Patents

Literature

98results about How to "Avoid construction risks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

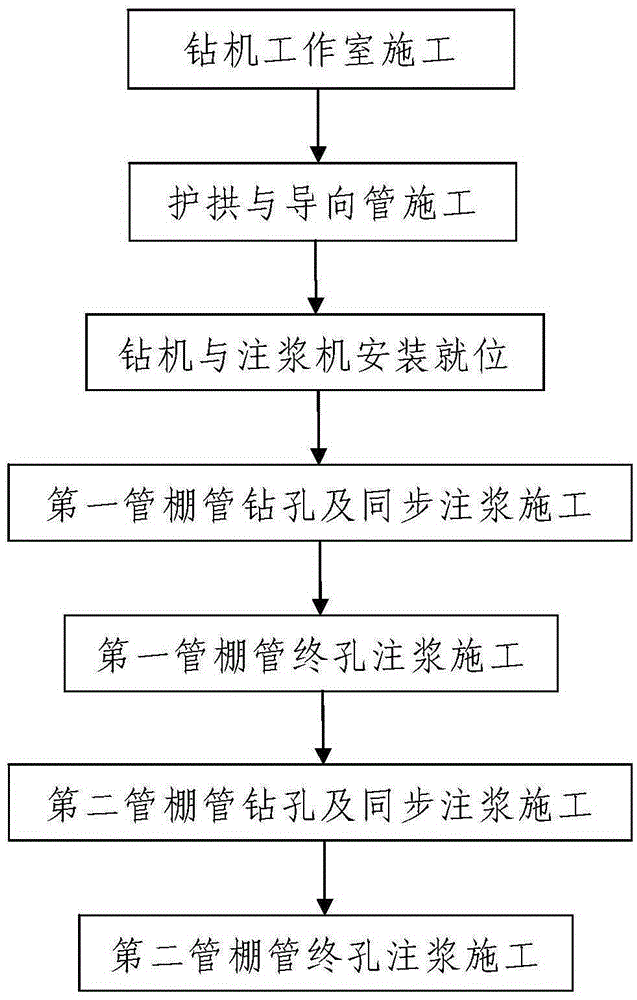

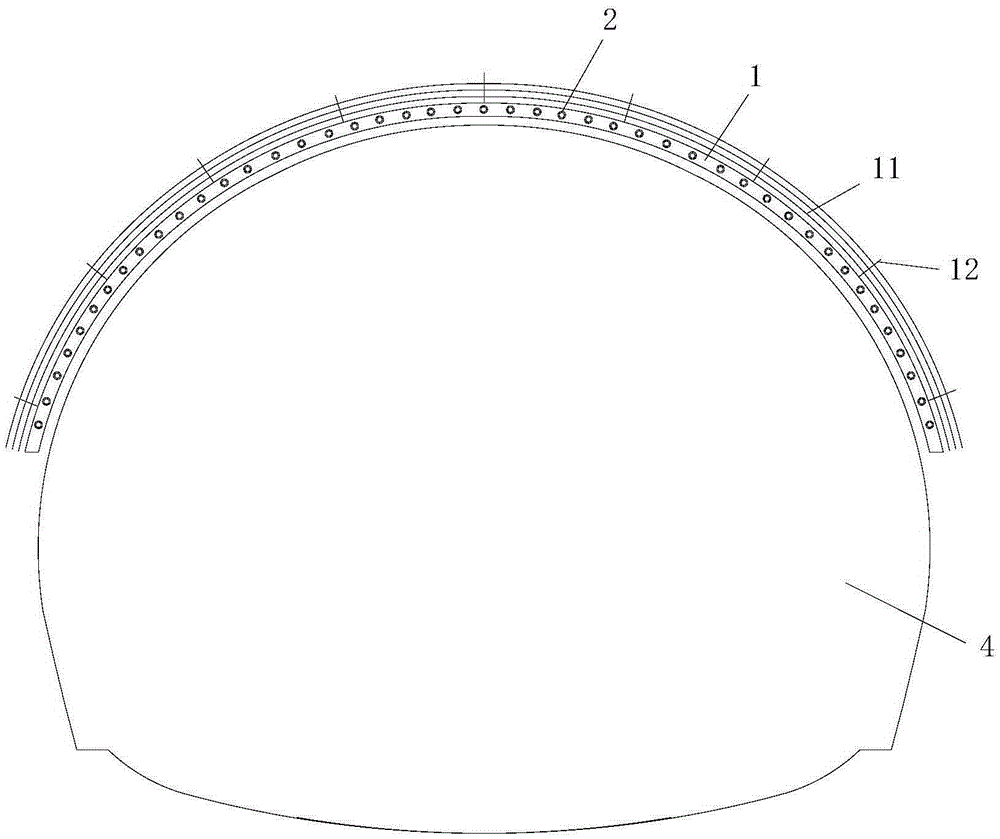

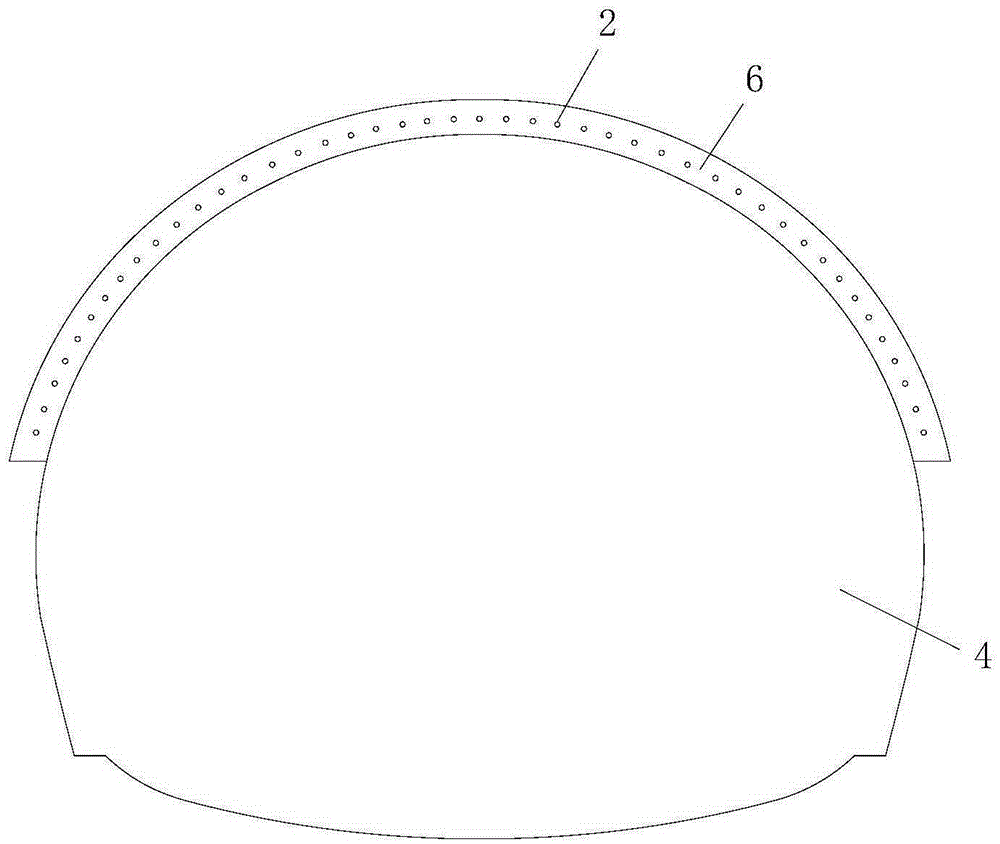

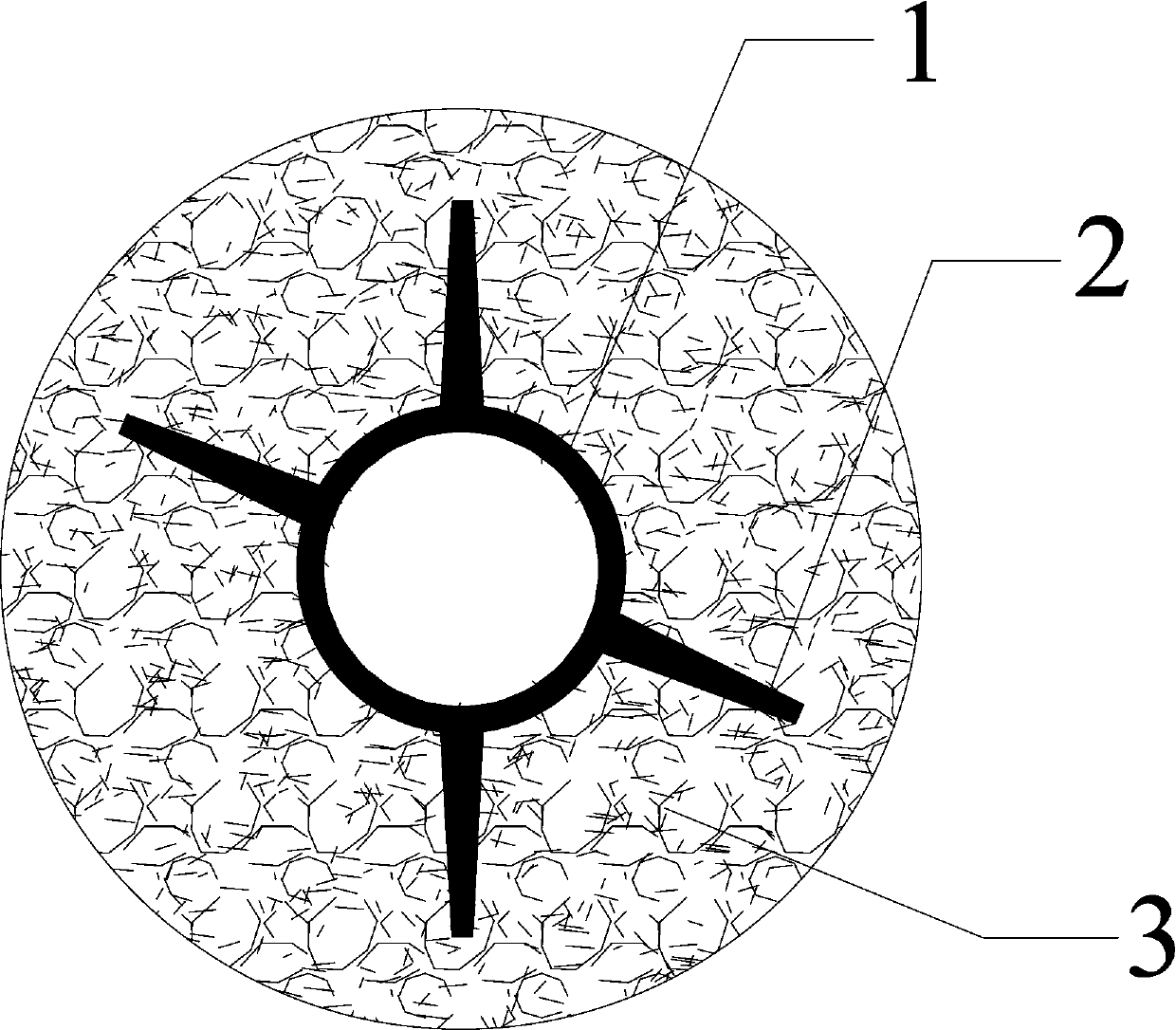

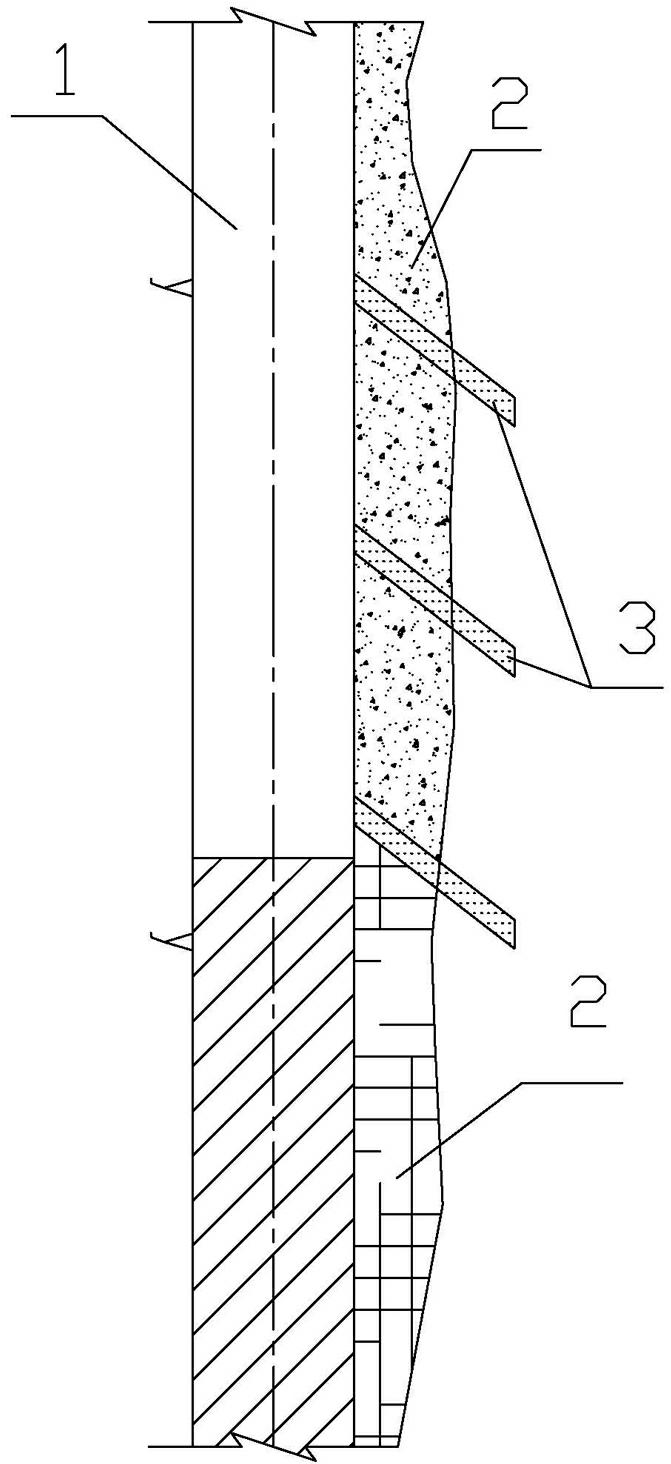

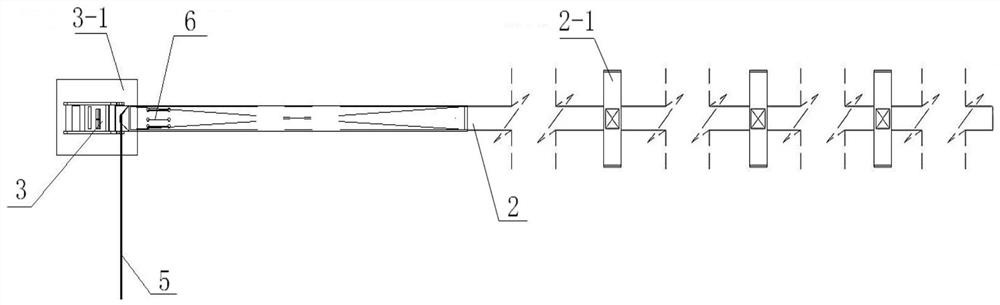

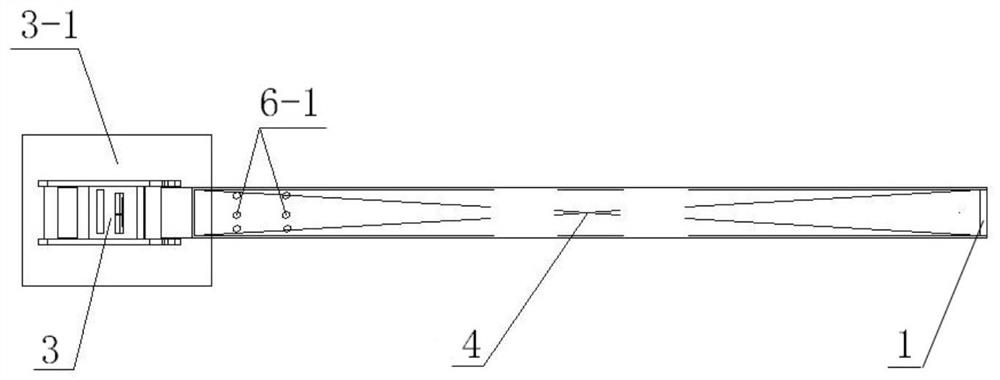

Soft and weak wall rock tunnel advance reinforced support construction method

InactiveCN105298517AThe method steps are simpleEasy to implementUnderground chambersTunnel liningGuide tubeDrilling machines

The invention discloses a soft and weak wall rock tunnel advance reinforced support construction method. When a pipe roof advance support construction is carried out on one segment of the constructed tunnel, the construction method comprises the following steps: (1) support arch and guide pipe construction, wherein a plurality of guide tubes for carrying out guiding on a plurality of pipe roof pipes are arranged on a support arch; each pipe roof pipe comprises a pipe body and a drill bit; each pipe body is formed by splicing a plurality of pipe joints; each drill bit is coaxially arranged at the front end of the pipe body; the pipe joints are spiral steel pipes; the pipe roof pipes are first pipe roof pipes or second pipe roof pipes; and the first pipe roof pipes and the second pipe roof pipes are staggered; (2) drilling machine and slip casting machine installation and emplacement; (3) pipe roof advance support construction, which comprises the following processes: first pipe roof pipe drilling and synchronous grouting construction, final hole grouting construction of the first pipe roof pipes, second pipe roof pipe drilling and synchronous grouting construction and final hole grouting construction of the second pipe roof pipes. The method disclosed by the invention is simple in steps, reasonable in design, simple and convenient to construct and good in support effect; and the soft and weak wall rock tunnel advance reinforced support process can be simply, conveniently and quickly finished.

