Assembly-type deep and large round vertical shaft structure for rock stratum area and construction method

A prefabricated, construction method technology, applied in vertical shaft equipment, well sinking, wellbore lining, etc., can solve the problems of high risk, high investment, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

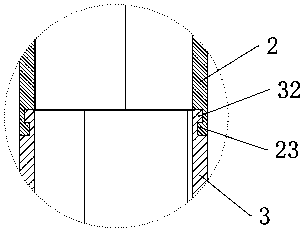

[0040] Example 1, please refer to Figure 1-6 , the present invention solves the above-mentioned technical problems through the following technical means: the present invention provides an assembled deep and large circular shaft structure in a rock formation area, including a locking ring beam 1 arranged at the wellhead of the circular shaft, and the locking ring beam 1 The lower end is provided with a first annular segment 2, and the first shaft segment includes multiple pieces, and the plurality of first annular segments 2 surround a circular first section shaft 21, and the first annular segment 2 Connected by bolts in the ring direction, the lower end of the first annular segment 2 is connected with the second annular segment 3, and a plurality of the second annular segment 3 surrounds the second shaft 31, and the first shaft 21 The lower connection has multiple second section shafts 31, which are arranged sequentially from top to bottom. The inner ring of the locking ring ...

Embodiment 2

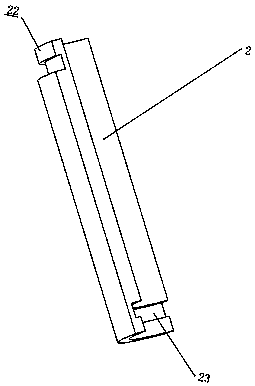

[0045] Example 2, please refer to Figure 7-11 , the joint part 11 is an "L"-shaped protrusion arranged on the inner ring of the locking ring beam, the first upper interface 22 is an "L"-shaped notch matching the joint part 11, and the first upper The interface 22 is arranged on the outer wall of the upper end of the first annular pipe, and is recessed from the outer wall of the first annular pipe to its inside. "L"-shaped notch, the first lower interface 23 is arranged on the inner wall of the lower end of the first annular tube, and is recessed from the inner wall of the first annular tube toward the outer wall, and the second annular segment 3 is connected to the first annular tube Segment 2 has exactly the same structure. The joint part 11 with the "L"-shaped protrusion and the "L"-shaped notch is connected with the first upper interface 22, so that the connection is convenient and fast, and the first annular segment 2 is directly hooked to the locking ring beam 1 Just p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com