Patents

Literature

49results about How to "Improve tensioning efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

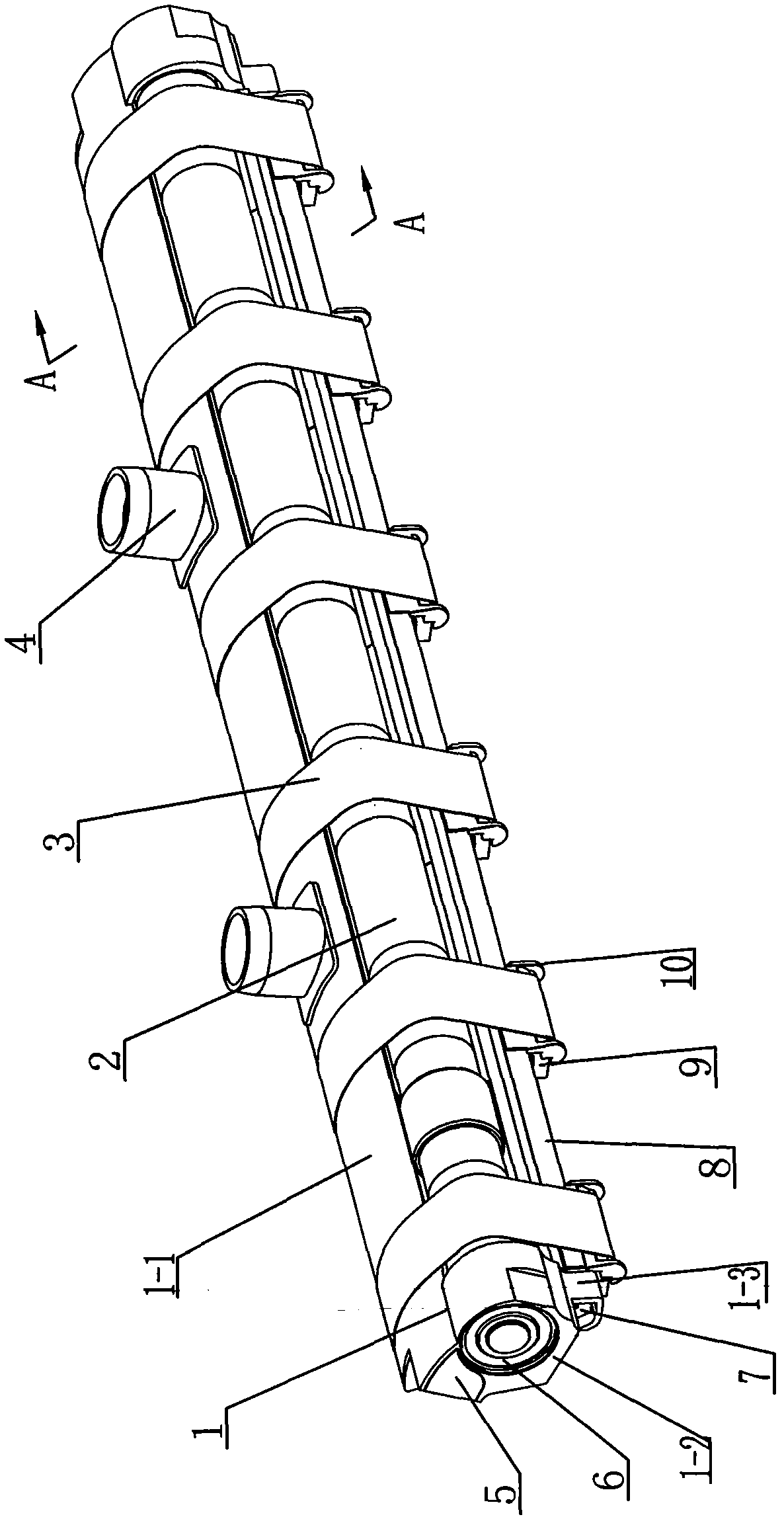

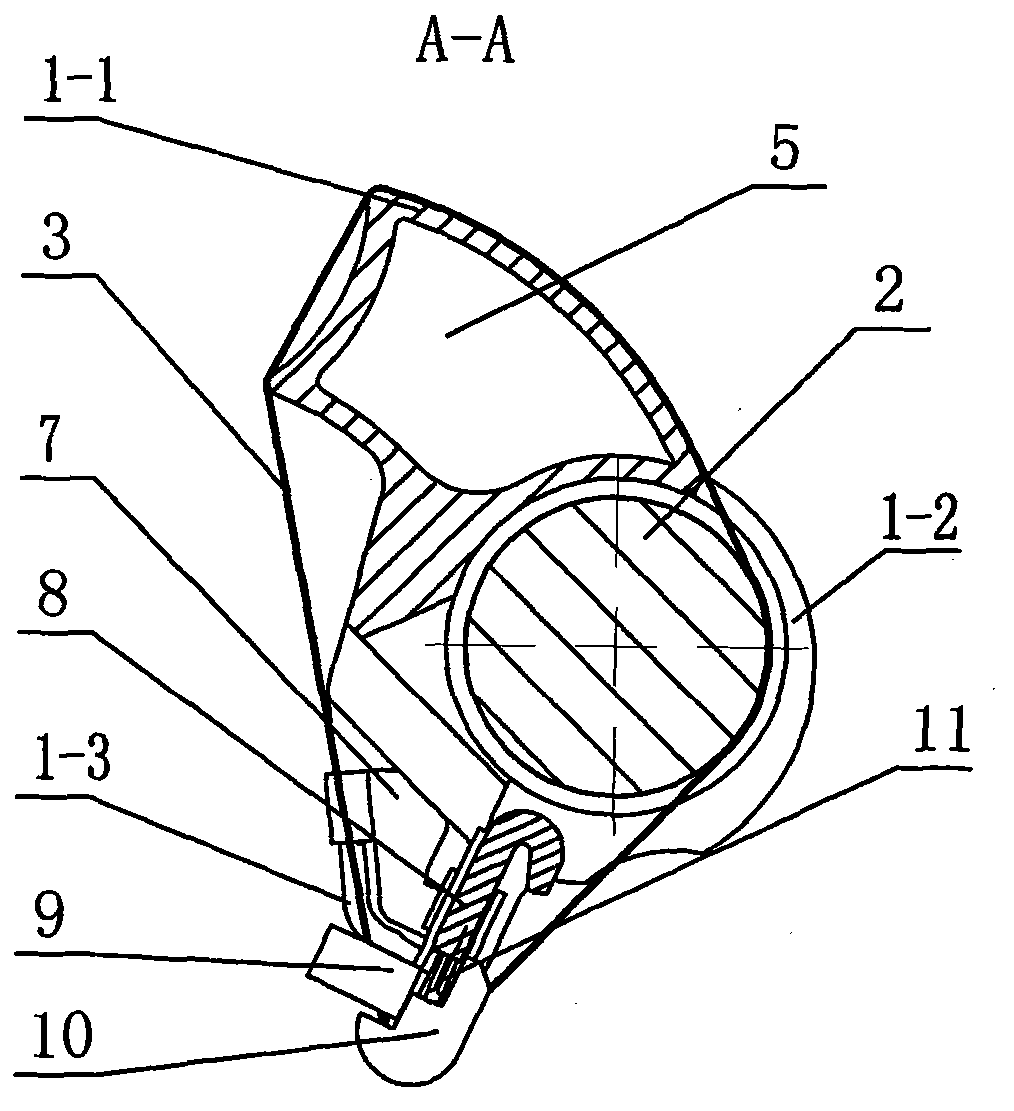

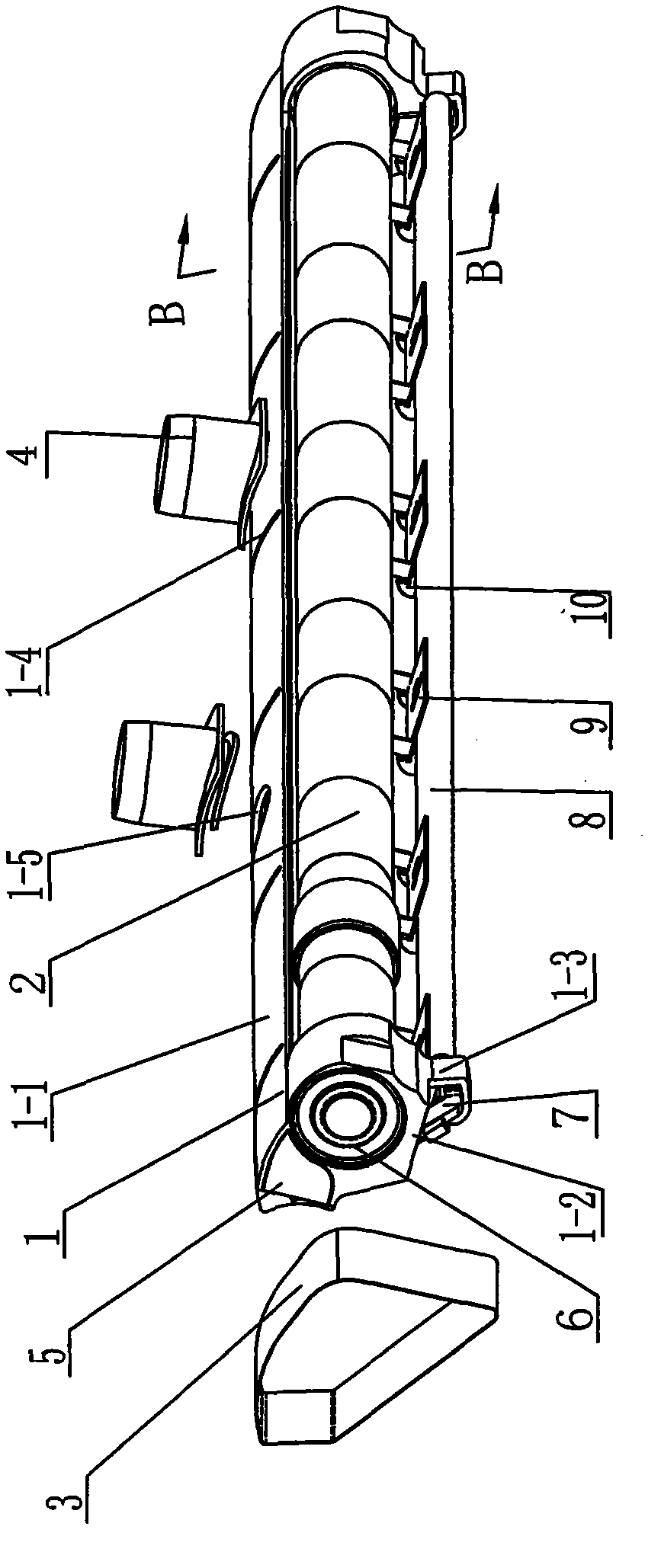

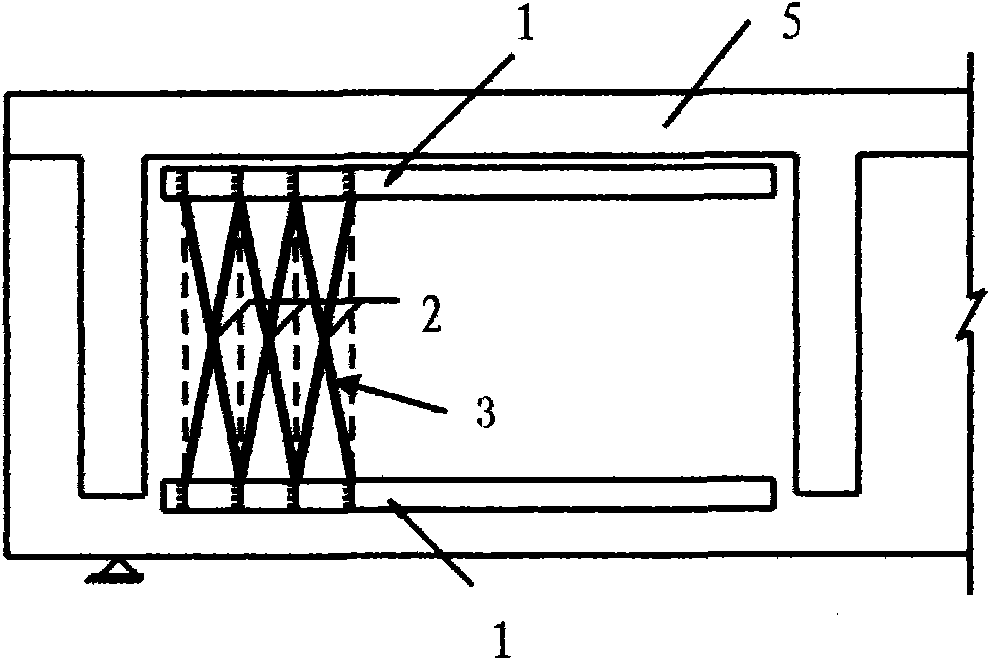

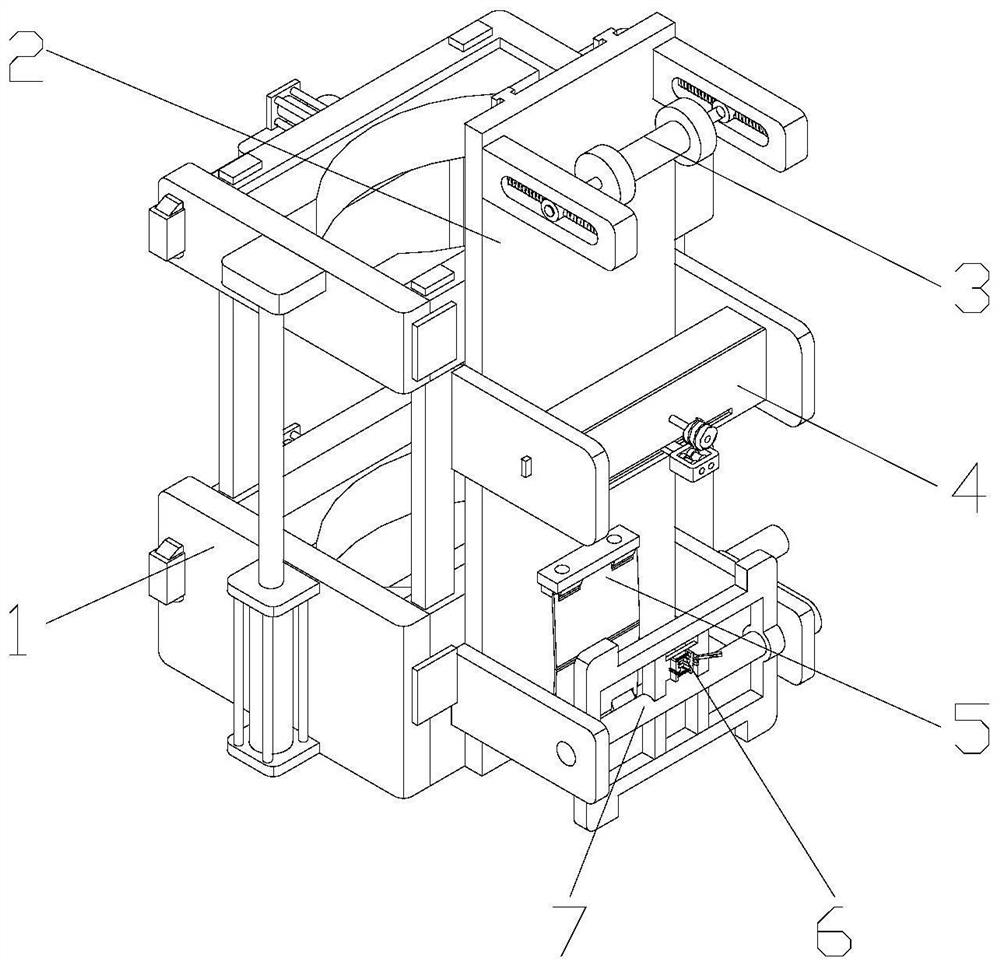

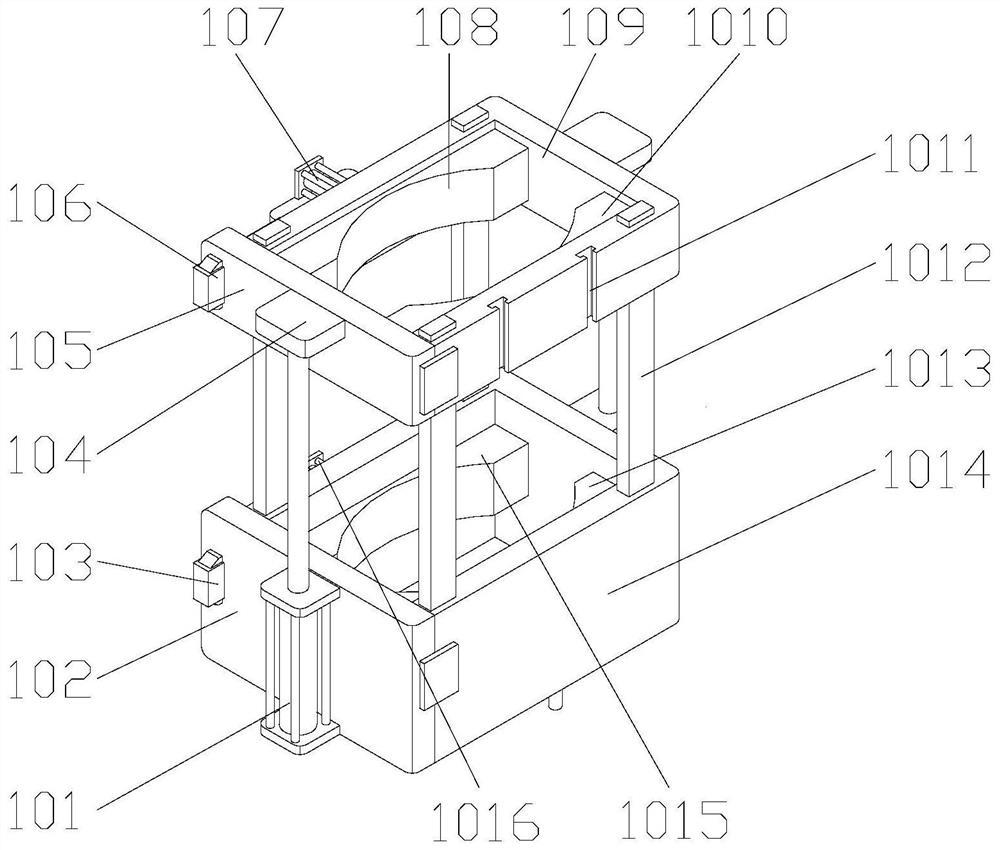

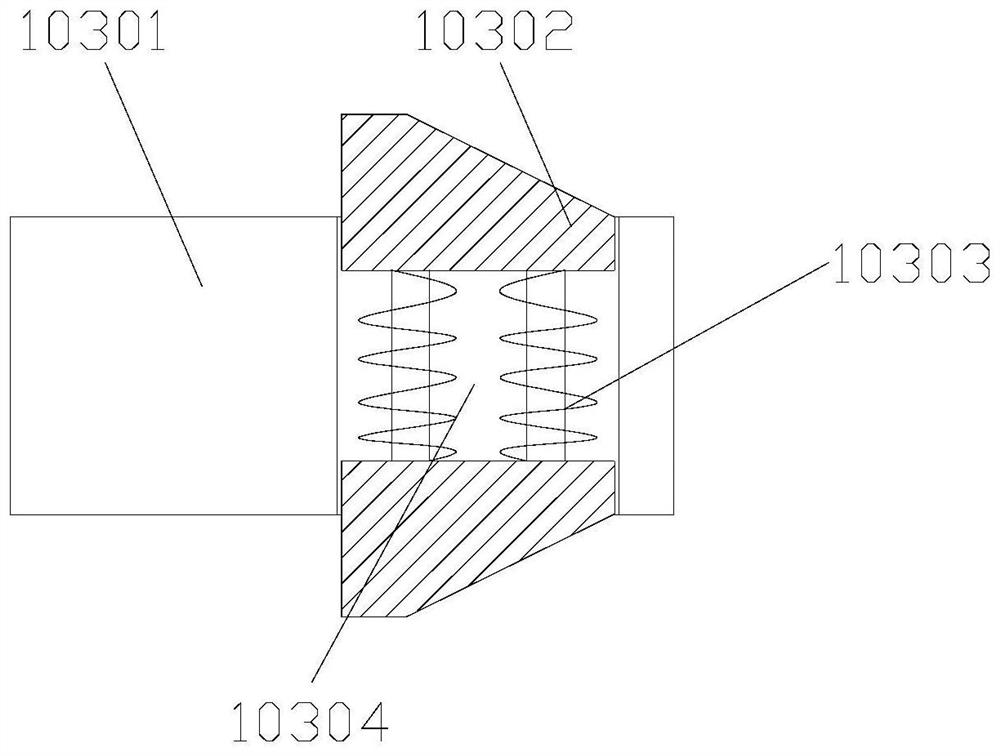

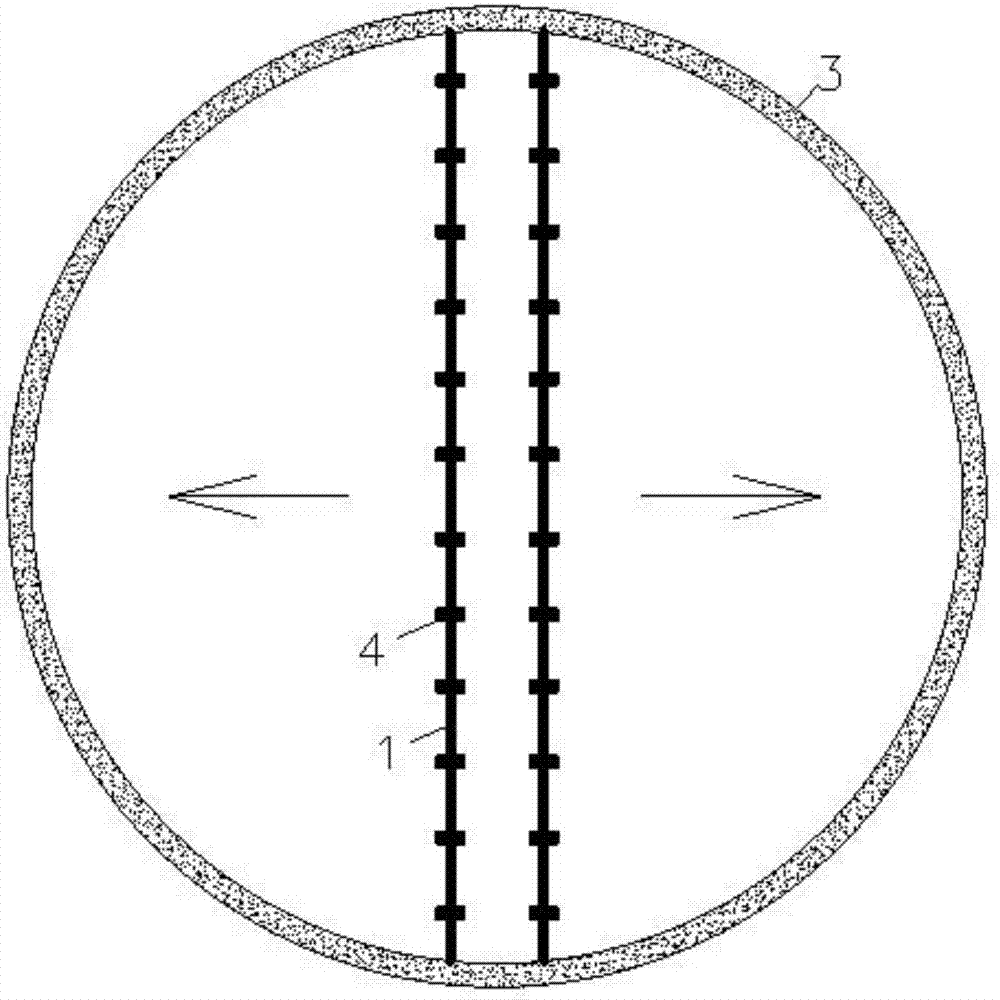

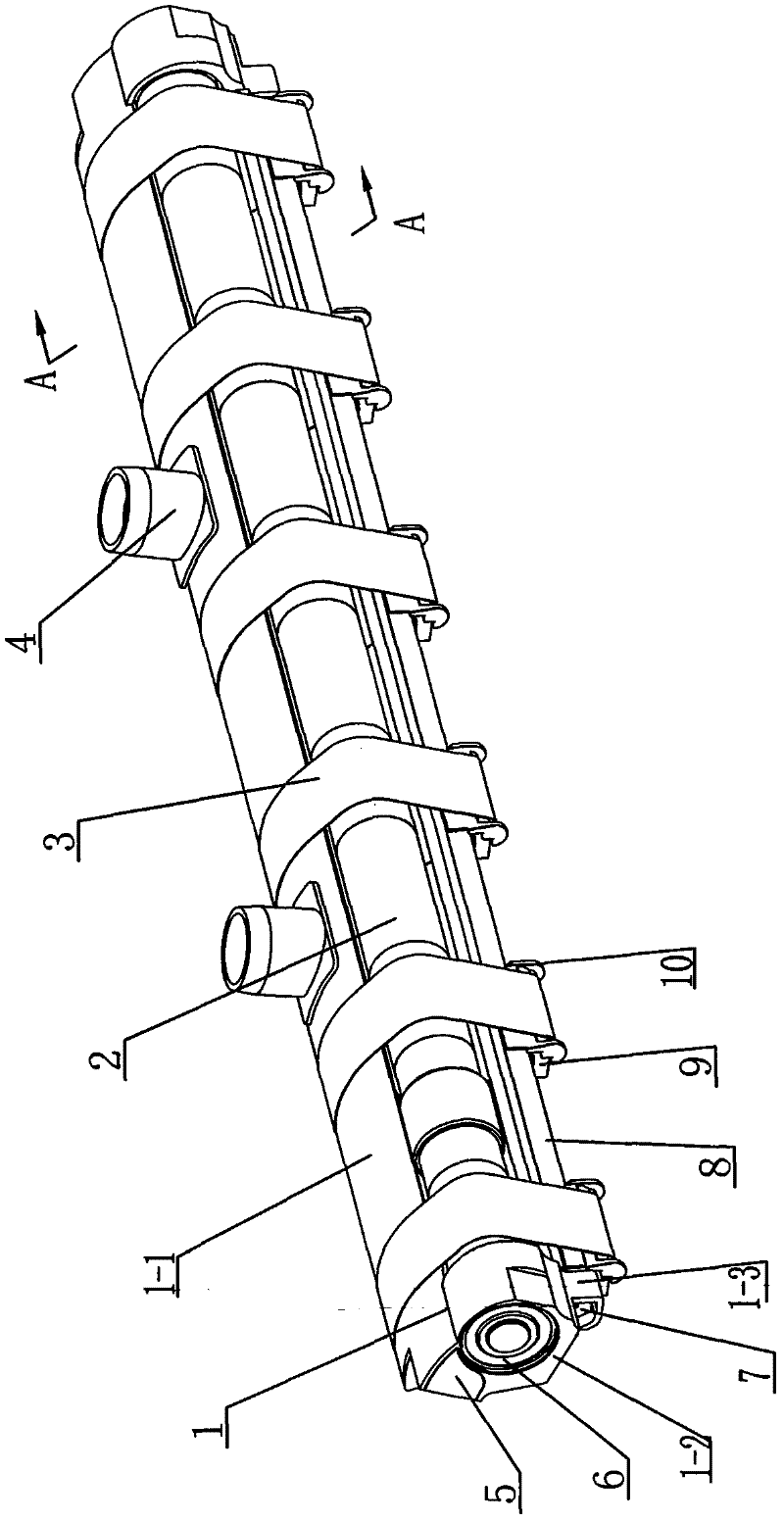

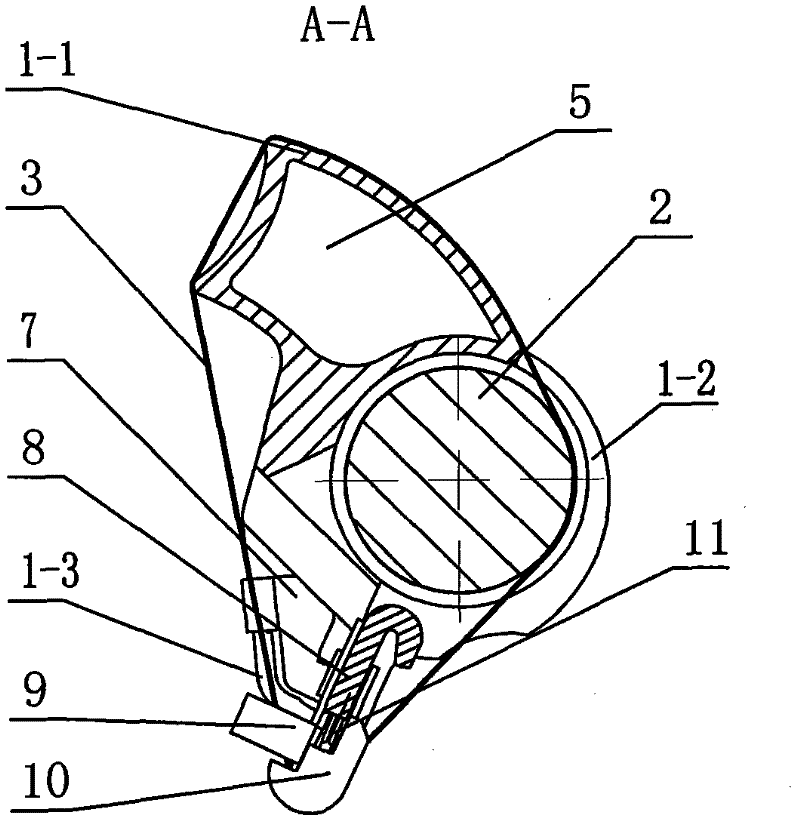

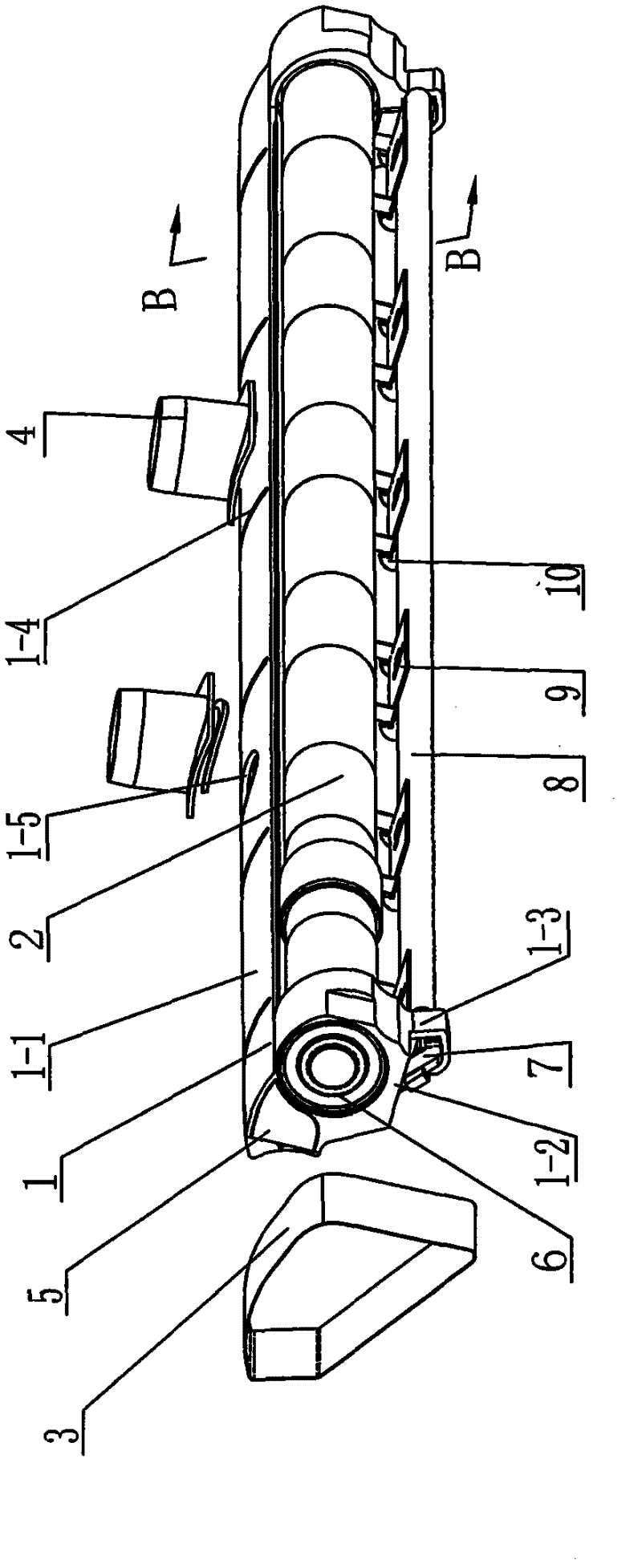

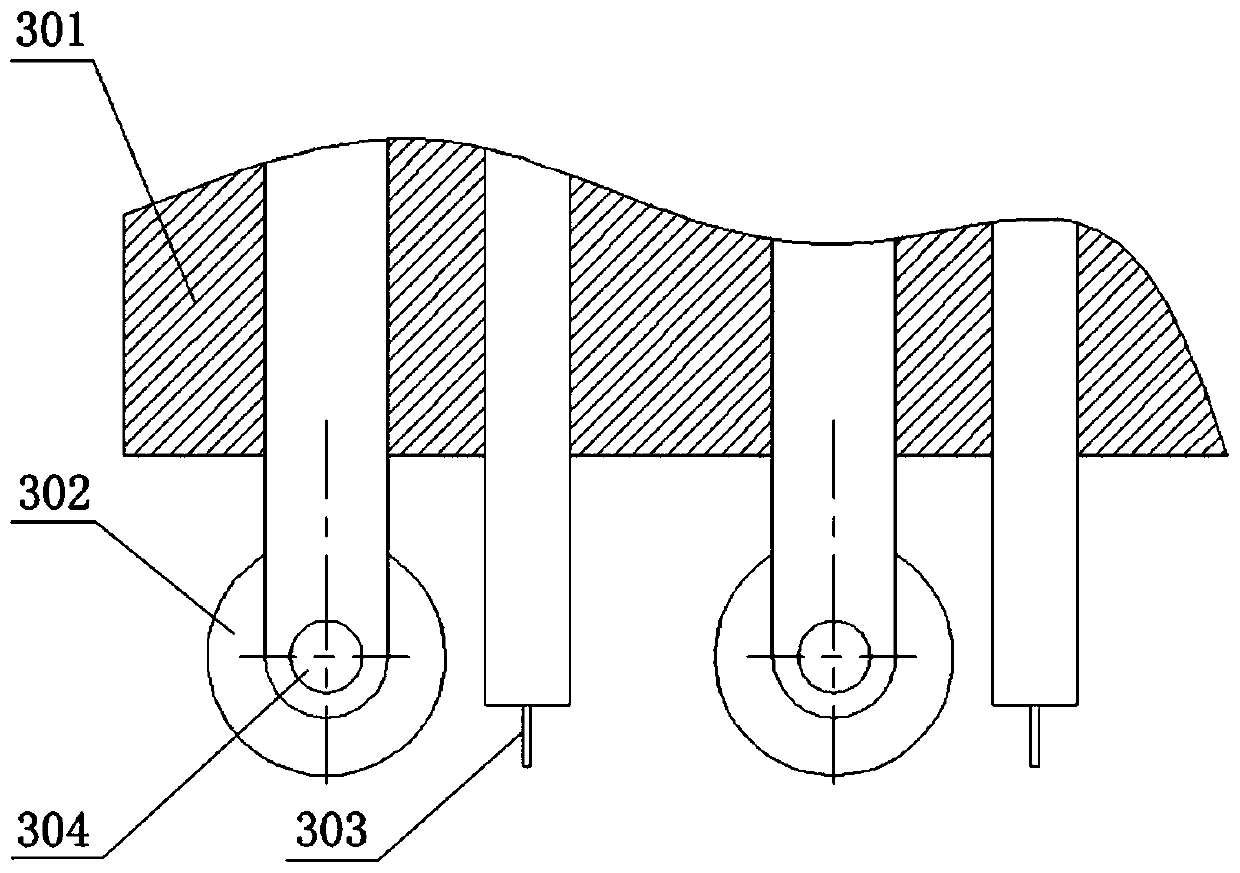

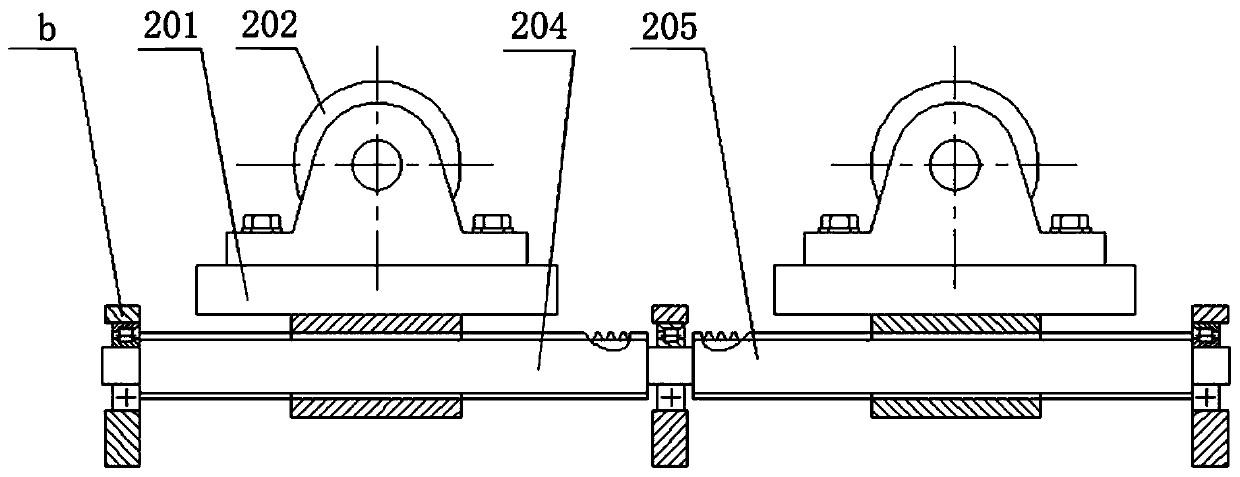

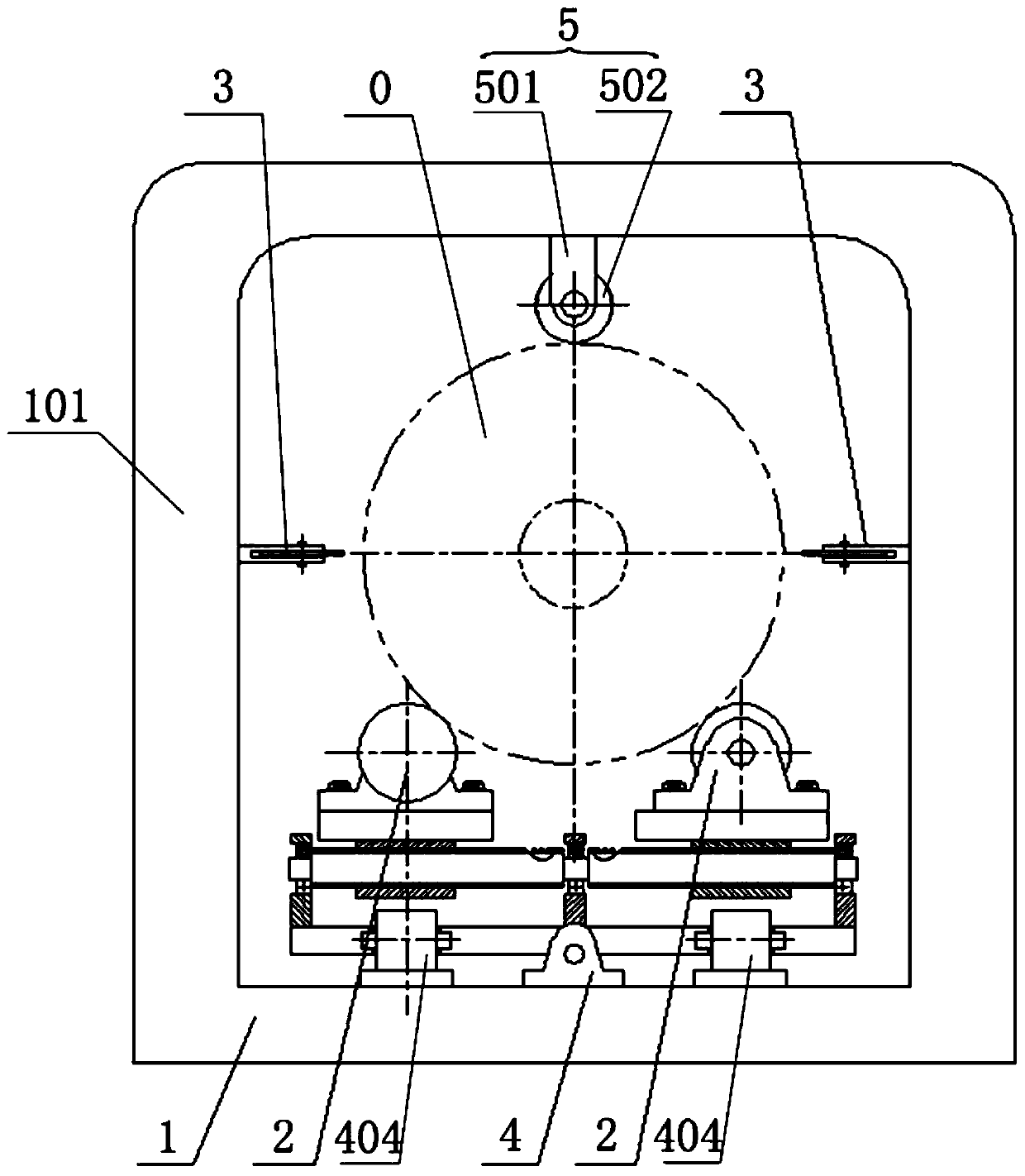

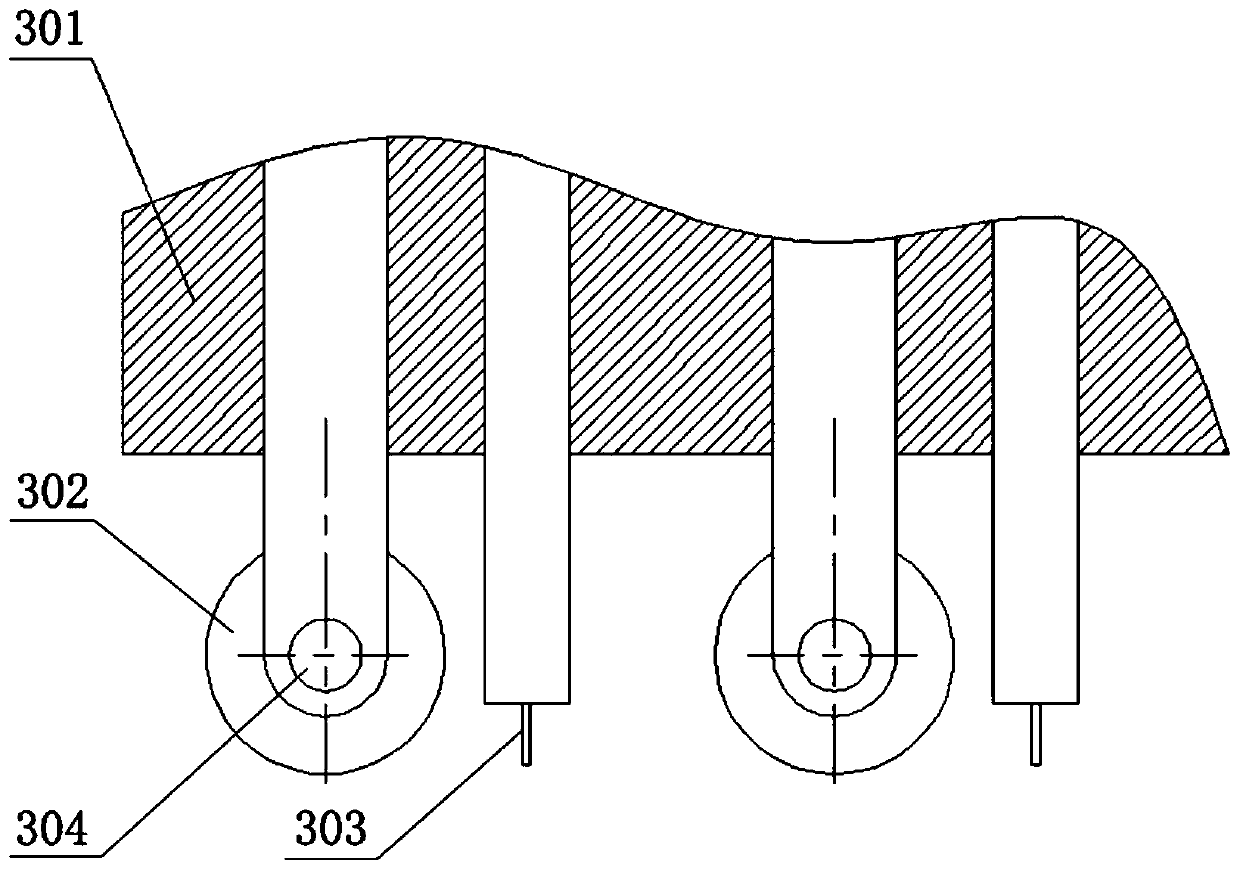

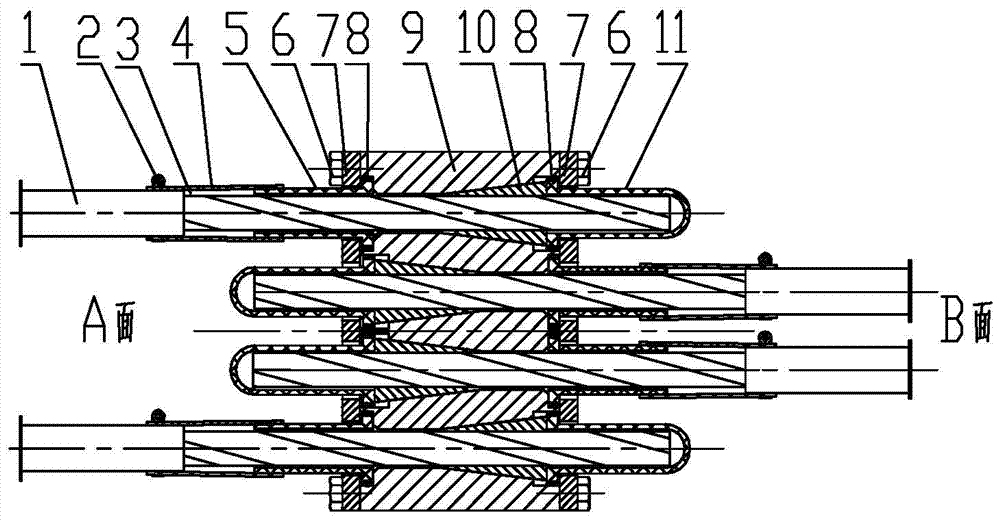

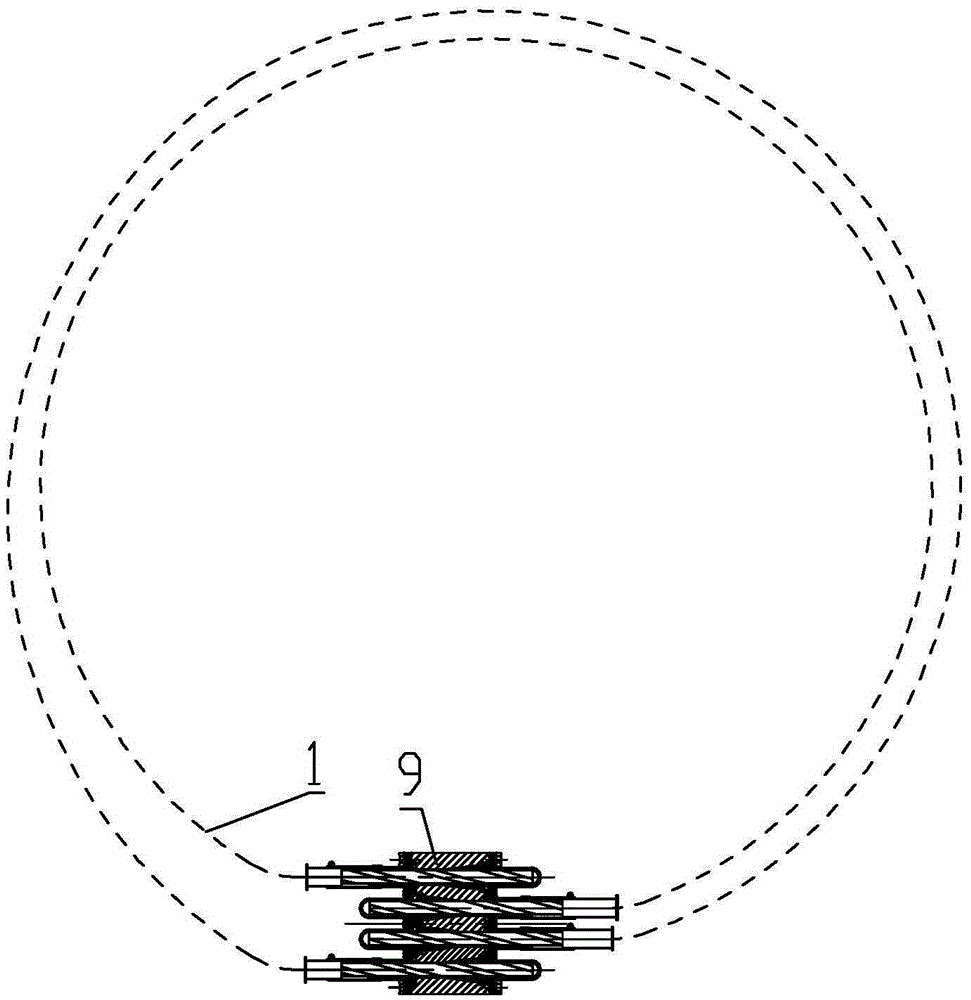

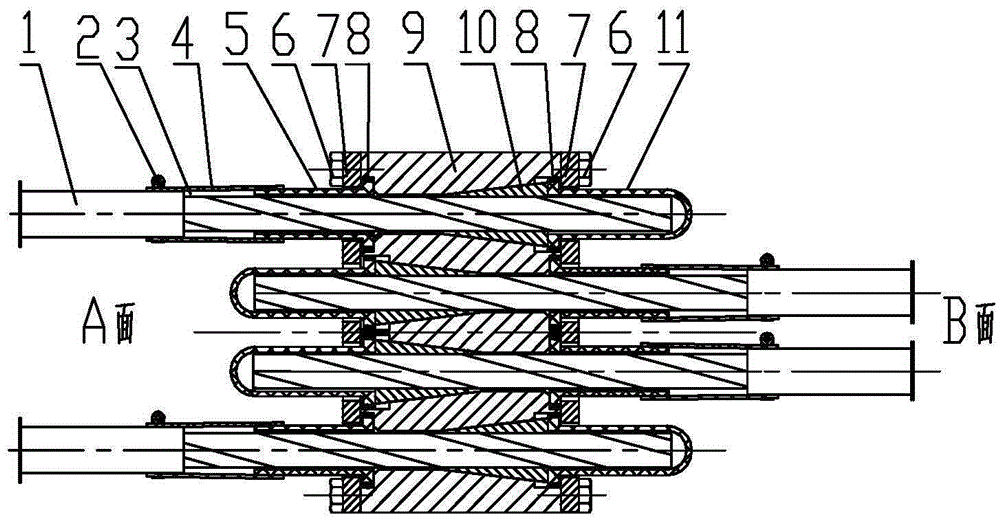

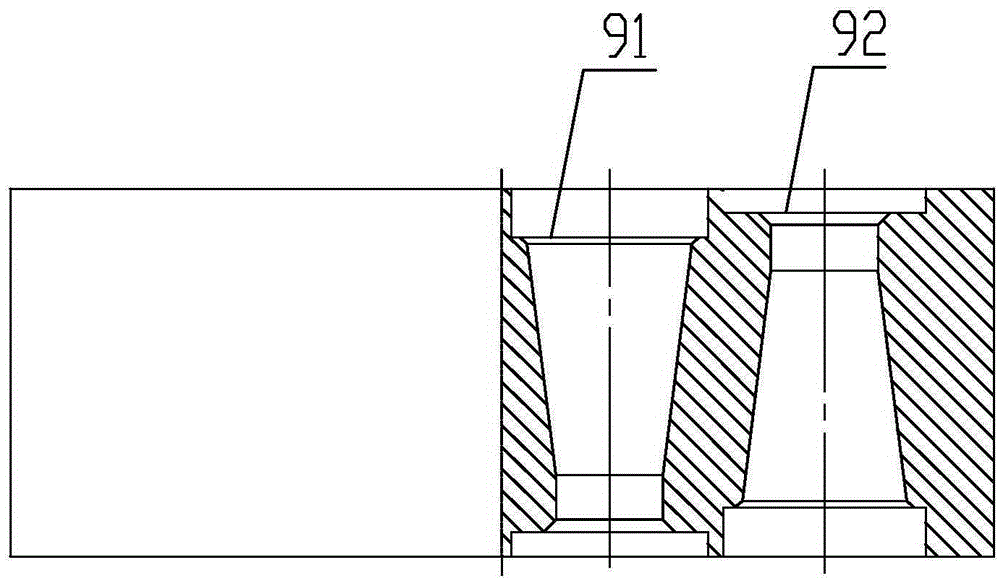

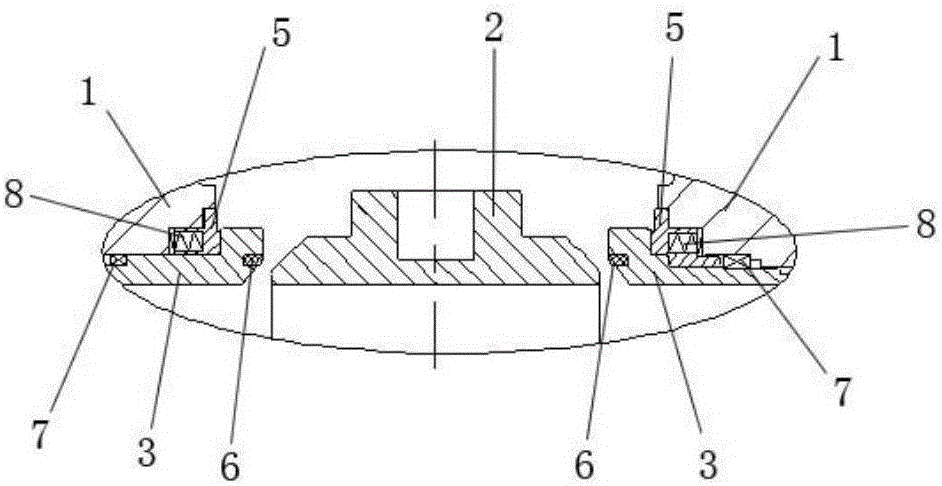

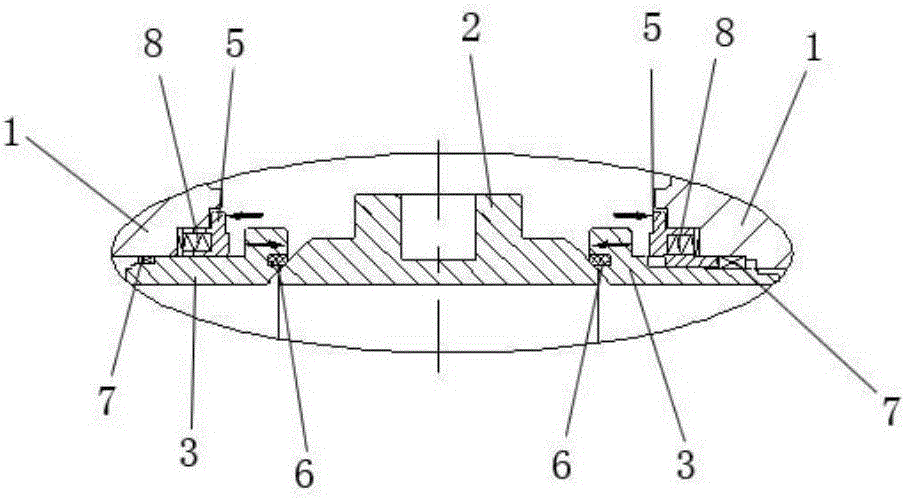

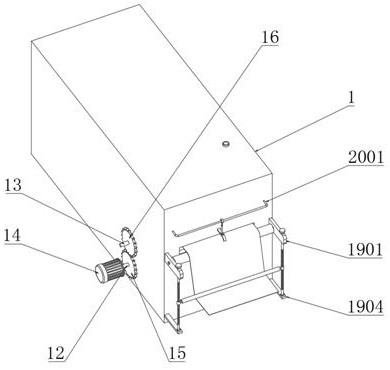

