Backfill construction method for vertical shaft cave

A construction method and shaft technology, which are applied to shaft equipment, well sinking, earthwork drilling, etc., can solve problems such as voiding of backfill concrete foundations, construction difficulties, and instability, and achieve the effect of reducing construction difficulty and avoiding construction risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

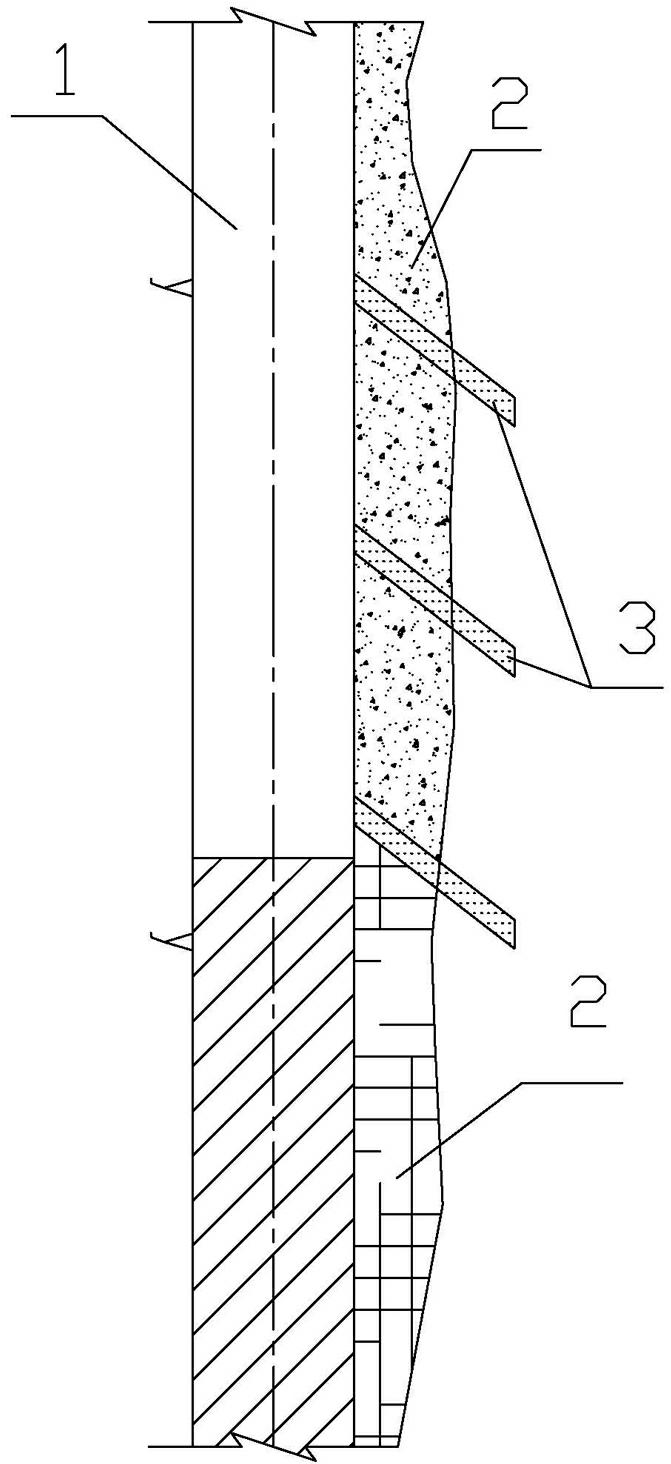

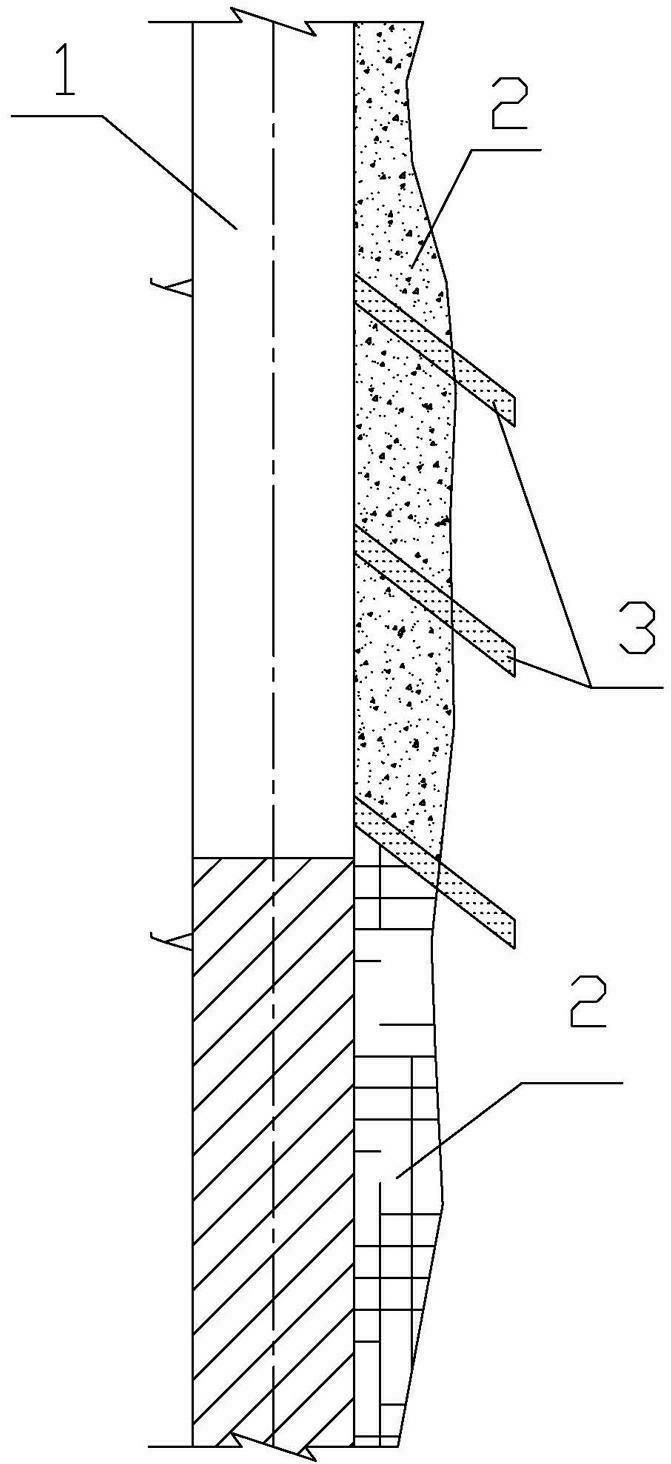

[0015] Such as figure 1 As shown, the present embodiment has a vertical shaft 1 excavated in the karst area. The vertical shaft is excavated in layers. The excavation depth of each layer is 3-5m, and it is arranged in the karst cavity 2 at the bottom of each layer. There is a row of pipe sheds 3, and the steel pipes of the pipe sheds 3 are required to be closely connected (if there is a gap between the pipe sheds, concrete or cement mortar can be used to block them). concrete.

[0016] The specific implementation of this embodiment is as follows:

[0017] a. Excavate the first layer of shaft 1 at a selected location in the karst area;

[0018] b. During the excavation process of the vertical shaft 1, the karst cavity 2 on the shaft wall is also continuously exposed. Pipe row shed 3, the pipe shed reaches into the surrounding rock;

[0019] c. Clean up the accumulations in the karst cavity 2 that have been exposed, and use the pipe shed 3 as the bottom formwork for the back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com