Shale gas well no-killing production tubular column capable of being lifted up and put down under no pressure and construction method

A technology for shale gas wells and production pipe strings, which is applied to wellbore/well components, wellbore/well valve devices, drilling pipes, etc. Due to the difficulty of pipeline crossing and high construction costs, the effect of avoiding construction risks and costs, avoiding energy losses and safety accidents, and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

[0037] This embodiment provides a shale gas well production string without snubbing without snubbing, including a packer setting-dropping string and a tie-back completion string.

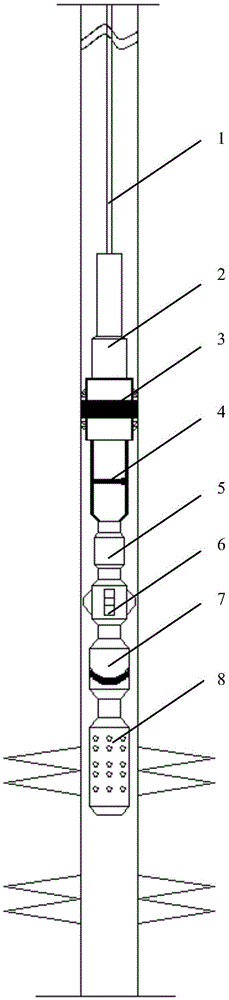

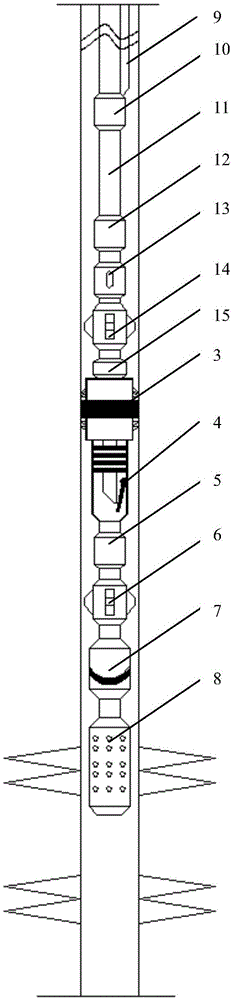

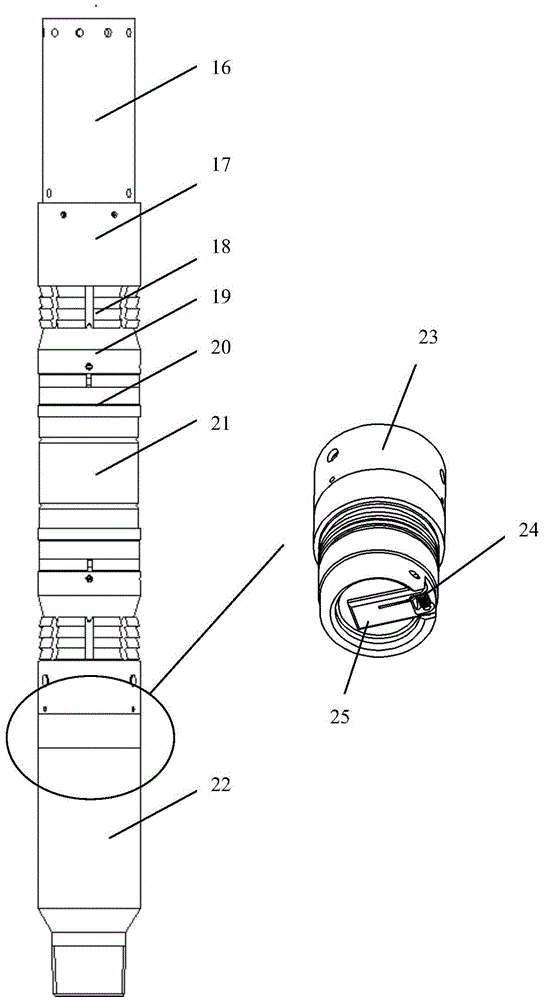

[0038] Such as figure 1 As shown, the packer setting-drop string includes a tripping tool, a setting tool 2, a permanent intubation packer 3, a lower mandrel 5, a centralizer 6, Rupturing disk 7, screen pipe 8; among them, the lifting tool is cable or coiled tubing 1. When the setting tool is run in by cable, it is set by gunpowder, and when it is run in by coiled tubing, the setting tool is hydraulically set. Such as image 3 As shown, the permanent intubation packer 3 includes a hand-off joint 17, a central pipe 16, a slip 18 sleeved on the central pipe, a cone 19, a rubber cartridge protection mechanism 20, a rubber cartridge 21, and the central pipe The lower end is connected with a top-op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com