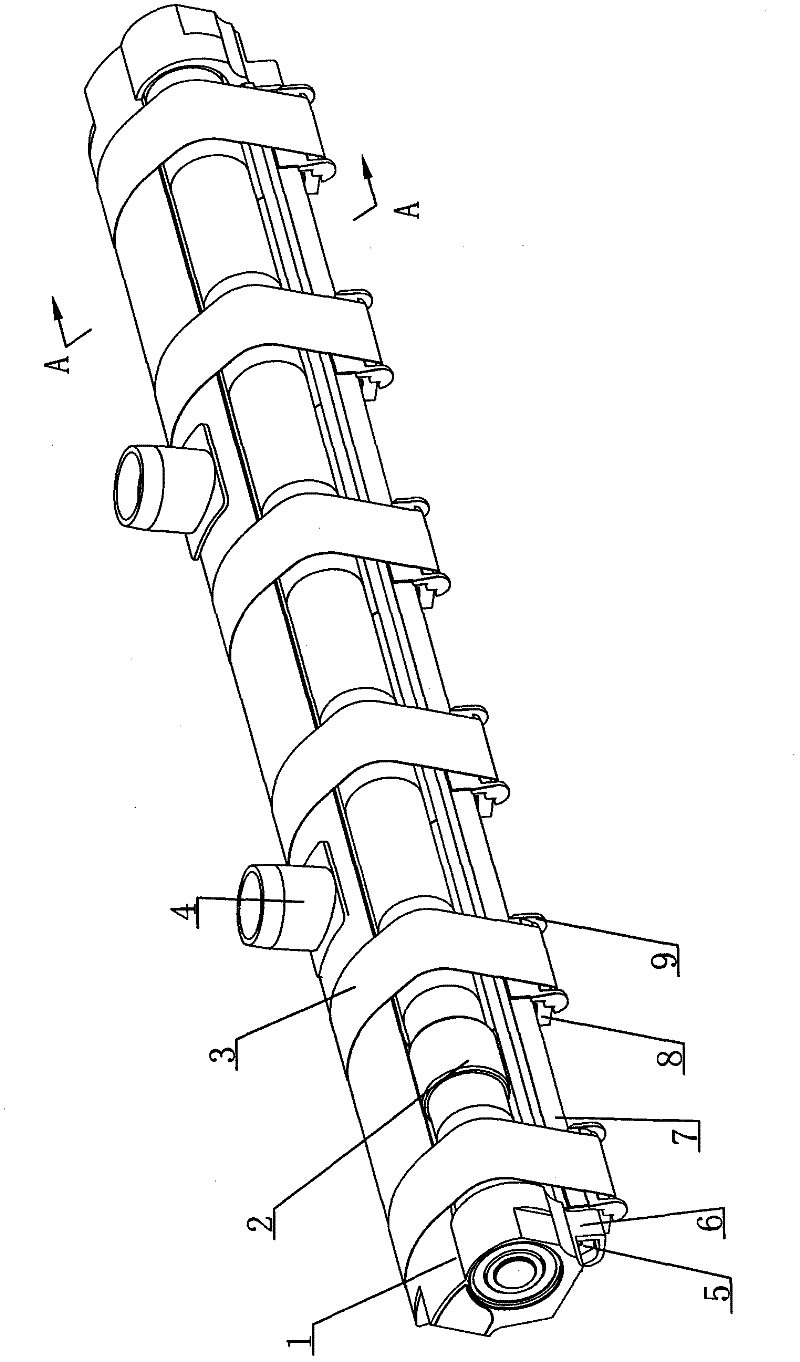

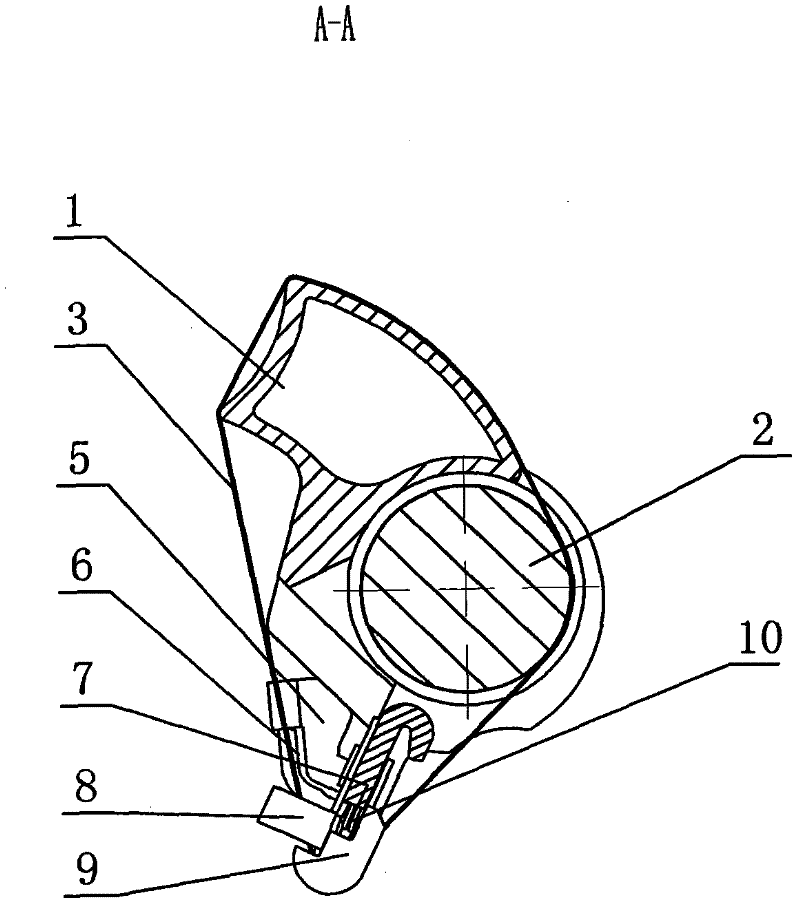

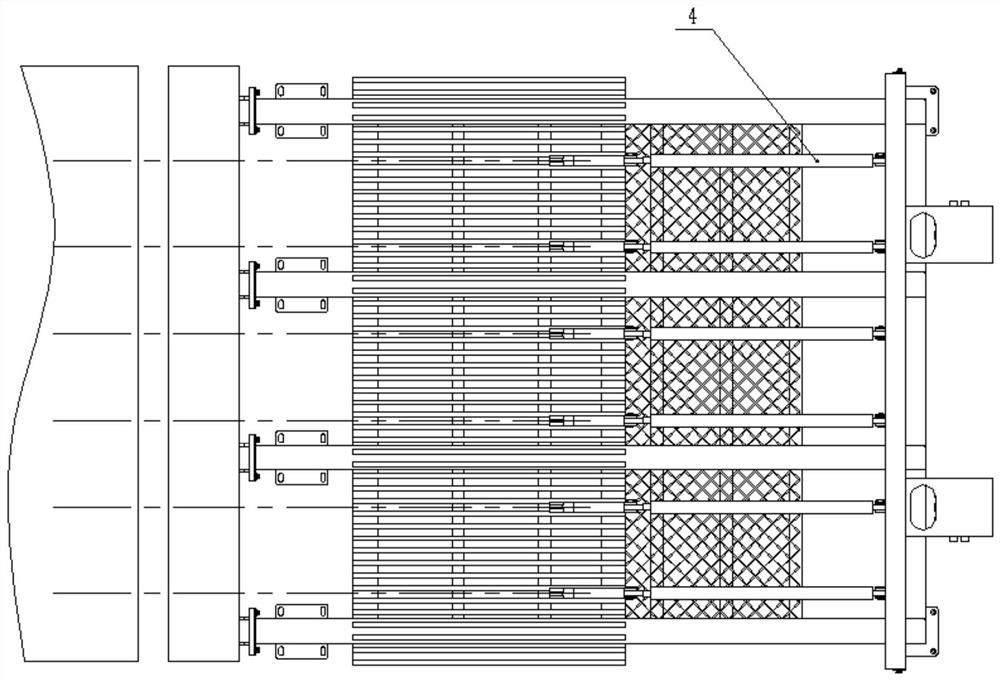

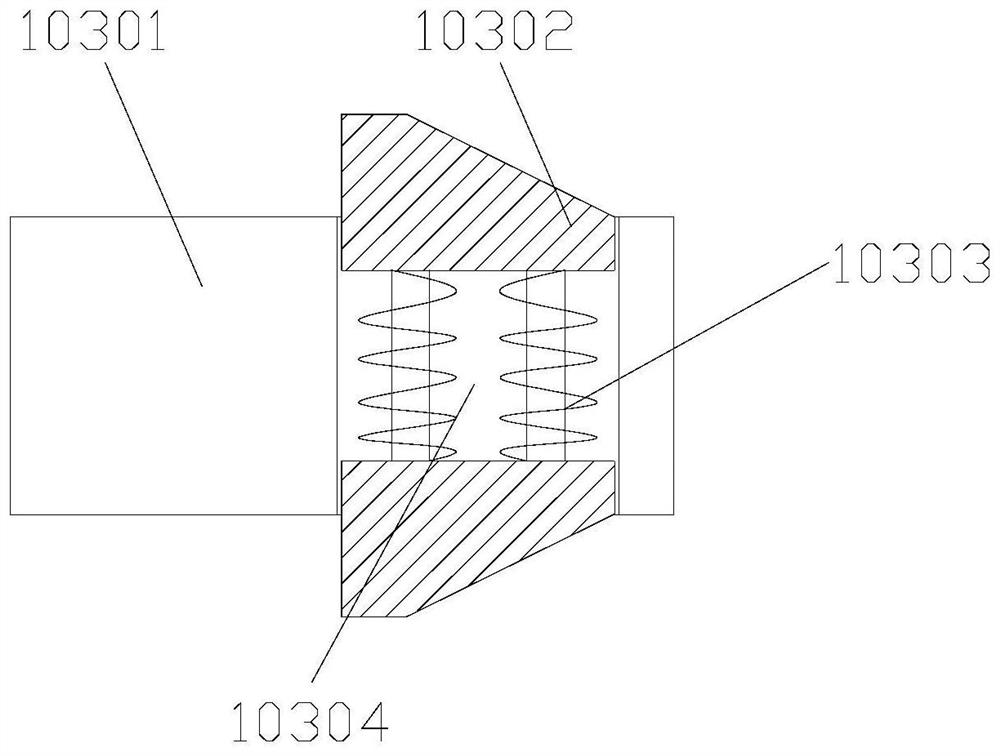

Integrated composite spinning device of ring spinning frame

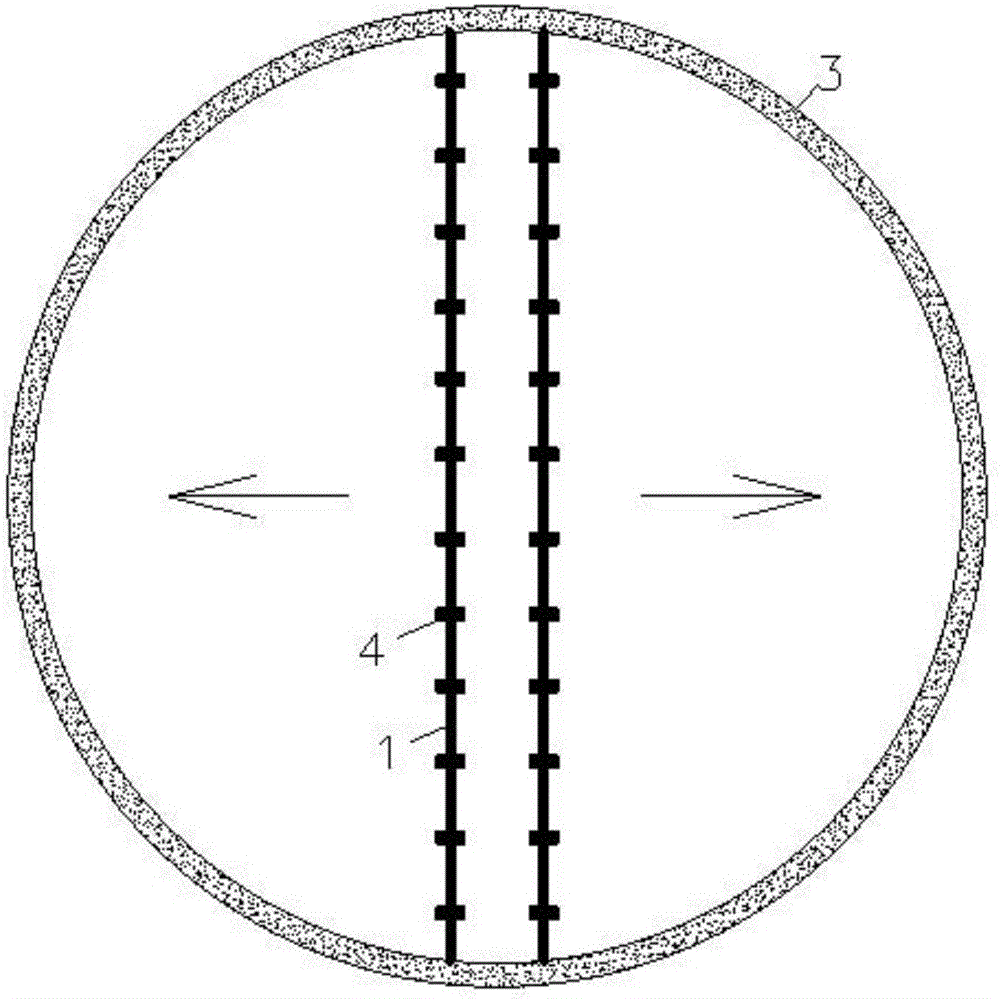

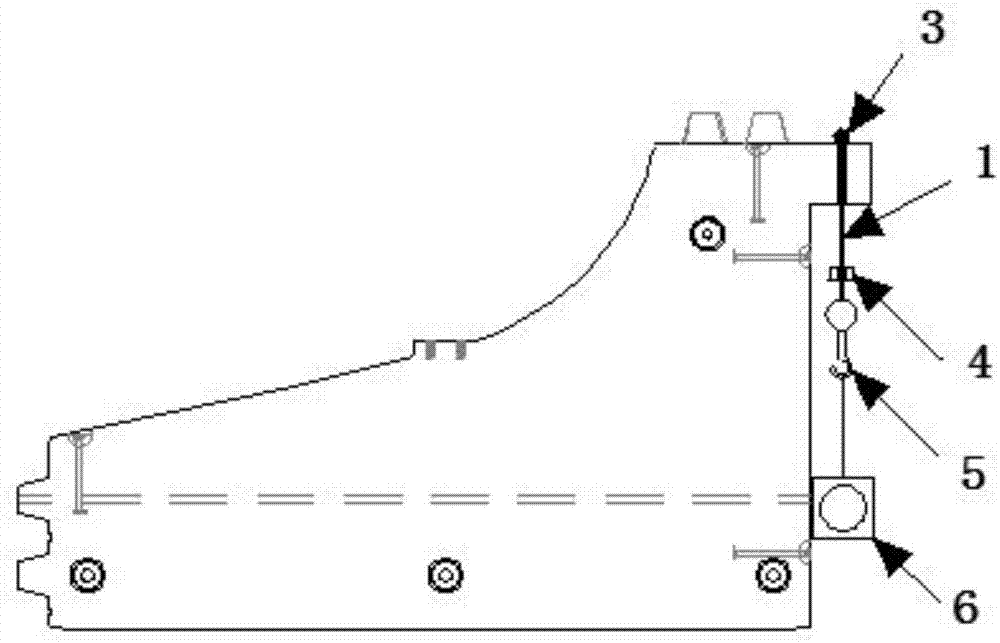

The invention relates to an integrated composite spinning device of a ring spinning frame. The device comprises a special-shaped tube, a grid ring, an integrated composite roller and a tension supporting mechanism; negative pressure integrated composite tubes are positioned at two ends of a front tube wall on one side of a fiber whisker outlet line and provided with two extended roller supporting seats with closed peripheries, tension supporting seats are arranged below the two roller supporting seats, and the negative pressure integrated composite tubes are provided with more than two positioning surfaces; the tension supporting mechanism comprises a tension supporting frame and two positioning spring plates; the tension supporting frame comprises a