Auxiliary device for starting and receiving of shield machine

An auxiliary device and shield machine technology, which is applied to mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of time-consuming and labor-intensive assembly, large manpower and material resources, fine-tuning, etc., so as to reduce assembly procedures, reduce equipment loss, The effect of avoiding construction risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0040] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

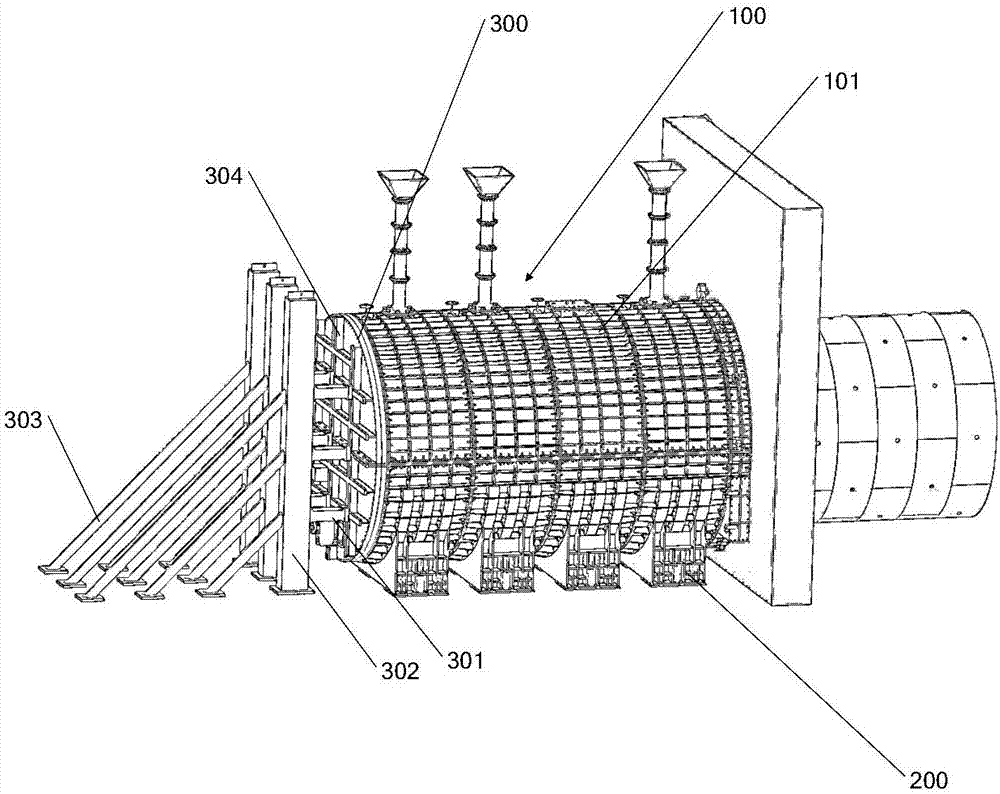

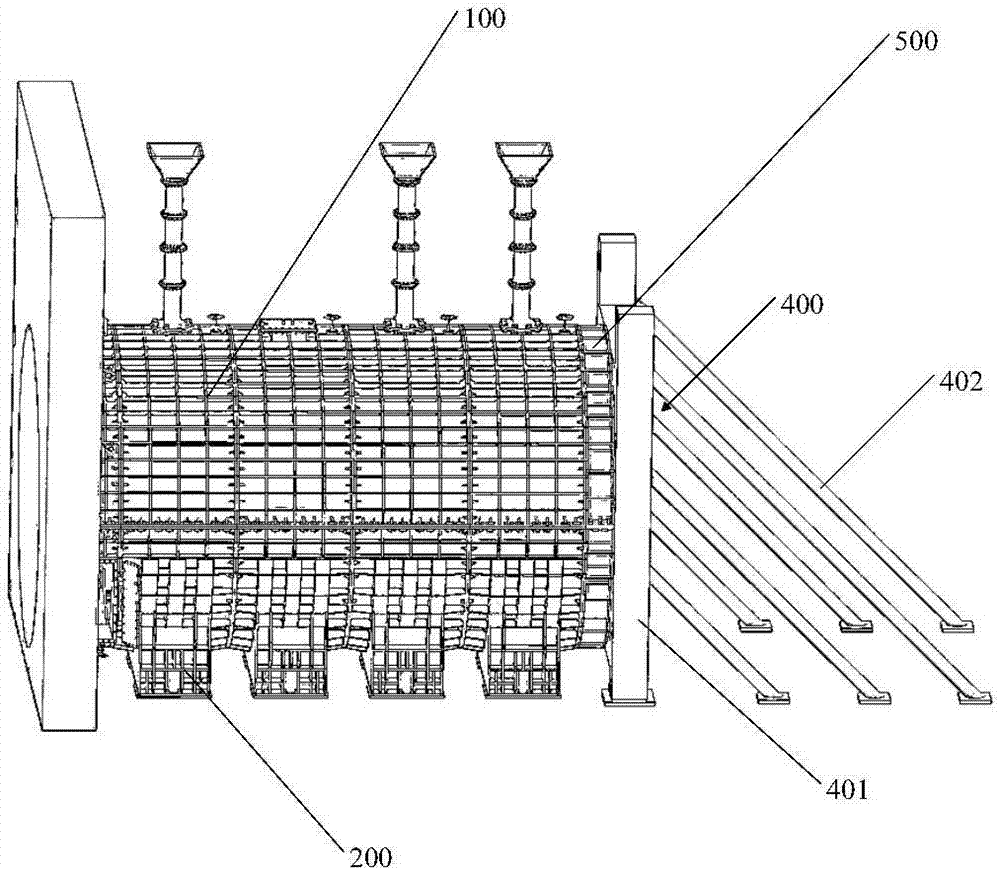

