Method for installation of 3 MW wind generating set

A technology for a wind turbine and an installation method, which is applied in the directions of assembly machines, cranes, metal processing equipment, etc., to achieve the effects of improving construction safety, speeding up construction progress, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention is mainly a method adopted for the installation of a 3MW wind power generating set. The present invention will be further described below in conjunction with accompanying drawing.

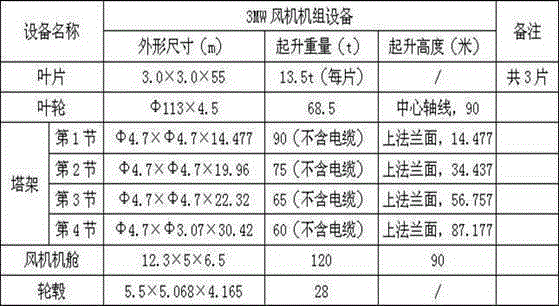

[0066] The main parameters of the 3MW fan equipment are as follows:

[0067]

[0068] The main steps and installation requirements of the 3MW wind turbine installation method of the present invention are as follows:

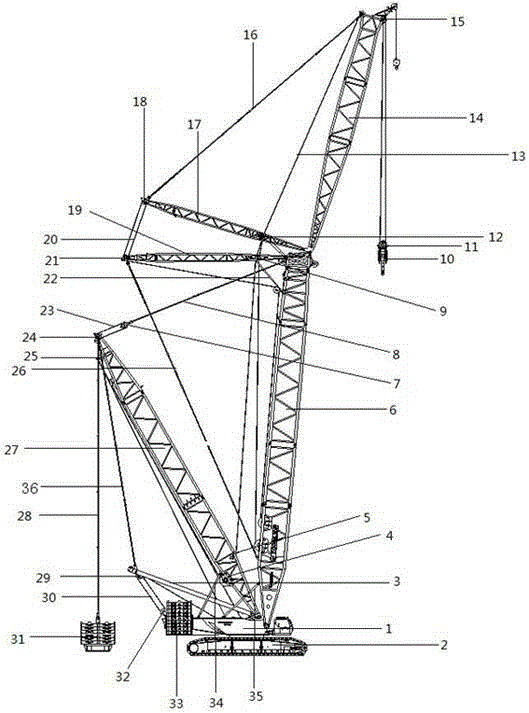

[0069] 1. Main crane selection

[0070] From the above table, it can be seen that the tonnage and volume of the 3MW fan unit equipment are much larger than that of the 2.5MW and below fan unit equipment. The weight of the cabin has reached 120t, and the size parameters (length, width, height) Reached 12.3m x 5m x 6.5m. When the main crane is hoisting the unit equipment, not only the load of the main crane must be considered, but also whether the hoisted unit equipment will collide with the boom of the main crane during construction to avoid dangero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com