tension rod and more than three limit sliding seats arranged transversely at intervals along the tension rod; the limit sliding seats are propped on the lower part of the tension rod by adjusting springs, and the bottom of each limit sliding seat is provided with a stop block; and the connecting surfaces of the two positioning spring plates are connected with the two tension supporting seats respectively, and the adjusting and installation surfaces of the two positioning spring plates are in pressing connection with two ends of the tension rod respectively. The device can improve the assembly precision, adjust the axial position of the grid ring in time and conveniently adjust the tension of the grid ring.

Owner:常州市同和纺织机械制造有限公司

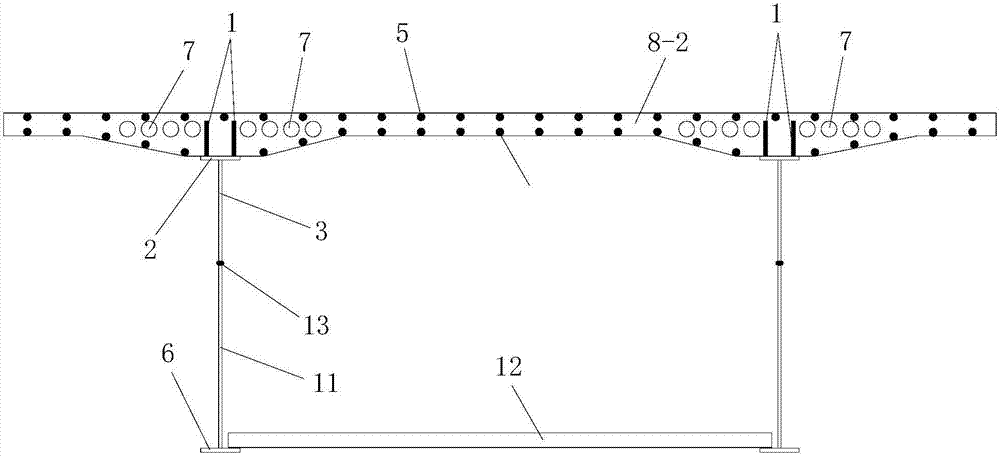

Method for reinforcing bonded prestressing force of transversely tensioning epoxy coating reinforcing steel bar of concrete beam slab

InactiveCN101929131AOptimize layoutReduce dependenceBuilding repairsBridge erection/assemblyPre stressConcrete beams

The invention relates to a method for reinforcing a bonded prestressing force of a transversely tensioning epoxy coating reinforcing steel bar of a concrete beam slab, which relates to the reinforcement of reinforced concrete and prestressed concrete bridges and is suitable for the reinforcement of house buildings and other building structures. In a prestressing force reinforcing technique of the invention, a novel transversely tensioning corrosion-resistant epoxy coating reinforcing steel bar is used for substituting for a longitudinally tensioning high-strength steel strand or common hot-rolled reinforcing steel bar and a transversely clamping device is used for substituting transverse tensioning for longitudinal tensioning, so that low-cost composite mortar or concrete can be used for substituting for high-cost high-performance tensile composite mortar or polymer mortar to perform a structure treatment and construction process, and the problems of low utilization efficiency of materials, high reinforcing cost and inconvenient reinforcing construction are solved.