Owner:中铁二十局集团第二工程有限公司

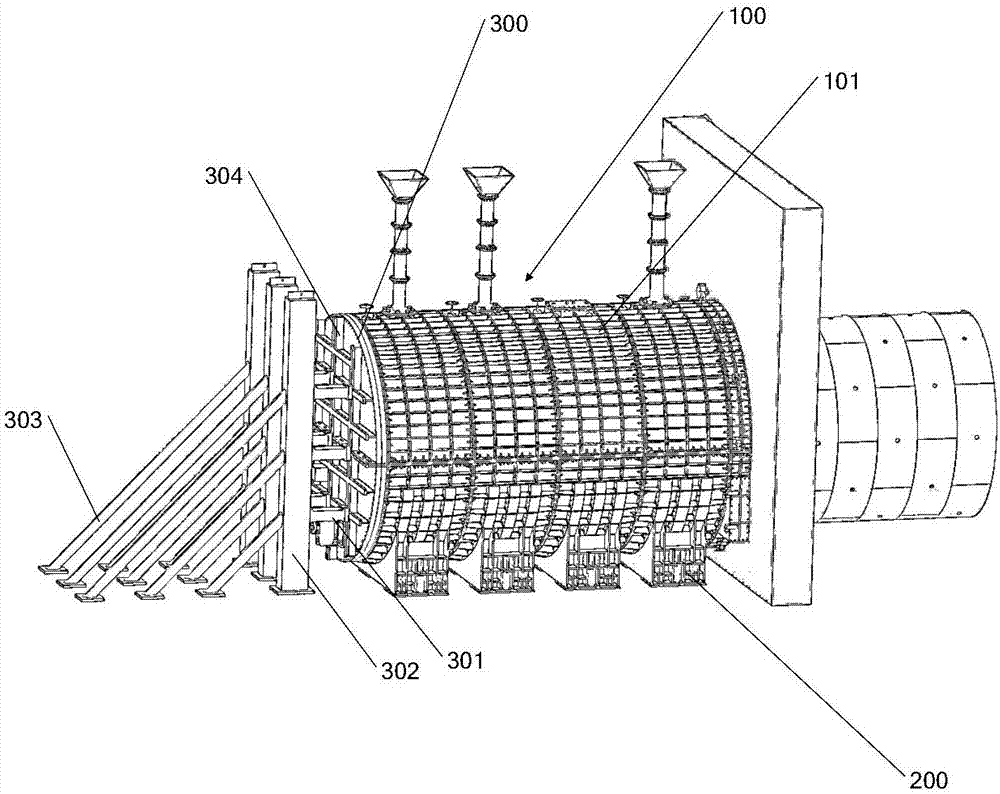

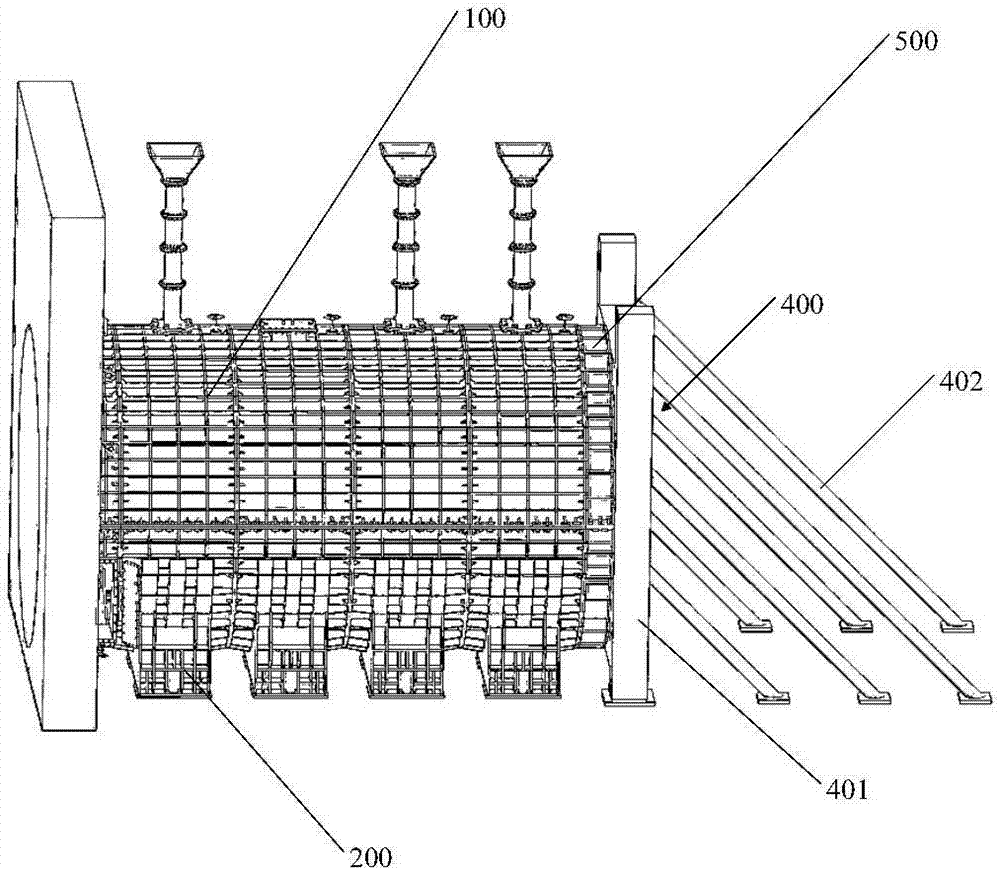

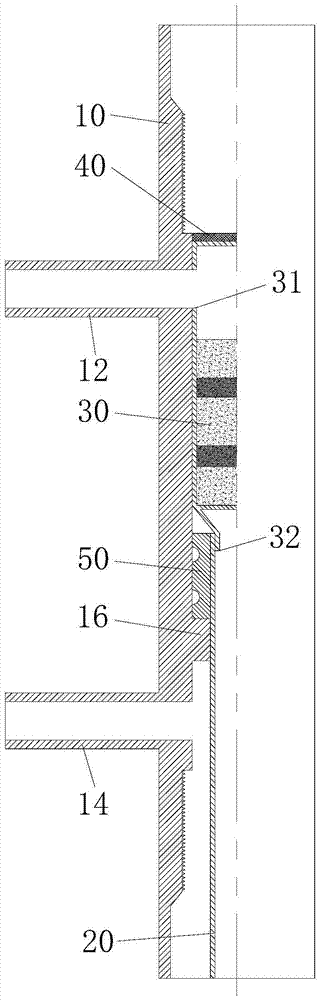

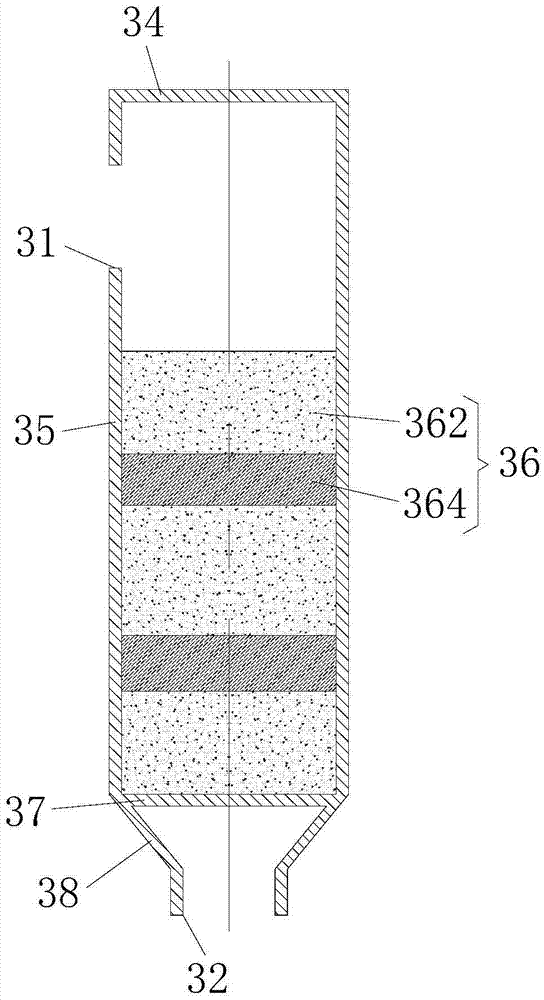

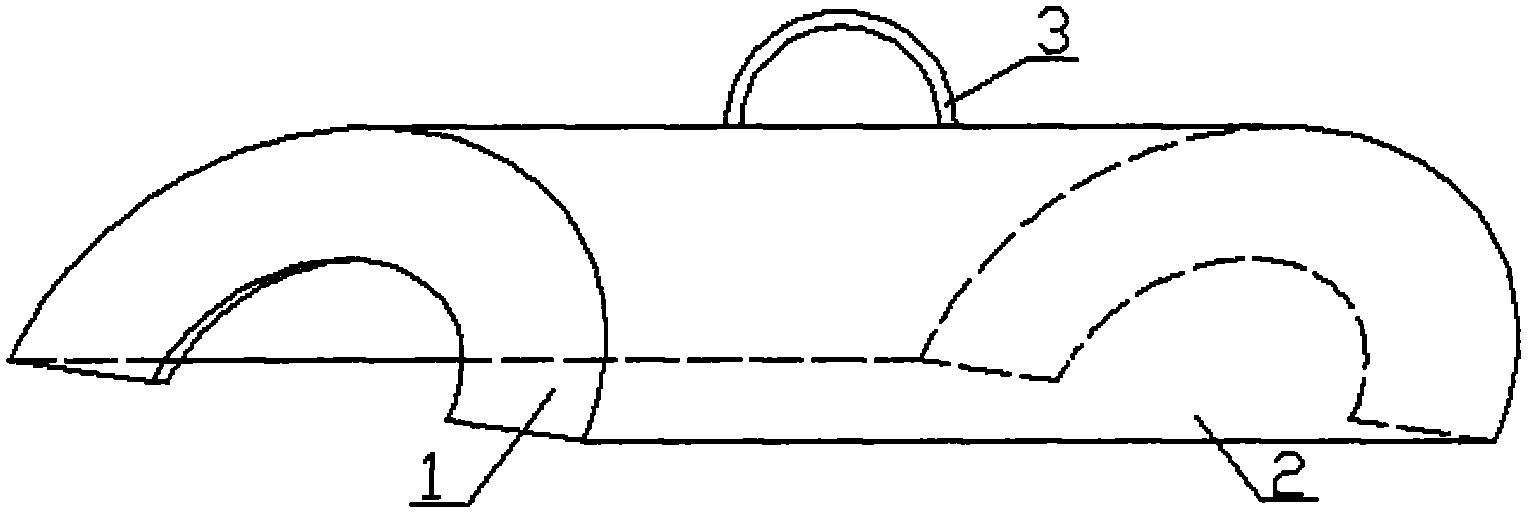

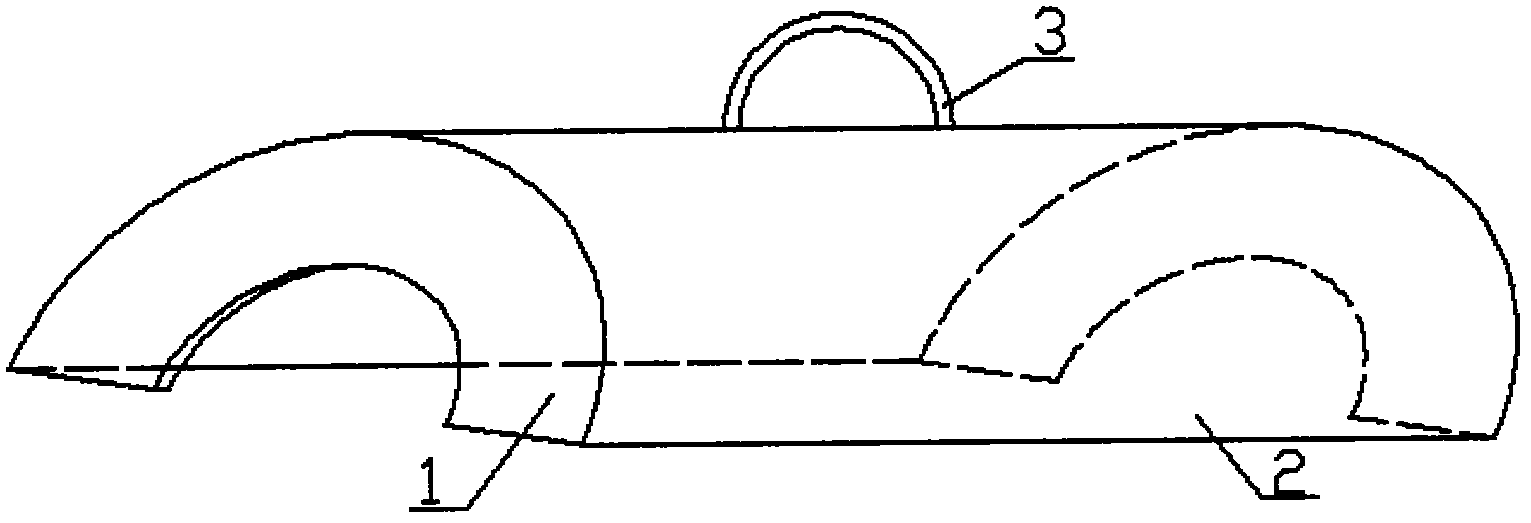

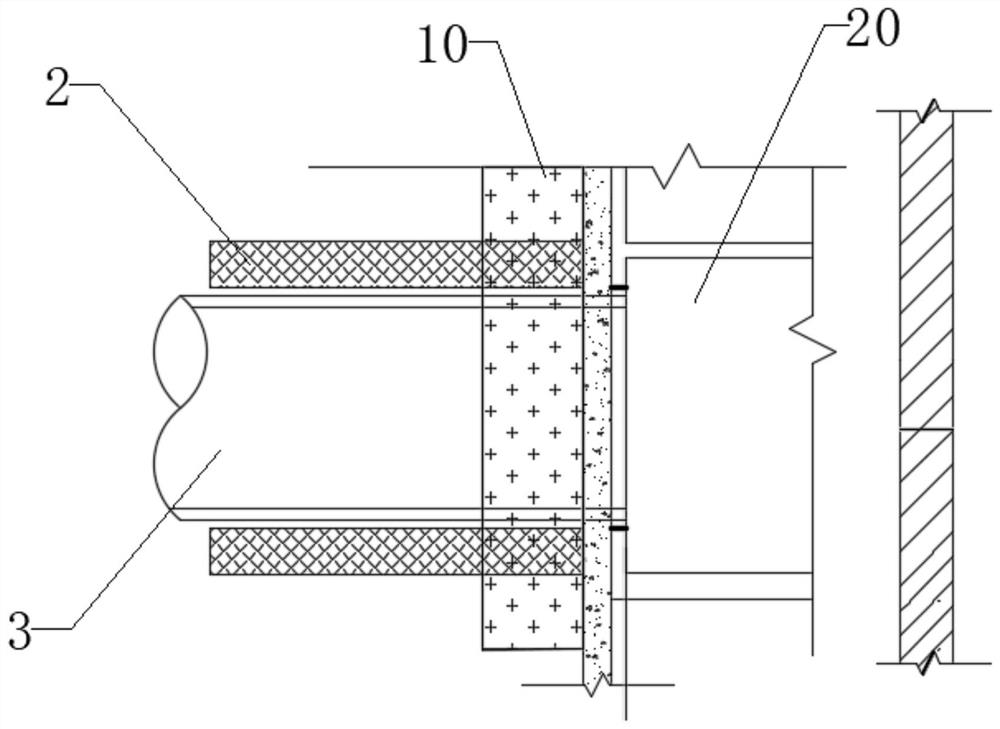

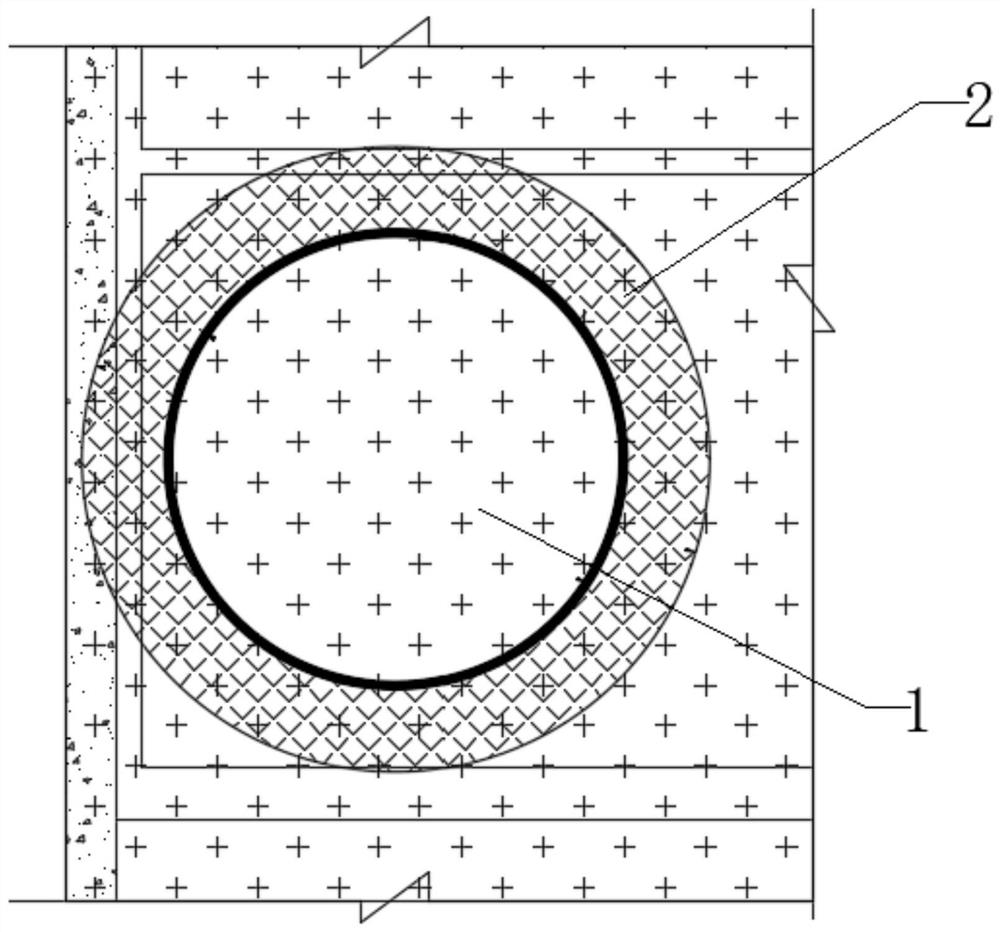

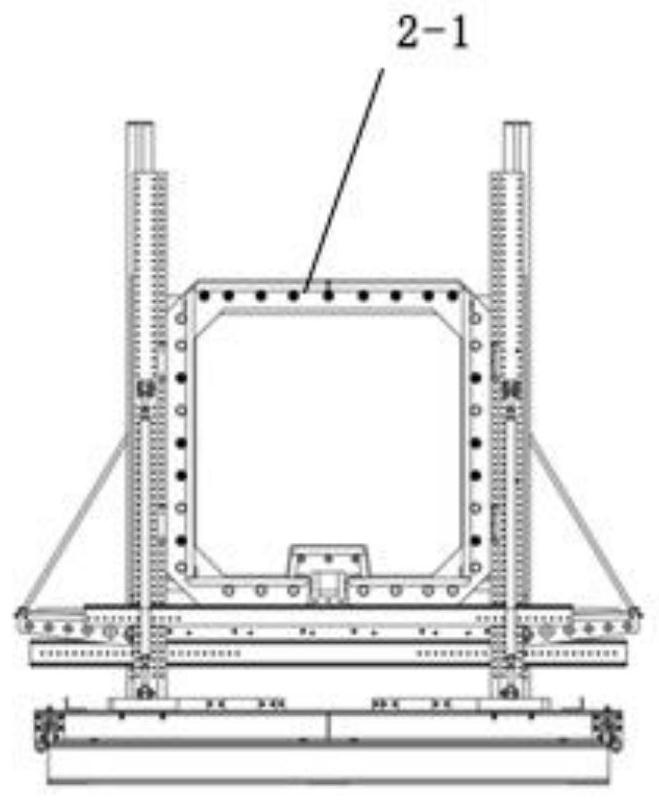

Auxiliary device for starting and receiving of shield machine

The invention discloses an auxiliary device for starting and receiving of a shield machine. The auxiliary device comprises a steel sleeve, a bottom framework, and a bearing board, wherein the steel sleeve is formed by connecting a plurality of sleeve bodies, the bottom framework is arranged at the bottom of the steel sleeve, the bottom framework comprises a plurality of sections, the bottom framework comprises a bottom board that extends along a direction vertical to an axis of the steel sleeve, the bearing board extends along the direction vertical to the axis of the steel sleeve and has a side edge matched with the outer side wall of the sleeve body, the bearing board is vertical to the bottom board, lifting boxes are arranged at two ends of the bottom board, the lifting boxes comprise an external box that is formed by connecting a top board parallel to the bottom board with a part of the bearing board and an internal box that is arranged in the external box, the internal box is internally provided with a hydraulic device, and a plurality of vertical and horizontal steel boards are arranged in a clearance between the internal box and the external box so as to divide the clearance into a mesh structure. The auxiliary device can be used for starting and receiving of the shield machine, also can realize cross-station, lifting and translation of the shield machine, is low in device loss and long in service life.

Owner:淮安市中球盾构技术服务有限公司

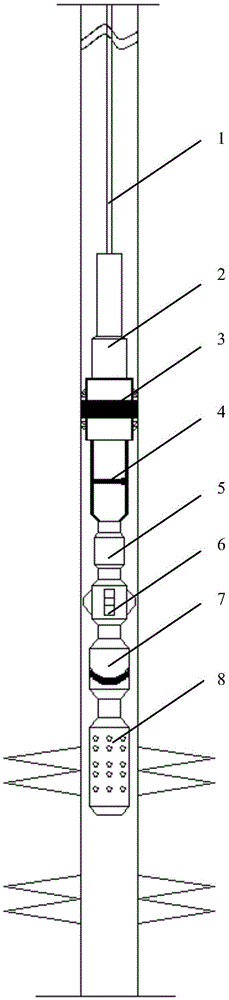

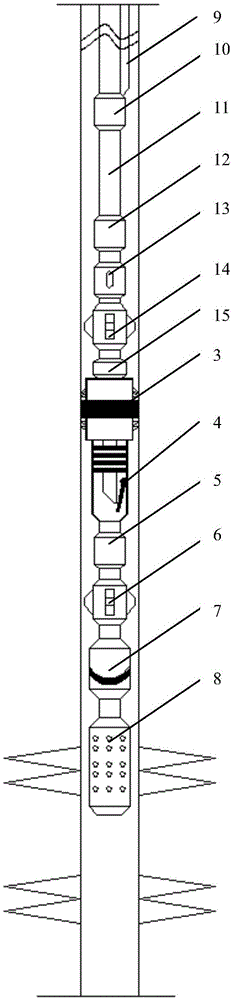

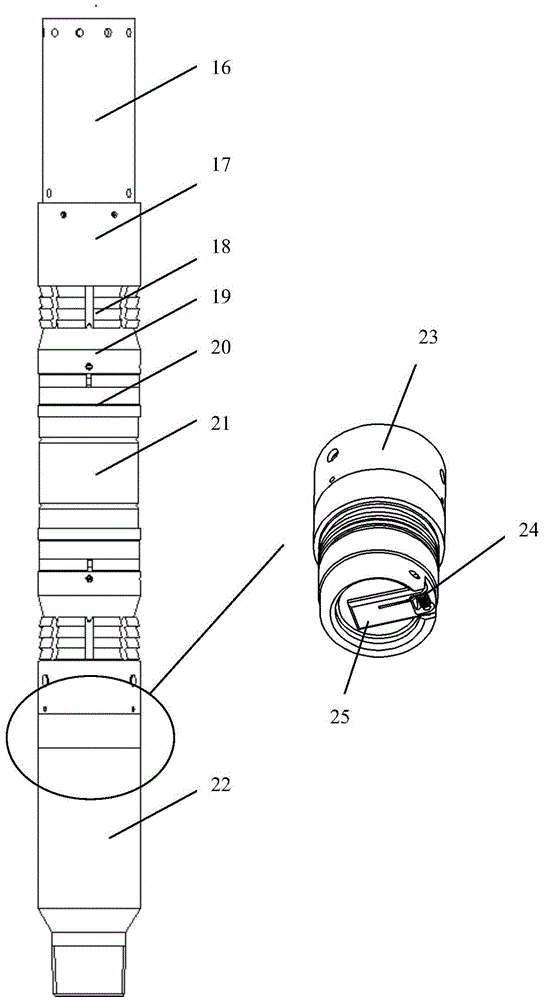

Shale gas well no-killing production tubular column capable of being lifted up and put down under no pressure and construction method

ActiveCN105545221AAvoid construction risks and costsConstruction safetyDrilling rodsWell/borehole valve arrangementsShale gasCheck valve

The invention discloses a shale gas well no-killing production tubular column capable of being lifted up and put down under no pressure and a construction method. The tubular column comprises a packer setting-releasing tubular column body and a tie-back completion tubular column body. The packer setting-releasing tubular column body comprises an up-down tool, a setting tool, a permanent type tube insert packer, a lower working cylinder, a centering guide, a cracking disc and a screen tube. An ejecting type check valve is arranged in the permanent type tube insert packer. The tie-back completion tubular column body comprises an underground hydraulic control safety valve, an upper working cylinder, a circulating slide sleeve, a centering guide and a sealed insert tube. The sealed insert tube is inserted in the packer and pushes open the ejecting type check valve to form a production channel. When needing to be taken out, the tie-back completion tubular column body is lifted up and rotates forwards, the sealed insert tube retreats out of the packer, and the ejecting type check valve is automatically closed. By arranging the ejecting type check valve in the permanent type tube insert packer, after a well shaft is packed by the packer, an upper well shaft is under no pressure; the tubular column can be lifted up and put down through a conventional workover rig, construction efficiency is improved, and under-pressure construction expanses are saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reinforced concrete superposed mixed girder bridge construction method

ActiveCN108547223ALight weight structureAvoid investmentBridge erection/assemblyConcrete beamsBridge deck

The invention discloses a reinforced concrete superposed mixed girder bridge construction method. The method includes the following steps that S1, concrete beam sections are constructed on adjacent piers at the same time, opposite front cantilever sections and opposite rear cantilever sections of the beam sections are formed, start number zero blocks are poured in place through a support, and other number blocks of the concrete beam sections are poured in a suspended mode through a hanging basket; S2, steel beams of reinforced concrete combination sections are hung and connected to the front cantilever sections of the beam sections and the rear cantilever sections of the beam sections; S3, the multiple small-section steel beams are hung section by section to the surfaces of the constructedconcrete beam sections and assembled into a large-section steel beam; S4, a front guide beam and a rear guide beam are installed at the two ends of the large-section steel beam to form a combined steel beam; S5, the large-section steel beam of the combined steel beam is hung; and S6, a bridge floor is paved. The method has the beneficial effects that the method is suitable for the construction conditions with the poor water transport environment and large stormy waves, construction is safe, construction efficiency is high, and the method can be widely applied to the technical field of bridgeconstruction methods.

Owner:CCCC SECOND HARBOR ENG +2

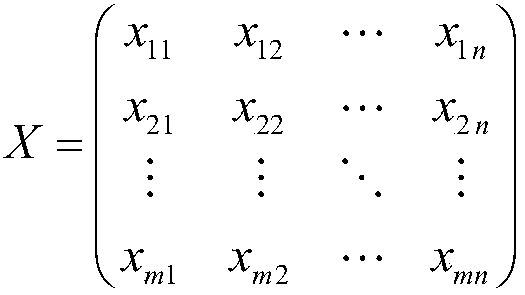

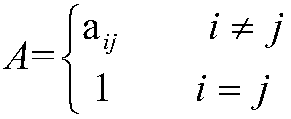

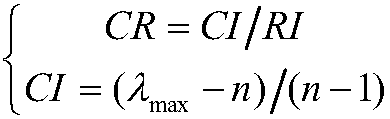

Subjective-and-objective mixed evaluation method for constructing power system cloud platform

InactiveCN107862455AAvoid construction risksResourcesData switching networksExpert opinionElectric power system

The invention relates to a subjective-and-objective mixed evaluation method for constructing a power system cloud platform. The method is characterized by comprising the following steps of1, analyzinginfluence factors for constructing the power system cloud platform, and constructing a power system cloud platform construction and evaluation index system; 2, solving an index weight value by meansof the subjective-and-objective mixed weight determining method in which a hierarchy analysis method and an entropy weight method are combined based on the power system cloud platform construction andevaluation index system which is established in the step 1, and establishing a subjective-and-objective mixed evaluation model for constructing the power system cloud platform; and 3, performing comprehensive evaluation on construction of the power system cloud platform, and obtaining a power system cloud platform construction evaluation valve F. According to the subjective-and-objective mixed evaluation method, the entropy weight method and the hierarchy analysis method are combined; the subjective-and-objective mixed weight determining method in which the hierarchy analysis method and an entropy weight method are combined is selected for solving the weight determining value; and defects of overhigh subjectivity of an expert option in a subjective weight determining method and overhigh randomness of measured data in a subjective weight determining method.

