water surge well gates 4, and the centerlines of the gate grooves 5 of all tail water surge well gates 4 are arranged on the same straight line. The connecting beam 7 is canceled in the middle of the bent frame 6 of the killing well 4 along the water flow direction; the gate 4 of the tailwater surge well is operated by a trolley 8; 1 >Trolley lifting head 10 upper limit size h t + The distance h between the centers of the upper and lower hanging heads of the hydraulic grab beam 11 y + Single door leaf 12 maximum height h when installed max ; Tail water surge well gate 4 and trolley 8 are transported to installation platform 14 through traffic hole 13.

...

Embodiment 2

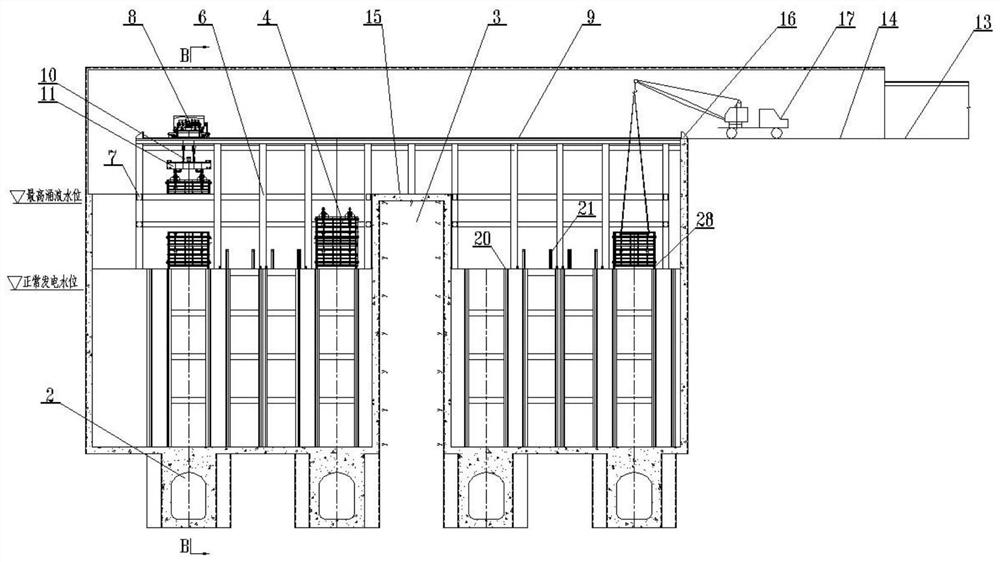

[0054] as attached image 3 , Figure 4 , Figure 7-10 As shown, in this embodiment, the tail water surge chamber 1 is composed of two independent tail water surge wells 2, and adjacent independent tail water surge wells 2 are separated by rock ridges 3 . Each independent tail water surge well 2 is provided with two tail water surge well gates 4, and the centerlines of the gate grooves 5 of all tail water surge well gates 4 are arranged on the same straight line. The middle part of the bent frame 6 of the killing well 4 is along the water flow direction, and the connecting beam 7 is cancelled; the gate 4 of the tailwater surge well is operated by a trolley 8; 1 >Trolley lifting head 10 upper limit size h t + The distance h between the centers of the upper and lower hanging heads of the hydraulic grab beam 11 y + Single door leaf 12 maximum height h when installed max ; Tail water surge well gate 4 and trolley 8 are transported to installation platform 14 through traffic h...

Embodiment 3

[0057] as attached Figure 5-10 As shown, in this embodiment, the tail water surge chamber 1 is composed of two independent tail water surge wells 2, and adjacent independent tail water surge wells 2 are separated by rock ridges 3 . Each independent tail water surge well 2 is provided with two tail water surge well gates 4, and the centerlines of the gate grooves 5 of all tail water surge well gates 4 are arranged on the same straight line. The connecting beam 7 is canceled in the middle of the bent frame 6 of the killing well 4 along the flow direction; the gate 2 of the tailwater surge well is operated by the portal crane 29, and the elevation of the rail platform 30 of the portal crane and the elevation of the bottom of the traffic tunnel 13 are the same as the elevation of the top platform 15 of the rock ridge. Lift H on gantry crane 29 rails gs >The distance h between the centers of the upper and lower lifting heads of the hydraulic grab beam 11 y + Single door leaf 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com