Owner:HARBIN INST OF TECH

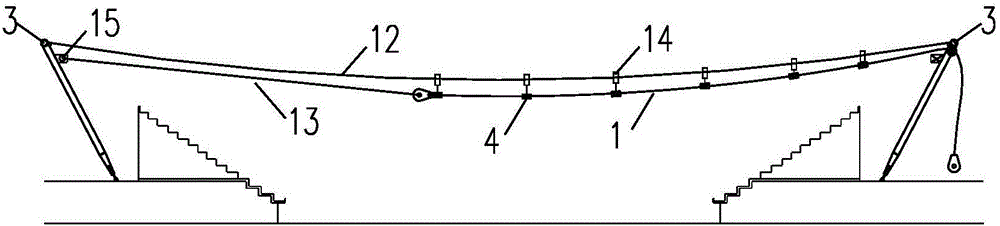

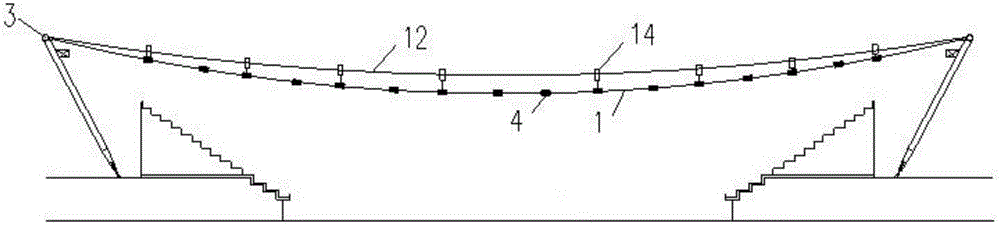

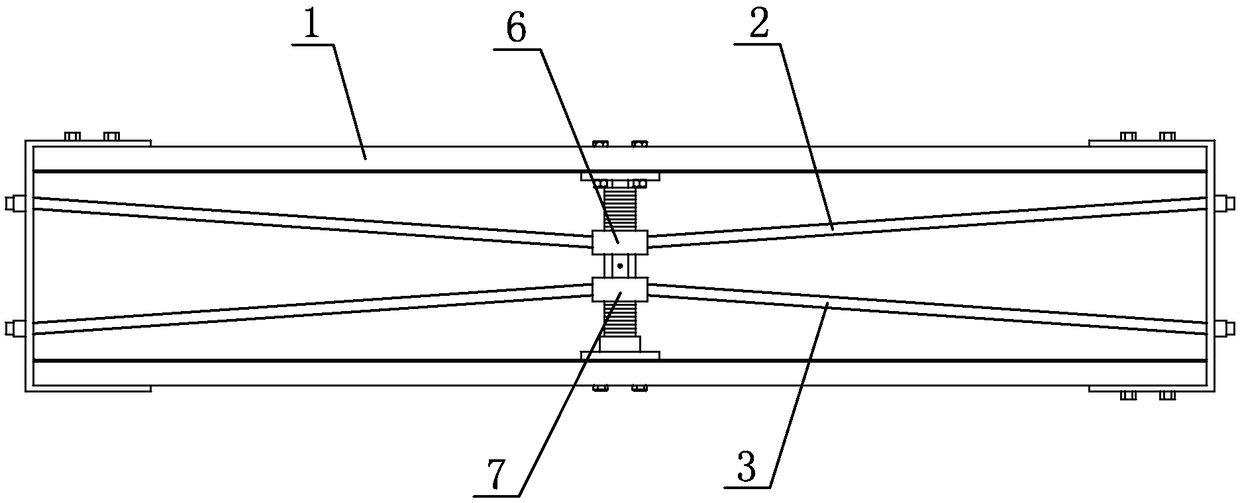

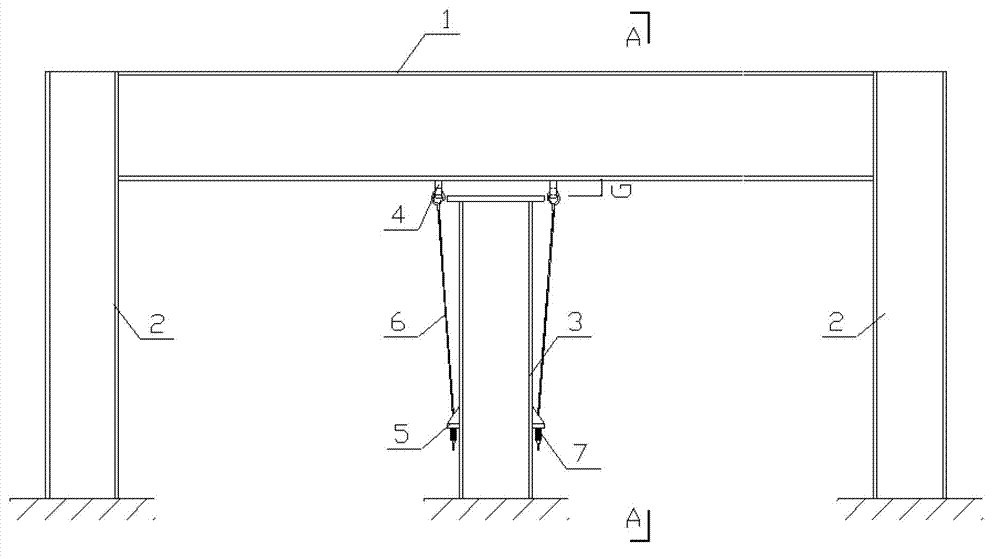

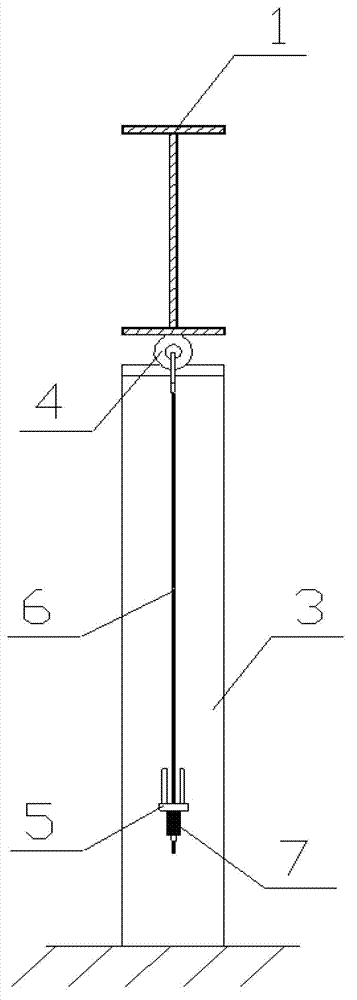

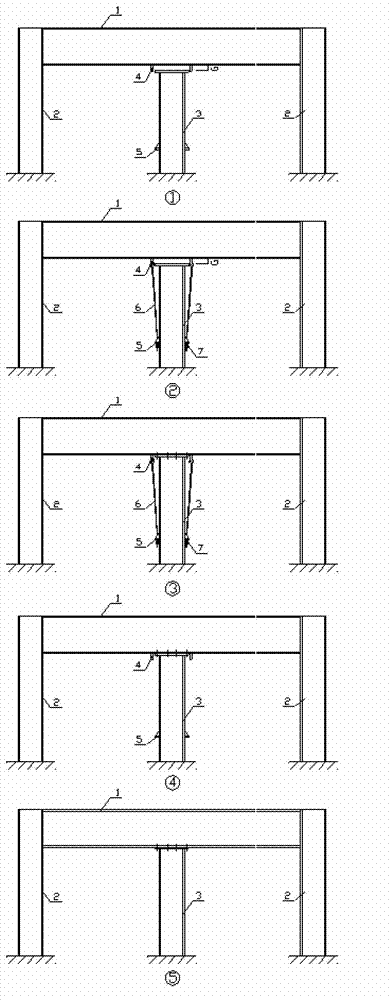

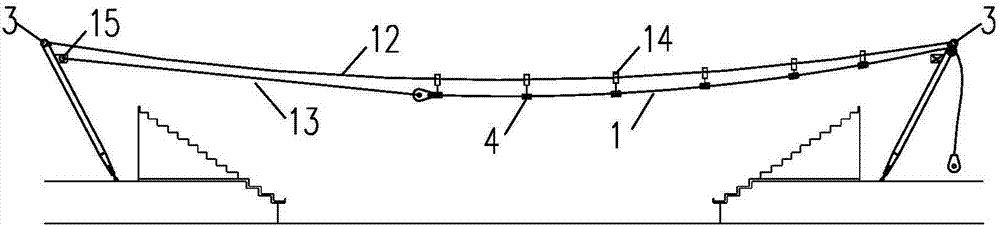

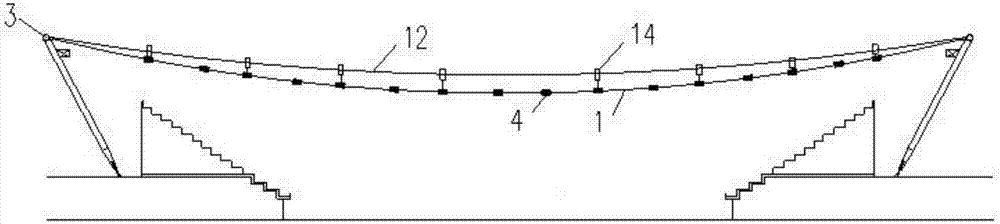

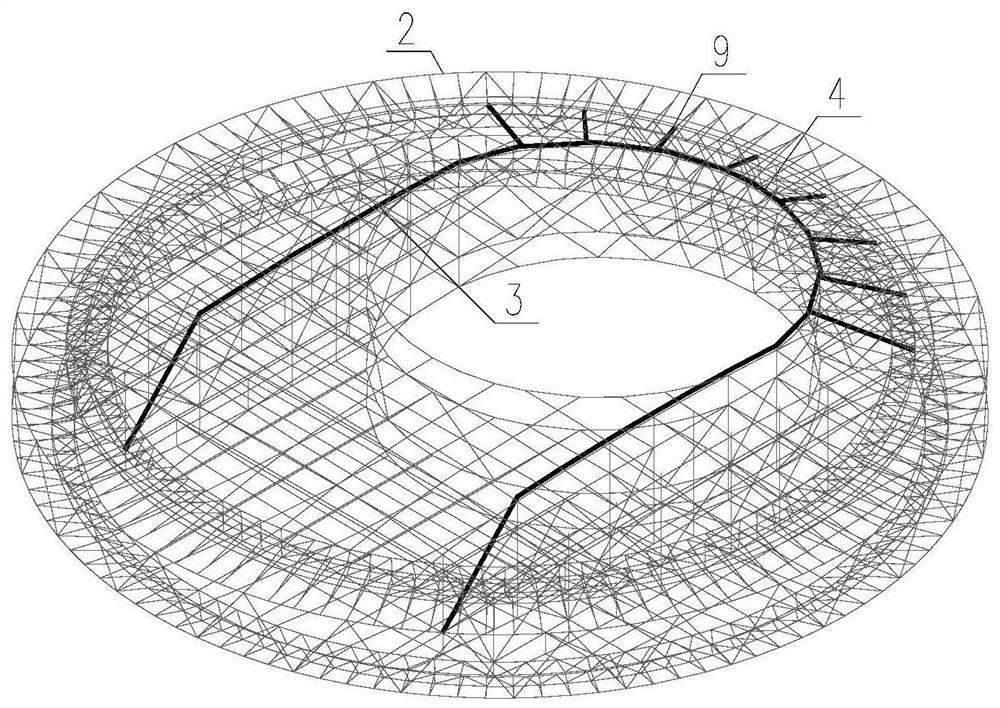

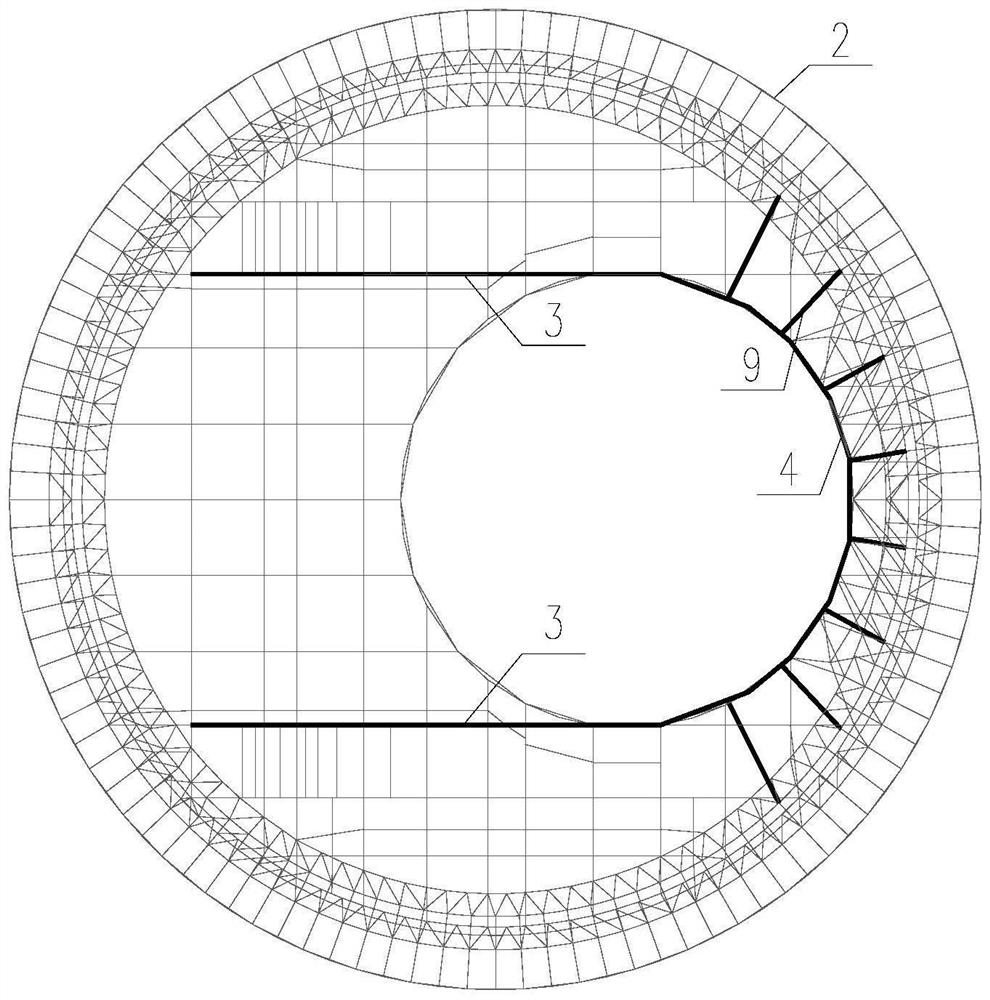

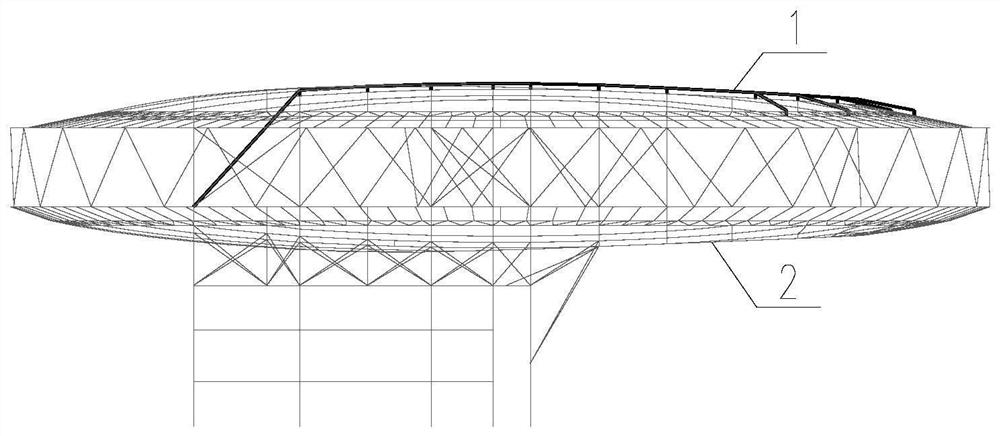

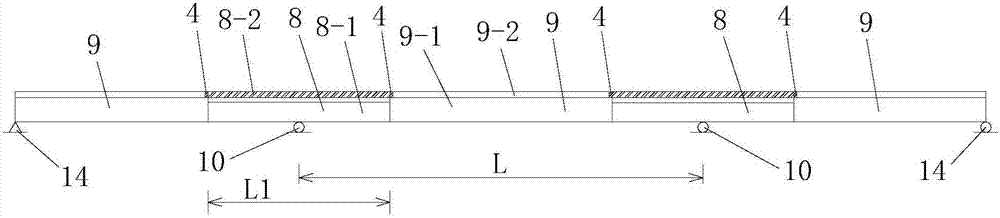

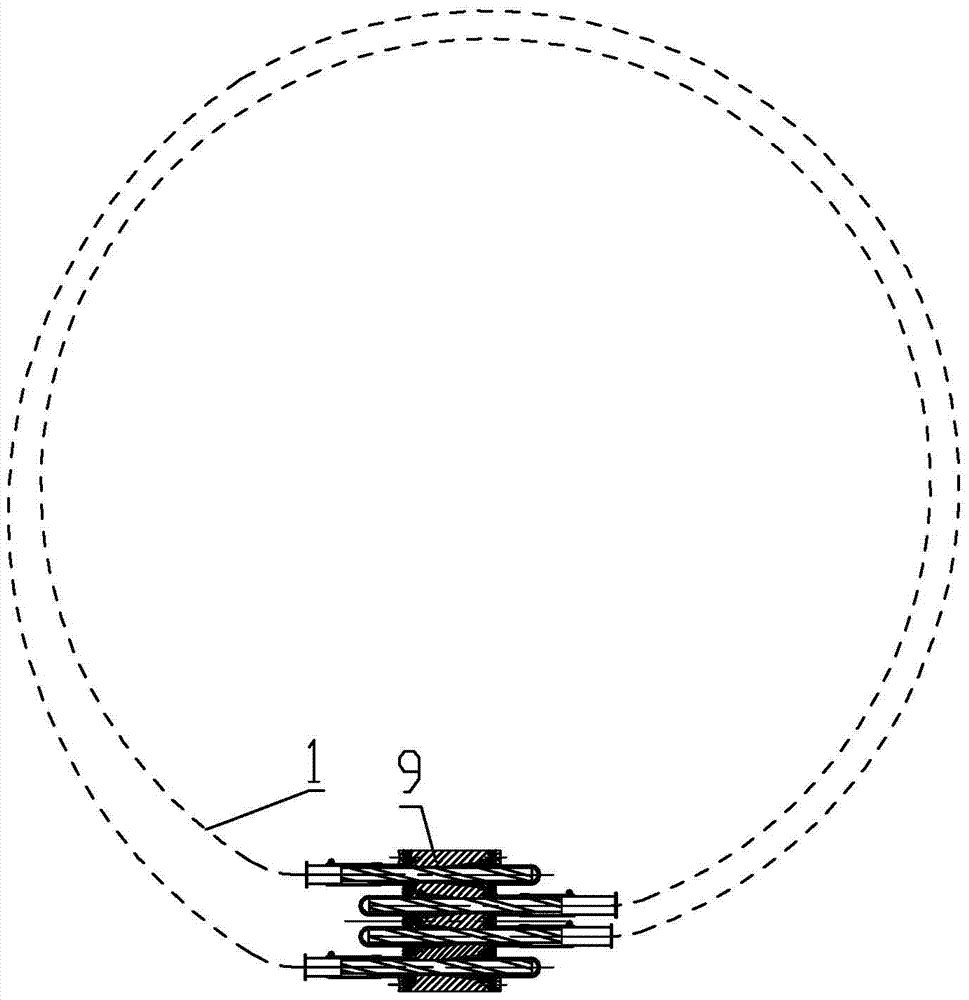

Support-free overhead zip line construction method of two-way single-layer cable net structure

ActiveCN106013812AProtectImprove tensioning efficiencyBuilding material handlingMono layerBuilding construction

The invention discloses a support-free overhead zip line construction method of a two-way single-layer cable net structure. An overhead zip line manner is adopted for sequentially installing track cables and stabilization cables, middle nuts and end nuts are arranged on high-strength bolts, and cable clamps are fastened twice in the achieving process for clamping the track cables and the stabilization cables correspondingly. The method includes the steps that firstly, the track cables are straightly expanded on the ground, bottom boards and middle boards of the cable clamps are installed and fastened, and the track cables are sequentially installed at the designed positions through guide cables and traction cables to be connected with and anchored to outer pressing rings; and then the stabilization cables are straightly expanded on the ground, catwalks are laid on the installed track cables in the directions of the stabilization cables, the stabilization cables are dragged to the overhead catwalks to be expanded, top boards of the cable clamps are installed and fastened, the stabilization cables are tensioned to be connected with and anchored to the outer pressing rings, and therefore the structure is tensioned and formed. By the adoption of the method, no support or large-area work face is needed, main equipment and tools are used in a circulating manner, and the input is small; inhaul cables run overhead, and protection is easy; and construction is easy and convenient, efficiency is high, the measure cost is low, and a construction period is short.

