Soil remediation bioreactor

A bioreactor and soil remediation technology, applied in the field of bioreactors, can solve the problems of long treatment period, acidification of underground layers, pollution of underground rivers, etc., and achieve the effect of convenient backfill treatment and avoid powdering of soil particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

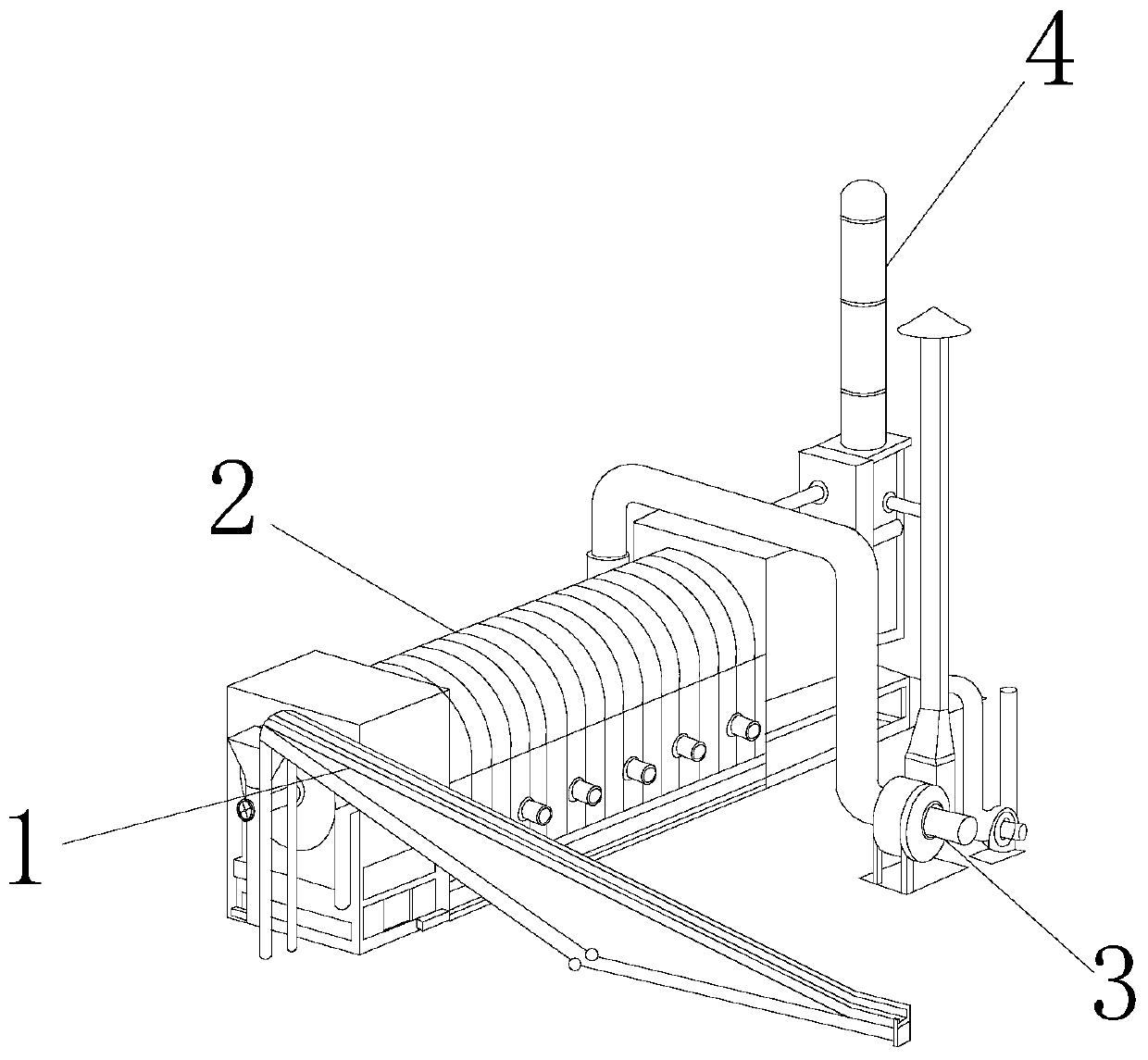

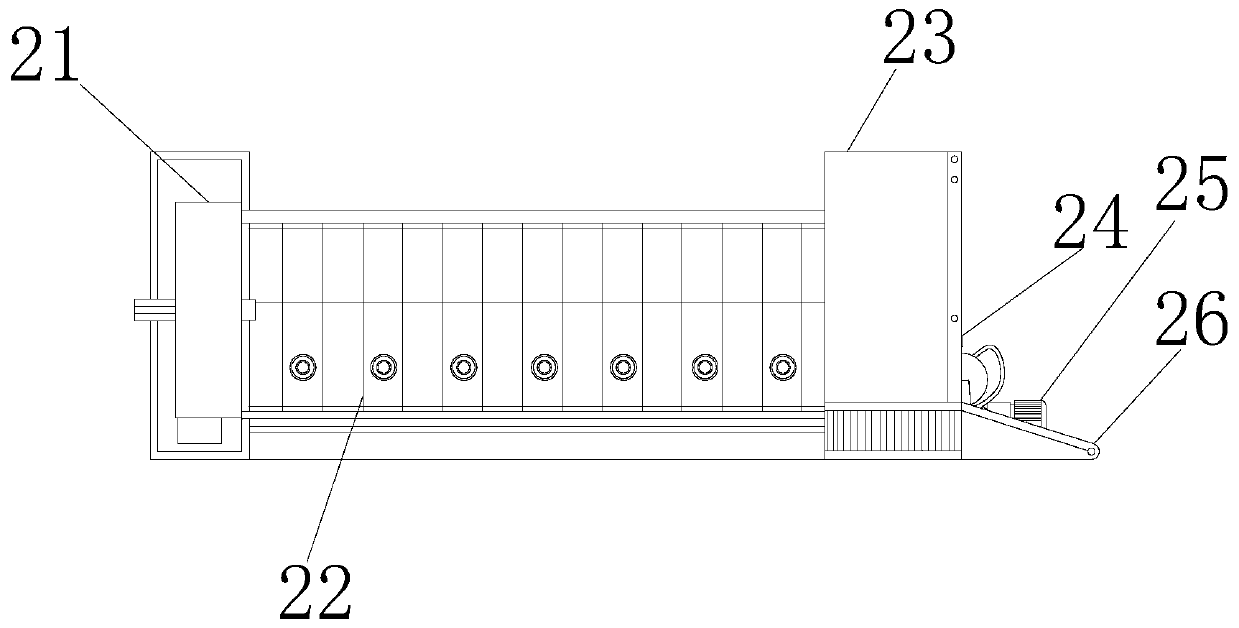

[0025] as attached figure 1 to attach Figure 6 Shown:

[0026] The present invention provides a soil repair bioreactor, the structure of which includes a feed belt 1, a repair box 2, a turbine 3, and a nutrient solution tank 4. The top of the feed belt 1 is attached to the side of the repair box 2, and the repair The side of the box 2 is connected to the side pipe of the turbine 3, the middle section of the nutrient solution tank 4 is connected to the top pipeline of the repair box 2, the middle section of the nutrient solution tank 4 is connected to the top pipe of the turbine 3, and the repair box 2 is provided with a preliminary screening plate 21 , mud mixing cylinder 22, reaction tank 23, winch 24, water pump 25, discharge belt 26, the side of the first screening plate 21 is connected to the side flange of the mud mixing cylinder 22, and the other side of the mud mixing cylinder 22 is connected to the reaction tank. The side flange of the tank 23 is connected, the bott...

