Fastening belt assembly and method for mounting and dismounting wind turbine generator turbulent flow strip

A technology of wind turbines and fastening belts, which is applied in the assembly of wind turbines, the configuration of installation/support of wind turbines, wind power generation, etc., and can solve problems such as potential safety hazards, hidden dangers for operators and unit safety, and difficulties in removing spoilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

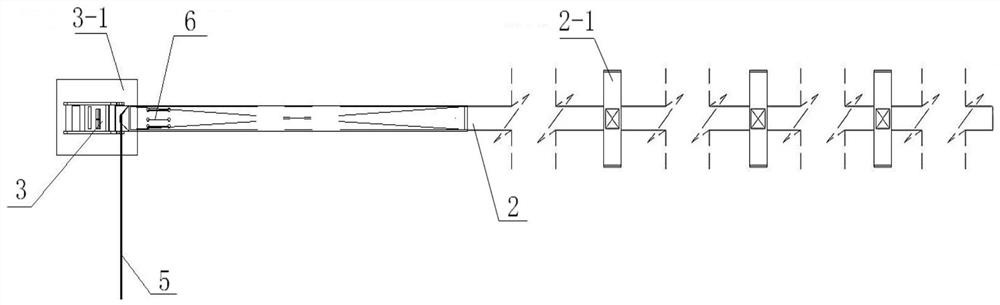

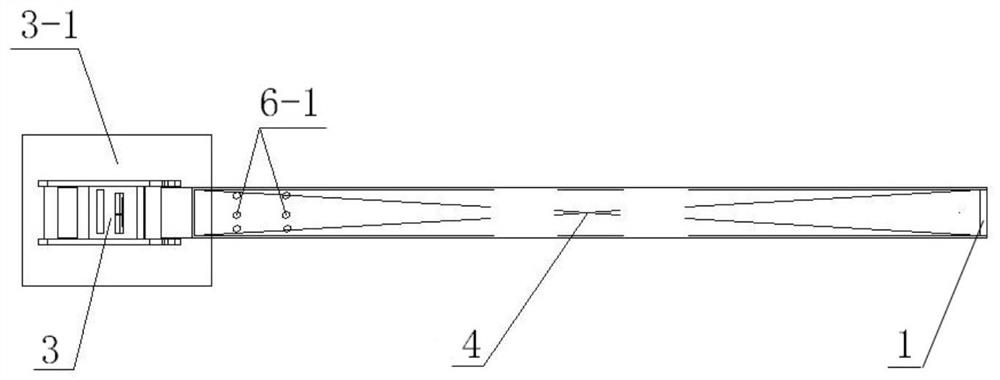

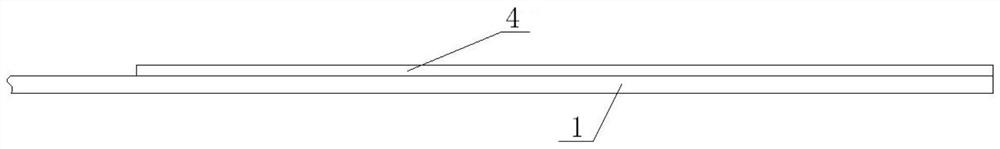

[0032] see Figure 1 to Figure 4 As shown, this embodiment provides a fastening strap assembly for the installation and removal of the wind turbine spoiler strip, including a first fastening strap 1, a second fastening strap 2, a fastener 3, a Velcro 4, Cable 5 and cable tie 6; one end of the first fastening belt 1 is connected to the fastener 3, the other end is glued with Velcro 4, and there are a plurality of through Velcro 4 and the first bolt on this end The cable tie hole 6-1 of the tightening belt 1; one end of the second tightening belt 2 is a free end, and the other end is provided with an installation position 2-2 for cable installation, and at the installation position 2-2 The side fastening belt part is glued with Velcro 4, and the second fastening belt 2 is provided with a plurality of cable tie penetration holes 6-2 that pass through the Velcro 4 and the second fastening belt 2, and the second The cable tie penetration holes 6-2 on the fastening belt 2 correspon...

Embodiment 2

[0035] see Figure 5 to Figure 7 As shown, this embodiment provides a method for installing and dismounting a wind turbine spoiler strip, which uses the fastening strap assembly described in Embodiment 1, and its specific implementation is as follows:

[0036] 1) Install a fastening belt assembly about 100mm away from the upper and lower flanges 7 and 8 of the tower of the wind turbine (staggered flange weld position), and then operate the second bolts of the two fastening belt assemblies respectively Wrap the free ends of the straps at least 2-3 times on the rotating shafts of the respective fasteners to tighten the straps, and then cover the fasteners with a protective sleeve to prevent the fasteners from automatically rebounding and the straps from falling off.

[0037] 2) Lift the tower about 1m above the ground to facilitate the installation of spoilers. The number of spoilers to be installed should be determined according to the actual situation of the vortex-induced vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com