Owner:SOUTHEAST UNIV

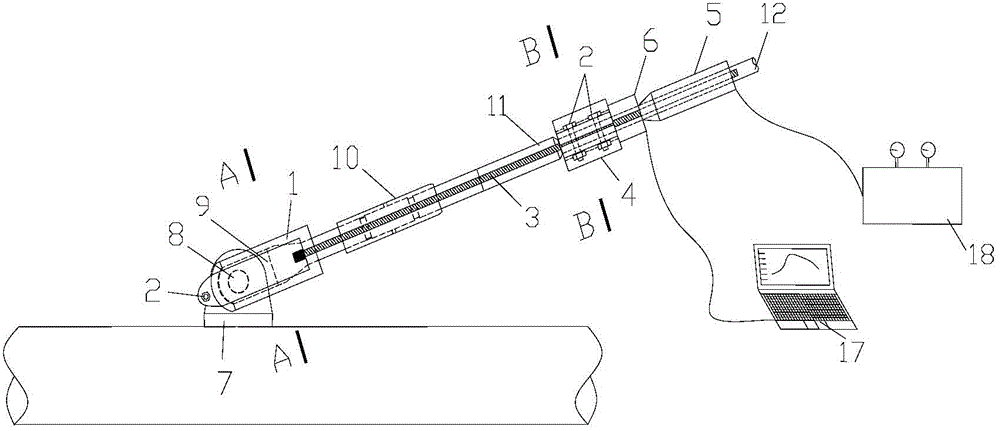

Tensioning device for stay cable which is provided with single-lug or double-lug sleeve and can be adjusted in one direction or two directions and construction method of device

InactiveCN104452595ASimple installationLow production costBridge structural detailsBridge erection/assemblyOil pressureEngineering

The invention provides the stay cable tensioning technology, and relates to a tensioning device for a stay cable which is provided with a single-lug or double-lug sleeve and can be adjusted in one direction or two directions and a construction method of the device. The tensioning device comprises a prefabricated lower clamping base, fastening bolts, a tensioning steel strand, a prefabricated upper clamping base, front-clamping type hydraulic jacks, a core-through load sensor and a sensor data collecting system, wherein an extrusion and anchoring end socket is arranged at one end of the tensioning steel strand. By means of the tensioning device for the stay cable and the construction method of the tensioning device, cable tensioning can be effectively finished, the two front-clamping type hydraulic jacks symmetrically tension the stay cable so that the device can bear stress evenly, the hydraulic jacks are controlled through readings of jack oil pressure gauges and the core-through load sensor, and errors can be reduced. The whole device is easy to manufacture and convenient to operate, and has high practical value and popularization value.

Owner:HOHAI UNIV

Cable tensioning device for high-altitude power construction

ActiveCN112909830AReduce labor intensityPrevent rotationApparatus for overhead lines/cablesControl theoryElectric cables

Owner:国网山东省电力公司曹县供电公司

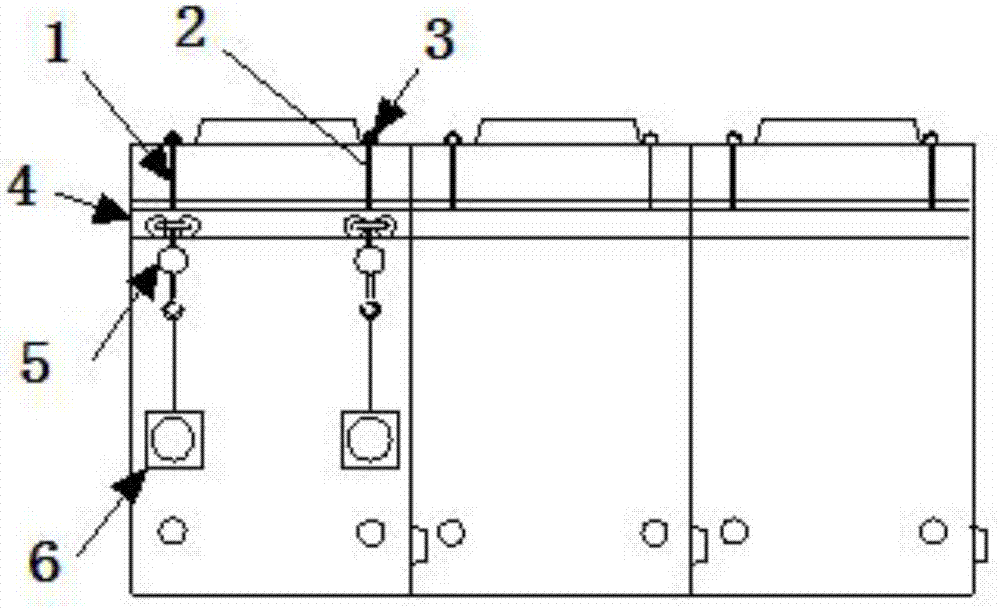

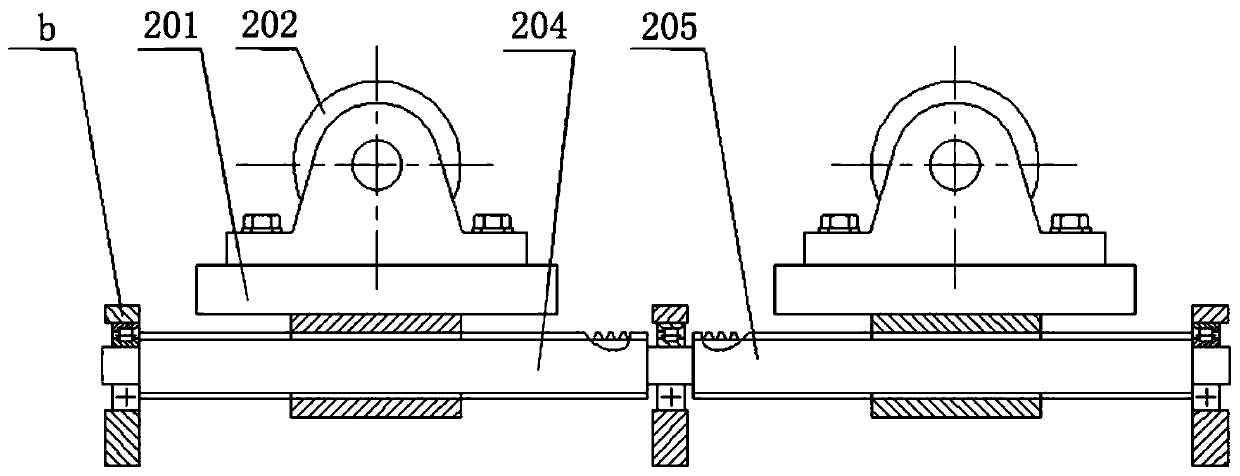

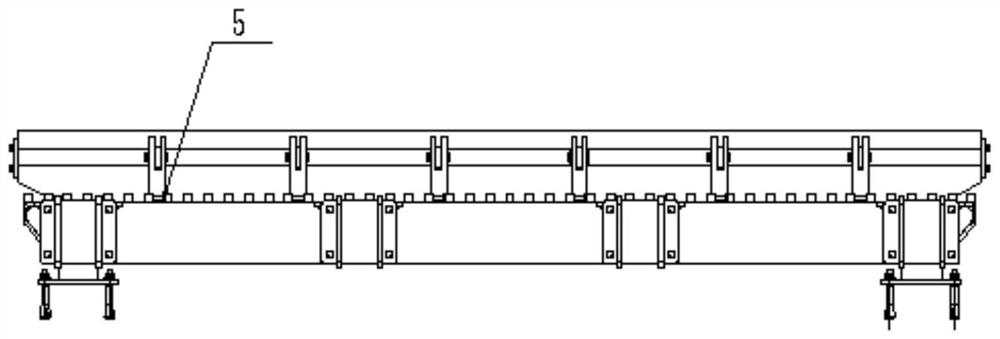

Rapid tensioning device and method of prefabricated members on both sides of prefabricated station bottom plate

ActiveCN107345401ARapid positioningImprove tensioning efficiencyArtificial islandsUnderwater structuresBlock and tackleArchitectural engineering

The invention discloses a rapid tensioning device of prefabricated members on both sides of a prefabricated station bottom plate. The rapid tensioning device comprises a steel wire rope I and a steel wire rope II, wherein the steel wire rope I passes through tensioning holes I of the prefabricated members on the both sides, the steel wire rope II passes through tensioning holes II of the prefabricated members on the both sides, the upper end of the steel wire rope I and the upper end of the steel wire rope II are fixed respectively by reinforcing bars, both ends of a double-spliced angle iron are respectively connected to the lower end of the steel wire rope I and the lower end of the steel wire rope II, a pulley block of a sliding type electric hoist is arranged on the double-spliced angle iron, and a tensioning penetrating jack is connected to the lower end of the sliding type electric hoist. The invention further provides a rapid tensioning construction method. According to the rapid tensioning device, the construction risk is avoided, and the effect that the jack is rapidly positioned and is rapidly tensioned is achieved; the rapid tensioning device has the advantages of wide source of materials, simplicity in manufacturing, convenience in operation and high tensioning efficiency, and more economic benefits are provided for an enterprise; and the problem of large difficulty in operation is solved, the safety risk during construction is reduced, and the construction efficiency is improved.

Owner:SUBWAY ENG CO LTD OF CHINA RAILWAY 16TH CONSTR BUREAU +1

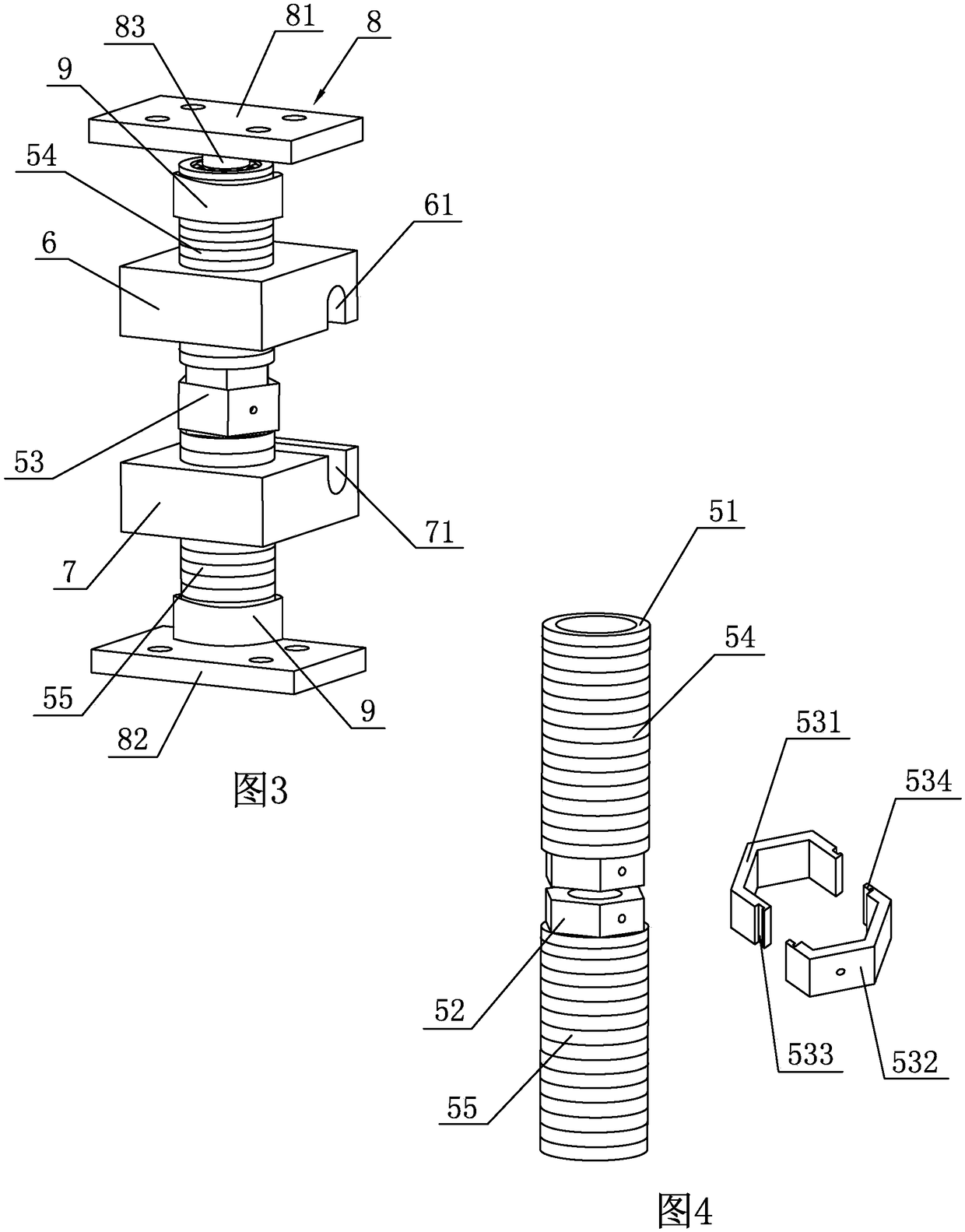

Reaction frame for stretching pre-stress anchor rope of steel wire rope

ActiveCN105803950AImprove accuracyImprove job stabilityBridge structural detailsBridge erection/assemblyPre stressPre stressing