Owner:STATE GRID TIANJIN ELECTRIC POWER +2

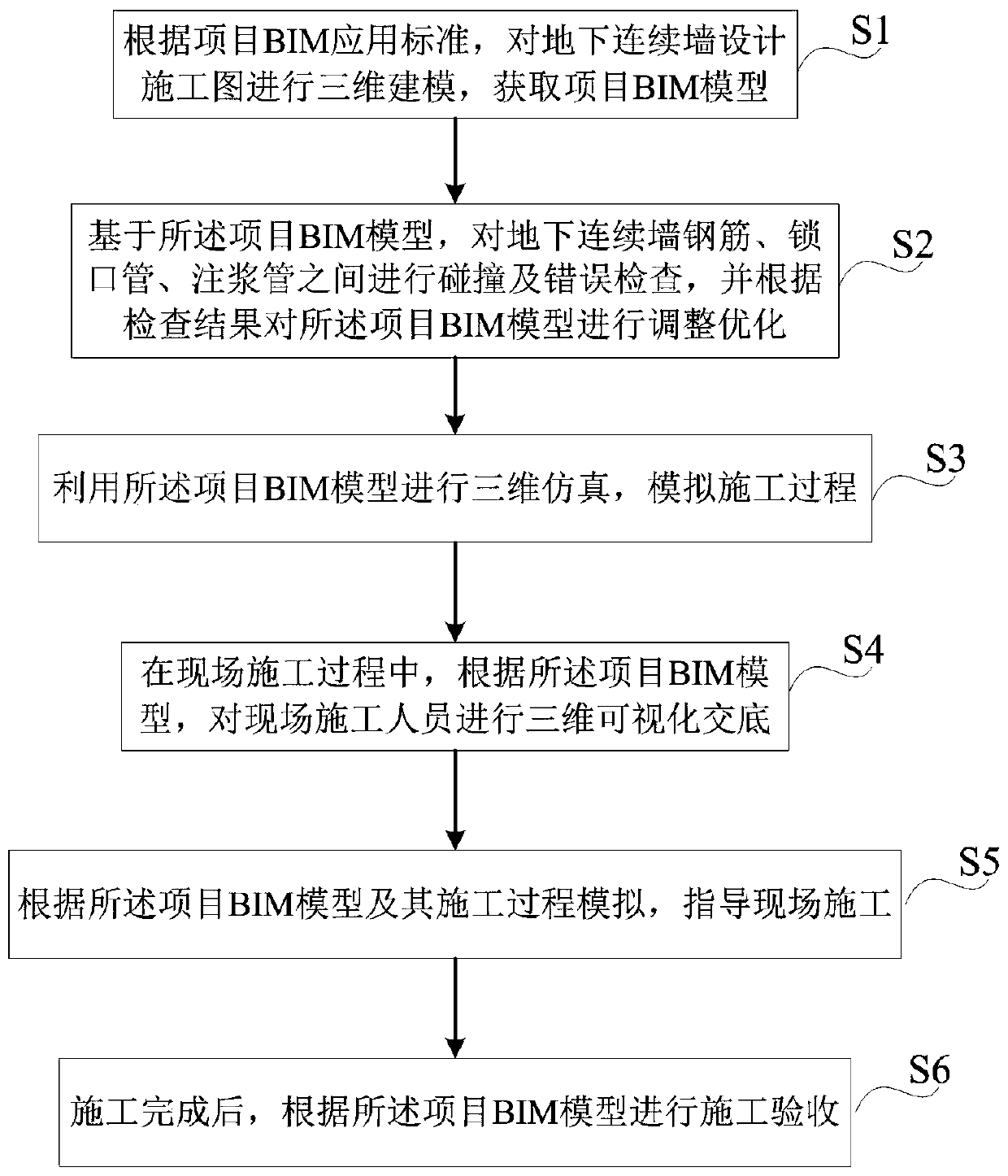

Underground diaphragm wall construction method based on BIM technology

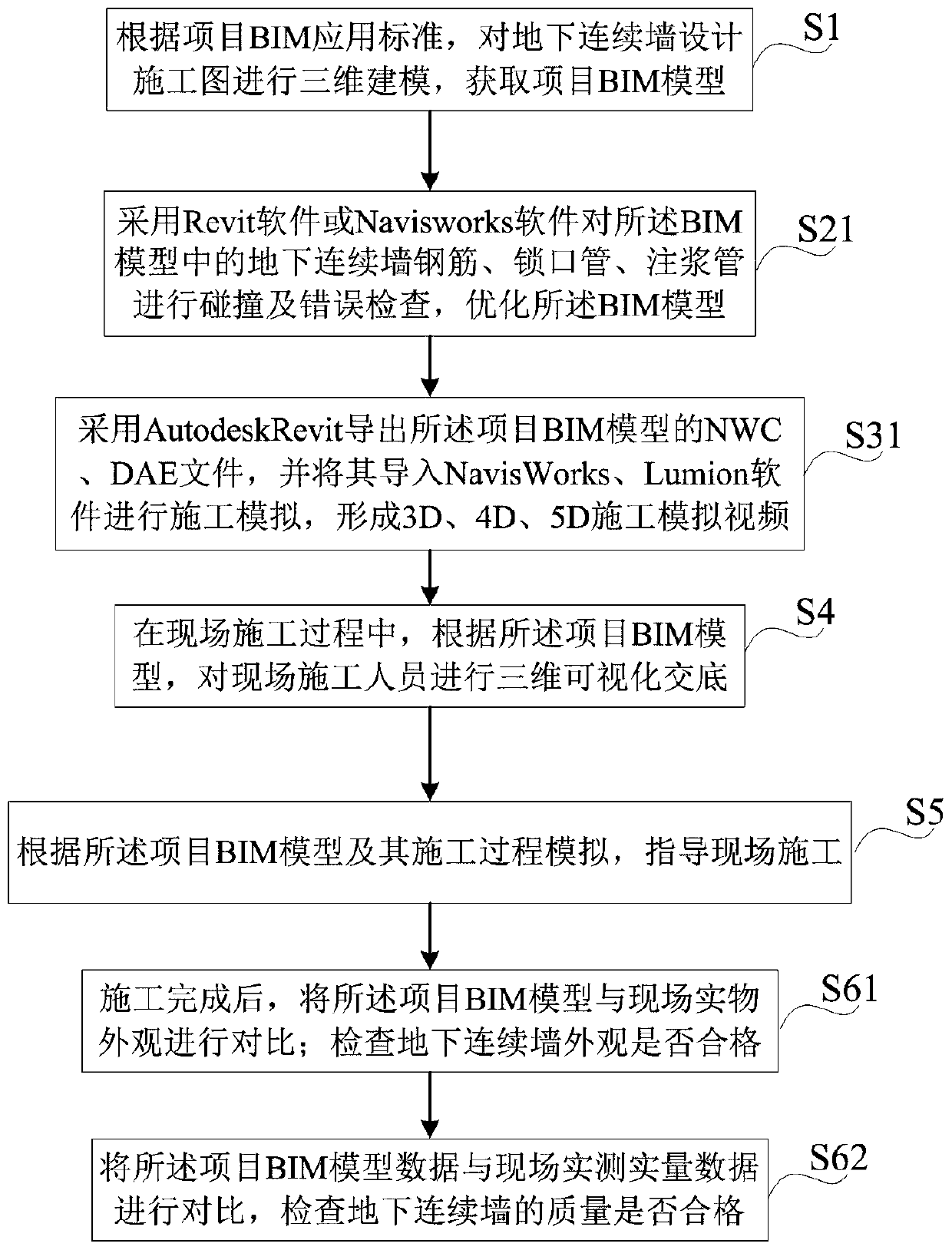

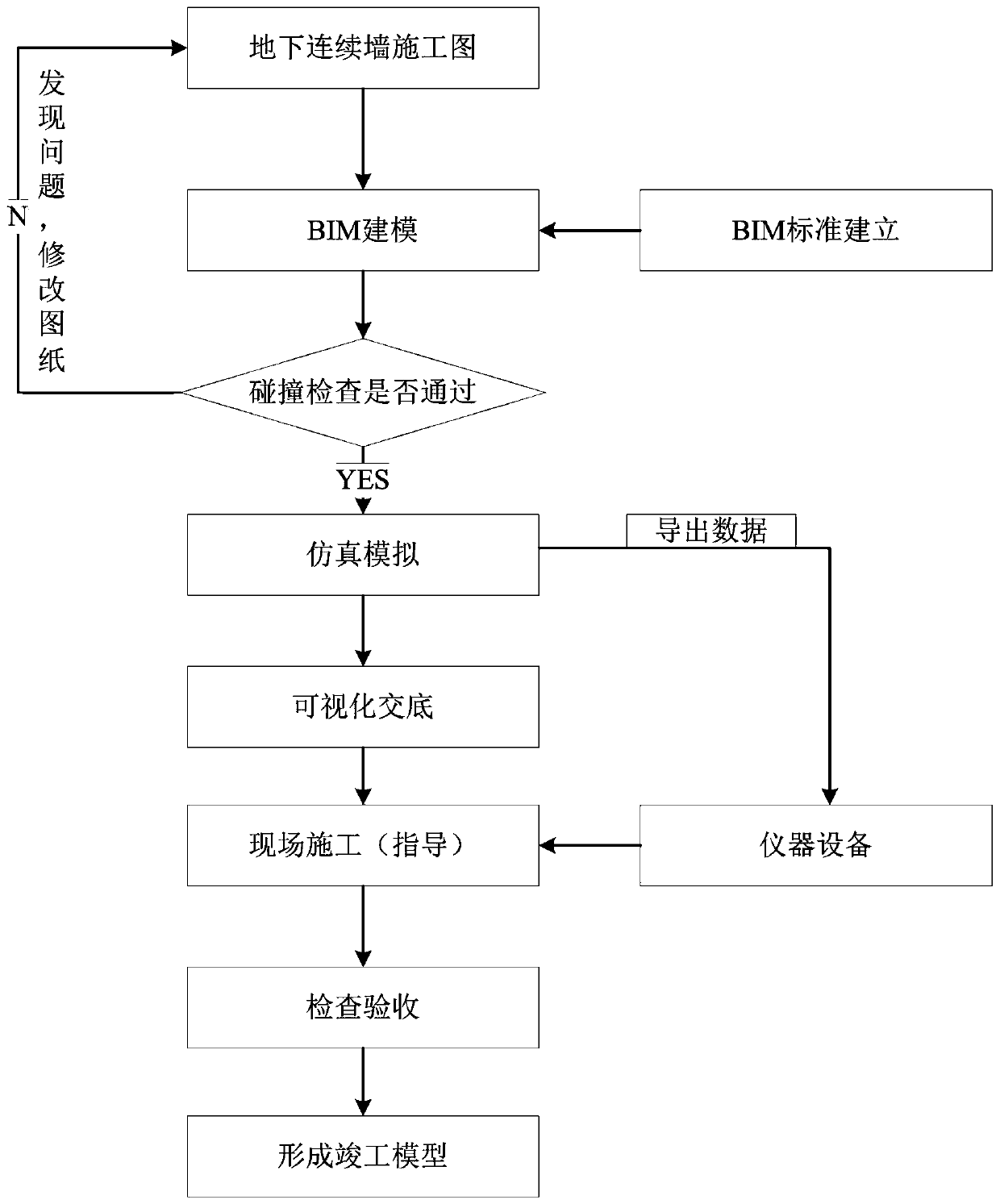

InactiveCN111062081AStrengthen construction managementReduce wasteGeometric CAD3D modellingSlurry wallError check

The invention discloses an underground diaphragm wall construction method based on a BIM technology, and the method comprises the steps: carrying out the three-dimensional modeling of an underground diaphragm wall design and construction drawing according to a project BIM application standard, and obtaining a project BIM model; based on the project BIM model, conducting collision and error inspection on underground diaphragm wall steel bars, fore shaft pipes and grouting pipes, and adjusting and optimizing the project BIM model according to the inspection result; performing three-dimensional simulation by using the project BIM model, and simulating a construction process; in the on-site construction process, conducting three-dimensional visual disclosure on on-site construction personnel according to the project BIM model; guiding field construction according to the project BIM model and the construction process simulation thereof; and after construction is completed, performing construction acceptance according to the project BIM model. By means of the construction method, the construction quality and precision of the underground diaphragm wall are improved, and the construction progress is accelerated.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

Offshore wind electricity single pile-wing plate-rockfill composite foundation and construction method thereof

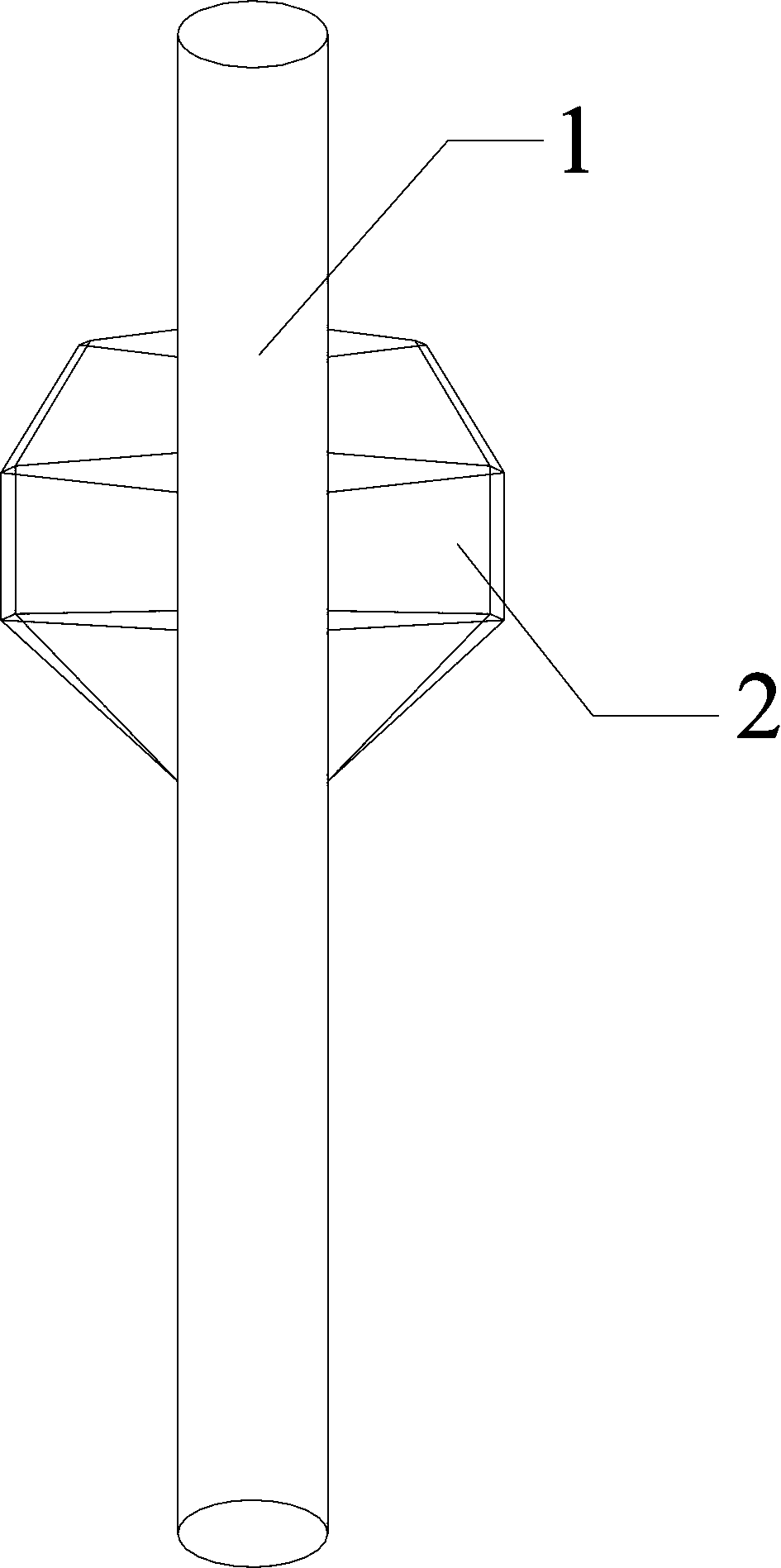

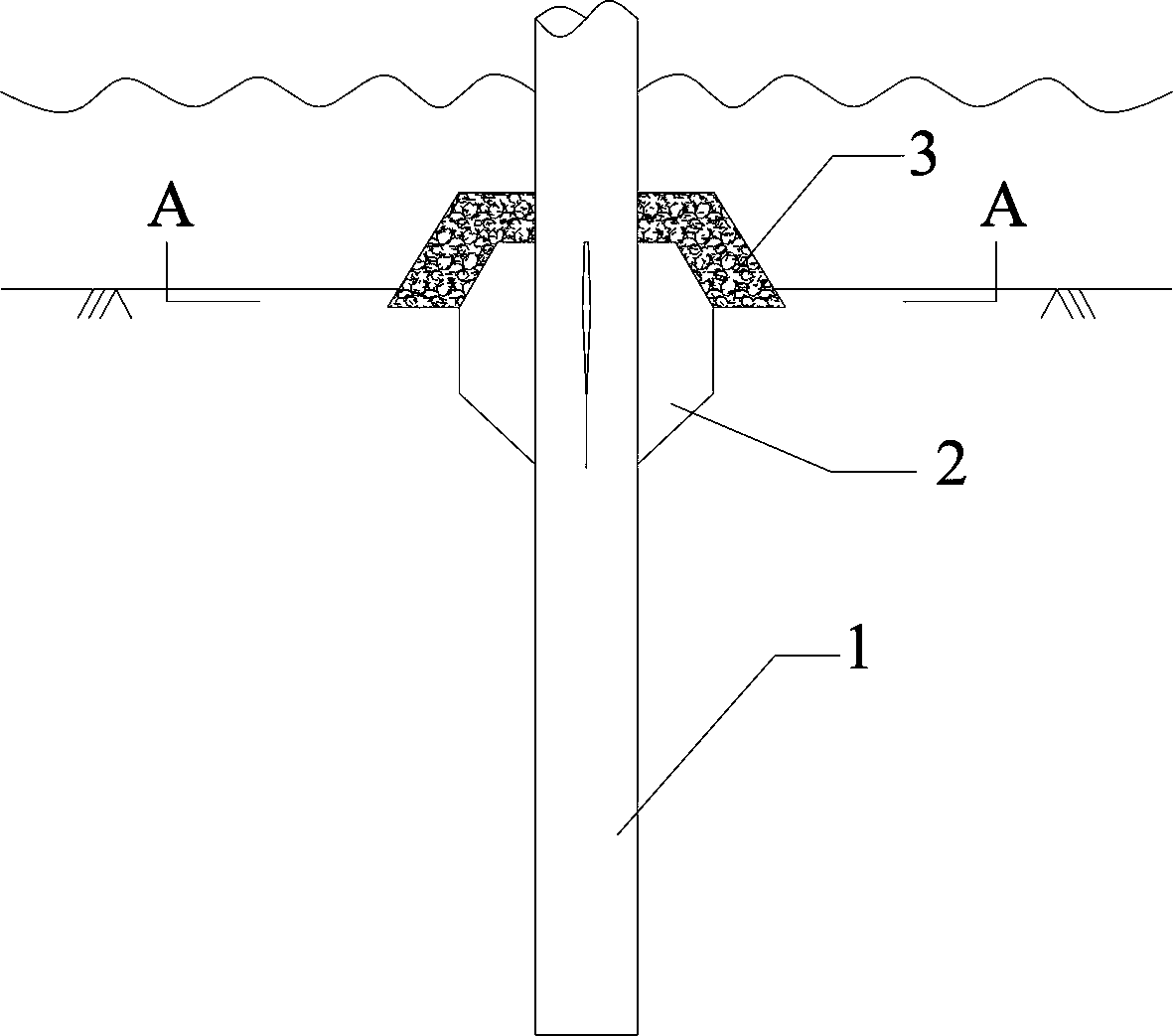

PendingCN110984214AImprove carrying capacityFully mobilize resistanceFoundation engineeringRockfill materialStructural engineering

The invention discloses an offshore wind electricity single pile-wing plate-rockfill composite foundation and a construction method thereof. The foundation comprises a single pile, a wing plate and rockfill, the wing plate is of a conical structure, and is welded to the outer wall of a pile body, the rockfill is formed through dense stacking of the rockfill, the upper end of the wing plate is located in the rockfill, and the lower end of a pile wing is located on a seabed supporting layer. The construction method of the offshore wind electricity single pile-wing plate-rockfill composite foundation comprises the following steps of S1, determining the sizes of the single pile, the wing plate and the rockfill; S2, driving the single pile with the wing plate by the designed anchorage depth; and S3, stacking the rockfill on a seabed nearby the single pile. The problems of the low single pile bearing force, the large pile wing of the wing plate pile, serious foundation washing and the like can be solved, the single pile, wing plate and rockfill combination structure uses pile periphery soil resistance and rockfill friction force, the pile foundation bearing force can be improved, the pile foundation horizontal displacement can be reduced, the wing plate size is reduced, a wing plate stress mechanism is changed, washing of waves and ocean currents to seabed soil can be blocked, and safe and stable running of an offshore wind generation set can be ensured.

Owner:CHINA THREE GORGES CORPORATION

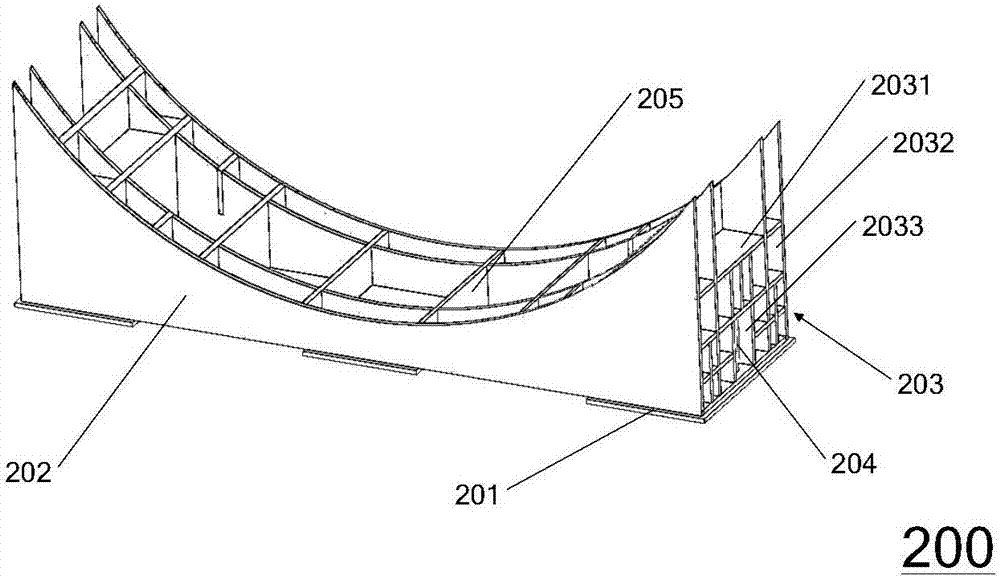

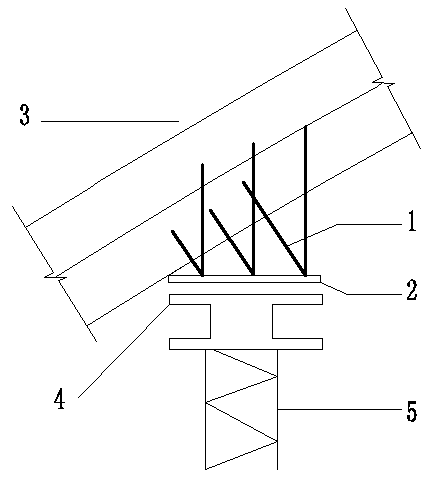

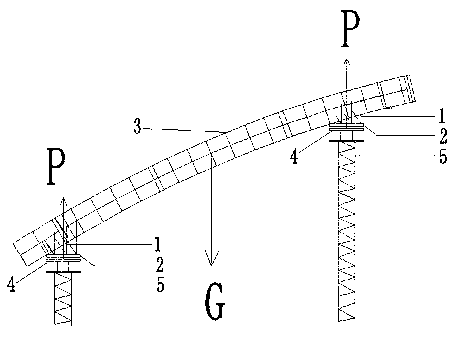

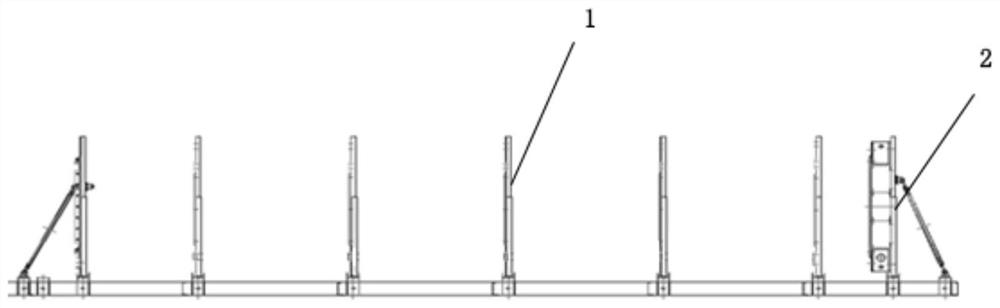

Arch rib of reinforced concrete arch bridge and erection support and manufacture method of arch rib

ActiveCN102995553AImprove stabilityImprove securityBridge structural detailsBridge erection/assemblyReinforced concreteEngineering

The invention discloses an arch rib of a reinforced concrete arch rib, an erection support and a manufacture method of the arch rib. The manufacture method can be applied to manufacture and erection of the arch rib of conventional reinforced concrete bridge and the arch rib of a reinforced concrete tied-arch bridge, and can improve the stability of an arch rib support during erecting the arch rib and after erecting and positioning the arch rib, as well as ensuring the safety in erecting of the arch rib. The arch rib disclosed by the invention comprises an arch rib body; a thrust switching support saddle is arranged in a position, corresponding to the arch rib support, of the arch rib body. The erection support is provided with an I-shaped support body, and the upper end surface of the erection support is a horizontal plane; and the support body is welded at the top part of the arch rib support and is in horizontal contact with a bottom plate of the thrust switching support saddle. The manufacture method of the arch rib comprises the following steps in sequence: pouring concrete in positions, corresponding to the arch rib support, at two ends of the arch rib body in order to fix embedded steel bars; marking a vertical line which is only formed after the arch rib main body is erected on the arch rib body before the erection is carried out; and welding the bottom plate with the lower ends of the embedded steel bars. By adopting the manufacture method, the safety in construction can be improved, and the risk in construction can be avoided.

