Detonator cover structure for limiting fragment scattering in detonator detonating process

A technology of fragment scattering and detonator cover, applied in the protection field of blasting engineering, can solve problems such as hidden dangers of blasting work and the generation of blind shots, and achieve the effect of improving the success rate and eliminating construction risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is described in conjunction with accompanying drawing and specific embodiment:

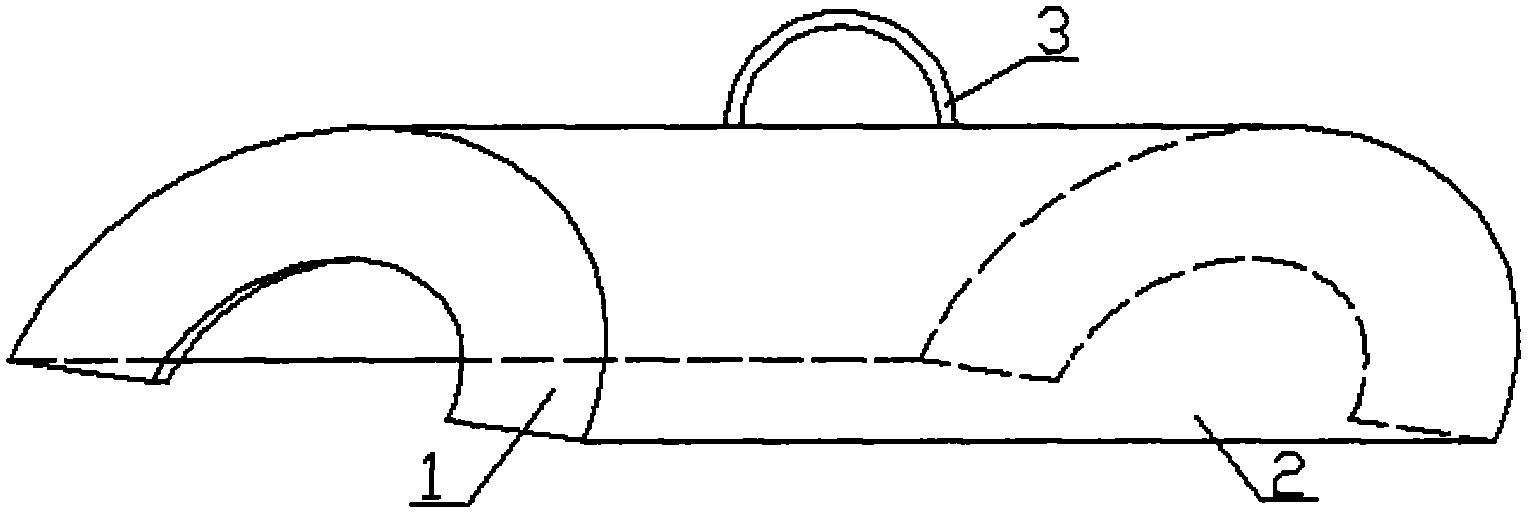

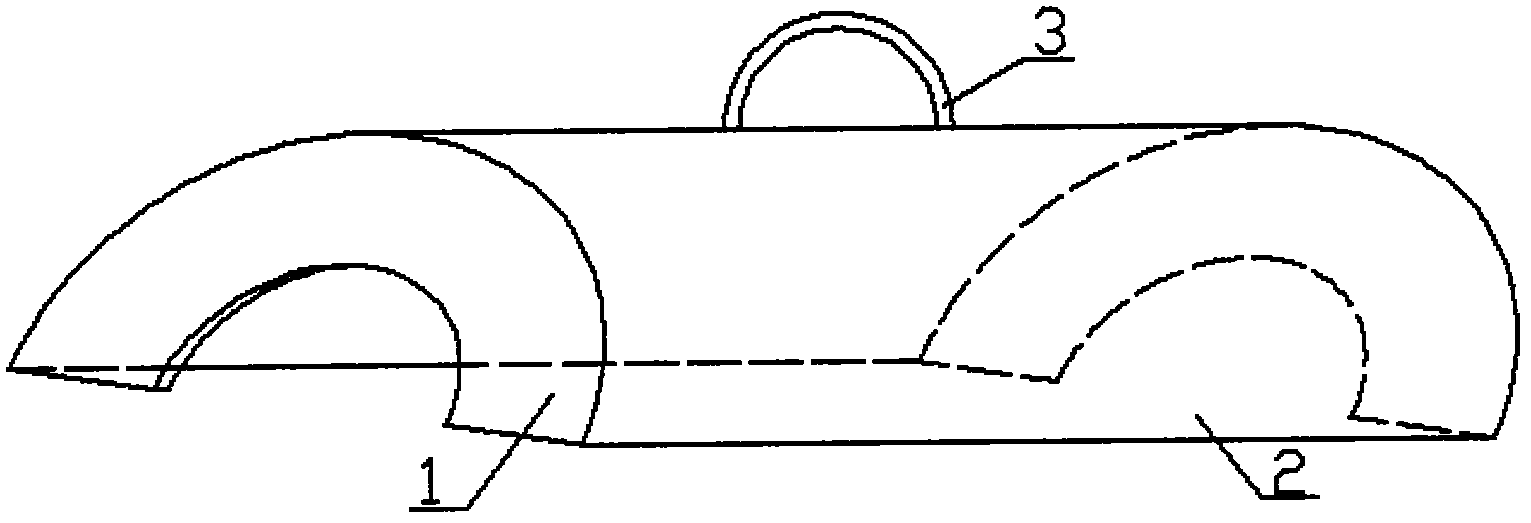

[0010] like figure 1 , a detonator cover structure that limits the scattering of fragments during the detonation process of the detonator. The detonator cover structure is composed of steel plates with different shapes; Shaped cylinder 2 and two semicircular steel plates 1 symmetrically arranged on both ends of the semicircular cylinder are welded to form a cover structure with a semicircular cross-sectional shape and closed semicircular steel plates at both ends; the cover structure The radius of the semicircular openings on both end surfaces is smaller than the radius of the semicircular cylinder body 2 . The steel plate constituting the semicircular cylinder 2 and the two semicircular steel plates 1 symmetrically arranged on both ends of the semicircular cylinder are processed from steel plates with a thickness not less than 5 mm.

[0011] The length of the detona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com