Hoisting equipment for large welding workpiece

A technology for welding workpieces and equipment, applied in the field of hoisting equipment and hoisting equipment for large welding workpieces, can solve problems such as the inability to solve the problem of accurate positioning of workpieces and safe operation of equipment, so as to avoid the falling off of the spreader, ensure safety, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

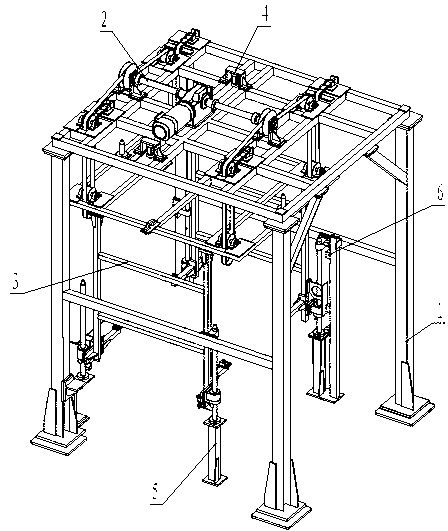

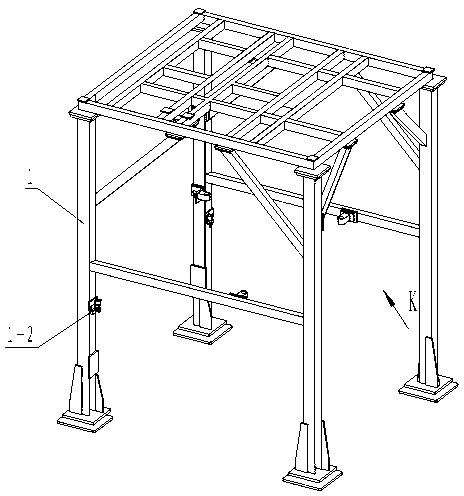

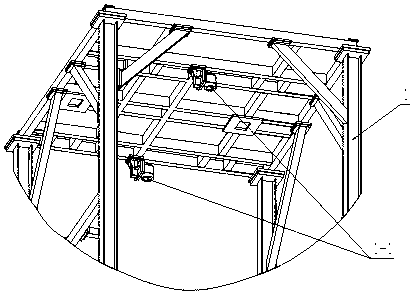

[0028] See Figure 1, figure 2 , image 3 , the present invention includes a fixed frame 1, a drive mechanism 2, an executive mechanism 3, a mechanical locking mechanism 4, a guide mechanism 5 and a position monitoring mechanism 6, and the fixed frame 1 is installed on both sides of the transport trolley track of the welding production line, on the The top of the fixed frame 1 is provided with a positioning pin hole 1-1 matching with the components of the actuator, and a set of movable latches 1-2 is provided on the fixed frame 1, and the driving mechanism 2 and the mechanical locking mechanism 4 are installed on the fixed frame 1, they are matched with the actuator 3, the actuator 3 is assembled with the guide mechanism 5, and the guide mechanism 5 and the position monitoring mechanism 6 are fixed on the level ground.

[0029] See 4, Figure 5 , the driving mechanism 2 of the present invention comprises a motor drive unit 2-1, a universal coupling 2-2, a large pulley 2-3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com