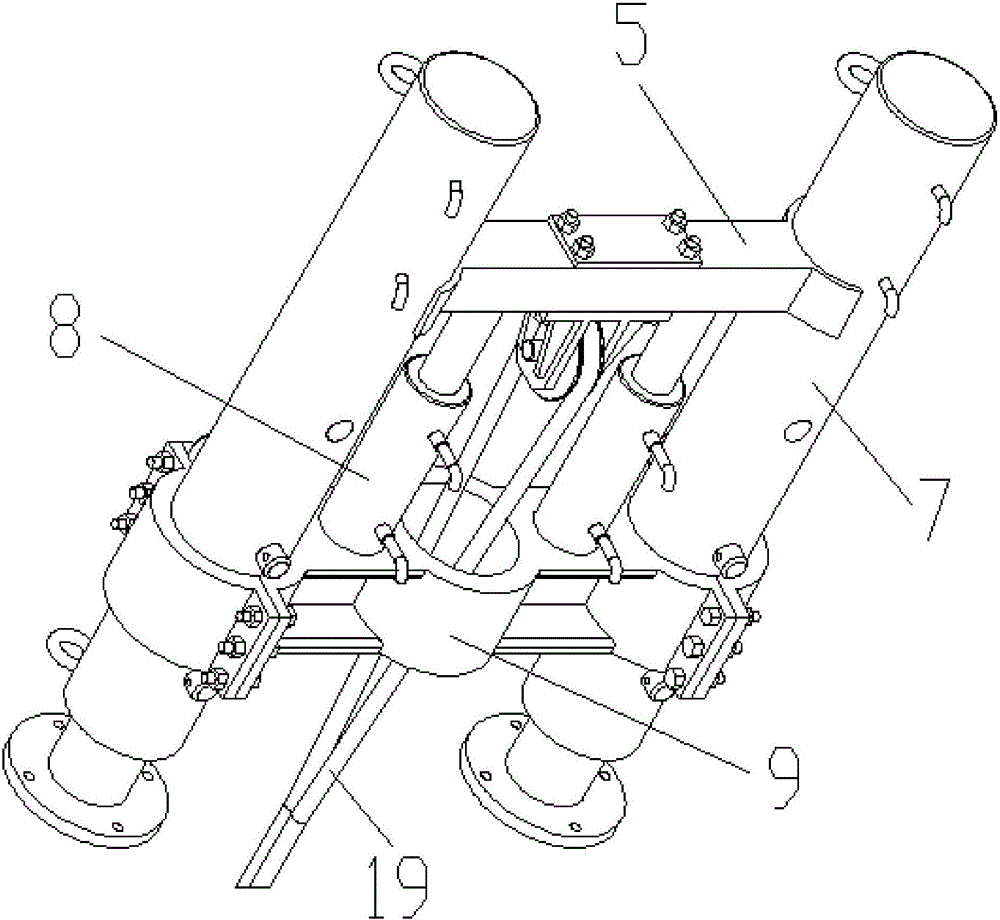

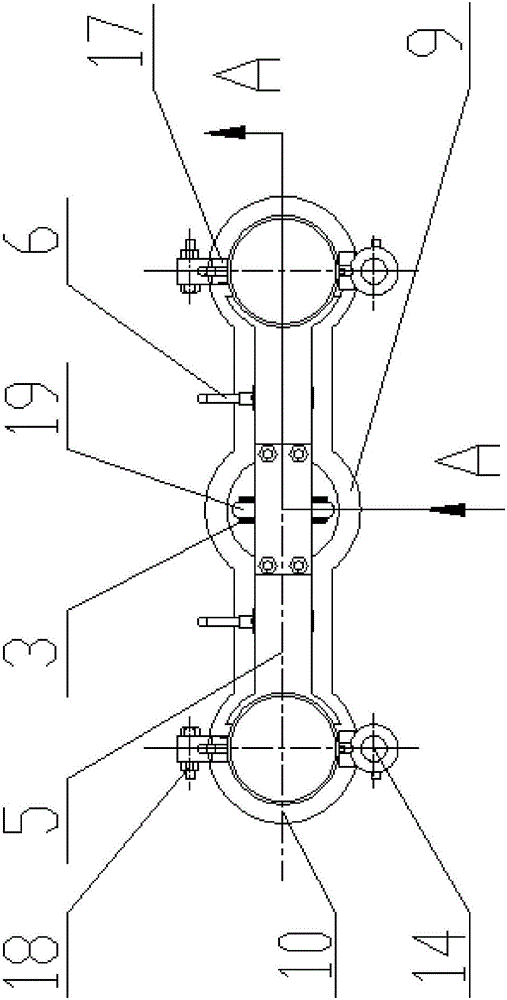

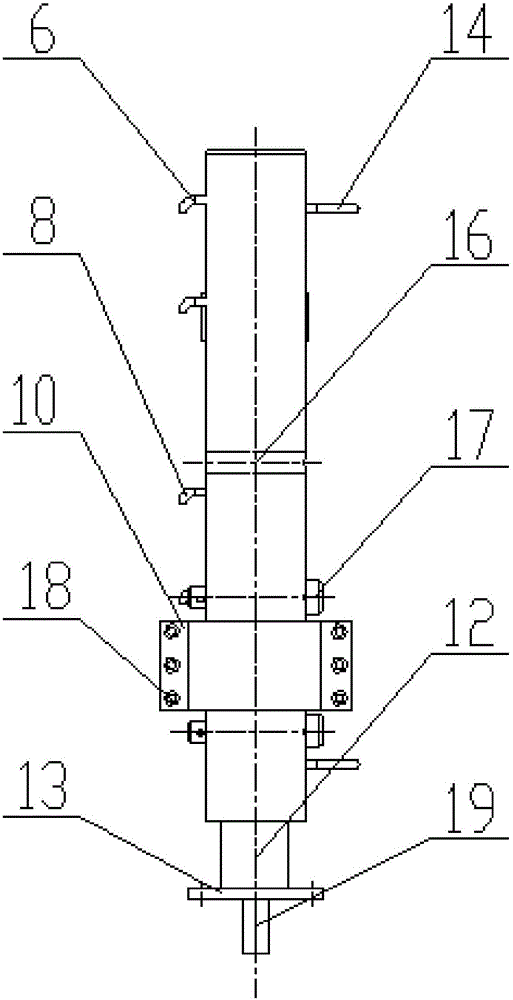

The invention provides a reaction frame for stretching a pre-stress anchor rope of a steel wire rope. The reaction frame comprises a movable transverse beam (5), a tensioning hydraulic jack (8), a fixed transverse beam (9), a guide reaction stand column (7) and an adjusting mechanism, wherein the movable transverse beam (5) can be connected and fixed with an inserting section of a steel wire rope anchor rope (19); the tensioning hydraulic jack (8) is connected with the movable transverse beam (5); the fixed transverse beam (9) is used for supporting the tensioning hydraulic jack (8); the fixed transverse beam (9) is connected with the tensioning hydraulic jack (8); the tensioning hydraulic jack (8) enables the movable transverse beam (5) to get close or be far away relative to the fixed transverse beam (9); the guide reaction stand column (7) is connected with the fixed transverse beam (9); the adjusting mechanism can be used for adjusting the position, relative to one end or the other end of the guide reaction stand column (7), of the fixed transverse beam (9). The reaction frame for stretching the pre-stress anchor rope of the steel wire rope has the characteristics of rapid installation speed, synchronization of the jack, capability of adjusting the position of the jack through a hydraulic system, accurate stretching force and accurate elongation amount, and low manual labor intensity in a stretching process and the like.

Owner:CHINA FIRST HIGHWAY ENG +1

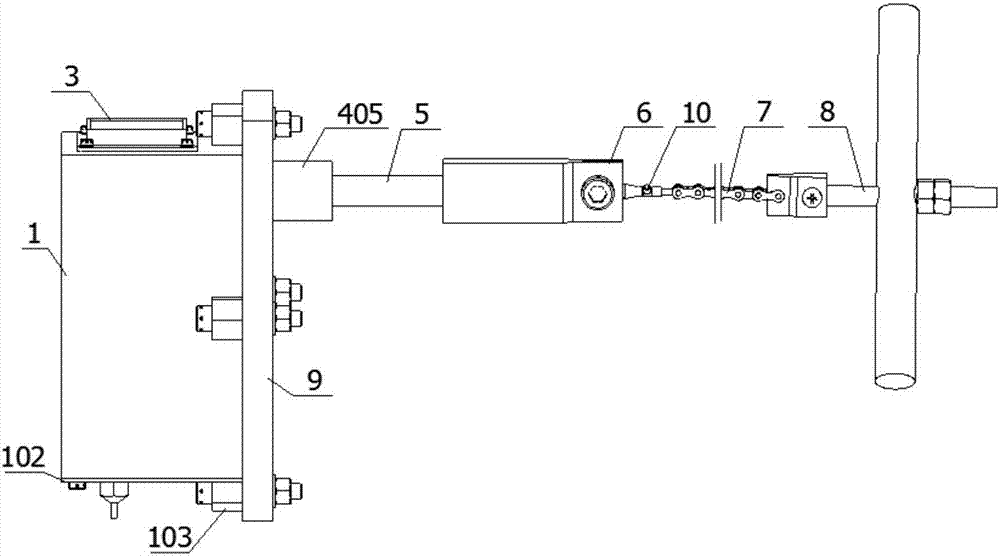

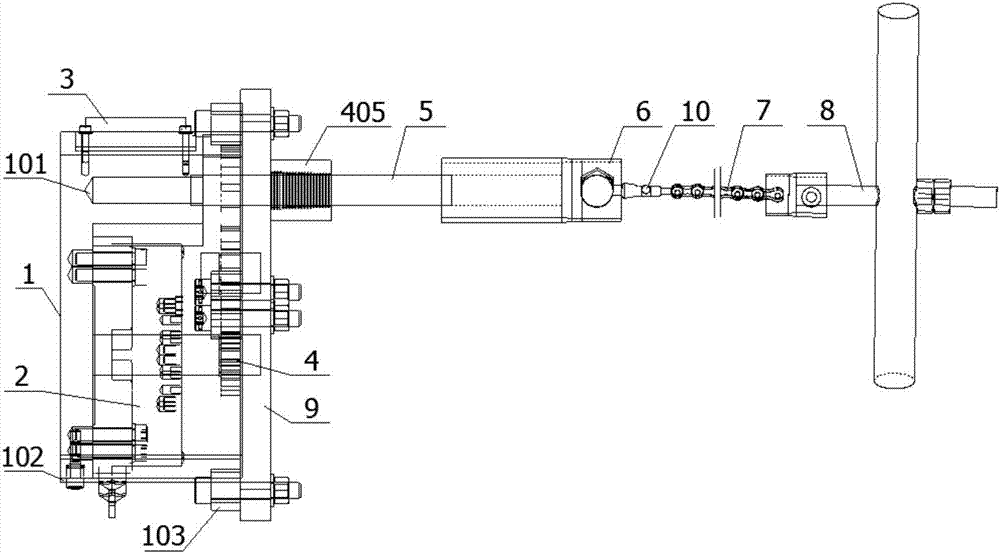

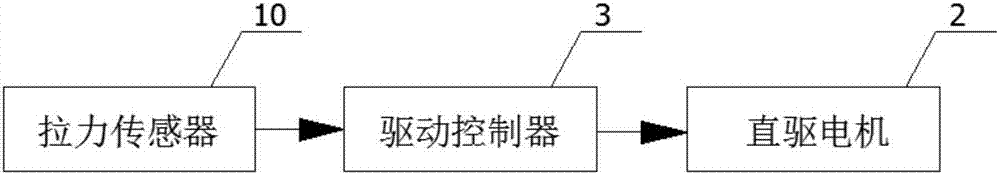

Chain tensioning adjusting mechanism

ActiveCN106931110AImprove driving precisionAvoid chain dropGearingElectric machineryWorking environment

The invention relates to a chain tensioning adjusting mechanism which comprises a shell, a direct drive motor, a drive controller, a transmission device, a transmission lead screw, a first connector device, a chain and a second connector device. The direct drive motor is arranged in the shell, and the drive controller is arranged at the upper end of the shell and is connected with the direct drive motor through a line; a supporting plate is arranged on the outer side of the shell, the transmission device is arranged on the side, close to the shell, of the supporting plate, and the direct drive motor is connected with the transmission device; one end of the transmission lead screw penetrates the supporting plate to be connected with the output end of the transmission device, and the other end of the transmission lead screw is connected with one end of the first connector device; the other end of the first connector device is connected with the second connector device through a chain; and a tension sensor is arranged at the connecting position of the first connector device and the chain and is connected with the drive controller through a line. By means of the chain tensioning adjusting mechanism, automatic chain tensioning is achieved, the chain driving accuracy is improved, chain falling is prevented, the chain tensioning adjusting mechanism can adapt to the wicked work environment, and the reliability coefficient is high.

Owner:GUILIN UNIV OF ELECTRONIC TECH

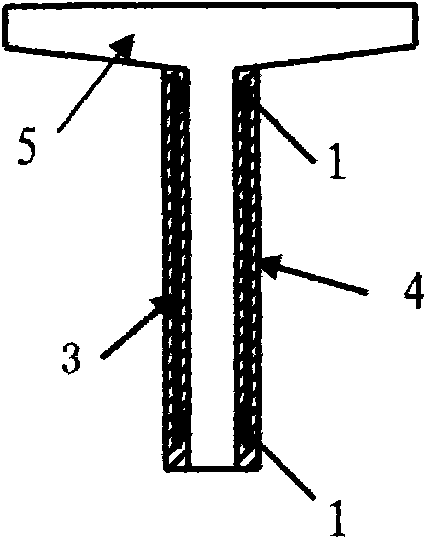

Exerting device for I-beam prestressing

PendingCN109441122AGood shock resistanceImprove tension efficiencyBuilding material handlingSelf lockingEngineering

The invention discloses an exerting device for I-beam prestressing. The exerting device for I-beam prestressing is characterized in that two-way tension mechanisms arranged in flanges on both sides ofan I-beam are included, upper steel stranded wires and lower steel stranded wires are arranged in each side flange of the I-beam, and the two ends of the upper and lower steel stranded wires are correspondingly and fixedly connected with the corresponding two ends of the I-beam. The two-way tension mechanisms comprise upper sleeves, lower sleeves, connection sleeves, upper drawing blocks, lower drawing blocks and brackets. The brackets are vertically fixed between the upper and lower flanges of the I-beam, the upper sleeves and the lower sleeves vertically sleeve the brackets, the upper drawing blocks are spirally connected with the upper threads of the upper sleeves, and the lower drawing blocks are spirally connected with the lower threads of the lower sleeves. The upper steel strand wires are connected with the upper drawing blocks, the lower steel strand wires are connected with the lower drawing blocks, self-locking mechanisms are arranged on the upper sleeves and the lower sleeves, and the connecting sleeves are used for connecting the upper sleeves and the lower sleeves. The exerting device for I-beam prestressing has the advantages of flexible use, good seismic-proof performance and can be applied to different using sites.

Owner:NINGBO UNIV

Synchronous belt tensioning device and system

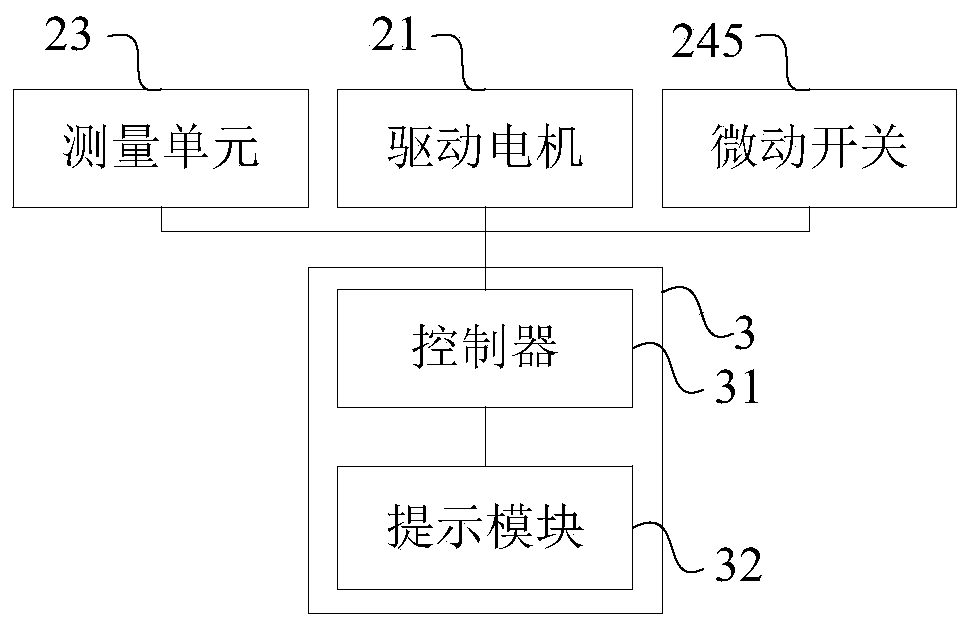

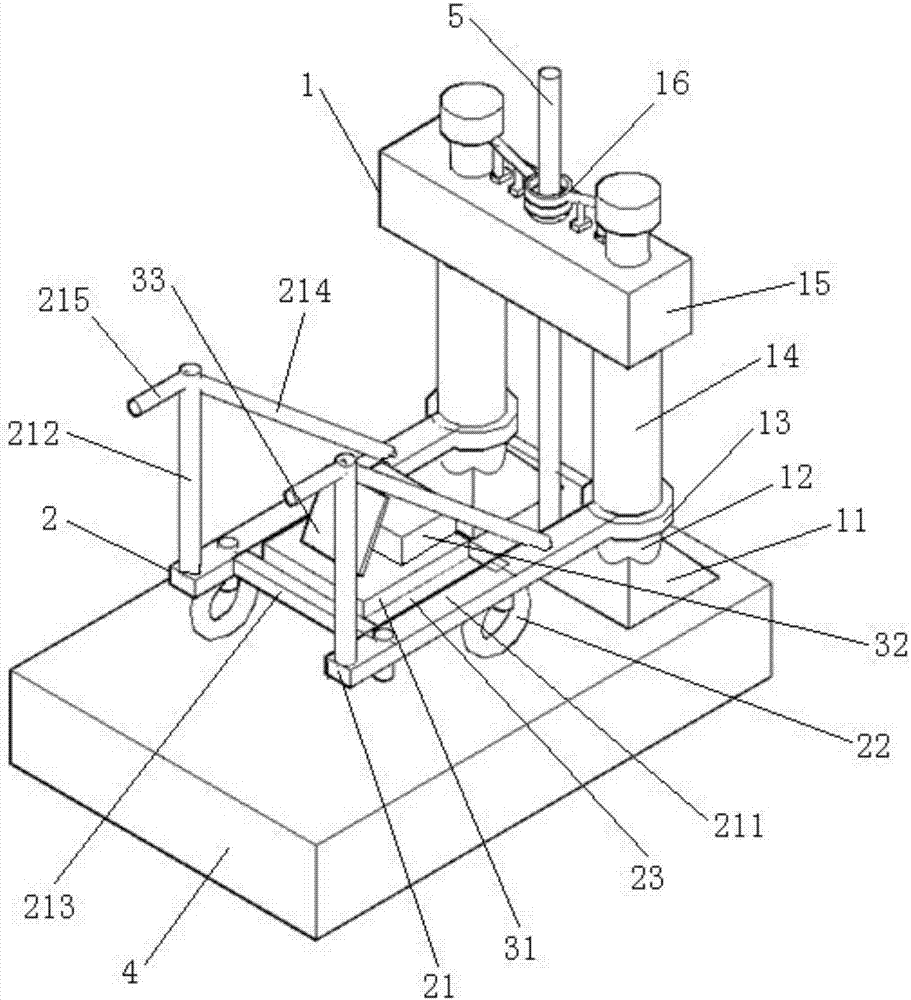

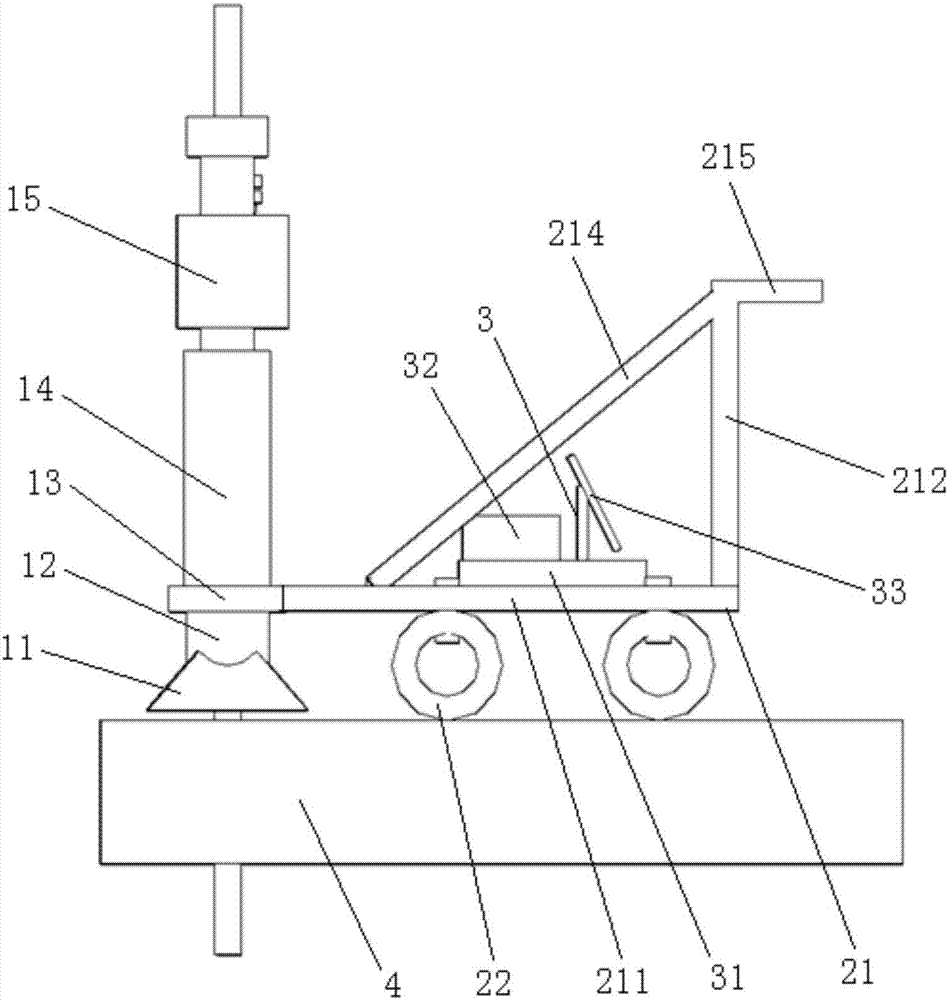

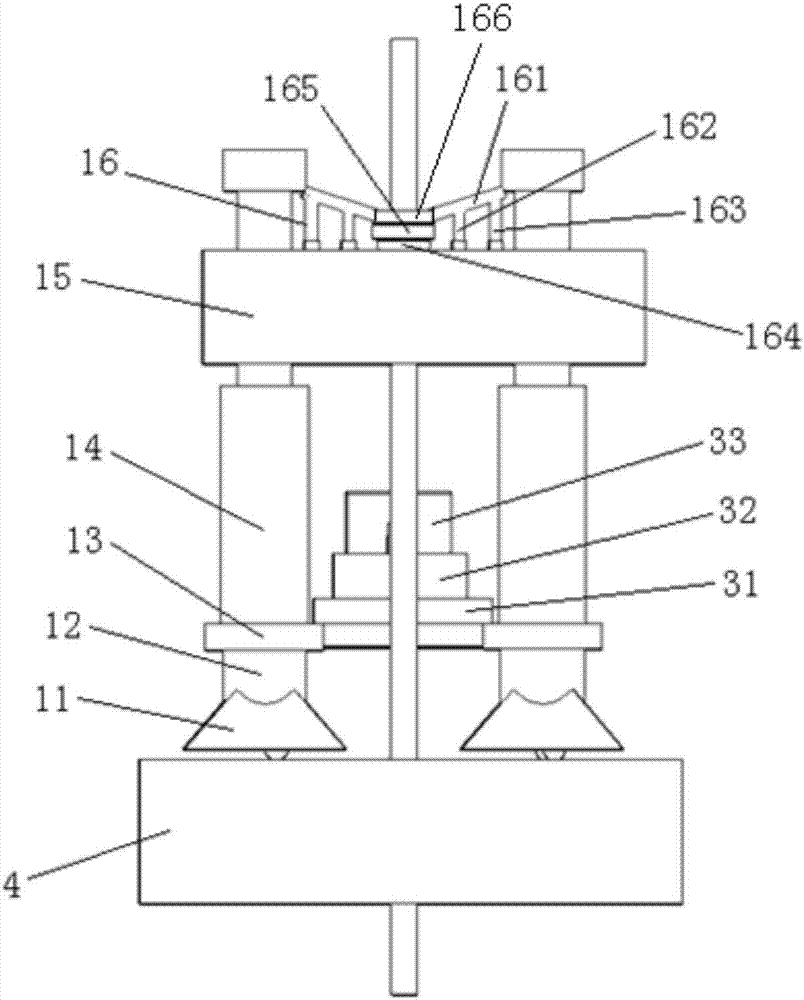

ActiveCN111059235AImprove tensioning efficiencyImprove controllabilityGearingElectric machineryDrive motor