Owner:中石化石油工程技术服务有限公司 +1

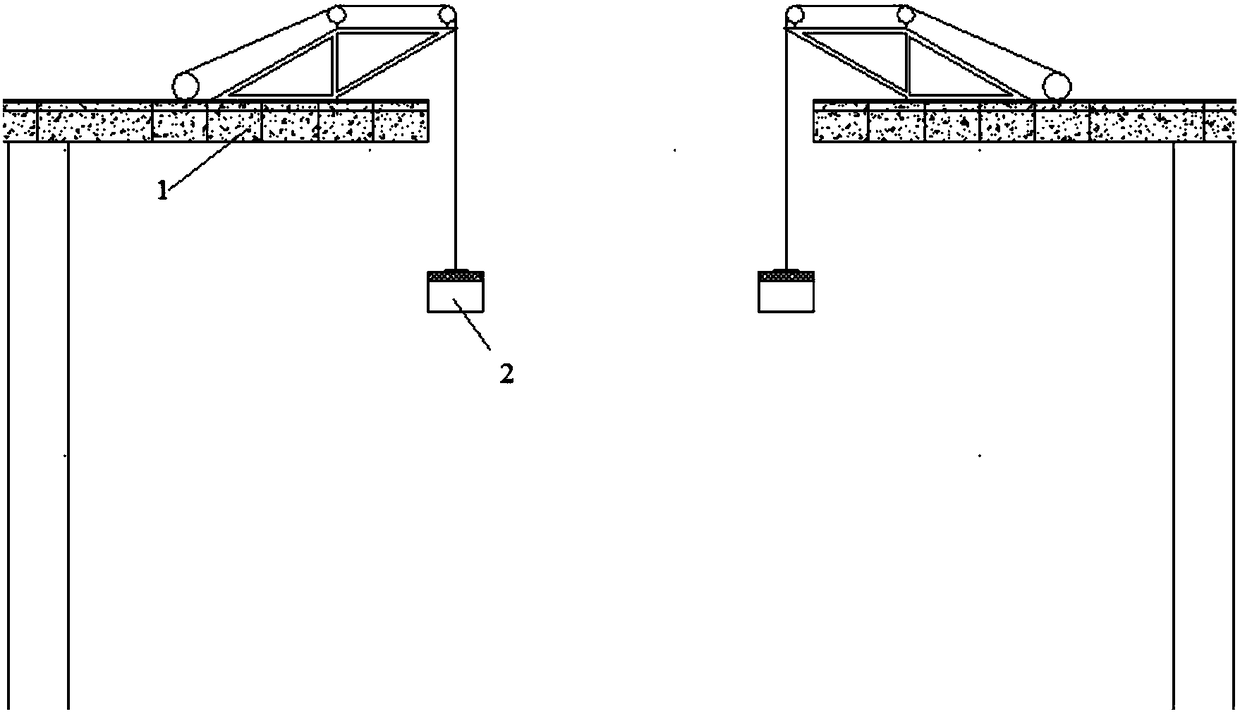

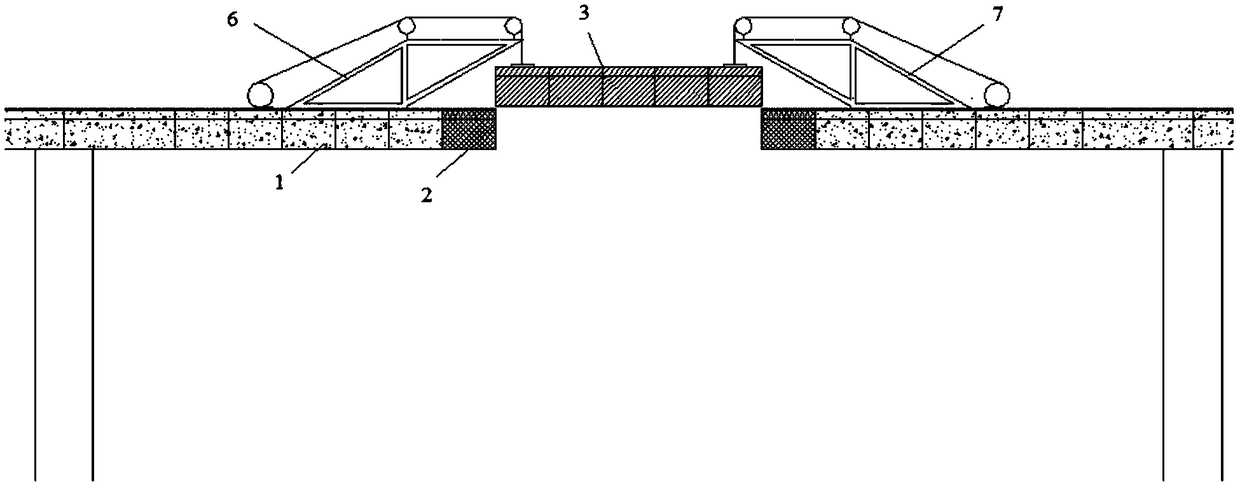

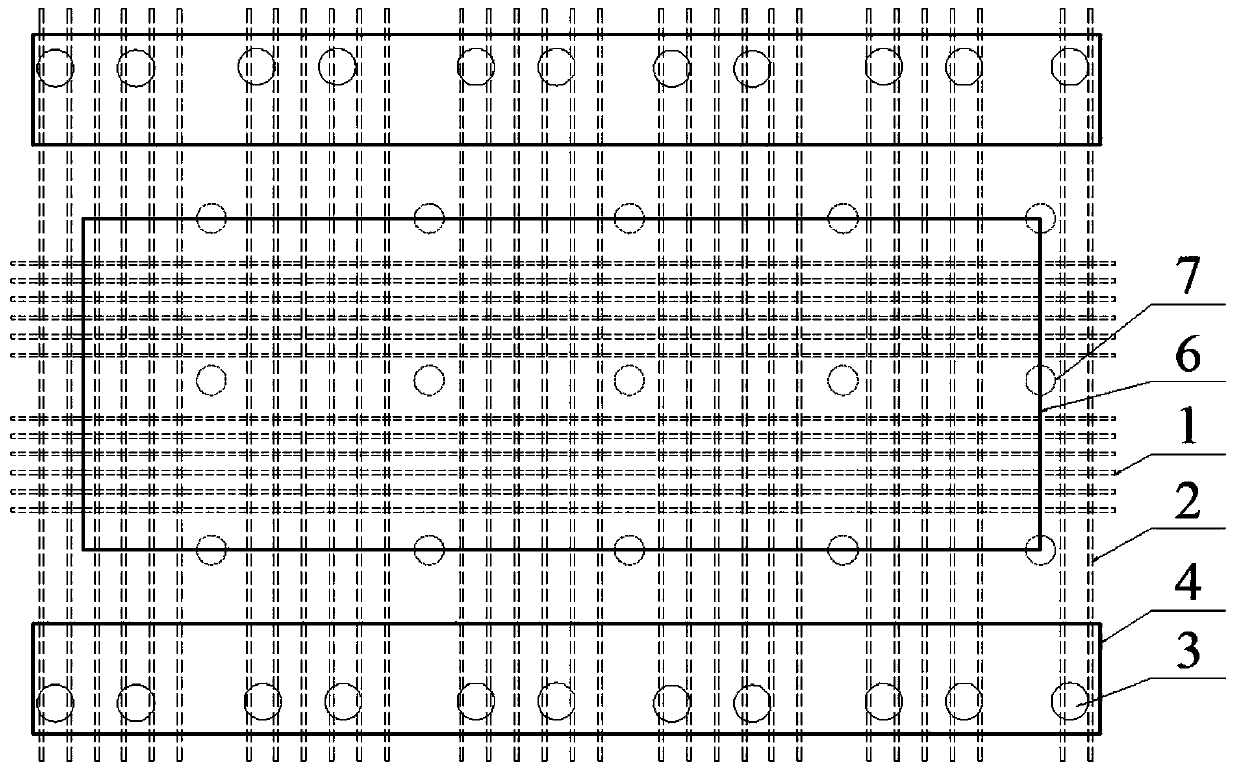

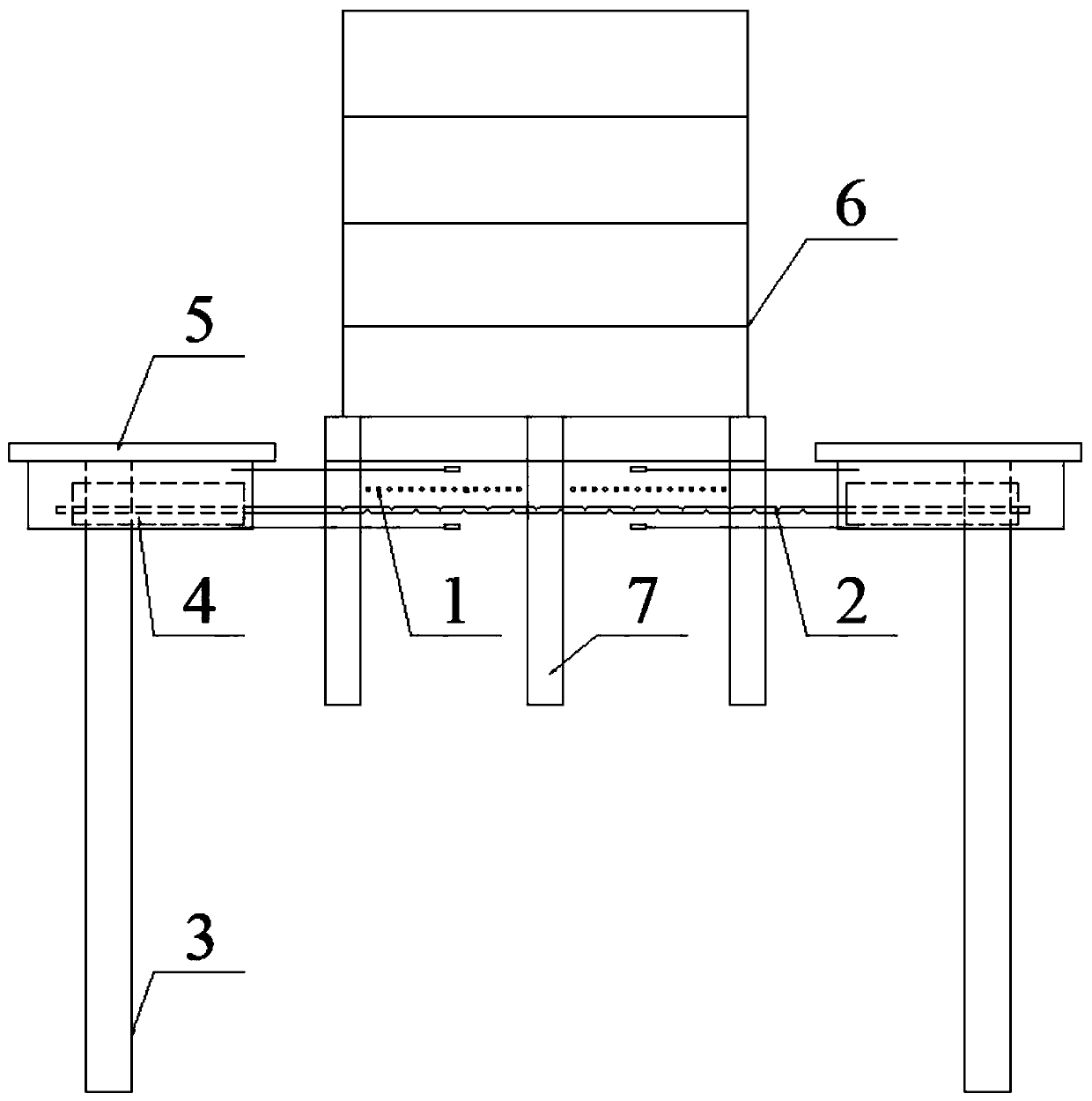

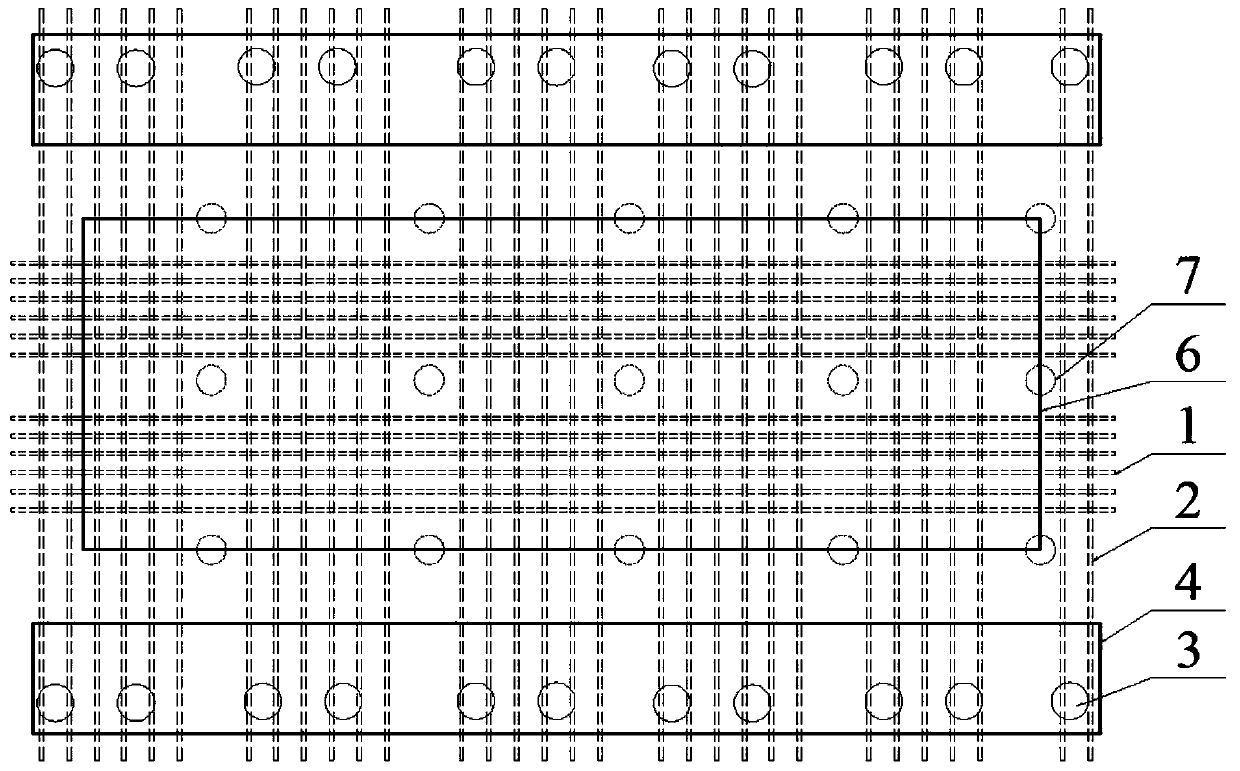

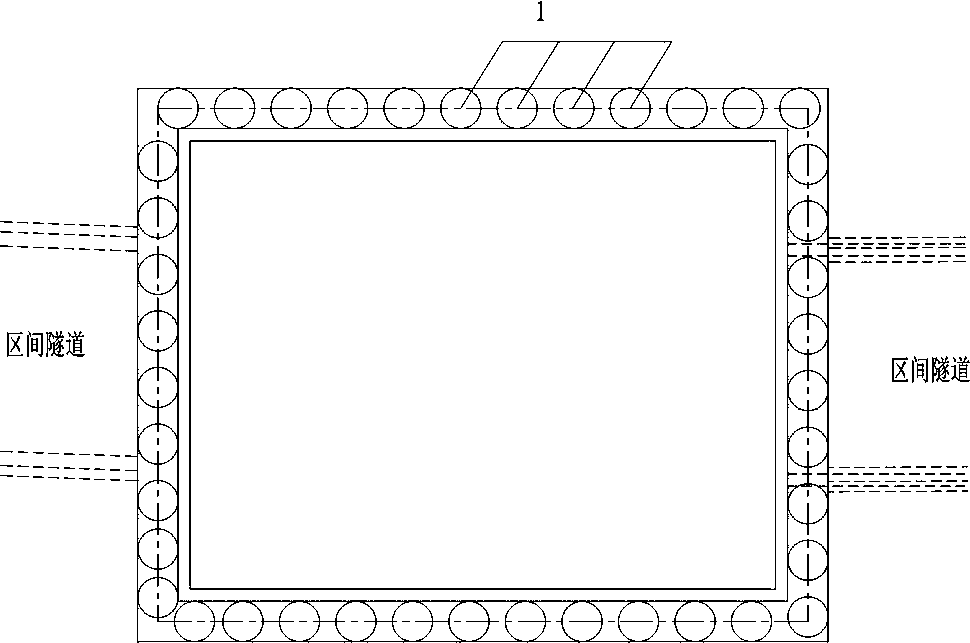

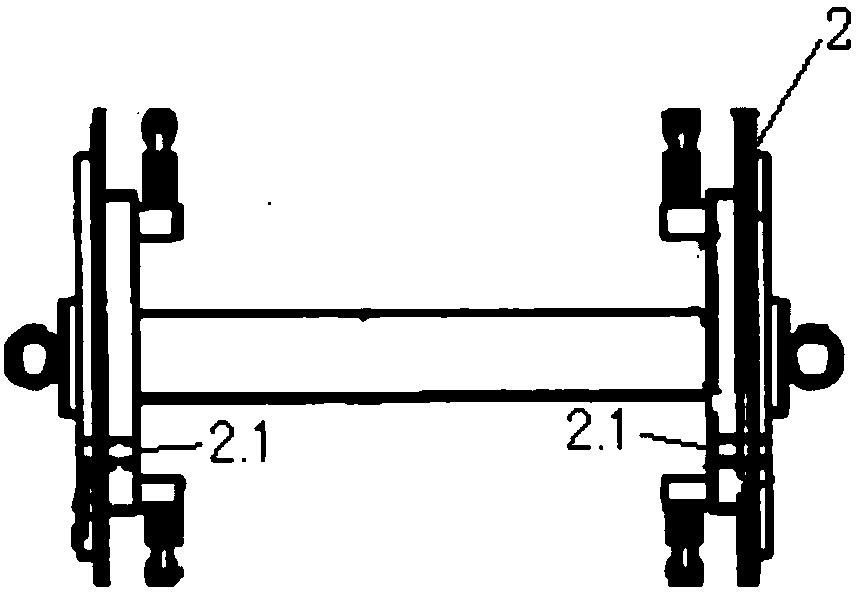

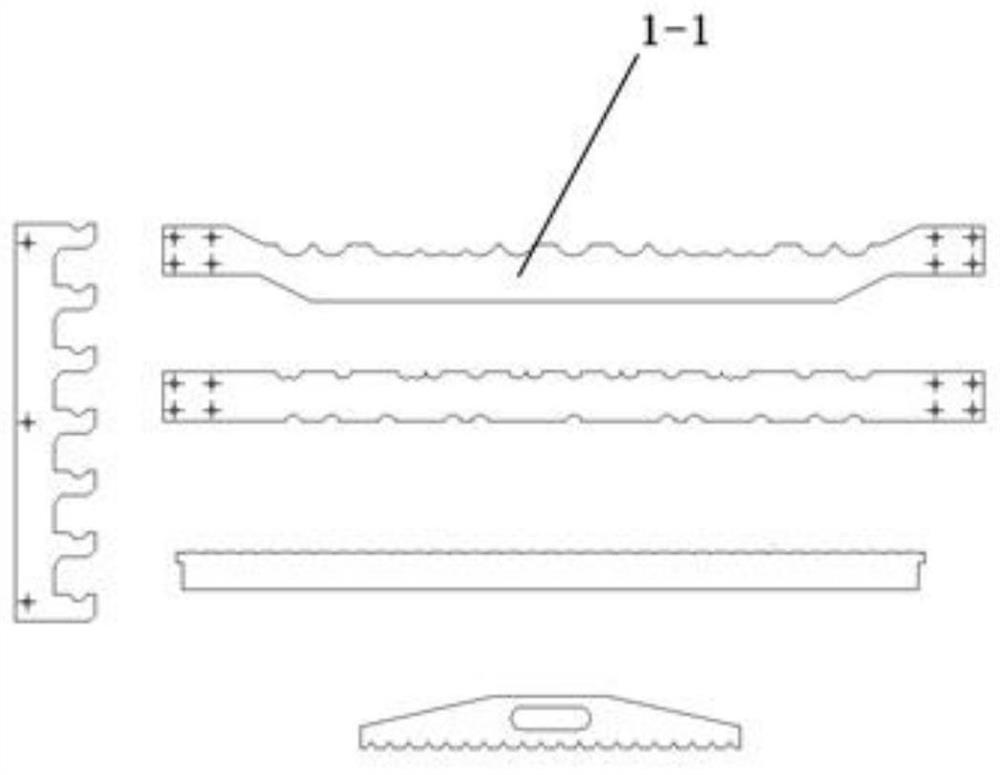

Rapid tensioning device and method of prefabricated members on both sides of prefabricated station bottom plate

ActiveCN107345401ARapid positioningImprove tensioning efficiencyArtificial islandsUnderwater structuresBlock and tackleArchitectural engineering

The invention discloses a rapid tensioning device of prefabricated members on both sides of a prefabricated station bottom plate. The rapid tensioning device comprises a steel wire rope I and a steel wire rope II, wherein the steel wire rope I passes through tensioning holes I of the prefabricated members on the both sides, the steel wire rope II passes through tensioning holes II of the prefabricated members on the both sides, the upper end of the steel wire rope I and the upper end of the steel wire rope II are fixed respectively by reinforcing bars, both ends of a double-spliced angle iron are respectively connected to the lower end of the steel wire rope I and the lower end of the steel wire rope II, a pulley block of a sliding type electric hoist is arranged on the double-spliced angle iron, and a tensioning penetrating jack is connected to the lower end of the sliding type electric hoist. The invention further provides a rapid tensioning construction method. According to the rapid tensioning device, the construction risk is avoided, and the effect that the jack is rapidly positioned and is rapidly tensioned is achieved; the rapid tensioning device has the advantages of wide source of materials, simplicity in manufacturing, convenience in operation and high tensioning efficiency, and more economic benefits are provided for an enterprise; and the problem of large difficulty in operation is solved, the safety risk during construction is reduced, and the construction efficiency is improved.

