Assembled crane sling

A crane and assembly technology, applied in the field of hoisting and hoisting equipment and auxiliary equipment, can solve the problems of insufficient working arm length, inability to realize mechanized hoisting operation, etc., to increase the horizontal coverage, facilitate packing and transportation, and avoid excessive use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

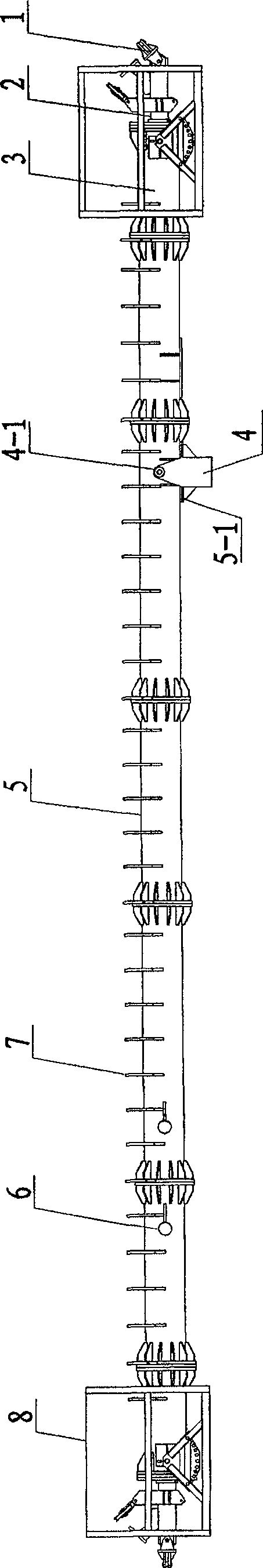

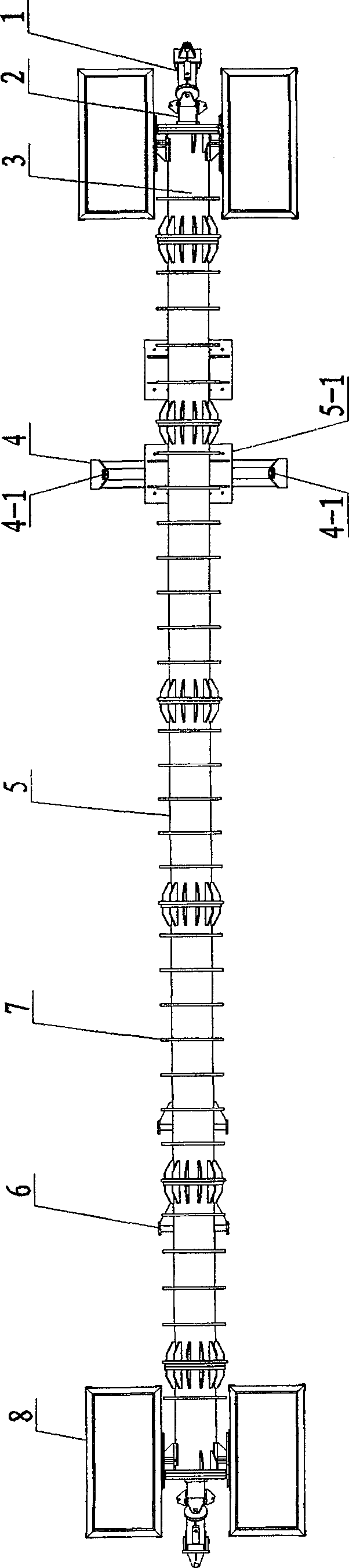

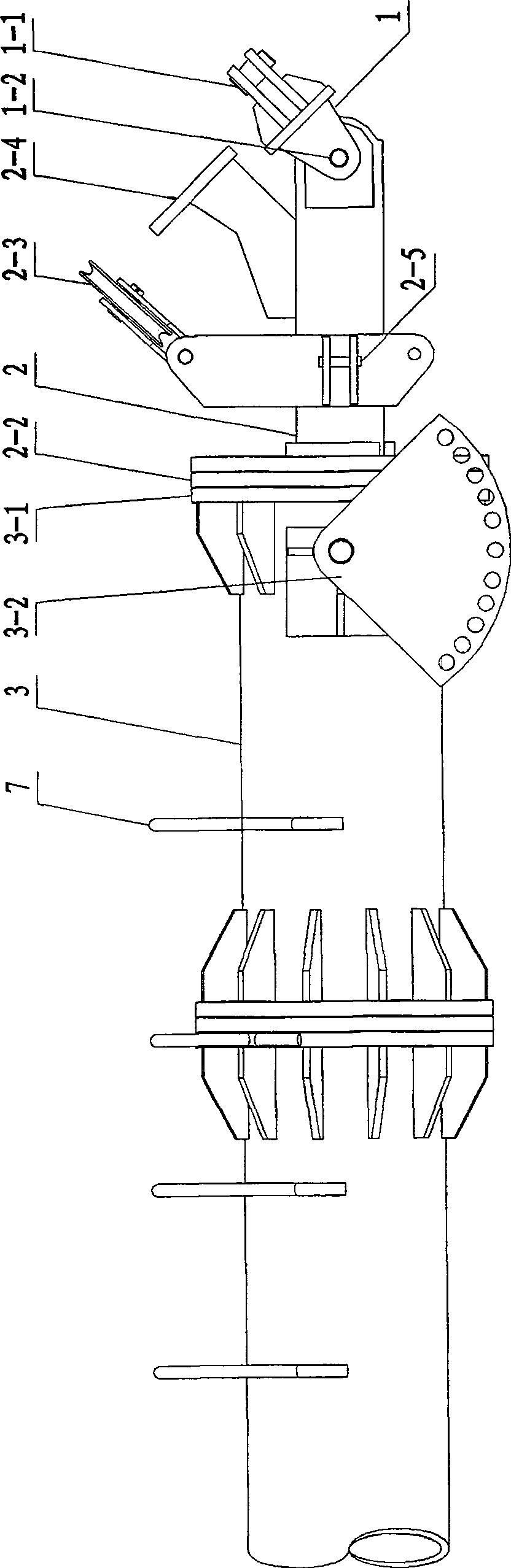

[0039] The two ends of the spreader are composed of two lifting heads 1 with a cross shaft structure, two movable rods 2 with a rectangular steel structure, two round tube-shaped basic rods 3, and 5 round tubes of different specifications matched according to the actual length The shape connects the long rod 5, a rectangular balance suspension beam 4, a pair of single hook suspension shaft 6 and two end work platforms 8 to form. Both the basic rod 3 and the extension rod 5 are assembled and connected by hinged bolts at the universal flange. Such as figure 1 , 2 .

[0040] The movable rod 2 is set in the basic rod 3, and its middle part is supported on the outer circumference of the basic rod 3 through the inner socket of the guide flange 2-2; its outer end is pinned to the hanger 1; its inner end is passed through the support seat 2- 1 is supported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com