A method of using a self-locking nut

A self-locking nut and nut body technology, which is applied to nuts, screws, bolts, etc., can solve the problems of high product maintenance costs, interference damage, and failure to meet the locking performance requirements, and solve the problem of large attenuation of locking performance and lower cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

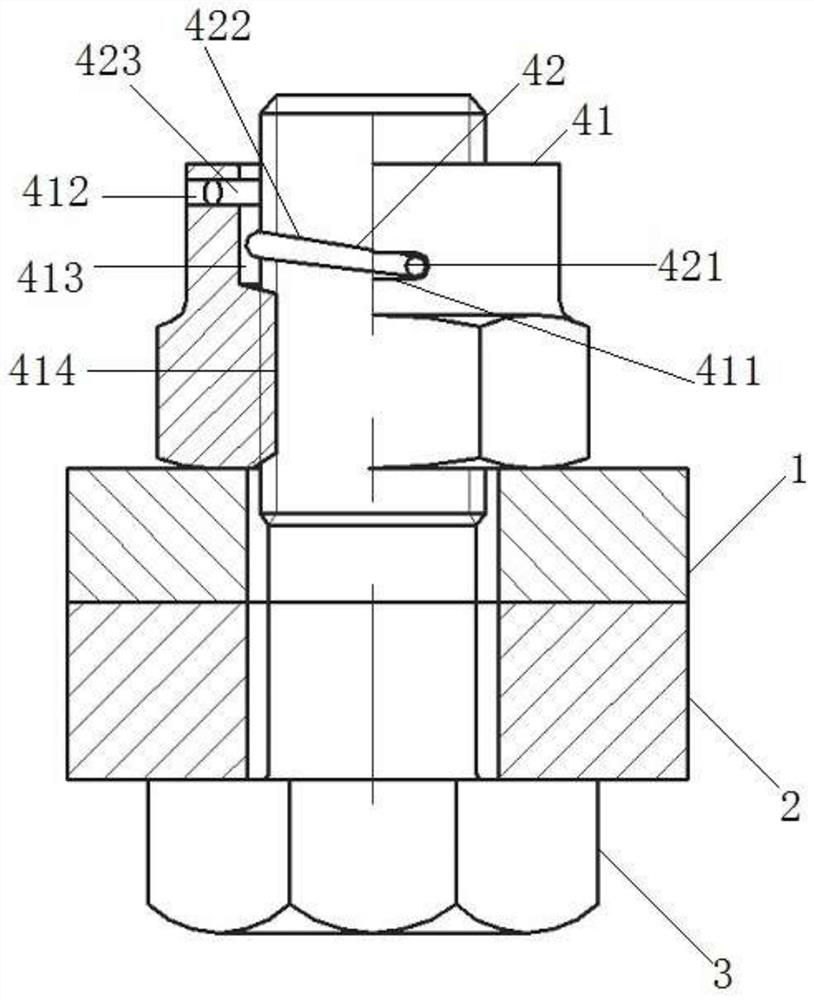

[0034] see Figure 1 to Figure 6 shown.