Owner:SUBWAY ENG CO LTD OF CHINA RAILWAY 16TH CONSTR BUREAU +1

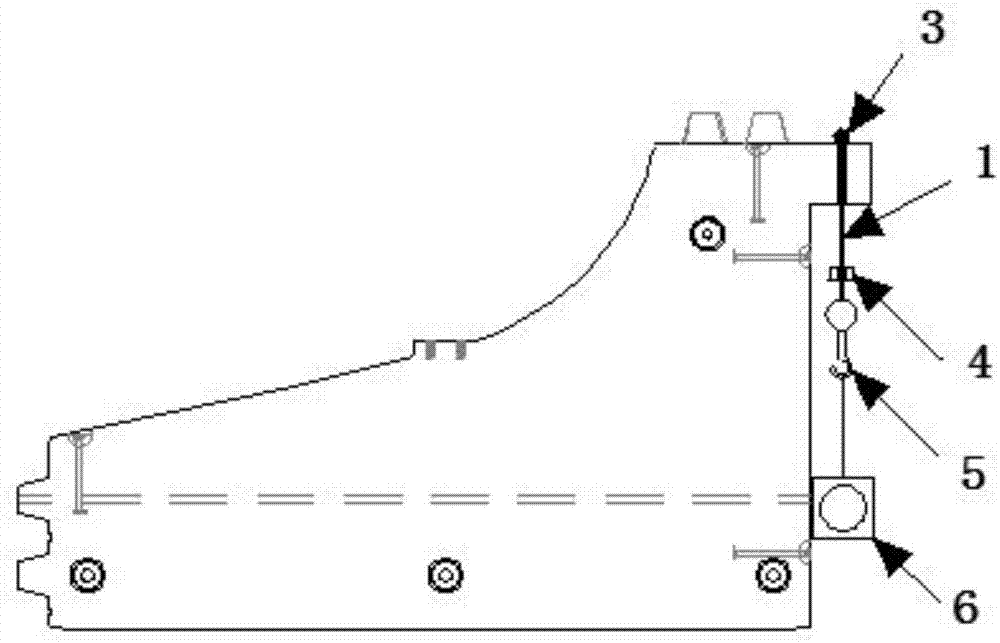

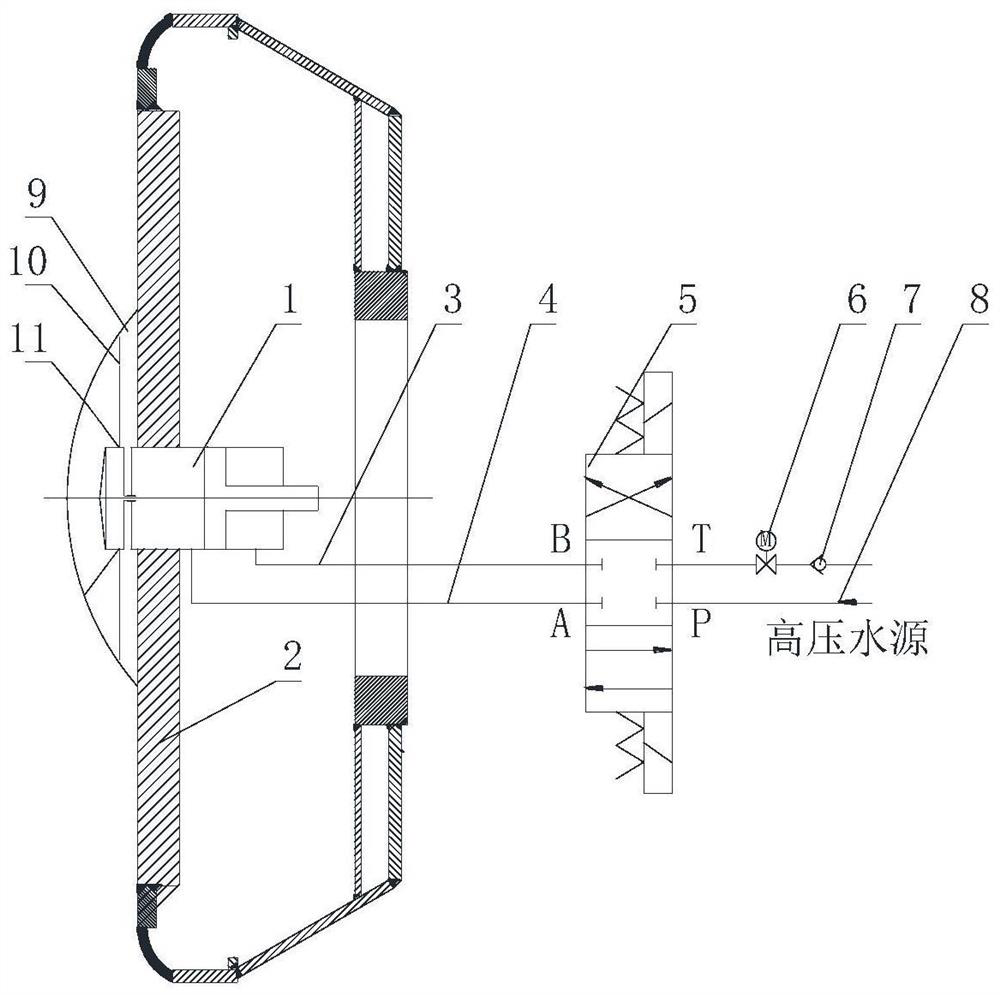

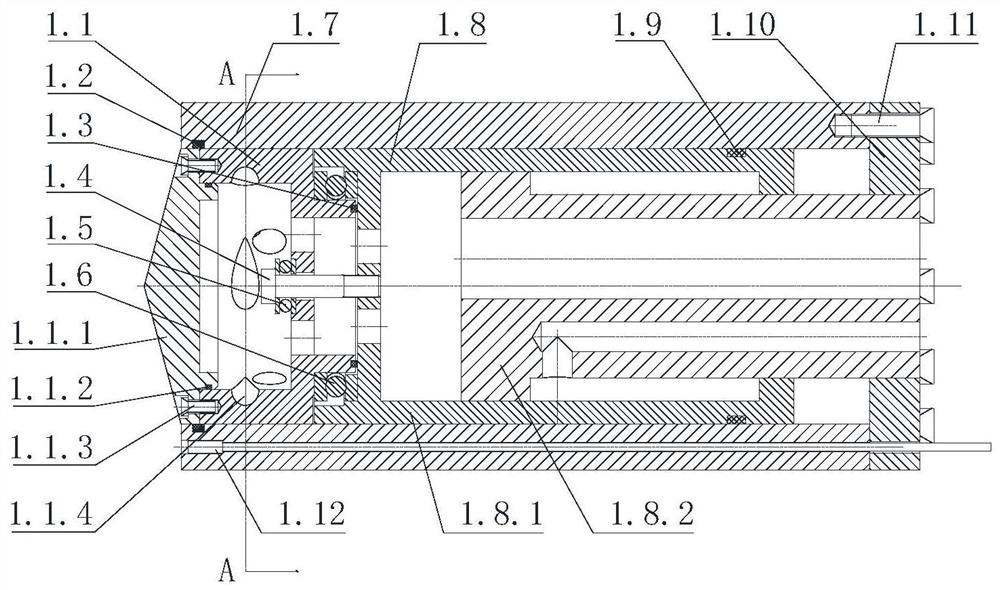

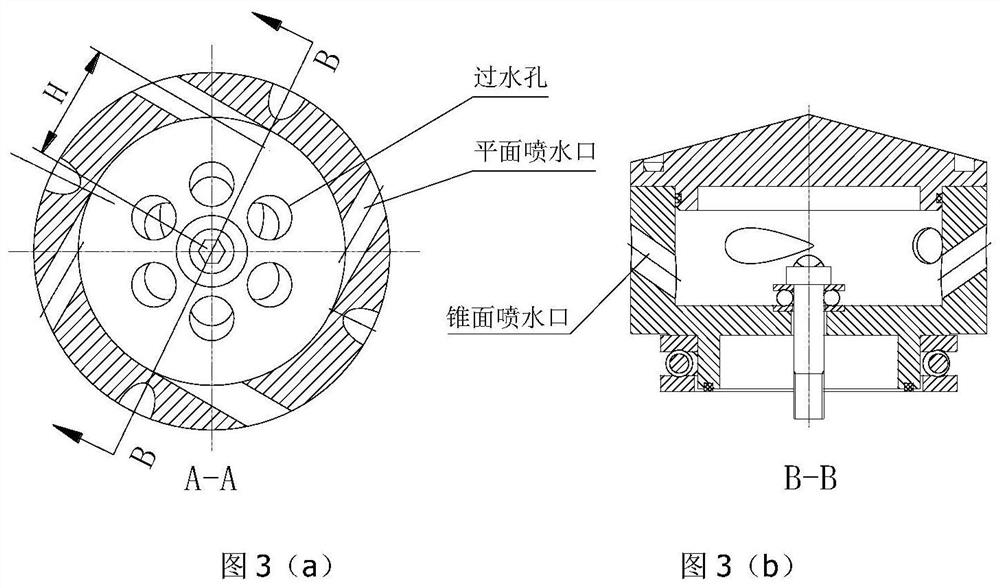

Shield tunneling machine cutter head with mud cake detecting and removing device and using method

The invention provides a shield tunneling machine cutter head with a mud cake detecting and removing device and a using method. The mud cake detecting and removing device on the cutter head comprisesa rotary spray head, a sleeve, a telescopic cylinder, an end cover, a temperature sensor, a thrust bearing, a sealing ring and a fastener. When the cutter head is provided with a mud cake, the mud cake area and an excavation face are continuously rubbed to enable the temperature of the cutter head to rise, the cutter head stops rotating when abnormal temperature rise is monitored through the temperature sensor, an electric valve is opened, and mud cake removing operation is conducted. According to the shield tunneling machine cutter head with the mud cake detecting and removing device and theusing method, an electromagnetic reversing valve connected with the mud cake detecting and removing device is adjusted to the left position, high-pressure water enters a rodless cavity, a cylinder barrel of the telescopic cylinder is pushed to extend outwards to penetrate into the mud cake, when a spray opening is exposed out of the sleeve, the high-pressure water flow pushes the rotary spray headto rotate, and muck around the spray head is removed; and after mud cake removing is completed, the reversing valve is adjusted to the right position, the high-pressure water enters a rod cavity of the telescopic cylinder to enable the cylinder barrel to retract into the sleeve, detecting and automatic rapid removing of the cutter head mud cake are achieved, the risk of under-pressure bin entering operation is avoided, and the efficiency and safety of shield construction are improved.

Owner:STATE KEY LAB OF SHIELD & TUNNELING TECH +1

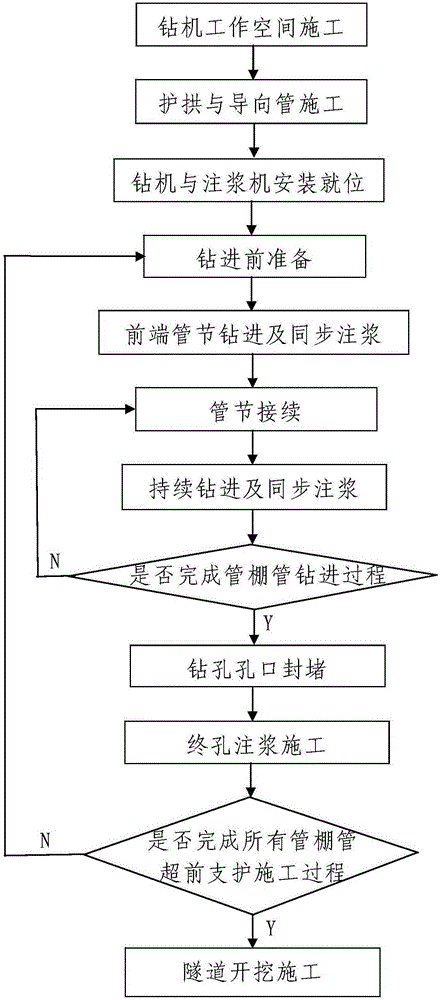

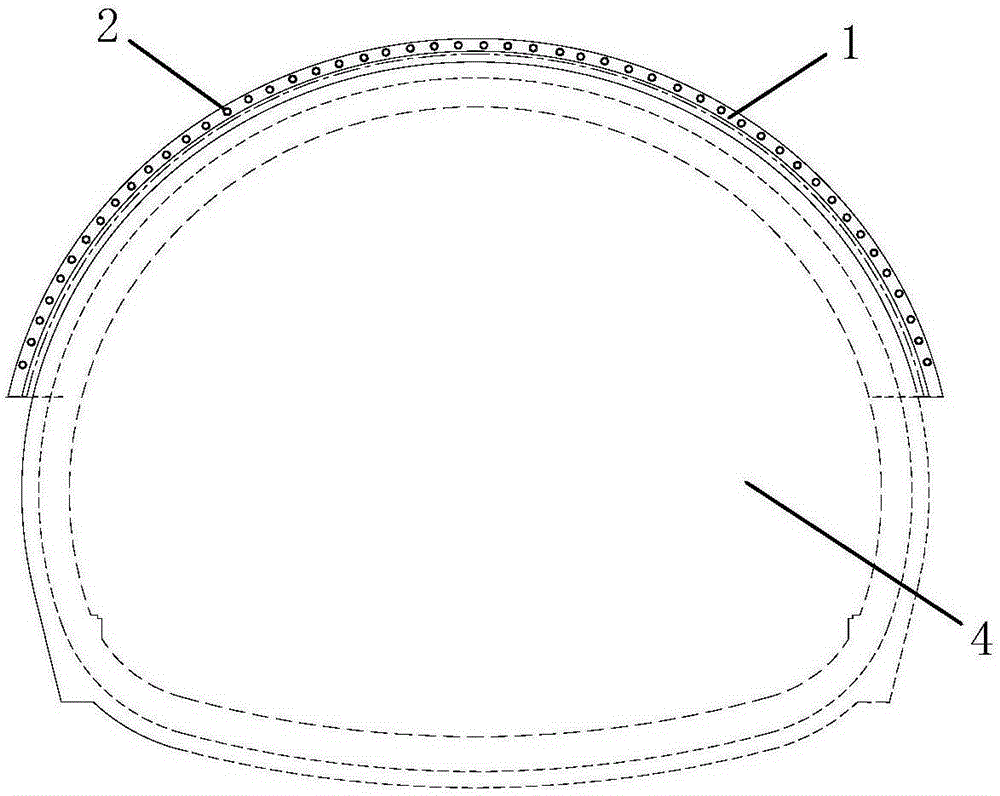

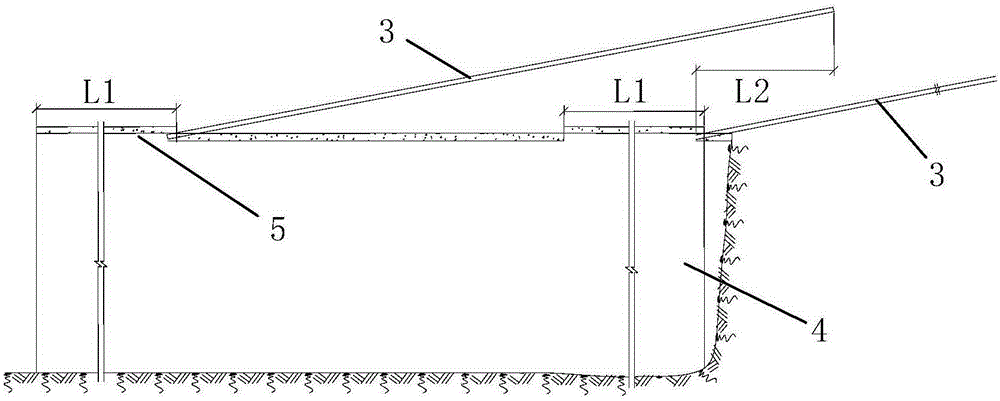

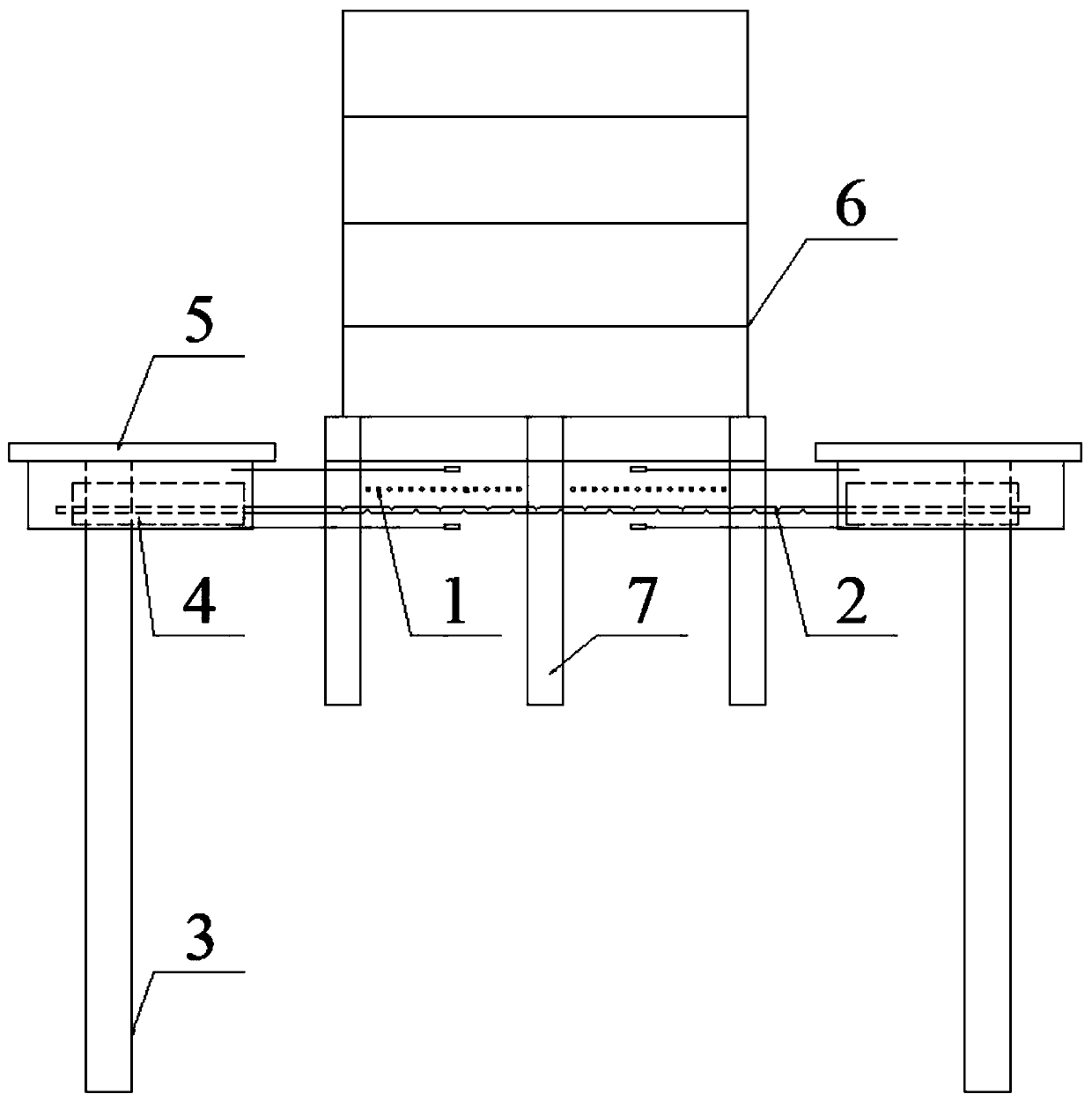

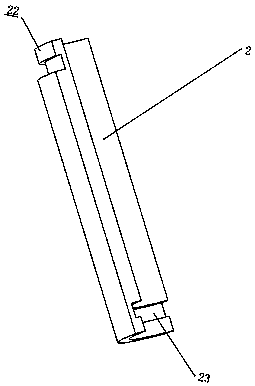

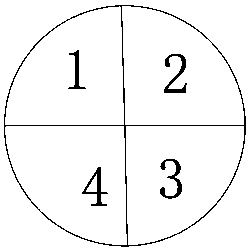

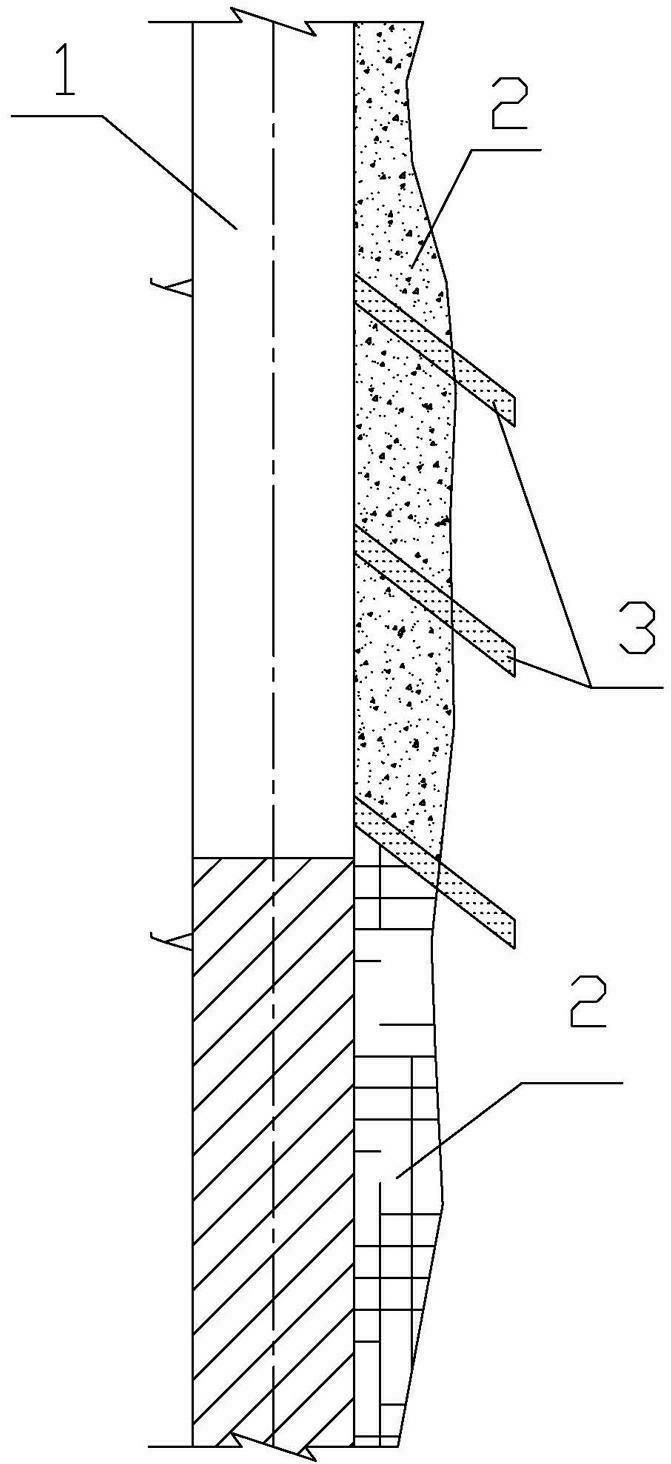

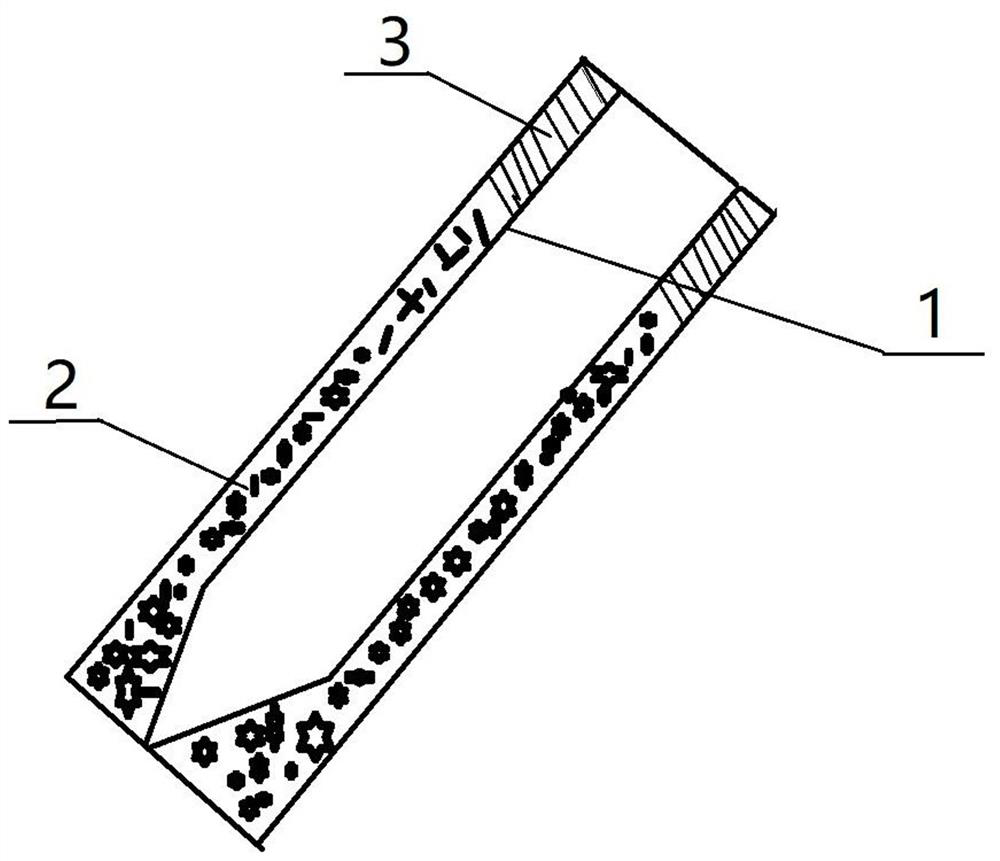

Advance support construction method for high-strength pipe shed of tunnel

InactiveCN105201517AShort construction periodImprove construction efficiencyUnderground chambersTunnel liningDrill holeHigh intensity

The invention discloses an advance support construction method for a high-strength pipe shed of a tunnel. A process for carrying out advance support construction on a pipe shed of one segment of a constructed tunnel comprises the following steps: (1) constructing support arches and guide pipes; (2) installing a drilling machine and a grouting machine in place; (3) carrying out advance support construction on the pipe shed: (301) preparing before drilling; (302) drilling pipe joints at front ends and synchronously grouting; (303) connecting the pipe joints; (304) continuously drilling and synchronously grouting; (305) repeating the steps (303) and (304) many times until the drilling processes of pipes of the current constructed pipe shed are finished; (306) blocking drill holes; (307) carrying out grouting construction on final holes; (308) repeating the steps (301) to (307) many times until all advance support construction processes of the pipes of the pipe shed are finished; and (4) carrying out excavation construction on the tunnel. The method disclosed by the invention is simple in step, reasonable in design, simple and convenient in construction and good in support effect; and by adopting automatic drilling type high-strength pipes of the pipe shed, the advance support process of the tunnel can be simply, conveniently and quickly finished.

Owner:CHINA RAILWAY 20 BUREAU GRP

Reinforcement method for passing through existing building under shield tunnel

ActiveCN109944593AAvoid damageAvoiding the risks of constructionTunnelsAnchoring boltsReinforced concreteSlurry

The invention relates to the technical field of tunnel construction methods, in particular to a reinforcement method for passing through an existing building under a shield tunnel. Reinforcement pilesare added on both sides of the existing building in a transverse direction during construction, an anchor cable is arranged in a soil body between the existing building and the shield tunnel, and after the anchor cable is pulled to achieve design strength, both ends of the anchor cable are fixed to the reinforcement piles; then, slurry is poured into the soil body below the existing building, andthe poured slurry wraps the anchor cable to form a reinforced concrete structure bearing the existing building; after the poured slurry achieves the design strength, reinforcement of the existing building is completed. According to the method, a reinforcement structure is simple, pile foundations and internal structures of the existing building are completely avoided, damage caused to the existing building is avoided, the integrity and safety of the existing building are completely protected, and the method has a high popularization value.

