Pouring material for forsterite tundish slag stop wall and production process thereof

A forsterite and production process technology, applied in the field of slag retaining weir castable and its production process, and slag retaining wall for continuous casting tundish, can solve the problems of enterprise benefit impact, poor corrosion resistance and erosion resistance, fracture and other problems, and achieve The effect of good burst resistance, formulation cost reduction, and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

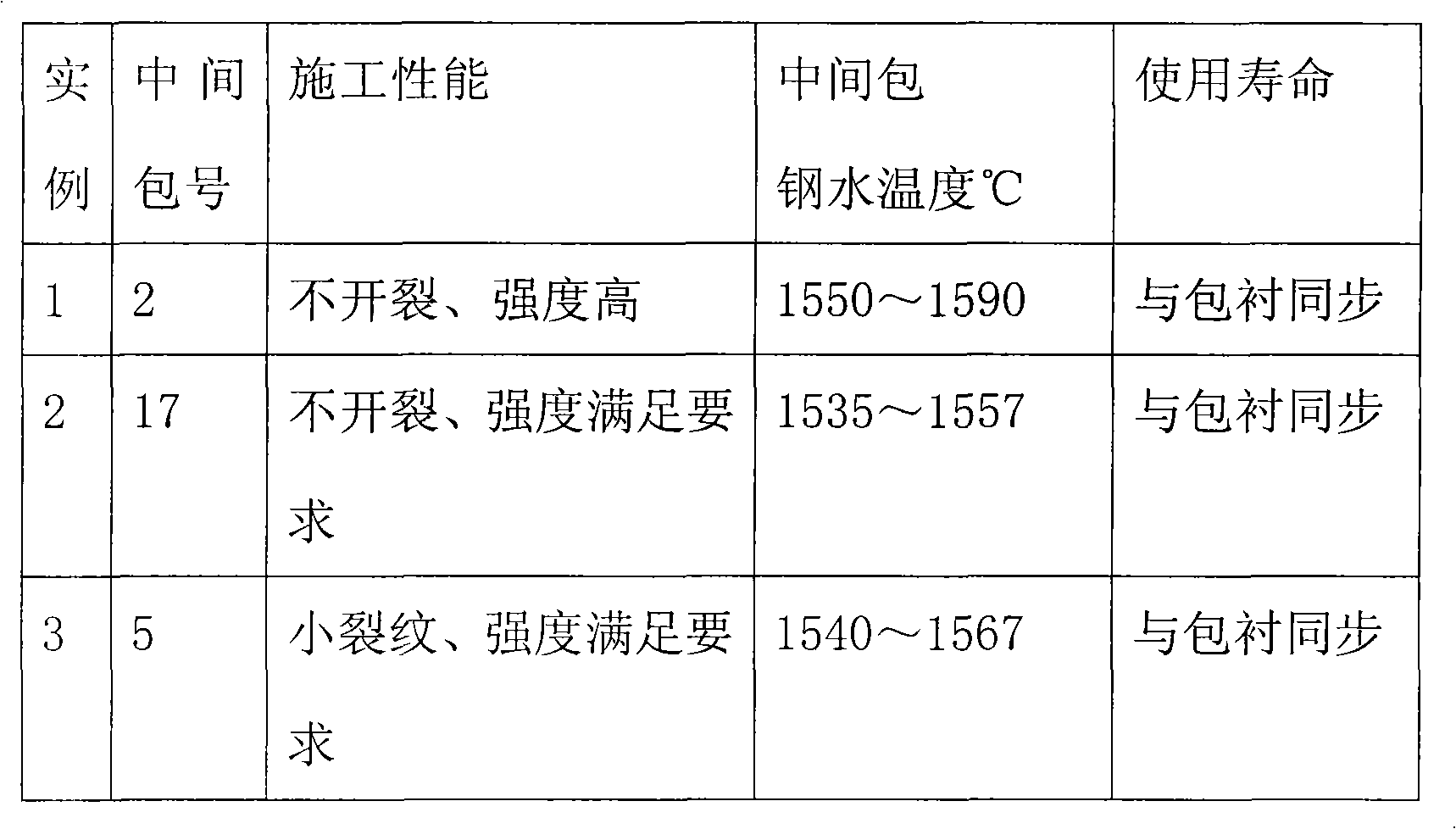

Examples

Embodiment 1

[0024] Raw materials: 50 kg of forsterite, 40 kg of magnesia, 5 kg of corundum powder, SiO 2 Micro powder 3.5 kg, sodium tripolyphosphate 0.5 kg, steel fiber 1 kg, organic fiber 0.1 kg. The weight percentage of the above-mentioned forsterite MgO is 43%-50%, the particle size is ≤8mm, and the particle size is 8mm-5mm, 5mm-3mm, 3mm-1mm, and 1mm-0mm respectively, and the weight percentage of forsterite is 35% %, 30%, 35%, 0%. The particle size of the magnesia is ≤1mm, the particle sizes are respectively in two gradations of 1mm-0mm and ≤0.088mm, and the weight percentages of the magnesia are 50% and 50% respectively. SiO 2 The particle size of fine powder is 5μm; the length of organic fiber is ≤3mm; the length of steel fiber is 20mm~30mm.

[0025] Preparation Process:

[0026] Weigh the above raw materials according to the formula, first add the aggregate and mix in the forced mixer evenly, then add fine powder and compound additives and stir for 2 to 3 minutes, when the mate...

Embodiment 2

[0028] Raw materials: 70 kg of forsterite, 15 kg of magnesia, 10 kg of corundum powder, SiO 2 1 kg of fine powder, 0.2 kg of sodium tripolyphosphate, 2.8 kg of SR-71 cement, 1 kg of steel fiber, and 0.1 kg of organic fiber. The weight percentage of the above-mentioned forsterite MgO is 43%-50%, the particle size is ≤8mm, and the particle size is respectively 8mm-5mm, 5mm-3mm, 3mm-1mm, and 1mm-0mm. %, 20%, 25%, 30%. The particle size of the magnesia is ≤1mm, the particle sizes are respectively in two gradations of 1mm-0mm and ≤0.088mm, and the weight percentages of the magnesia are 0% and 100% respectively. SiO 2 The particle size of fine powder is 5μm; the length of organic fiber is ≤3mm; the length of steel fiber is 20mm~30mm.

[0029] Preparation Process:

[0030] Weigh the above raw materials according to the formula, first add the aggregate and mix in the forced mixer evenly, then add fine powder and compound additives and stir for 2 to 3 minutes, when the materials ar...

Embodiment 3

[0032] Raw materials: 85 kg of magnesia, 5 kg of forsterite, 15 kg of corundum powder, SiO 2 Micro powder 2.5 kg, sodium hexametaphosphate 0.5 kg, steel fiber 1 kg, organic fiber 0.1 kg. The weight percentage of the above-mentioned forsterite MgO is 43%-50%, the particle size is 1mm-0mm, and the weight percentage of the forsterite is 100%, the particle size of the above-mentioned magnesia is ≤1mm, and the particle size is 8mm-5mm, 5mm-3mm, and 3mm respectively ~1mm, 1mm~0mm, ≤0.088mm five gradations, accounting for 20%, 20%, 20%, 20% and 20% of the weight of magnesia respectively. SiO 2 The particle size of fine powder is 5μm; the length of organic fiber is ≤3mm; the length of steel fiber is 20mm~30mm.

[0033] Preparation Process:

[0034] Weigh the above raw materials according to the formula, first add the aggregate and mix in the forced mixer evenly, then add fine powder and compound additives and stir for 2 to 3 minutes, when the materials are evenly mixed, add water a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com