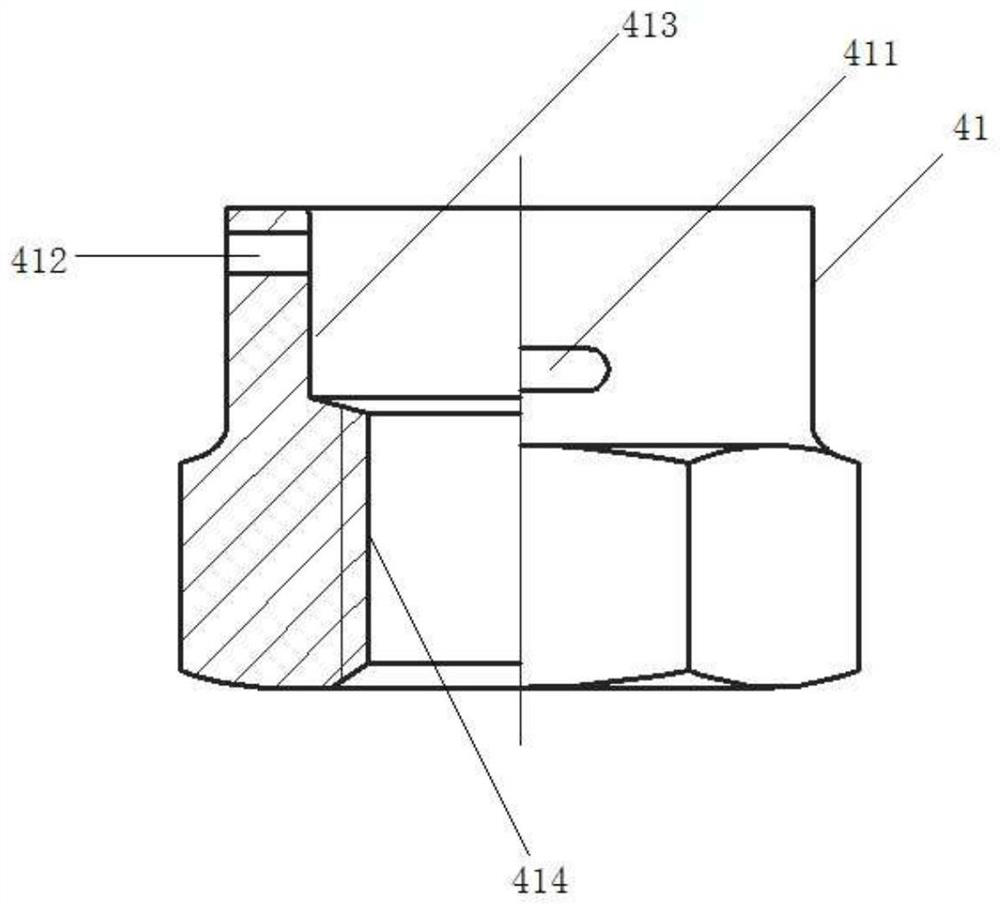

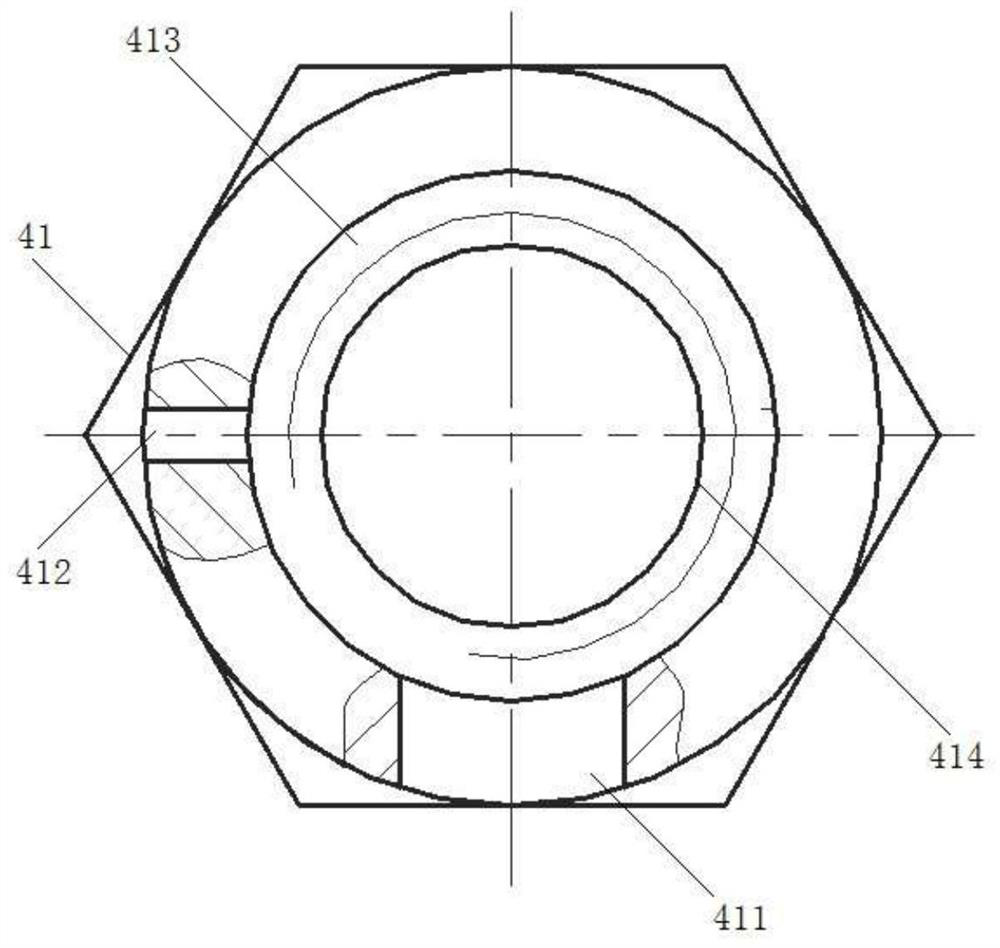

[0035] A kind of self-locking nut of the present invention, wherein, comprises: lock spring body 42 and nut body 41, and lock spring body 42 is installed in the nut body 41;

[0036] The lock spring body 42 includes a clamping end A421, a helical section 422, and a clamping end B423, and the clamping end A421 and the clamping end B423 are respectively fixedly connected to two ends of the helical section 422;

[0037] The nut body 41 is provided with an upper hole 413 and an internally screwed hole 414. The diameter of the upper hole 413 is larger than the inner screw hole 414. After the upper hole 413 is communicated with the internally screwed hole 414, the nut body 41 is formed to be able to penetrate and screw together. through holes for bolts;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com