Owner:中交(广州)建设有限公司

Reinforcing structure for shield tunnel underneath penetrating existing building

PendingCN109779636ASedimentation barrierAvoid damageTunnelsAnchoring boltsShield tunnellingTunnel construction

The invention relates to the technical field of tunnel construction structures, in particular to a reinforcing structure of a shield tunnel underneath penetrating an existing building. Vertical supporting structures are located on two transverse sides of an existing building, and a transverse supporting structure is located between the existing building and a shield tunnel. Each vertical supporting structure is a pile foundation structure inserted into soil bodies on the two transverse sides of a shield tunnel advancing route. The two transverse ends of the transverse supporting structure arefixed to the vertical supporting structures on the two sides to form a portal structure for supporting an existing building, and a tensioning structure for transversely tensioning the transverse supporting structure is arranged between the vertical supporting structures on the two sides. The reinforcing structure is simple; the pile foundation and the internal structure of an existing building arecompletely avoided; damage to the existing building is avoided; the integrity and safety of the existing building are completely protected; and the reinforcing structure has great popularization value.

Owner:中交(广州)建设有限公司

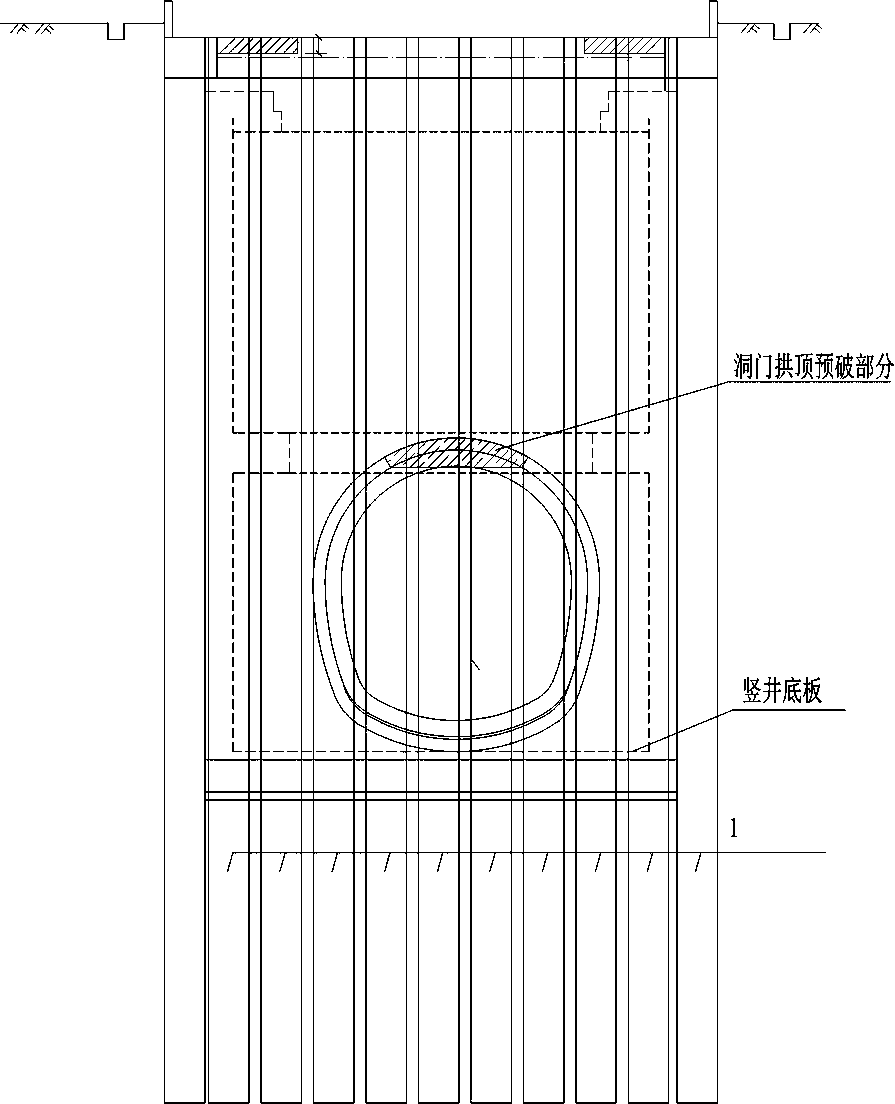

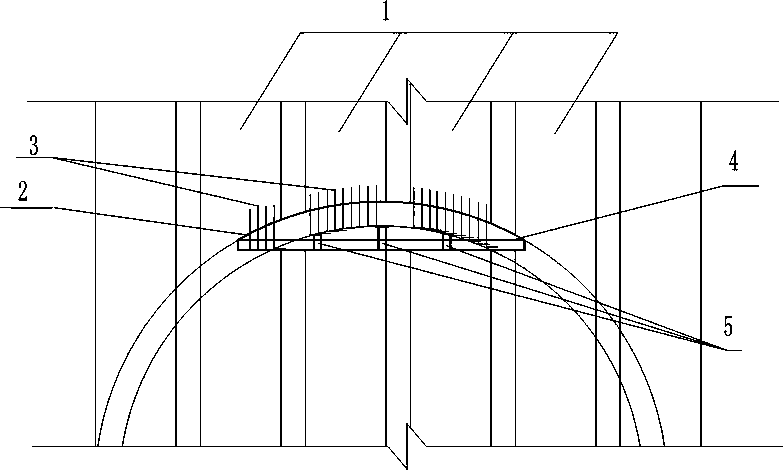

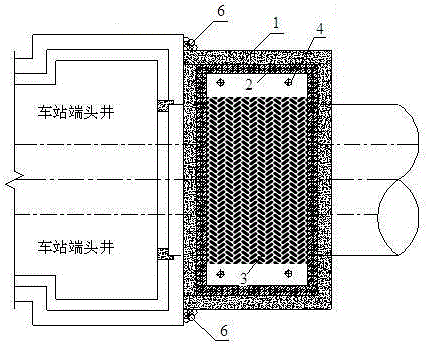

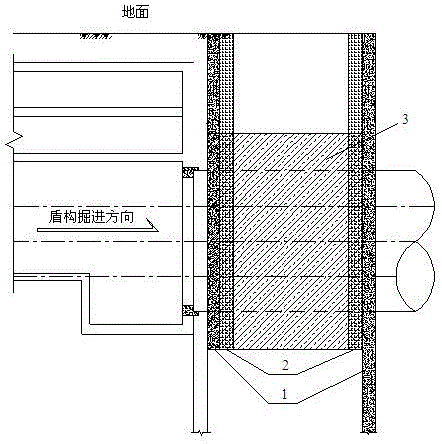

Construction method for subway tunnel to enter subsurface excavation interval tunnel door from shaft

ActiveCN110145328AEnsure safetyAvoid breakingUnderground chambersTunnel liningStructural engineeringEngineering

Provided is a construction method for a subway tunnel to enter a subsurface excavation interval tunnel door from a shaft. According to the construction method, a pre-hanging structure for the arch portion of the tunnel door is designed in the stage of excavation from the shaft to the top elevation position of the tunnel door; when the shaft is excavated to the arch portion of the tunnel door, parts of enclosure piles are broken ahead under effective construction monitoring, and construction of the arch portion of the tunnel door is carried out; the construction of the part which may require reverse breaking of the arch portion of the horsehead of the interval subsurface excavation tunnel is carried out in advance, the conventional construction methods which may involve the high-place operation of a bracket at the bottom of the shaft and the safety hazard caused by manually upwardly breaking enclosing piles can be effectively avoided, the operation difficulty and construction risks of similar engineering processes are lowered, the processing requirements of the bad formation during the operation are avoided, and meanwhile the construction period can be shortened to a certain extent.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Enclosed waterproof reinforced structure of original plain wall of shield and construction technology

ActiveCN106812540AEffective reinforcementEffectively reinforced and closedUnderground chambersTunnel liningSlurry wallPrecipitation

The invention discloses an enclosed waterproof reinforced structure of an original plain wall of a shield and construction technology. The waterproof reinforced structure comprises underground continuous walls of C15 plain concrete (including pre-burying grouting pipes), two rows of rotary jet grouting pipes, three-axis mixing piles and many precipitation wells. The specification for the rotary jet grouting pipes is Phi800@500, and the specification for the three-axis mixing piles is Phi850@600. C15 plain underground continuous walls with embedding rocks of concave type are arranged on the periphery of the reinforced area, forming an enclosed waterproof curtain structure with underground continuous walls of station, then the sedimentation influencing ranges of the soil body outside the pits caused by precipitation inside the pits can be decreased and the effect of exclusion of water can be ensured effectively. Grouting pipes are pre-buried on both inner and outer sides of the underground continuous wall seams of the plain concrete, thereby achieving the operation of grouting and preventing leakage on the seams where leakage exists.

Owner:CHINA RAILWAY SHISIJU GROUP CORP

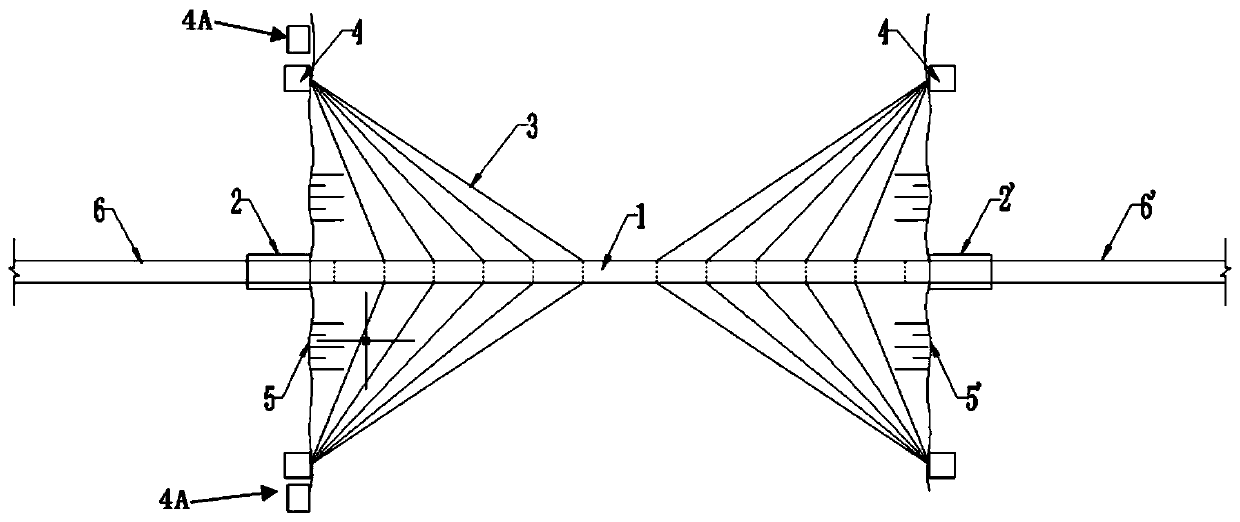

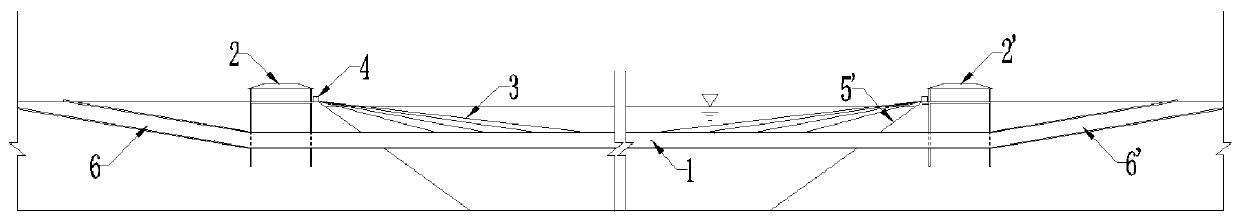

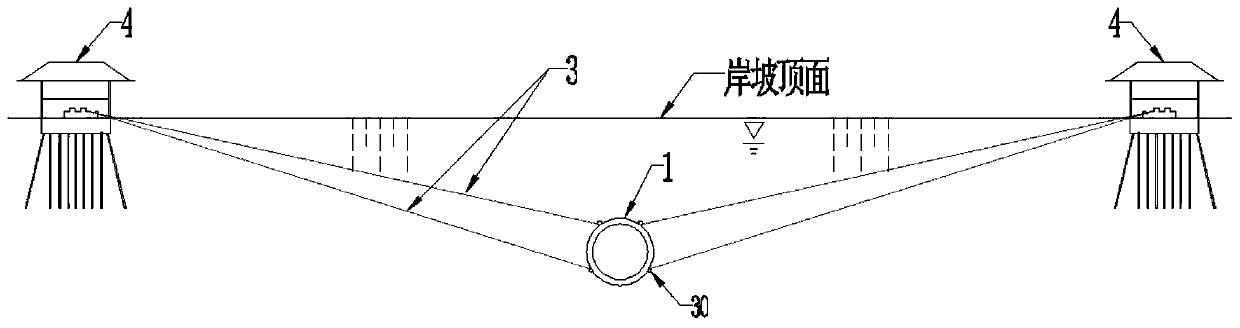

Incremental launching technology of submerged cable-stayed floating tunnel

ActiveCN111254982AReduce security risksAvoid construction difficultyArtificial islandsUnderwater structuresWind waveArchitectural engineering

The invention discloses incremental launching technology of a submerged cable-stayed floating tunnel. The incremental launching technology of the submerged cable-stayed floating tunnel comprises the following steps that all pipe joints of the submerged floating tunnel in a land area prefabrication yard are prefabricated, then the pipe joints are transported to an incremental launching side shore connecting structure through a land area slope tunnel, secondary outfitting is successively carried out, the pipe joints are docked with the subsequent pipe joints and sealed into water, then the pipejoints are in a receiving side shore connecting structure section by section in an incremental launching manner; stay cables are installed on the pipe joints one by one along with incremental launching and pulled to a stay cable anchorage pier; and after incremental launching is completed, concrete on the outer surface of the pipe joints at both ends of the submerged floating tunnel is poured intothe incremental launching side shore connecting structure and the receiving side shore connecting structure, the consolidation of the pipe joints at both ends of the submerged floating tunnel is completed, then the buoyant weight ratio can be adjusted by adjusting the ballast water volume in each pipe joint, and the cable force adjustment of the stay cable is carried out and the sealing anchor iscarried out at the stay cable anchorage pier. The incremental launching technology of the submerged cable-stayed floating tunnel has little influence by wind, wave, current, ship traveling wave and the like, greatly reduces the safety risk of man-machine for offshore construction, and has high construction efficiency and short construction period.

Owner:CCCC THIRD HARBOR ENG +1

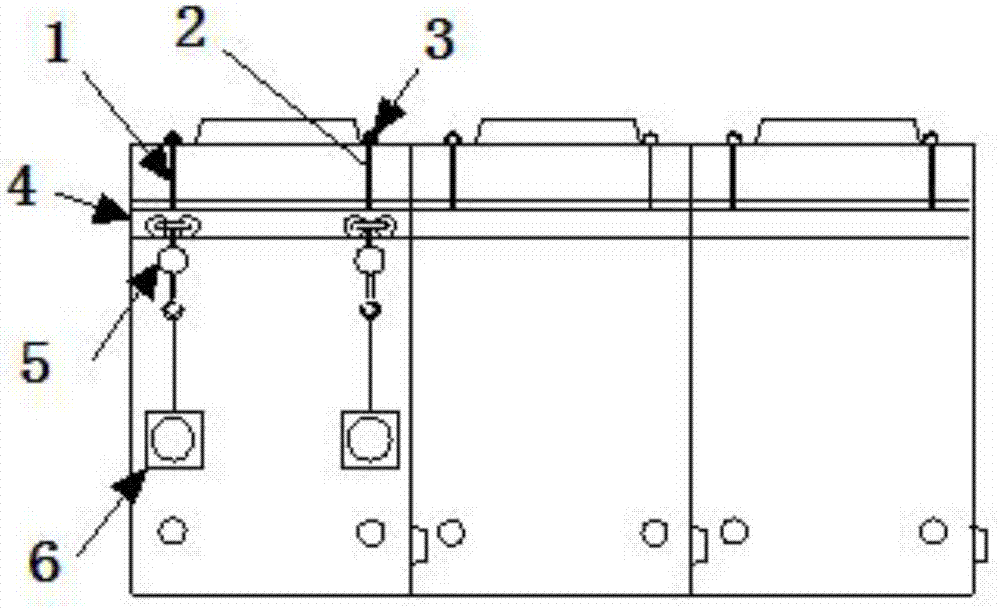

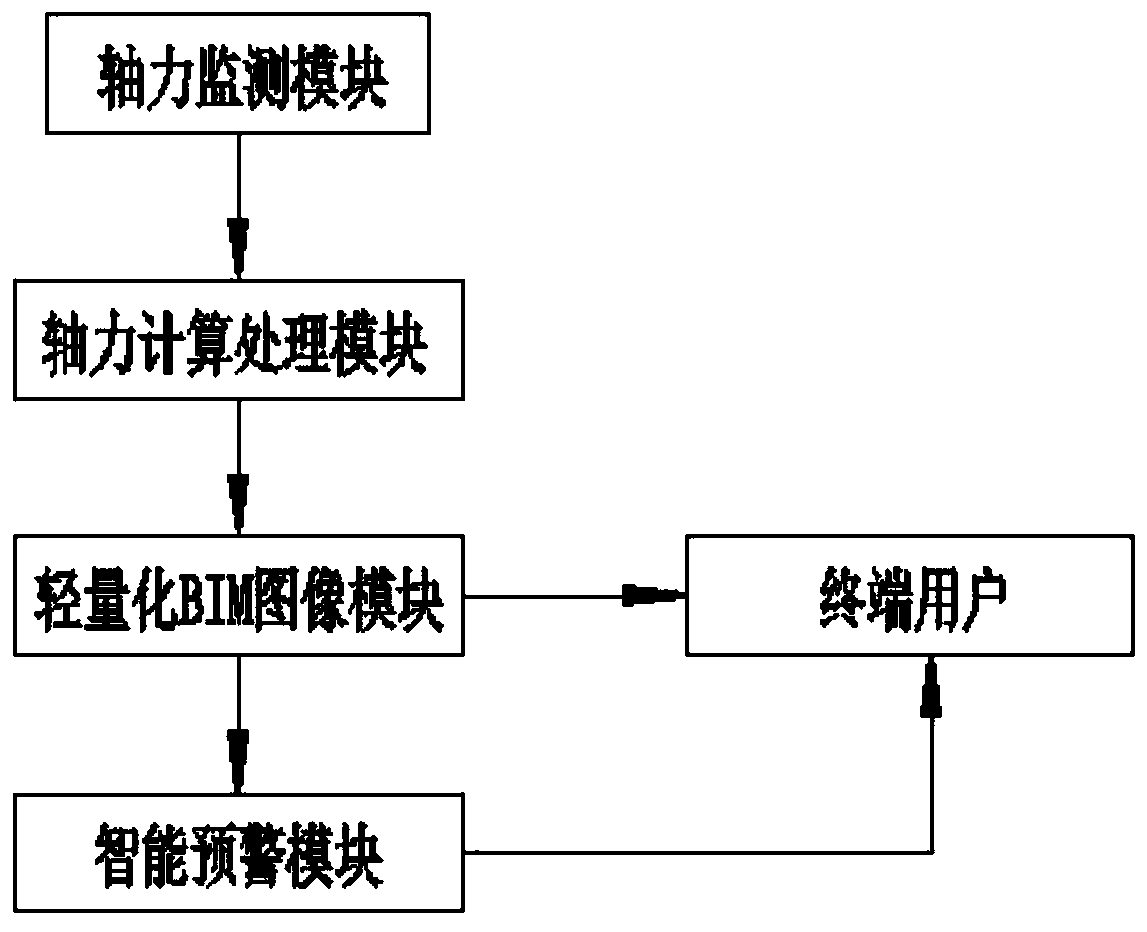

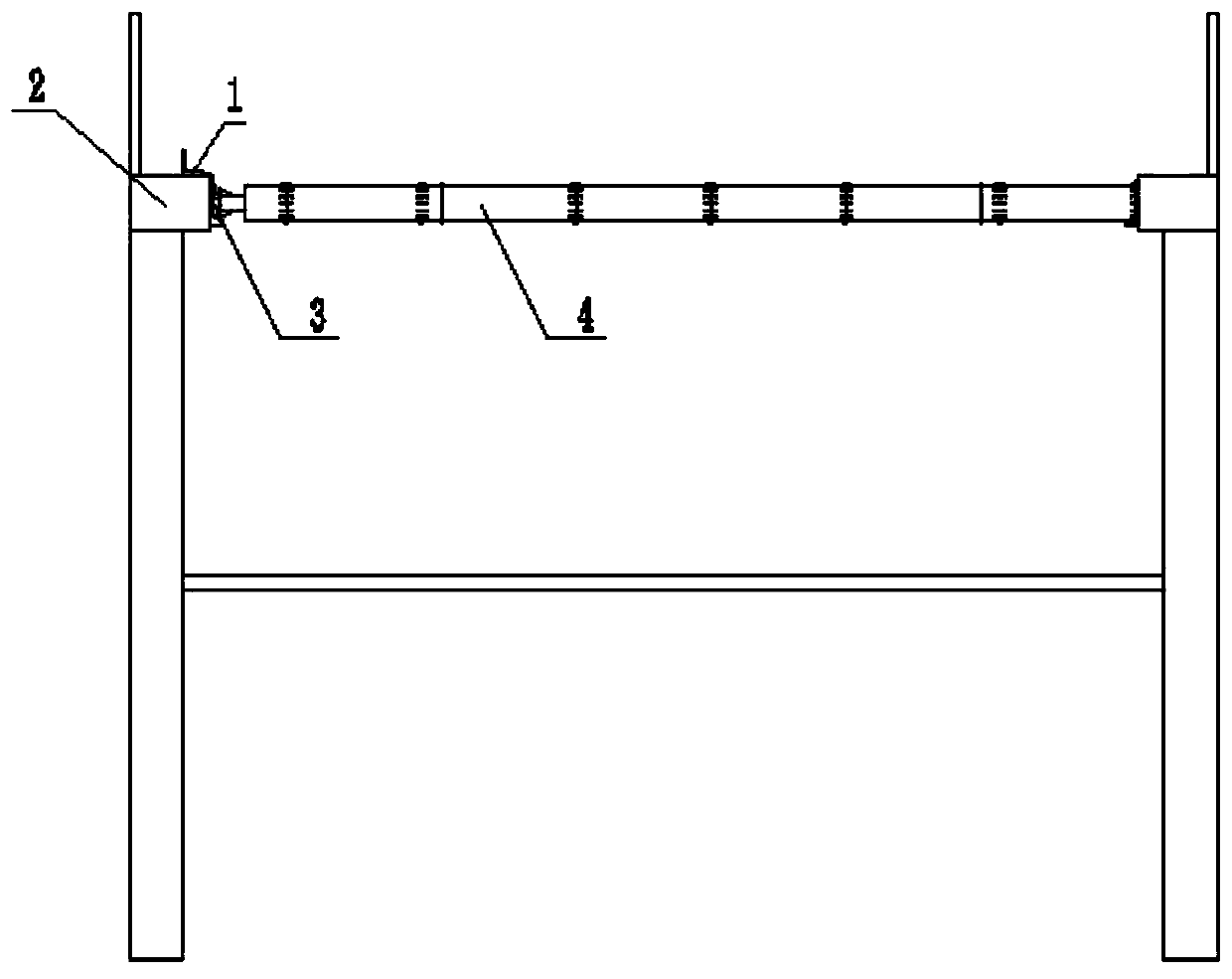

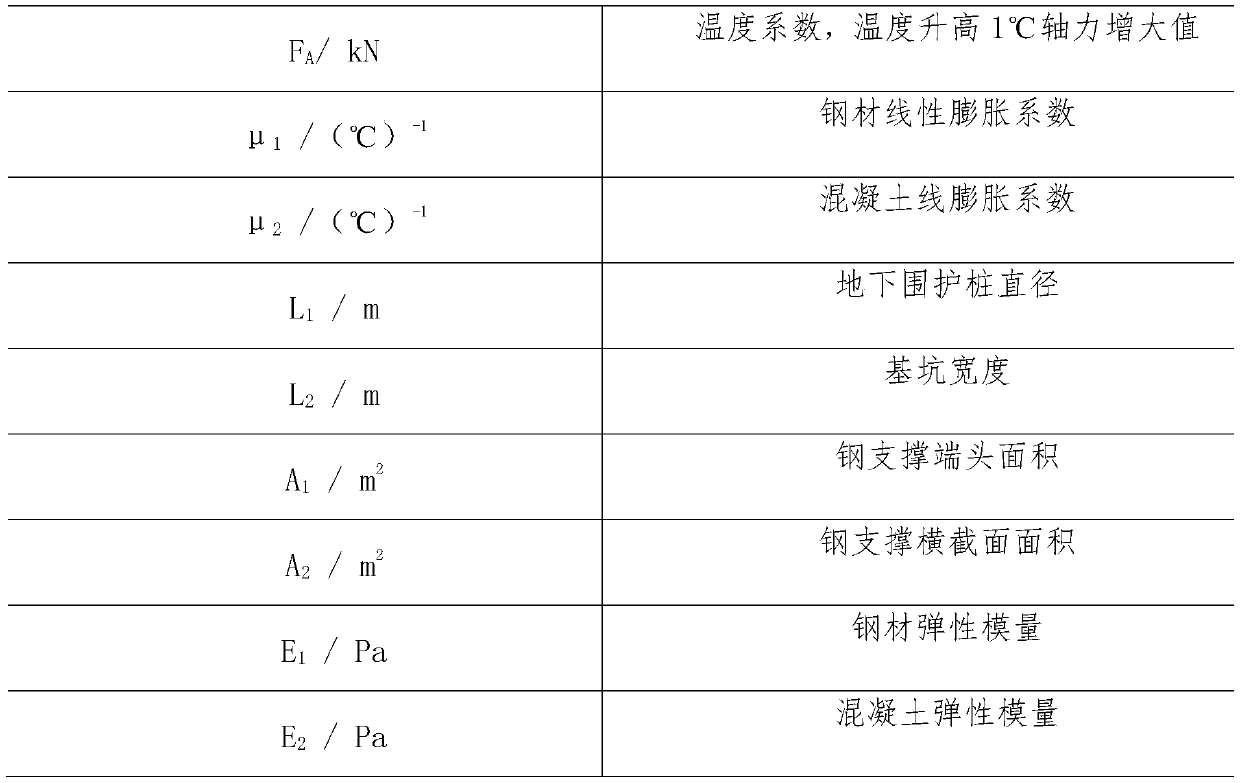

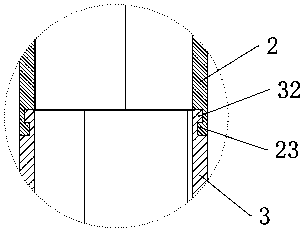

BIM based monitoring and supporting axial force system and method for open excavation foundation pit of subway

InactiveCN110468891AAvoid construction risksReal-time monitoringFoundation testingExcavationsVisual monitoringComputer module

The invention discloses a BIM based monitoring and supporting axial force system and method for an open excavation foundation pit of a subway. The BIM based monitoring and supporting axial force system includes an axial force monitoring module, an axial force calculation and processing module, a lightweight BIM image module, an intelligent early warning module and an end user. According to the BIMbased monitoring and supporting axial force system and method, a BIM information technology and equipment Internet of Things are used for completing a dynamic early warning of a subway construction visualization site, the structure is simple, the design is scientific and reasonable, conception is ingenious, the force and deformation of the axial force monitoring of a subway station can be accurately monitored in real time, and accurate positioning and real-time monitoring of the early warning can be achieved through the real-time visual monitoring of the end user to effectively avoid the construction risk. The BIM based monitoring and supporting axial force system and method are simple in structure, scientific and reasonable in design, ingenious in conception, and each axial force point can be monitored accurately in real time. When a value of a certain axial force point is higher than a threshold value, an alarm is given to the end user in time, the safety of construction is effectively improved, and the value of popularization and application is wide.

