Installation method of submarine pipeline buckling detector

A submarine pipeline and installation method technology, which is applied in the direction of special pipes, pipe components, pipes/pipe joints/pipe fittings, etc., can solve the problems of loosening and falling off of wire rope nuts, adhesion of steel wire rope and welding spot welds of submarine pipelines, etc., to achieve smooth movement, The effect of reducing the probability of falling into the submarine pipeline and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

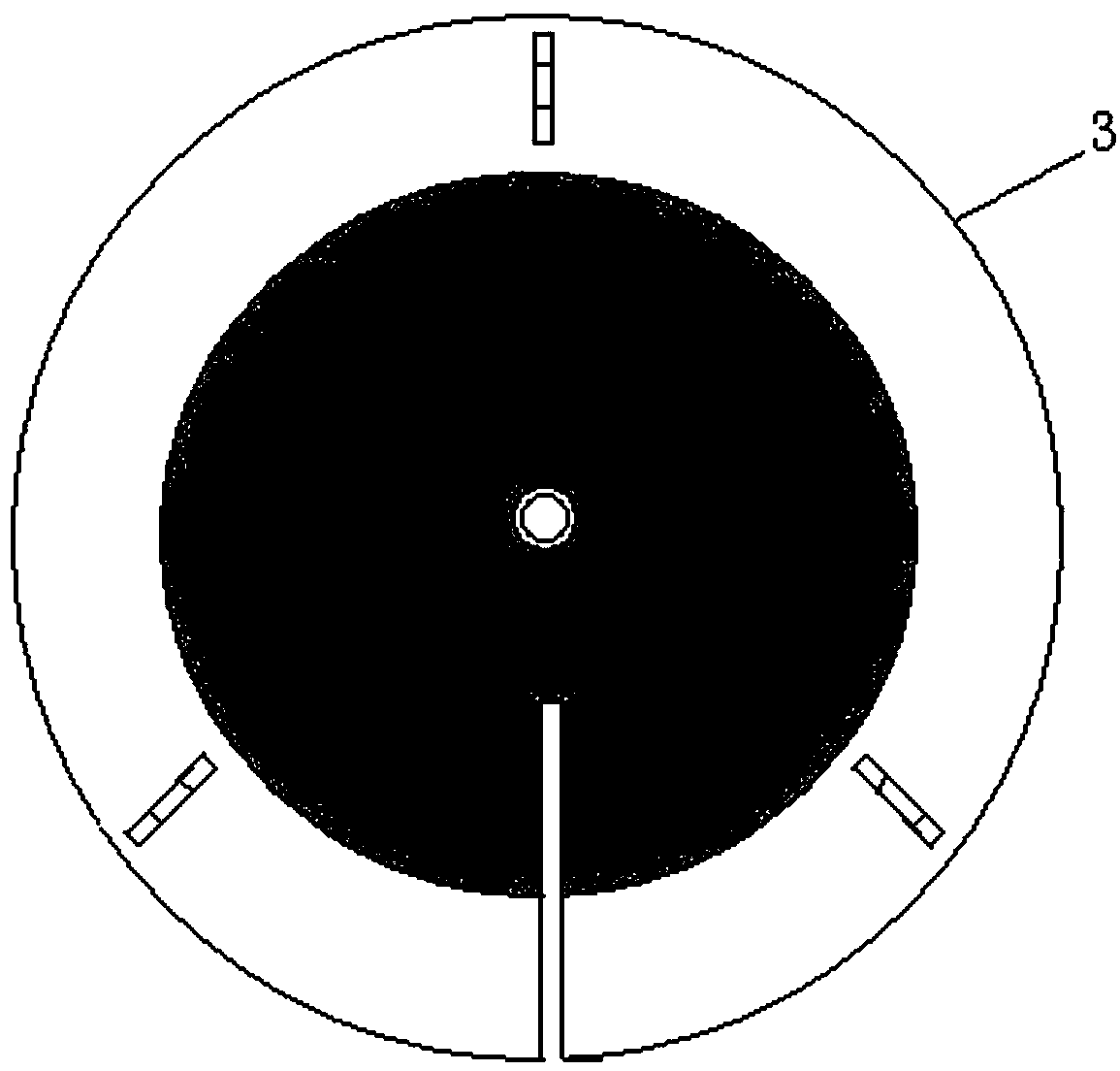

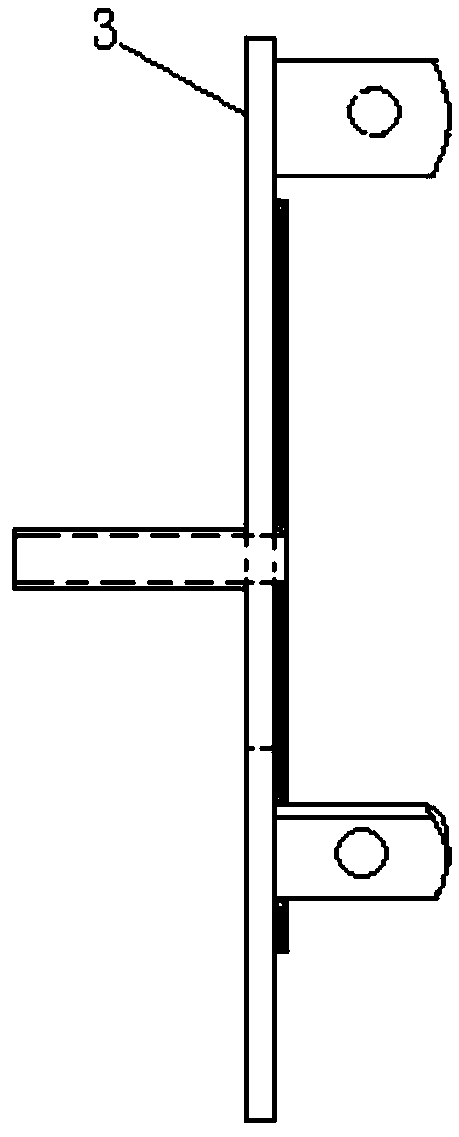

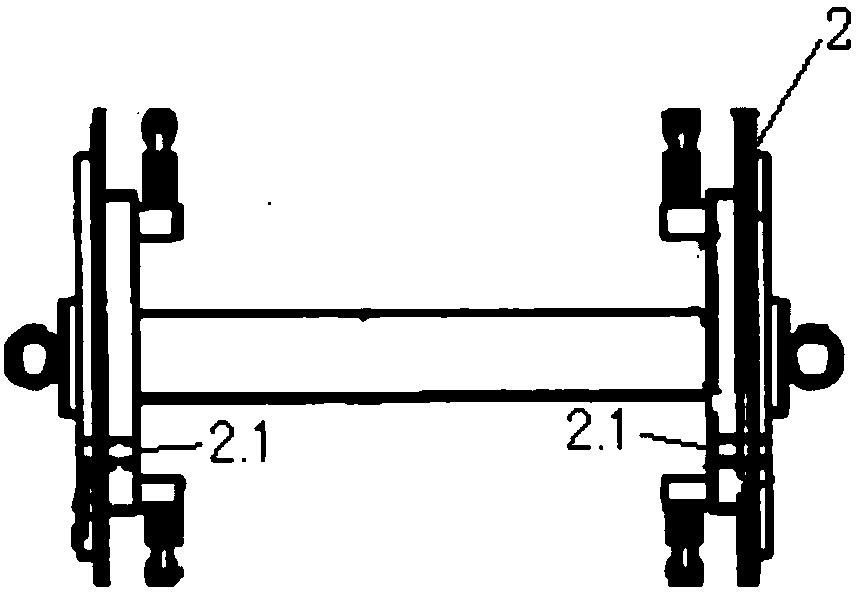

[0027] Such as figure 1 — Figure 4 As shown, the present invention adopts the following installation steps:

[0028] The first step: construction preparation, including:

[0029] 1) Determine the length of the required wire rope 5 according to the set position of the buckling detector 2 in the submarine pipeline 1, and mark the wire rope 5;

[0030] 2) According to the position of the welding point 7 of the submarine pipeline 1, determine the position of the copper pipe 4 on the steel wire rope 5;

[0031] 3) Set a section of copper pipe 4 on the set position of the steel wire rope 5 and fix it;

[0032] 4) Air vents 2.1 are provided on the buckling detector 2, and the vent holes 2.1 are arranged at any position on the baffles on both sides of the buckling detector, and each baffle is provided with a small hole;

[0033] Step 2: Connect the entire steel wire rope 5 to the buckling detector 2 through the snap ring 6, and put the buckling detector 2 into the submarine pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com