[0041] like figure 1 , 2 As shown, the present invention provides an auxiliary device for shield machine origination and reception, which includes:

[0042] The steel sleeve 100 is formed by connecting multiple sections of cylinders 101; the steel sleeve 100 is, for example, 10500mm long and 6700mm in inner diameter. The steel sleeve 100 is, for example, assembled from four cylinders 101 .

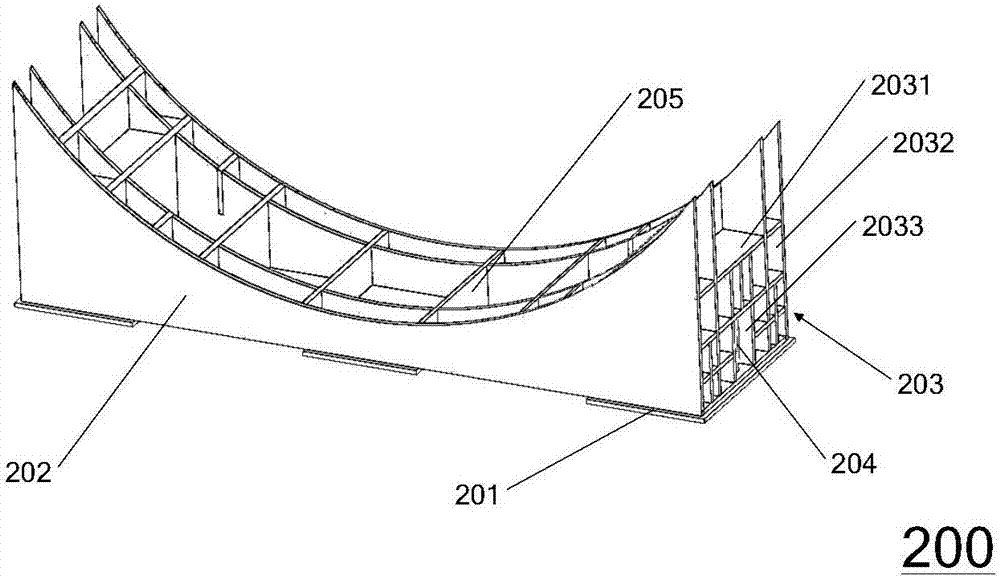

[0043] The bottom frame 200 is arranged at the bottom of the steel sleeve 100. The bottom frame 200 is also divided into multiple sections corresponding to the steel sleeve 100. Each section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com