Enclosed waterproof reinforced structure of original plain wall of shield and construction technology

A technology of strengthening structure and starting element, which is applied in the field of shield starting plain wall sealing water-stop reinforcement structure and construction technology, can solve the problems of long construction period and high cost of freezing method, achieve the purpose of strengthening the ground and blocking groundwater, and ensuring stability The effect of avoiding the dangerous situation of water gushing and sand gushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

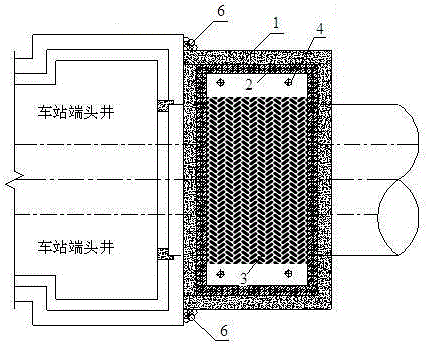

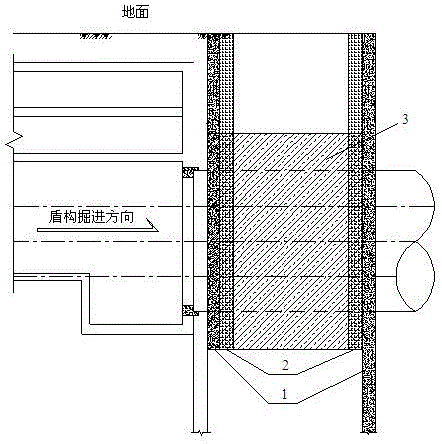

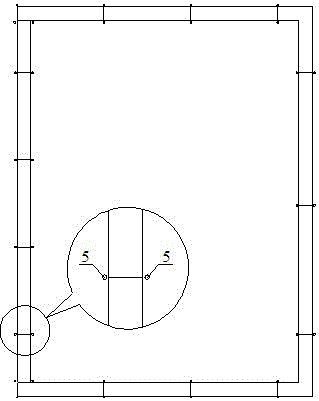

[0035] A shield water-stop reinforcement structure for the starting plain wall of the shield machine, the structure includes a mixing pile 3 arranged at the end of the shield starting shaft to reinforce the soil; Concrete underground diaphragm wall 1 forms a closed water-stop curtain structure with the enclosure wall of the station enclosure to reduce the influence of precipitation in the pit on the settlement of the soil outside the pit and ensure effective water isolation. The plain concrete underground diaphragm wall 1 The inner and outer sides of the joints are pre-embedded with grouting pipes 5, so as to perform grouting and anti-leakage operations on the joints with leakage; the plain concrete underground diaphragm wall 1 and the mixing pile 3 are closed with 2 rows of rotary grouting piles 2; More than one dewatering well 4 is also arranged in the reinforced area outside the tunnel diameter.

[0036] Stirring pile 3 adopts Φ850@600 three-axis stirring pile.

[0037] Th...

Embodiment 2

[0049] A shield water-stop reinforcement structure for the starting plain wall of the shield machine, the structure includes a mixing pile 3 arranged at the end of the shield starting shaft to reinforce the soil; Concrete underground diaphragm wall 1 forms a closed water-stop curtain structure with the enclosure wall of the station enclosure to reduce the influence of precipitation in the pit on the settlement of the soil outside the pit and ensure effective water isolation. To be safe, a concrete plain underground diaphragm wall 1 is set on the outer side of the enclosure wall of the station enclosure structure, the depth is 5m below the shield tunnel structure, and forms a closed connection with the "concave" plain concrete underground diaphragm wall 1 outside the reinforcement area of the mixing pile 3. "Mouth" structure. Pre-embed the grouting pipes 5 inside and outside the joints of the plain concrete underground diaphragm wall 1, so as to perform grouting and anti-leak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com