Embodiment 2

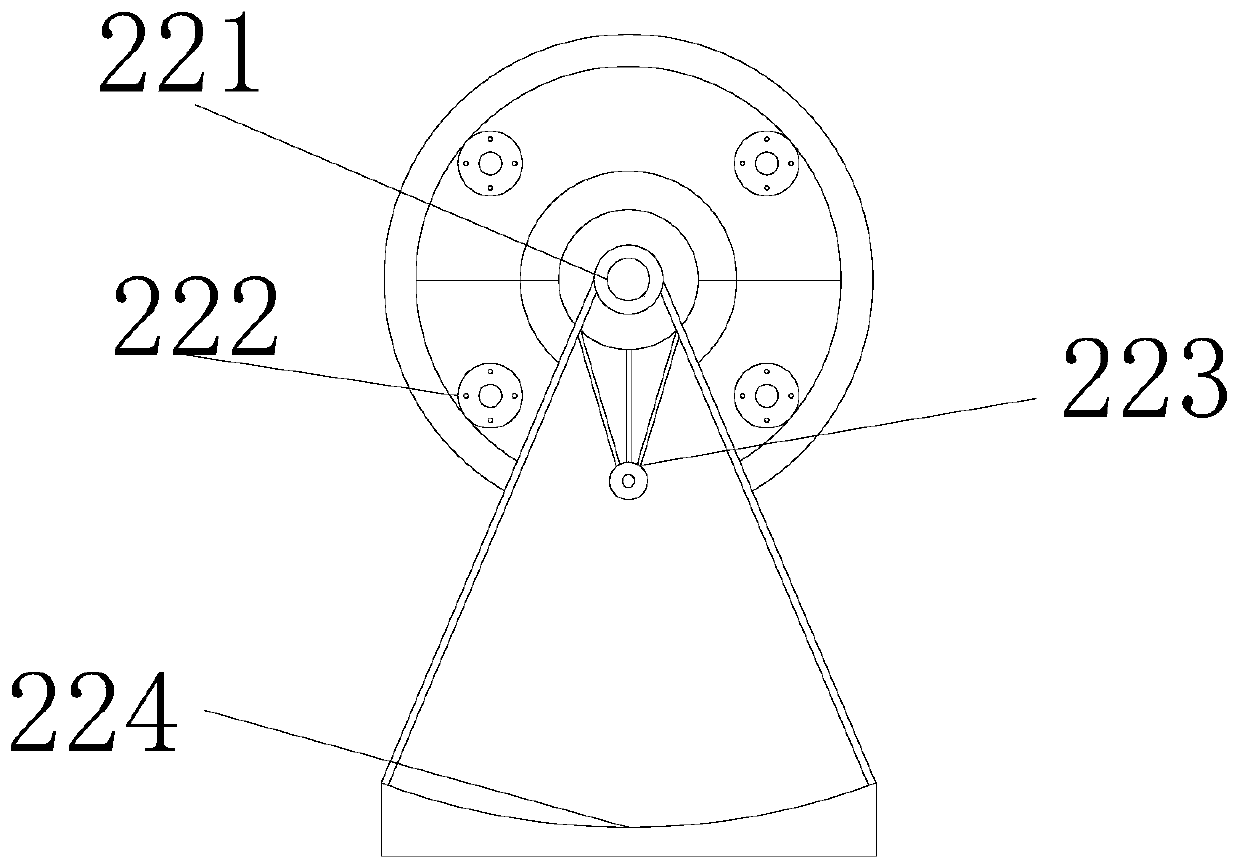

[0034] as attached Figure 7 Shown:

[0035] Wherein, the grinding tube 22b is provided with an inner pad h1, an inner container h2, a mesh h3, and a connection port h4, the outer surface of the inner pad h1 is movable with the inner surface of the inner container h2, and the outer surface of the inner container h2 is in contact with the grinding surface. The inner wall of the pipe 22b is nested and connected, the center of the screen hole h3 is connected with the surface wall of the inner tank h2, the side wall of the connecting port h4 is perforated and matched with the bottom of the inner tank h2, and the side wall of the connecting port h4 is embedded with the side of the connecting rod 22d. Sleeve connection, the sieve holes h3 are distributed symmetrically from left to right, and the surface of the inner pad h1 is in a ring-shaped distribution structure with dense grooves, which can better maintain the particle size during the grinding process and avoid grinding too fine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com