Owner:THE THIRD CONSTR CO LTD OF CTCE GRP +1

Assembly-type deep and large round vertical shaft structure for rock stratum area and construction method

ActiveCN111101948AAvoid contamination riskAvoid construction risksShaft sinkingShaft liningArchitectural engineeringStructural engineering

The invention provides an assembly-type deep and large round vertical shaft structure for a rock stratum area. The assembly-type deep and large round vertical shaft structure comprises fore shaft ringbeams arranged at the shaft mouth of a round vertical shaft, wherein the lower end of each fore shaft ring beam is provided with a first annular duct piece, a plurality of second vertical shaft sections are connected to the lower portion of the first vertical shaft section and are arranged in sequence from top to bottom, an inner ring of each fore shaft ring beam is provided with a joint part, and the first annular duct pieces are hung on the fore shaft ring beams through first upper connectors and joint parts. The round vertical shaft is a structure formed by assembling a plurality of annular duct pieces, the fore shaft ring beams are utilized for bearing, the joint parts, the first upper connectors, first lower connectors, second upper connectors and first lower connectors are adopted for connection, digging and assembly can be conducted simultaneously, the construction efficiency is effectively improved, preliminary bracing is reduced, the project period and project investment aresaved, and environmental pollution and construction risks brought by cast-in-situ concrete construction are avoided.

Owner:JIESHUN RAIL TRAFFIC TECH CHONGQING

Backfill construction method for vertical shaft cave

ActiveCN102644465AEasy backfill handlingSafe backfill handlingShaft sinkingShaft liningKarstEngineering

The invention relates to a backfill construction method for a vertical shaft cave. The invention aims at providing a backfill construction method for the vertical shaft cave to reduce the construction difficulty and improve the engineering safety. The technical scheme adopted by the invention is that the method comprises the steps of: a, excavating a first layer of a vertical shaft on a selected position; b, punching a circle of a pipe roof to a karst cavity of the wall on a position of the bottom part of the first layer vertical shaft; c, clearing deposits inside the karst cavity of the first layer, and backfilling the karst cavity after being cleared with concrete by adopting the pipe roof as a bottom template; d, continuing to excavate the vertical shaft after completing the concrete backfilling to reach the stadium of the concrete, carrying out the construction for the karst cavity disclosed by a second layer according to the steps b and c after reaching the position of the bottom part of the second layer vertical shaft, and backfilling and grouting the top part of the lower concrete layer by utilizing an upper layer pipe roof; and e, repeating the step d until reaching the requirement of the vertical shaft depth. The backfill construction method is applicable to hydraulic and hydro-power engineering and is particularly applicable to the excavation of the vertical shaft in karst regions.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

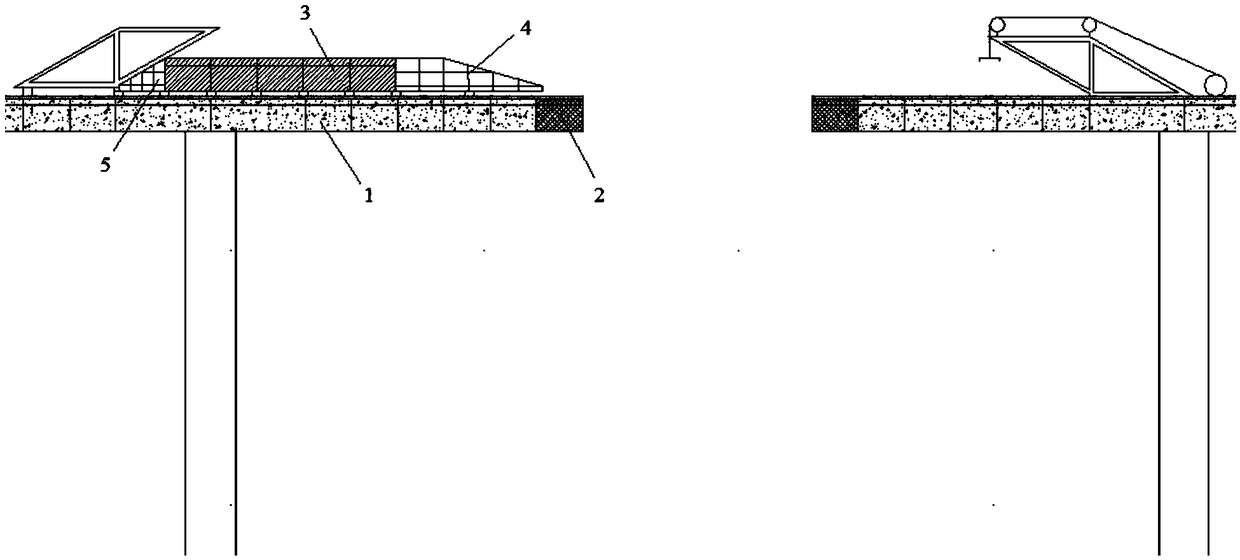

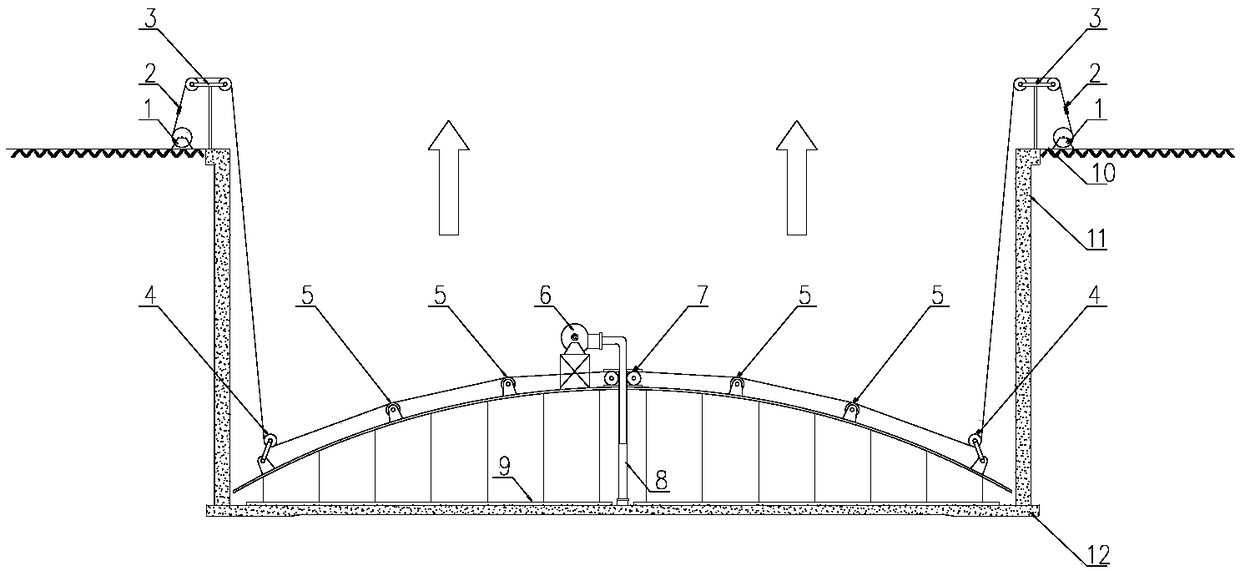

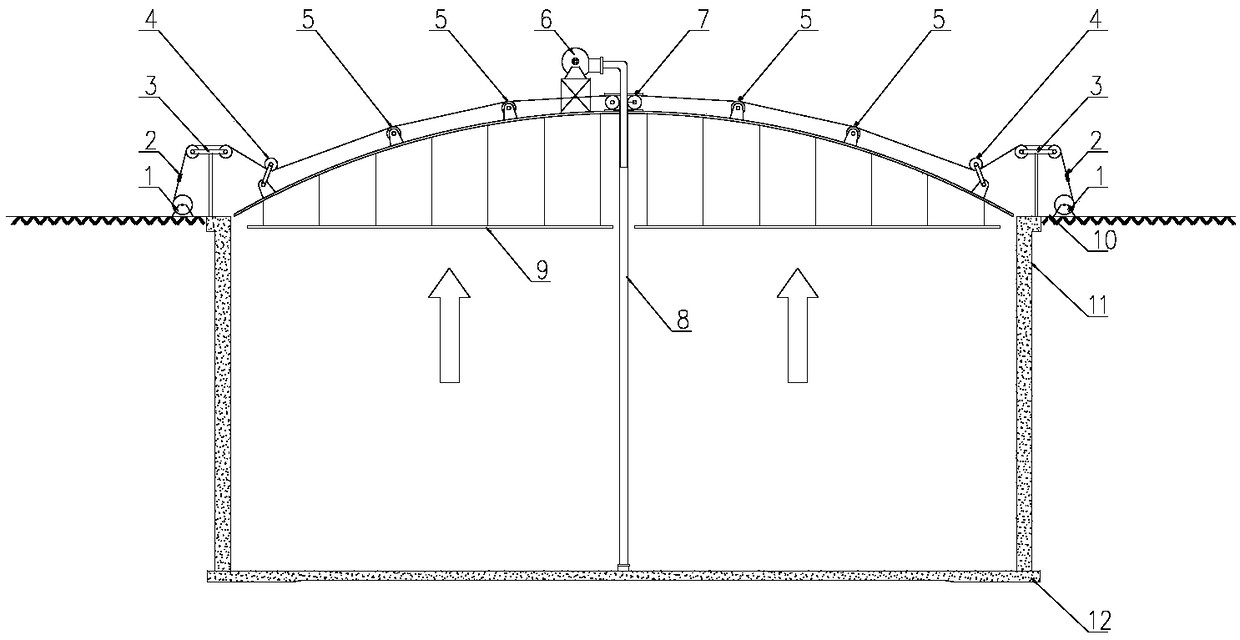

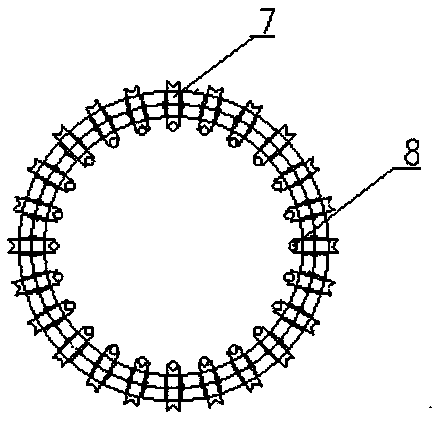

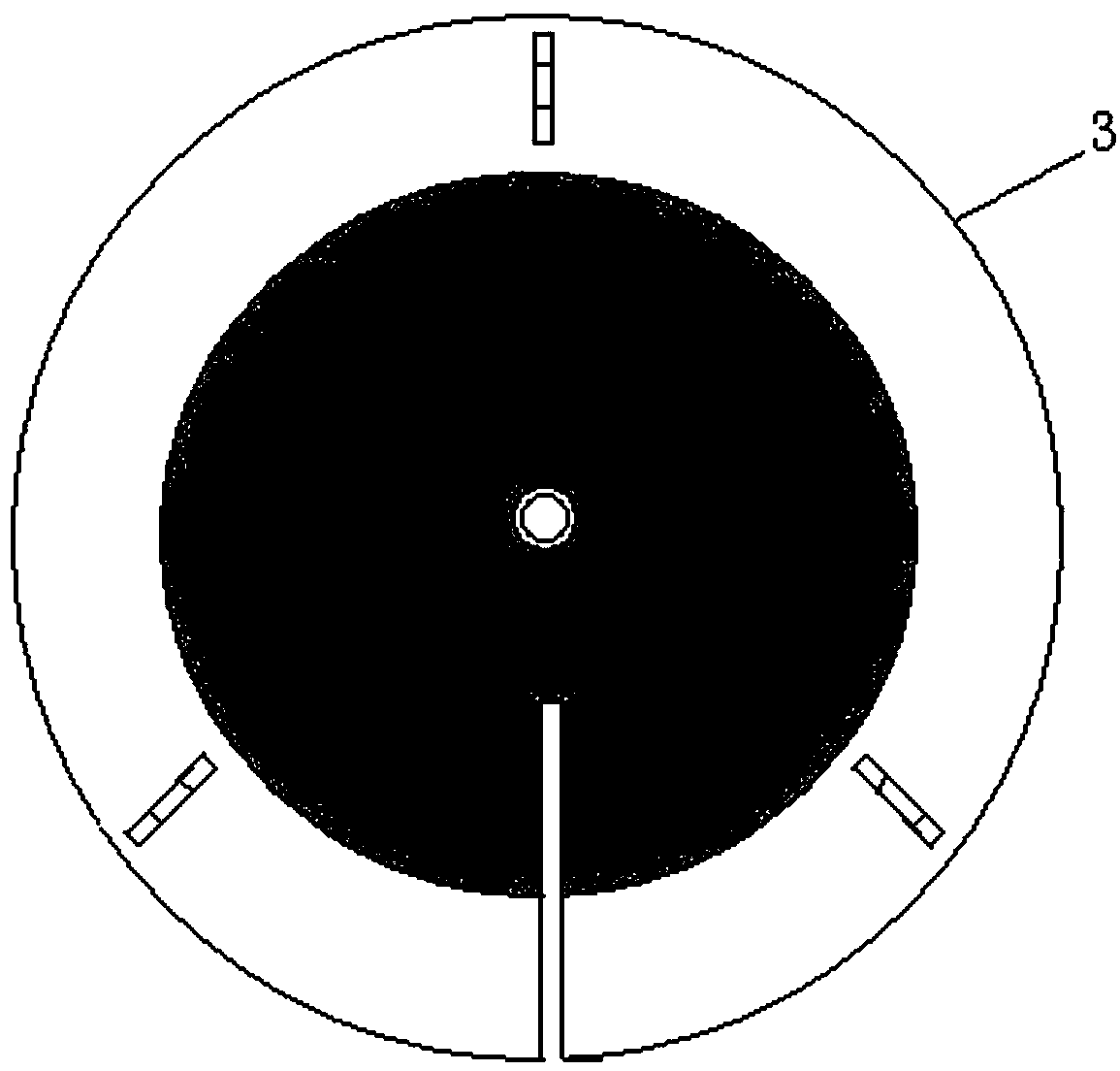

Fully-underground LNG storage tank with top air inlet jacking device

PendingCN109323121AAvoid leaningPrevent rotationVessel manufacturingVessel geometry/arrangement/sizeEngineeringWinch

The invention discloses a fully-underground LNG storage tank with a top air inlet jacking device. The fully-underground LNG storage tank with the top air inlet jacking device comprises an LNG storagetank body. The dome center of the LNG storage tank body is provided with an air inlet. The dome is provided with a plurality of guide pulleys around the air inlet. Each guide pulley is provided with asteel wire rope in a supporting manner, wherein one end of the steel wire rope penetrates through the air inlet to be fixed to a bearing platform of the LNG storage tank body, the other end of the steel wire rope is connected with a winch through a guide sliding trolley arranged on the edge of the dome, the winch is fixed outside the LNG storage tank body. According to the fully-underground LNG storage tank with the top air inlet jacking device, the problem that the fully-underground LNG storage tank cannot achieve a manner that the bottom of the tank wall is opened to achieve air inlet jacking like a common overground tank is solved; the dome structure is integrally installed, and the construction risk caused by high altitude bulk hoisting can be avoided; a bottom air inlet is omitted, and the integrity of a concrete tank wall structure is ensured; and in the whole jacking operation process, the position of a dome frame can be monitored and adjusted in real time through a pulley block balance guide device and an upper balance drafting device, and precision and stability of the whole jacking process are ensured.

Owner:CNOOC GAS & POWER GRP

Installation method of submarine pipeline buckling detector

InactiveCN109323082ASolve the problem of weld stickingSolve the problem of loosening and falling offPigs/molesMarine engineeringWeld seam

An installation method of a submarine pipeline buckling detector comprises the following installation steps that firstly, venting holes are formed in the buckling detector; secondly, the buckling detector is put into a submarine pipeline; thirdly, pipe openings of the submarine pipeline are sealed; fourthly, the submarine pipeline is filled with the compressed air, and the buckling detector forwards moves to the interior of the submarine pipeline; fifthly, a steel wire rope stops moving forwards; sixthly, air inflation of the submarine pipeline stops; seventhly, the fourth step to the sixth step are repeated until the buckling detector arrives at the set position of the interior of the submarine pipeline; eighthly, a steel wire rope with a copper pipe and the steel wire rope which enters the submarine pipeline are connected; and ninthly, the copper pipe is placed at the position of a welding point in the submarine pipeline. By the adoption of the installation method of the submarine pipeline buckling detector, the problem that weld seams at the welding points of the steel wire ropes and the submarine pipeline are adhesive is solved, movement of the buckling detector in the submarine pipeline can be smoother, and the detection speed is increased. In addition, the problem that nuts of connecting snap rings of the buckling detector are loosened and fall down is solved, and the probability of the phenomenon that the buckling detector falls in the submarine pipeline is reduced.

Owner:OFFSHORE OIL ENG

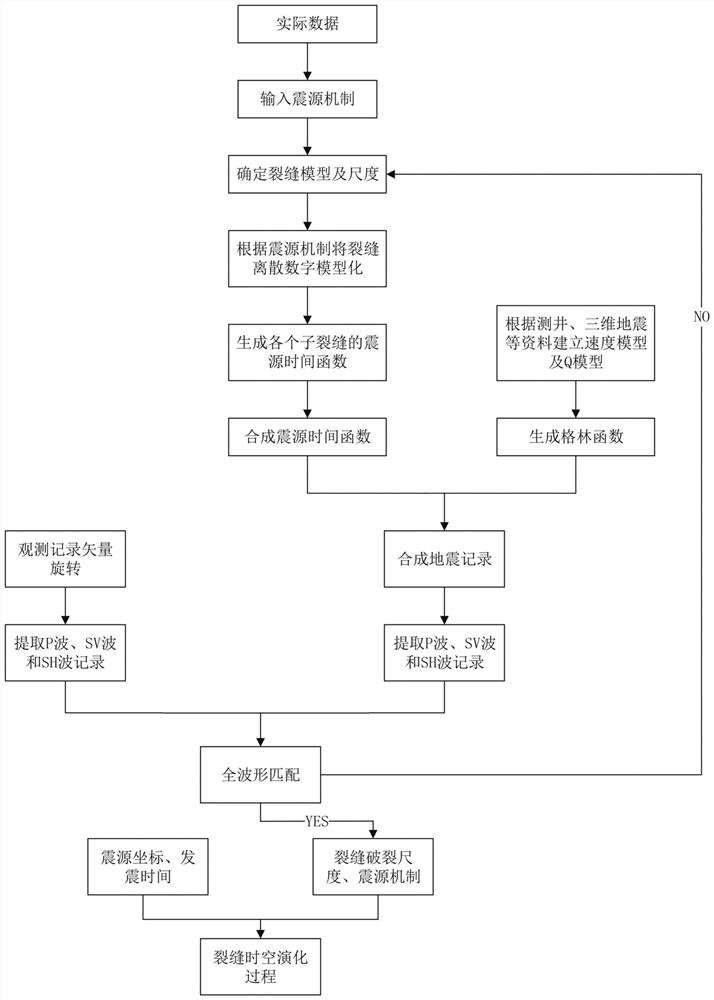

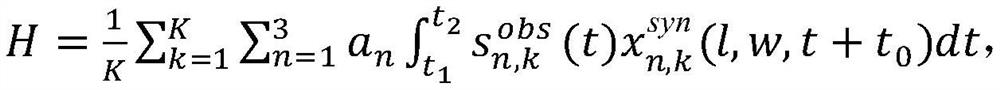

Description method of the crack fracture scale based on seismic wave full-waveform characteristics

ActiveCN112068198AImprove targetingImprove effectivenessSeismic signal processingCorrelation coefficientWell logging

The invention provides a description method of the crack fracture scale based on seismic wave full-waveform characteristics. The description method of the crack fracture scale comprises the followingsteps: generating a composite seismic source time function through modeling of the crack fracture scale, obtaining a Green function from a seismic source to an observation station through logging and / or three-dimensional seismic data, obtaining a synthetic micro seismic wave according to the composite seismic source time function, the Green function and a seismic moment tensor, and obtaining a composite micro seismic wave; calculating correlation coefficients of the synthetic microseismic waves and the microseismic waves recorded by the observation station based on the full waveform characteristics of the seismic waves, and selecting the fracture fracture scale recorded by the synthetic microseismic waves with the correlation coefficients within a preset coefficient allowable range as thefracture scale. The invention has the beneficial effects that the problem that the fracture dimension of the crack cannot be quantitatively described in passive earthquake monitoring can be solved.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

Double-pipe cyclic heating wellhead four-way device

ActiveCN105439307AAvoid cloggingPrevent scalingWaste water treatment from quariesDrilling rodsDouble tubeWater filter

The invention provides a double-pipe cyclic heating wellhead four-way device. The double-pipe cyclic heating wellhead four-way device comprises an outer pipe and an inner pipe, wherein the outer pipe sleeves the inner pipe in a fixed manner; an annular space is formed between the inner pipe and the outer pipe; a water inlet bypass and a water outlet bypass communicated with the annular space are arranged on the pipe wall of the outer pipe; the water inlet bypass is located above the water outlet bypass; a filtering assembly is arranged in the outer pipe and at the upper end of the inner pipe; the filtering assembly comprises a shell with a water filtering cavity and a filter element arranged in the water filtering cavity; a water inlet hole and a water outlet hole are formed in the shell; the water inlet hole is communicated with the water inlet bypass; the water outlet hole is communicated with the upper end opening of the inner pipe; and a liquid circulating channel is formed by sequentially making the water inlet bypass, the filtering assembly, an inner cavity of the inner pipe, the annular space and the water outlet bypass communicated. The double-pipe cyclic heating wellhead four-way device can be used for filtering water and the liquid circulating channel is prevented from being blocked.

