Process for separating protein, apple polyphenol, apple starch and pigment from apple juice

A technology for the separation of apple polyphenols, which is applied in the field of separating protein, apple starch and pigment in apple juice, and apple polyphenols. It can solve the problems of high production and operation costs, reduced juice acidity, and large consumption of raw materials, and achieve comprehensive utilization. High efficiency, increased output, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

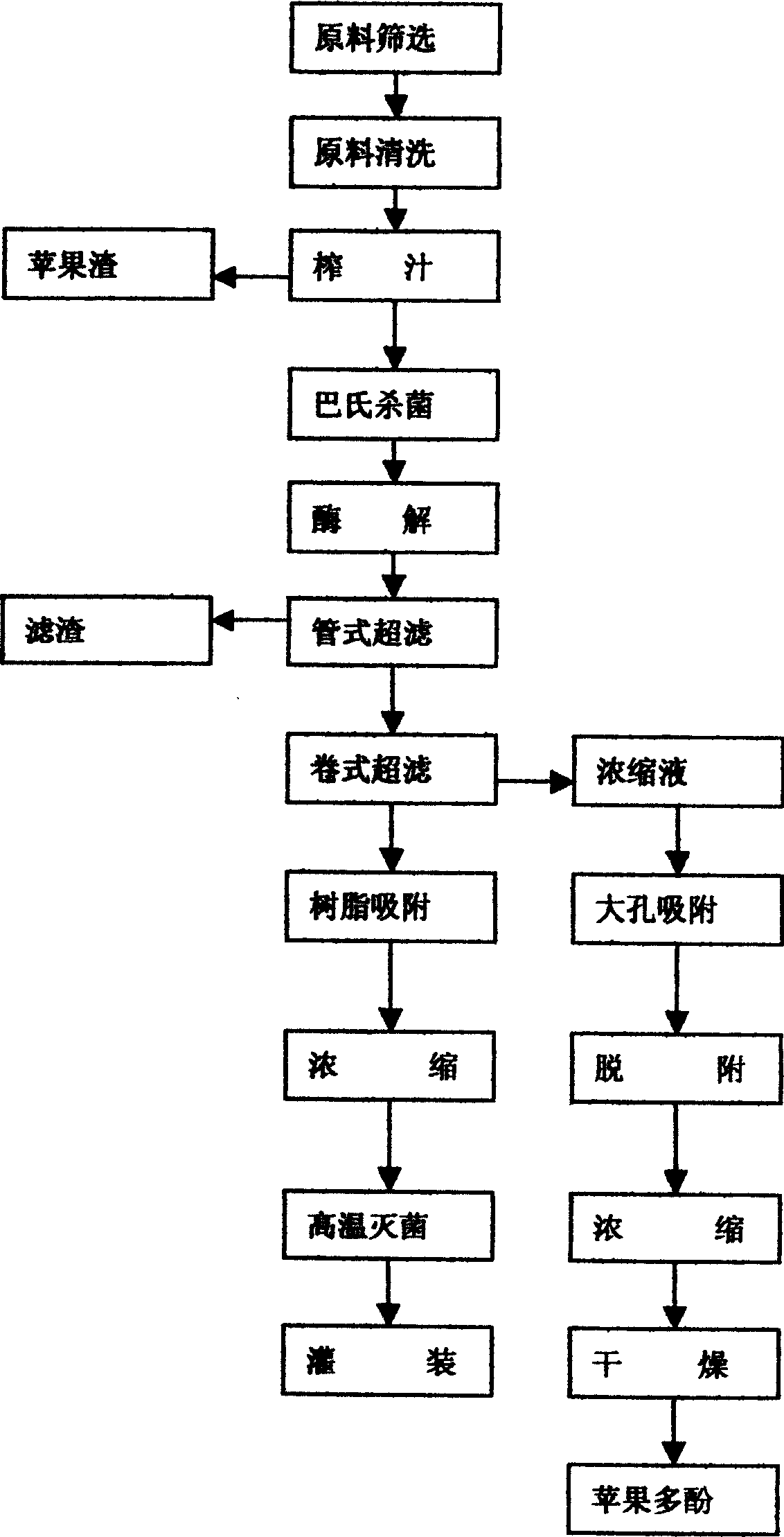

[0073] see figure 1 Block diagram of the process route. Take 540Kg of fresh apples and wash them, manually screen to remove impurities and rotten apples, and measure 500Kg of raw materials. The 500Kg apples that are screened are cleaned and drained through a trough type fruit washer. The apples that have been washed and drained are first pulverized with a pulverizer, and then squeezed with an apple juicer to obtain 452Kg of apple juice (stored in a juice storage tank), and 47.6Kg of pomace. 452Kg apple juice in the juice storage tank is pumped into heat sterilization equipment through a raw material pump, and sterilized at 85-100°C for 4-5 minutes to obtain sterilized apple juice. Then add 22g of pectinase and 115g of gelatin to the 452Kg of apple juice obtained by pasteurization, and enzymolyze it for 60 to 80 minutes at a pH of 3.4 to 3.5 and a temperature of 35 to 55°C (if necessary, take a sample and use an iodine reagent to test the starch The degree of hydrolysis unti...

Embodiment 2

[0084] Take 535Kg of fresh apples and wash them, artificially screen out impurities and rotten apples, and measure 500Kg of raw materials. The 500Kg apples that are screened are cleaned and drained through a trough type fruit washer.

[0085] The apples that have been washed and drained are first pulverized with a pulverizer, and then squeezed with an apple juicer to obtain 450Kg of apple juice (stored in a juice storage tank), and 49.5Kg of pomace. 450Kg apple juice in the storage tank is pumped into heat sterilization equipment through a raw material pump to sterilize at 85-100° C. for 5 minutes to obtain sterilized apple juice. 21g of pectinase and 120g of gelatin are added to 450Kg of apple juice obtained by pasteurization, and the enzyme is hydrolyzed for 70min under the condition of pH value of 3.4-3.5 and temperature of 35-55°C.

[0086] Pump the enzymolyzed apple juice into a tubular ultrafiltration system with a molecular weight cut-off of 150,000 for ultrafiltration...

Embodiment 3

[0092] Take 535Kg of fresh apples and wash them, artificially screen out impurities and rotten apples, and measure 500Kg of raw materials. The 500Kg apples of gained are cleaned and drained through a trough type fruit cleaner.

[0093] The apples that have been washed and drained are first pulverized with a pulverizer, and then squeezed with an apple juicer to obtain 454Kg of apple juice (stored in a juice storage tank), and 45.6Kg of pomace. 454Kg apple juice in the storage tank is pumped into heat sterilization equipment through a raw material pump and sterilized at 85-100° C. for 4 minutes to obtain sterilized apple juice. 23g of pectinase and 118g of gelatin were added to 454Kg of apple juice obtained by pasteurization, and enzymolysis was carried out for 80min at a pH value of 3.4-3.5 and a temperature of 35°C.

[0094] Pump the enzymatically hydrolyzed apple juice into a tubular ultrafiltration system with a molecular weight cut-off of 120,000 to carry out ultrafiltrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com