Owner:PETROCHINA CO LTD

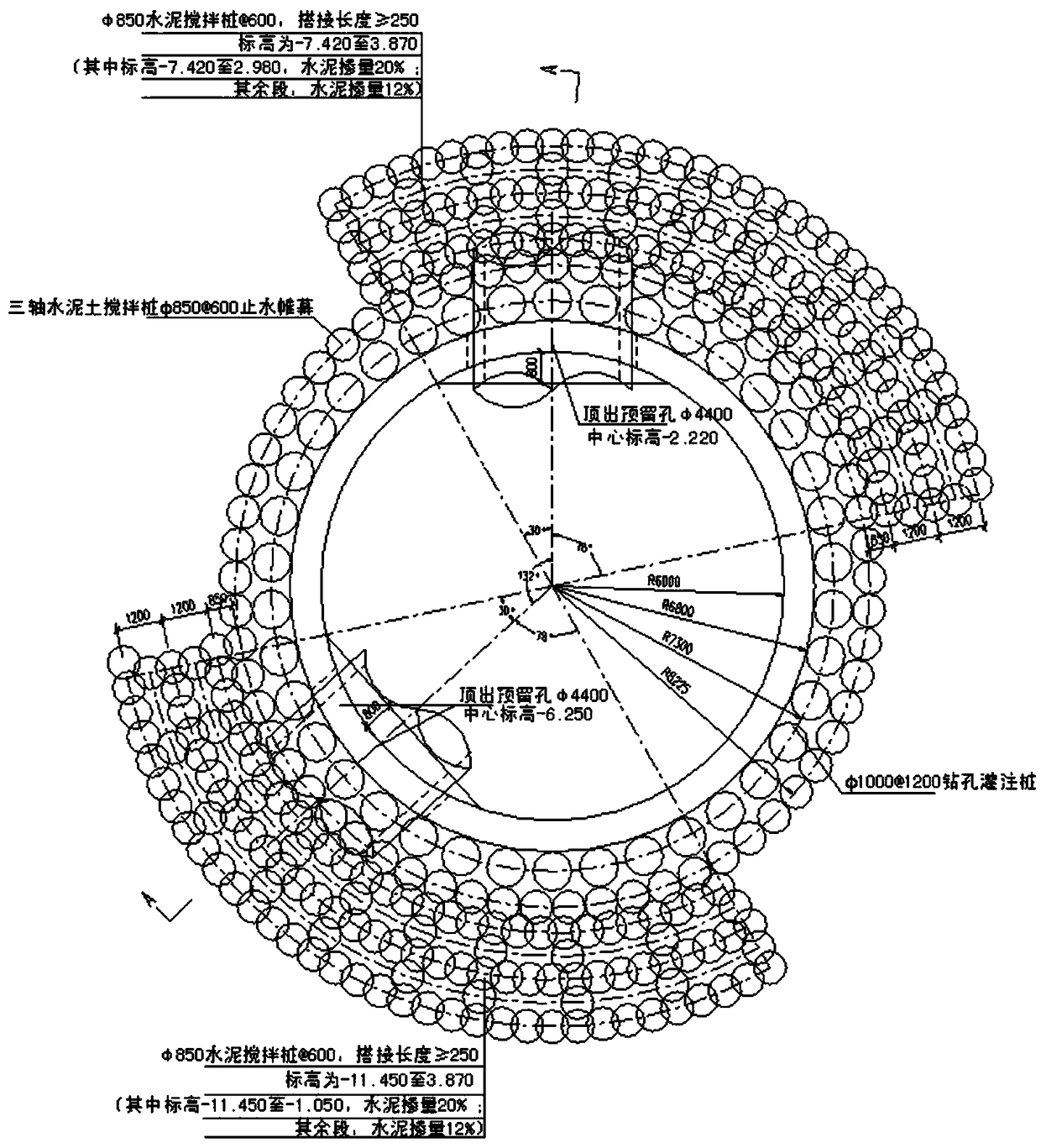

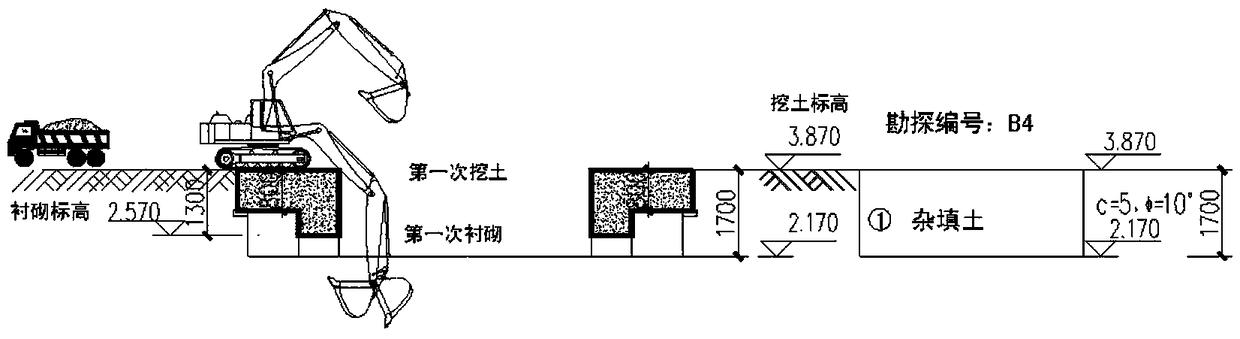

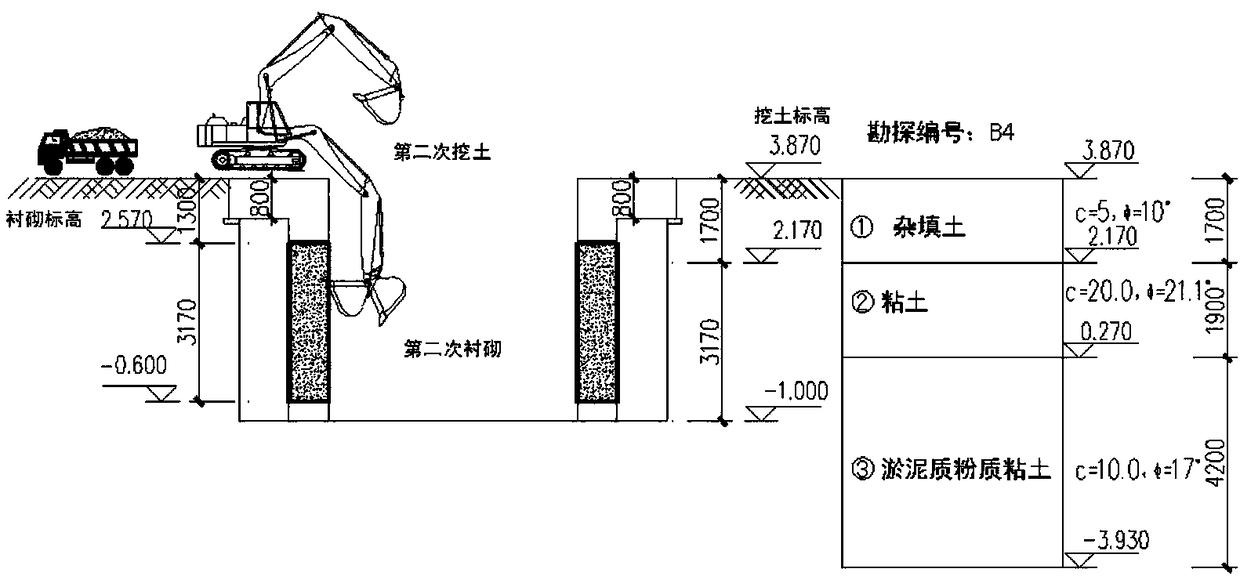

Construction method of pipe-jacking working well

InactiveCN109306712AEnsure construction safetySmall amount of workArtificial islandsUnderwater structuresFalseworkReinforced concrete

The invention discloses an inverse construction method for a pipe-jacking working well. The construction method comprises the following steps that the round working well is dug; a three-axis cement stirring column water-stopping curtain is adopted to form an enclosure structure; a pile top ring beam is manufactured on an enclosure pile through the working well, the self weight of the working wellstructure is borne by utilizing the ring beam, the self weight of the working well is guaranteed, the construction is constructed in a node-by-section mode, and a reinforced concrete lining is manufactured along with excavation; and the arch formed by the self structure serves as a horizontal support, the lateral soil pressure is resisted, and the safety of the well pit is guaranteed. The workingwell is constructed through the construction method, a foundation pit support can be carried out by utilizing the structure of the working well, so that the construction safety of a foundation pit isguaranteed; meanwhile, the engineering quantity of the foundation pit is reduced, the foundation pit enclosure pile and the support are reduced, and a structure construction scaffold is reduced by means of the reverse construction, the construction height is reduced, and the construction risk is avoided; and meanwhile, the workload of template turnover materials is reduced, the construction process is simplified, the construction period is shortened, and the influence on the adjacent building (structure) and the road and surrounding environment is reduced.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

Fastening belt assembly and method for mounting and dismounting wind turbine generator turbulent flow strip

PendingCN111810367AEasy to installEasy to disassembleFinal product manufactureWind motor assemblyManufacturing technologyMarine engineering

The invention discloses a fastening belt assembly and method for mounting and dismounting a wind turbine generator turbulent flow strip. The fastening belt assembly comprises two fastening belts, a fastener, a hook and loop fastener, a mooring rope and a binding belt. The binding belt and the hook and loop fastener are utilized for attaching and fixing the two fastening belts, and therefore the whole fastening belt assembly is stably connected, external force can be applied through the mooring rope to flexibly dismount the fastening belt assembly, and the manufacturing technology of the fastening belt assembly is simple and convenient. The method for mounting and dismounting the wind turbine generator turbulent flow strip specifically comprises the steps that the fastening belt assembly mounted on a wind turbine generator high tower barrel is utilized as a carrier, the turbulent flow strip is mounted on the fastening belt assembly, and mounting of the turbulent flow strip on a wind turbine generator can be achieved; and in the later period, the fastening belt assembly can be separated from the tower barrel only by pulling the mooring rope on the ground, manual dismounting of the turbulent flow strip can be achieved without other auxiliary hoisting, the beneficial effect of convenient dismounting and mounting is achieved, the dismounting cost of the turbulent flow strip is reduced, certain construction risks are avoided, and safety and reliability are achieved.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

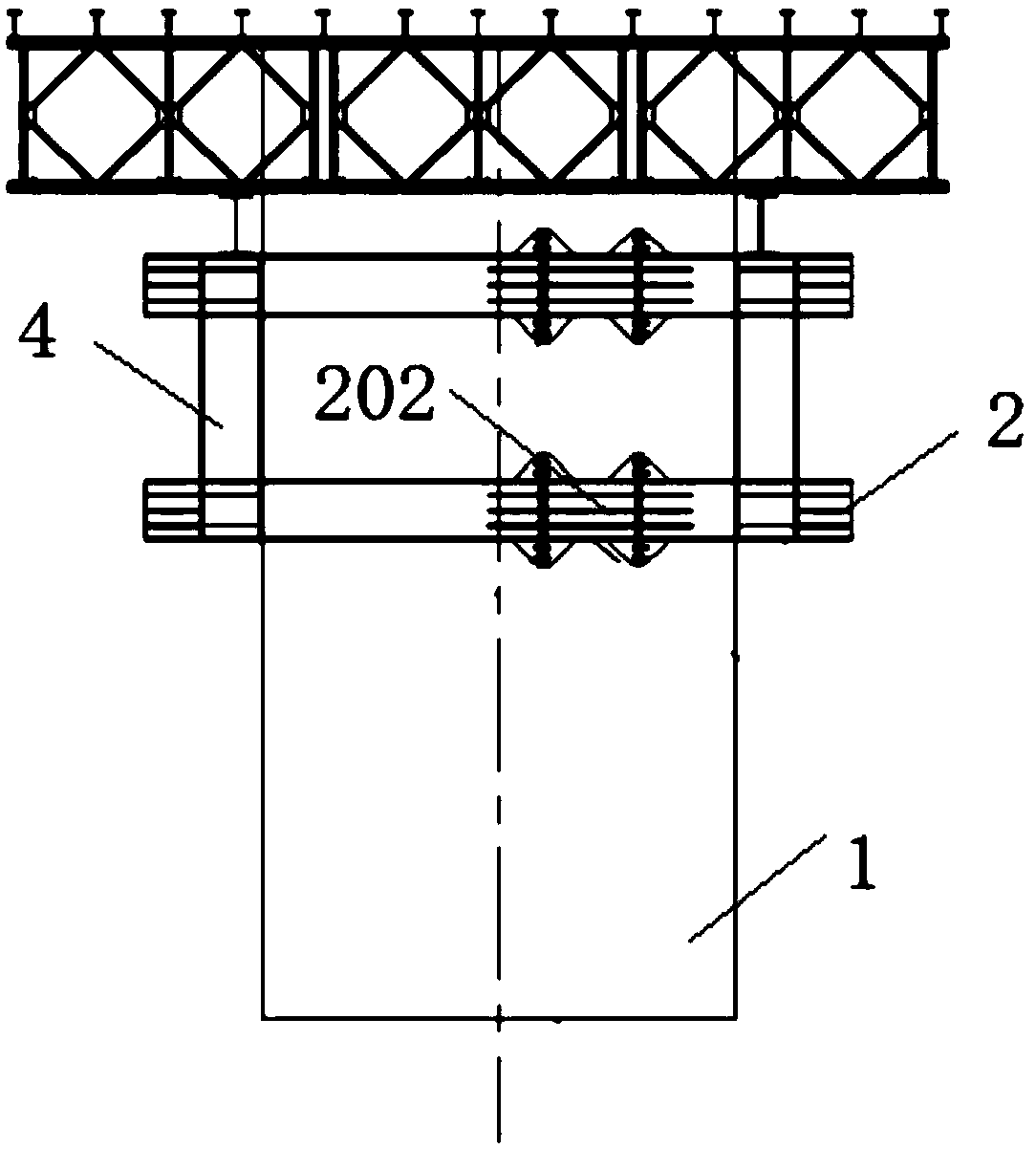

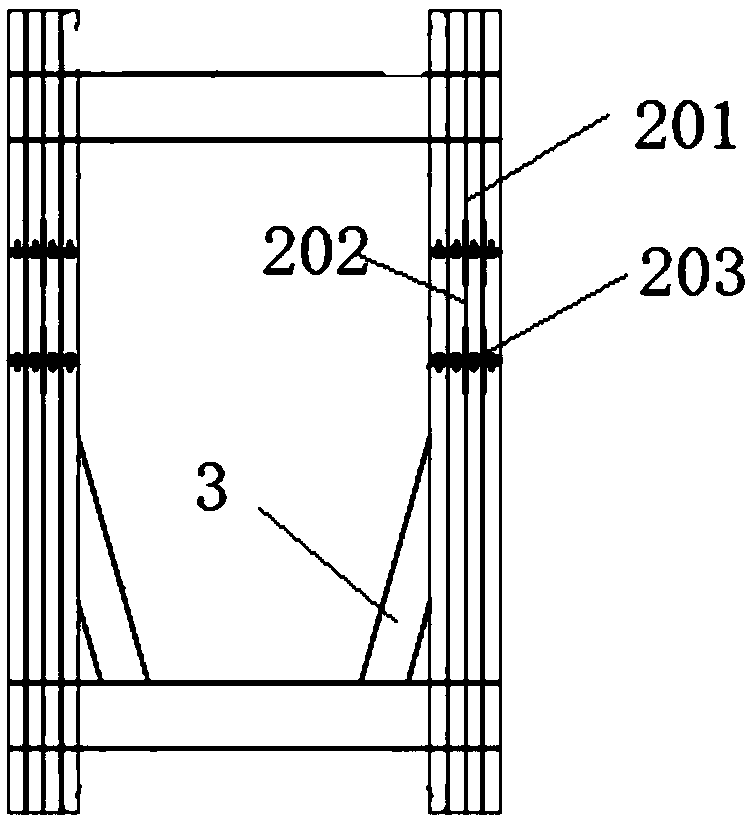

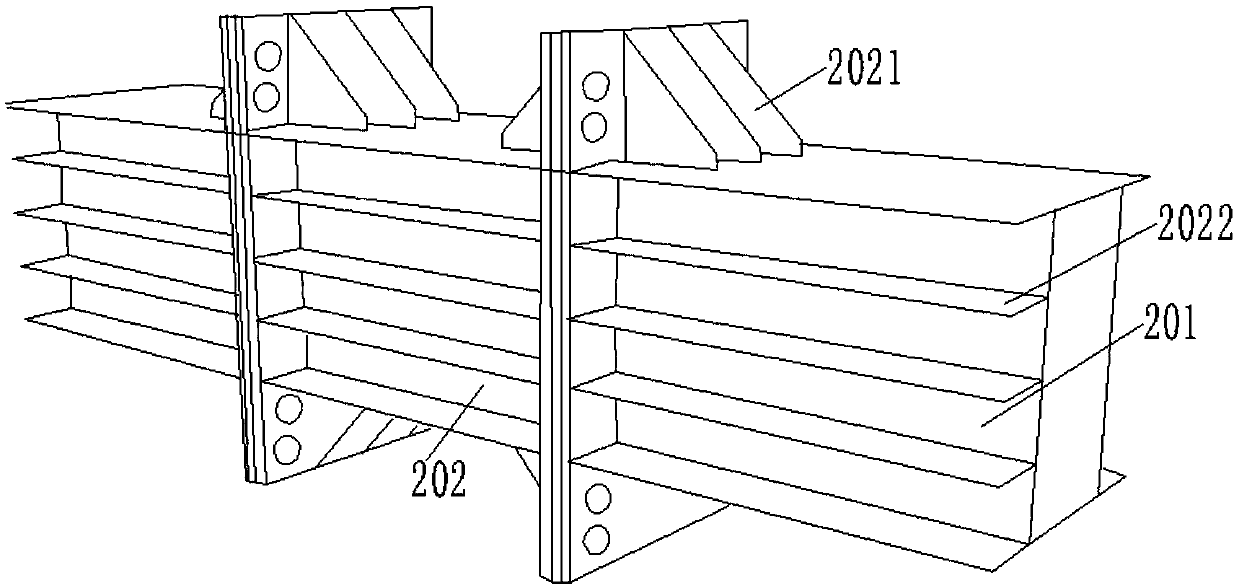

Assembled hoop support suitable for special pier and method for constructing capping beam by using same

ActiveCN109518595AAvoid construction risksReduce construction costsBridge structural detailsBridge erection/assemblyEngineeringBuilding construction

The invention discloses an assembled hoop support suitable for a special pier and a method for constructing a capping beam by using same. The assembled hoop support suitable for the special pier comprises a plurality of hoops; the plurality of hoops sleeve a bridge pier in a spaced manner; patching adjusting plates with adjustable lengths are contained in the hoops; adjusting plates are correspondingly mounted / not mounted at four internal corners in the hoops to adjust shapes and sizes of the internal spaces of the hoops and adjust the lengths of the patching adjusting plates in a matched manner to adapt to bridge piers with various special shapes; and therefore, the hoops stick to the bridge piers; the two adjacent hoops are connected with each other through connecting plates; and the number of the hoops is adjusted to adapt to the bridge piers with different heights. The assembled hoop support suitable for the special pier can adapt to the construction of the capping beams of the bridge piers with the various special shapes; and a lot of full supports are not needed in the capping beam construction process.

Owner:CCCC SECOND HARBOR ENG

Detonator cover structure for limiting fragment scattering in detonator detonating process

ActiveCN102628662ASolve the hidden danger of explosion failureAvoid construction risksBlastingDetonatorFailure causes

The invention belongs to the protection technology of blasting engineering and provides a detonator cover structure for limiting fragment scattering in the detonator detonating process. The detonator cover structure is formed by combining steel plates with different shapes; the detonator cover structure is formed by welding a semicircular tube body (2) and two semicircular steel plates (1), the semicircular tube body (2) is processed by a steel plate with a certain length, the semicircular steel plates (1) are symmetrically arranged at two end surfaces of the semicircular tube body (2), and the cover type structure with the semicircular cross section shape and the semi-annular steel plates at two ends for sealing is formed; and the radiuses of semicircular open holes arranged at two end surfaces of the cover structure are smaller than the radius of the semicircular tube body (2). The detonator cover structure has the advantages that the hidden danger of detonator blasting propagation failure caused by nearby detonator cut by scattered fragments after the detonator blasting in the detonator group connecting detonating structure is avoided, the blasting success rate is improved, and the construction risk of blind gun generation is avoided.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Shield reinforcing construction process

InactiveCN111911167AEasy constructionDisadvantages of preventing damage to hoop grouting effectTunnelsStructural engineeringRail traffic

The invention discloses a shield reinforcing construction process. A shield lanuching reinforcing soil body and a receiving reinforcing soil body are each divided into a first area soil body and a second area soil body along a shield excavation path, and the shield reinforcing construction process comprises the following steps that S1, reinforcing the first area soil bodies by adopting a high-pressure jet grouting pile and / or a three-axis mixing pile, and constructing the second area soil bodies by adopting a freezing method; and S2, performing freezing method construction on the outer ring ofa shield tunnel entrance door or a shield tunnel exit door in a lanuching well or a receiving well, and arranging freezing pipes in a circle shape, wherein the diameter of the circle is larger than that of the shield tunnel entrance door and that of the shield tunnel exit door. The shield reinforcing construction process can be applied to the situation that the surrounding environment is complexin the urban rail transit construction process, and a cutterhead can be effectively prevented from being frozen.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Precipitation inclined shaft in deep foundation pit and construction method of precipitation inclined shaft

PendingCN111851548AReduce construction depthSolve the problem of insufficient construction spaceFoundation engineeringLine tubingCrushed stone

The invention discloses a precipitation inclined shaft in a deep foundation pit and a construction method of the precipitation inclined shaft. A shaft pipe is arranged in the precipitation inclined shaft, a filling layer is arranged between the outer wall of the shaft pipe and the inner wall of the precipitation inclined shaft, the middle-lower section of the filling layer is a filter section, andthe upper section of the filling layer is a sealing section; the bottom end of the shaft pipe is closed, an opening is formed in the shaft wall of the shaft pipe of the filter section, and a 60-meshor 80-mesh filter screen is wound outside the shaft pipe; the filter section is filled with gravel with the particle size of 3-7 mm; the sealing section is filled with clay, and the filling degree isnot lower than 90%; centering supporting legs in three directions are arranged on the lower section, the middle section and the upper section of the shaft pipe in the circumferential direction, the interval between every two centering supporting legs is 120 degrees, a centering support is fixed to the outer wall of the shaft pipe wound with the filter screen through screws, and one supporting legfaces the position over the other supporting leg; and the included angle between the precipitation inclined shaft and the vertical direction is 30-70 degrees. The precipitation inclined shaft and theconstruction method thereof have the beneficial effects that the lower space around the foundation pit is fully utilized, the problem that the ground surface construction space is insufficient is thoroughly solved, and the construction risk of damaging underground facilities such as pipelines and structures is avoided; and the safety and the stability of foundation pit engineering are effectivelyimproved.

Owner:BEIJING URBAN CONSTR EXPLORATION & SURVEYING DESIGN RES INST

Bridge stand column support-free construction method

PendingCN112554070ATake advantage ofReduce adverse weather effectsBridge erection/assemblyBridge materialsArchitectural engineeringRebar

A bridge stand column support-free construction method comprises the steps: processing of a stand column reinforcement cage: the stand column reinforcement cage is machined through a reinforcement cage jig frame; measuring the pre-embedded position of the stand column: lofting the direction line of the outer side line of the stand column onto a bearing platform template, and pulling out the central outline of the stand column by using a fine line to serve as a reference line of a stand column pre-embedded reinforcement cage; and integrally hoisting the stand column reinforcement cage: inserting the reinforcement cage into the bearing platform and not installing opposite-pull hook ribs and inner stirrups of the part above the bearing platform surface, binding the part of steel bars insertedinto the bearing platform after the stand column reinforcement cage is hoisted in place and fixed, and mounting the opposite-pull hook ribs and the inner stirrups within the range of the part above the bearing platform surface after a concrete surface is roughened and cleaned. Compared with the prior art, centralized modular machining, manufacturing and mounting of steel bars are achieved, the reinforcing steel bar machining jig frame and the reinforcing steel bar end positioning frame are used for machining the bridge stand column reinforcing cage in a workshop, and the reinforcing steel barpositioning precision and machining efficiency are improved; and traditional scaffold erecting and formwork erecting procedures are combined, and scaffold-formwork integration is adopted.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com