The embodiment of the invention provides a synchronous belt tensioning device and system, relates to the synchronous belt tensioning technology, and aims at overcoming the defects that in the relatedtechnologies, the synchronous belt tensioning force error controllability is poor, and time consumed for adjusting the synchronous belt tensioning force is long. The synchronous belt tensioning devicecomprises a positioning installing frame, a drive motor arranged on the positioning installing frame, a sliding assembly which is connected with the output end of the drive motor and is arranged on the positioning installing frame in a sliding manner, and a measuring unit arranged on the sliding assembly and used for detecting the tensioning force of a synchronous belt, wherein the sliding assembly is used for driving an input synchronous belt wheel and a motor set to move relative to an output synchronous belt wheel and an output wheel set, and accordingly the tensioning force of the synchronous belt connected to the input synchronous belt wheel, the motor set, the output synchronous belt wheel and the output wheel set can be adjusted.

Owner:BEIJING DEEPGLINT INFORMATION TECH

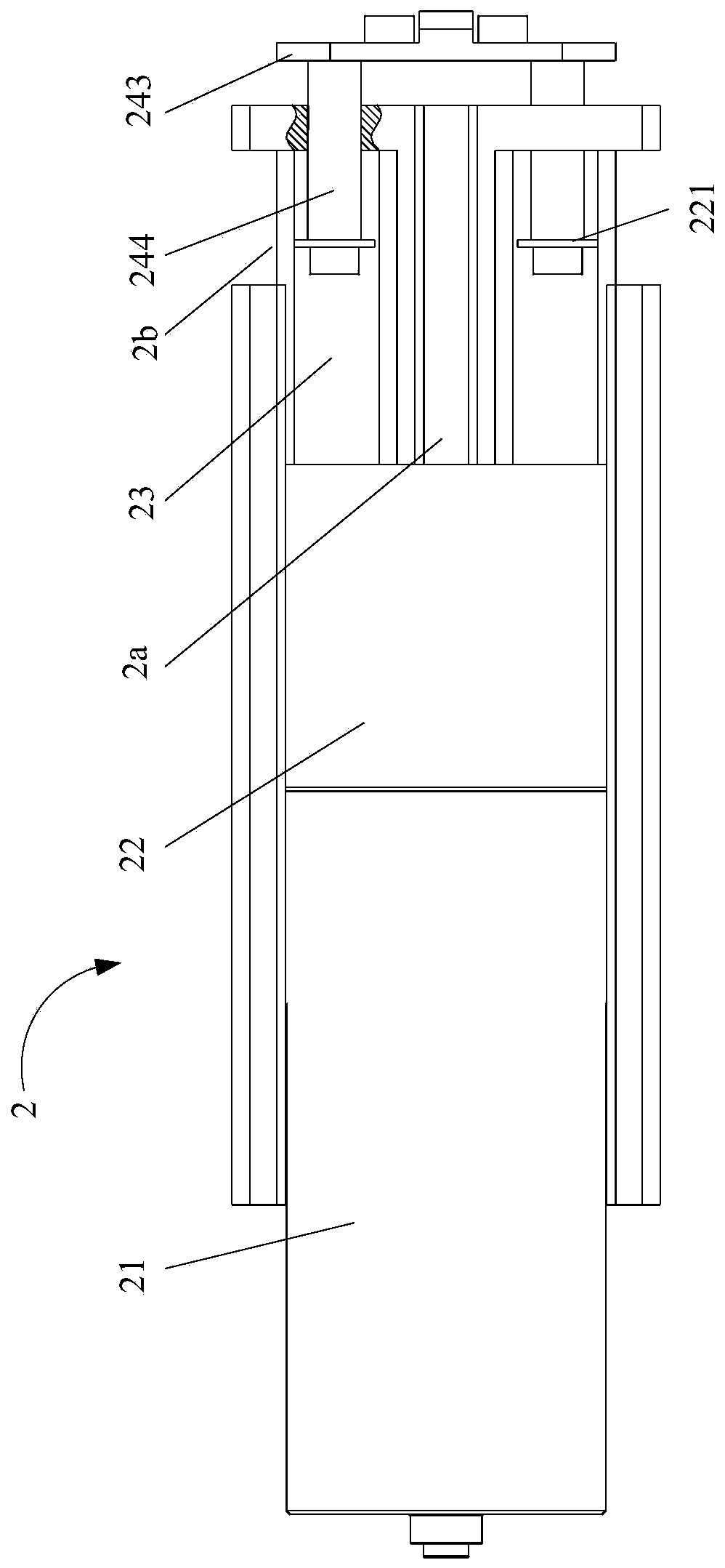

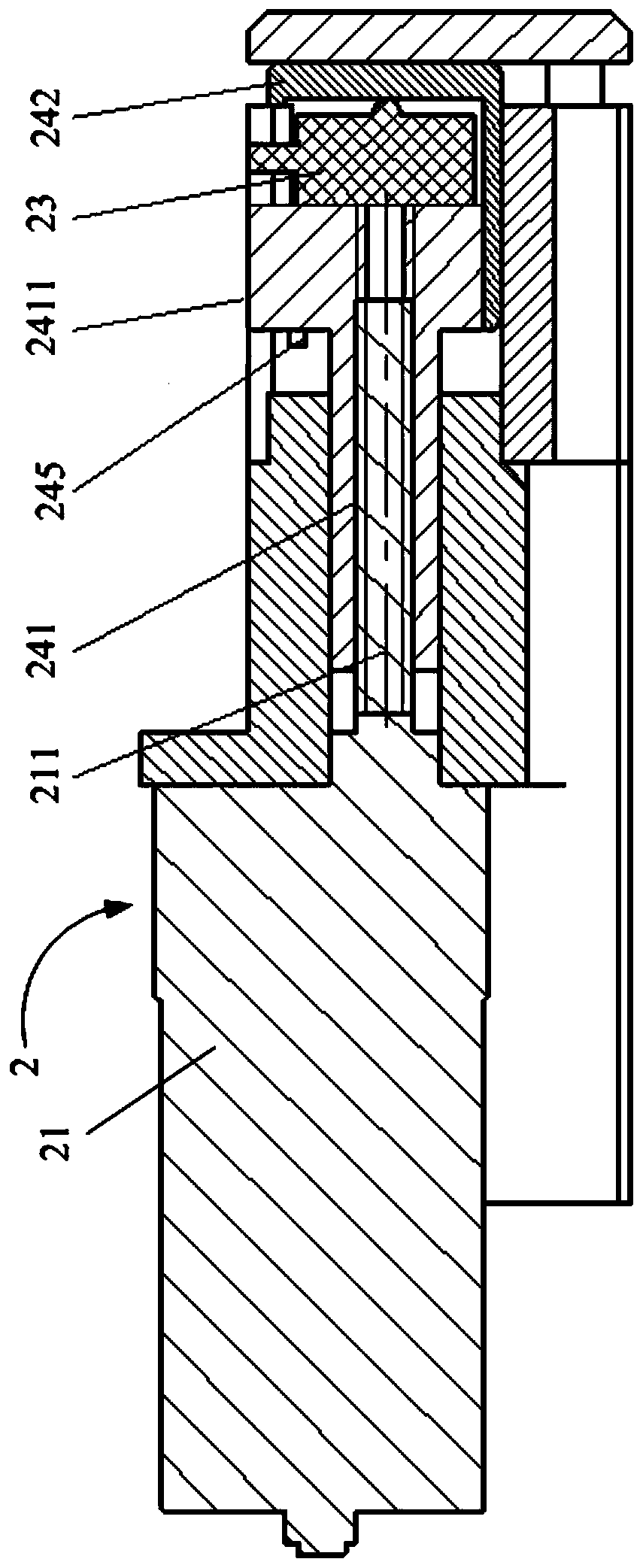

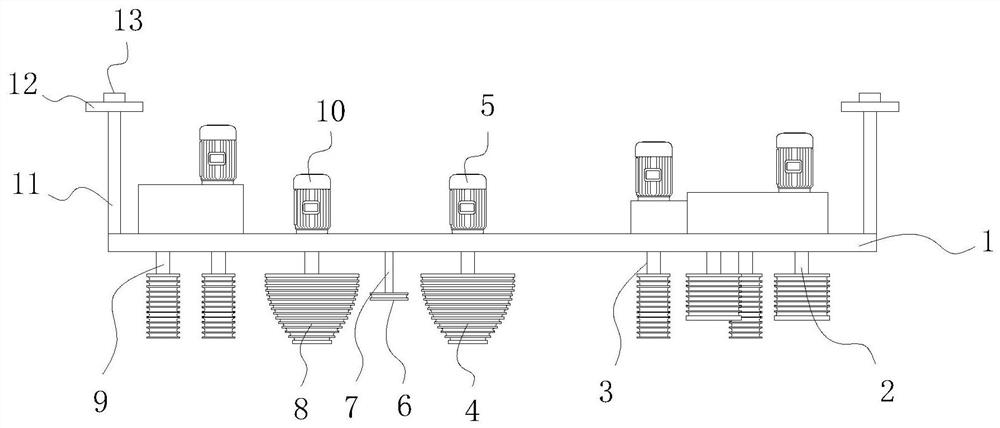

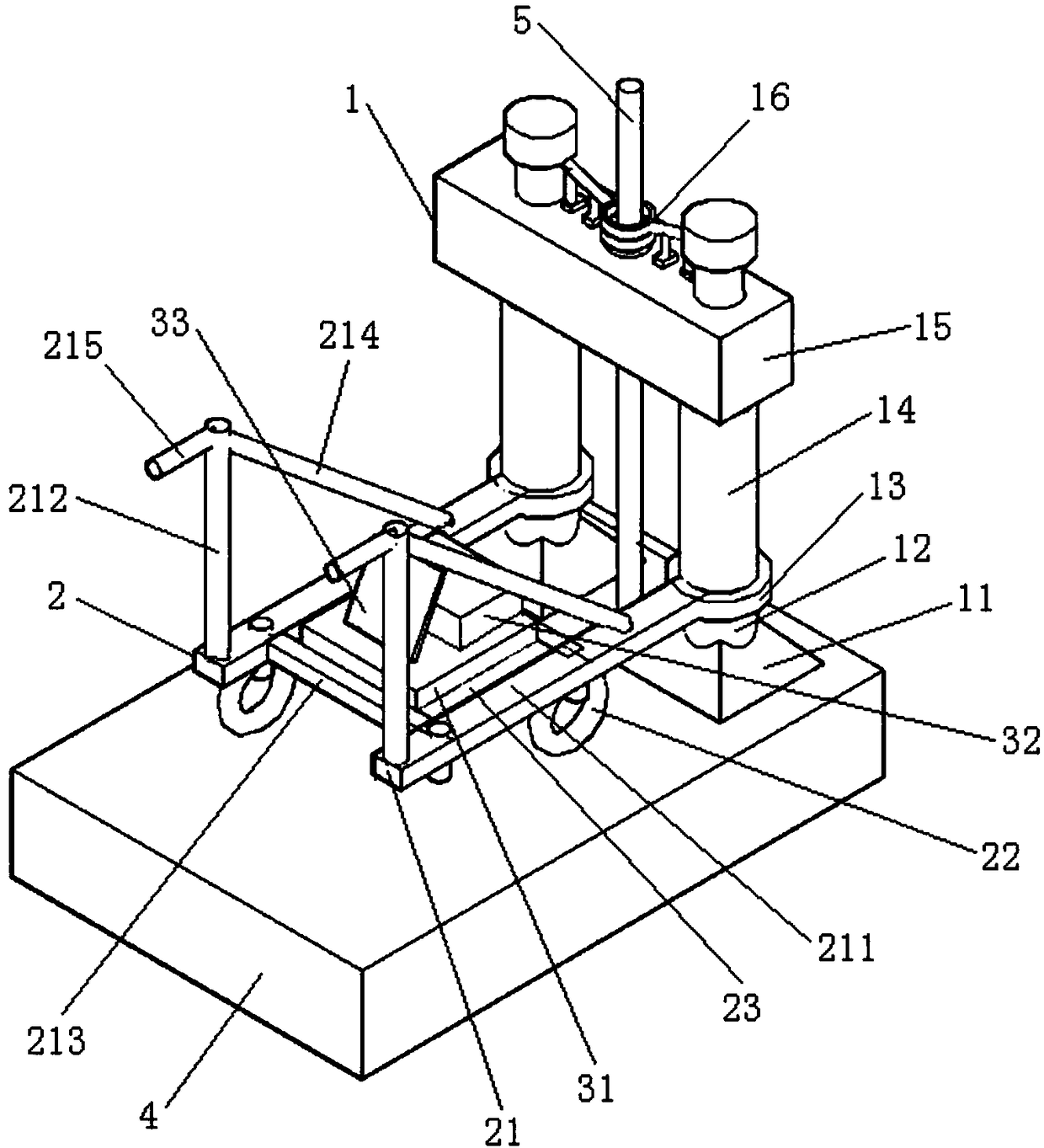

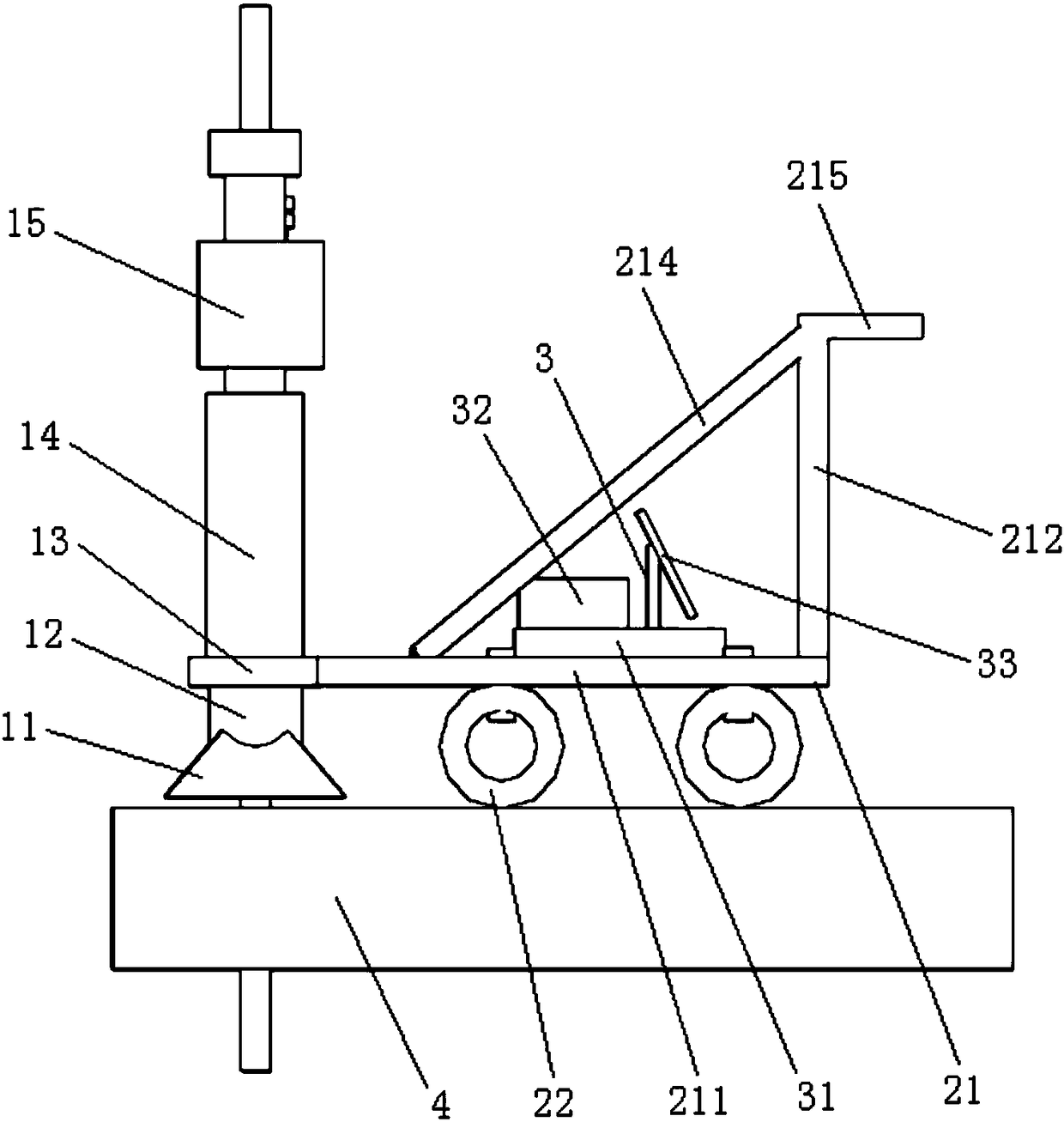

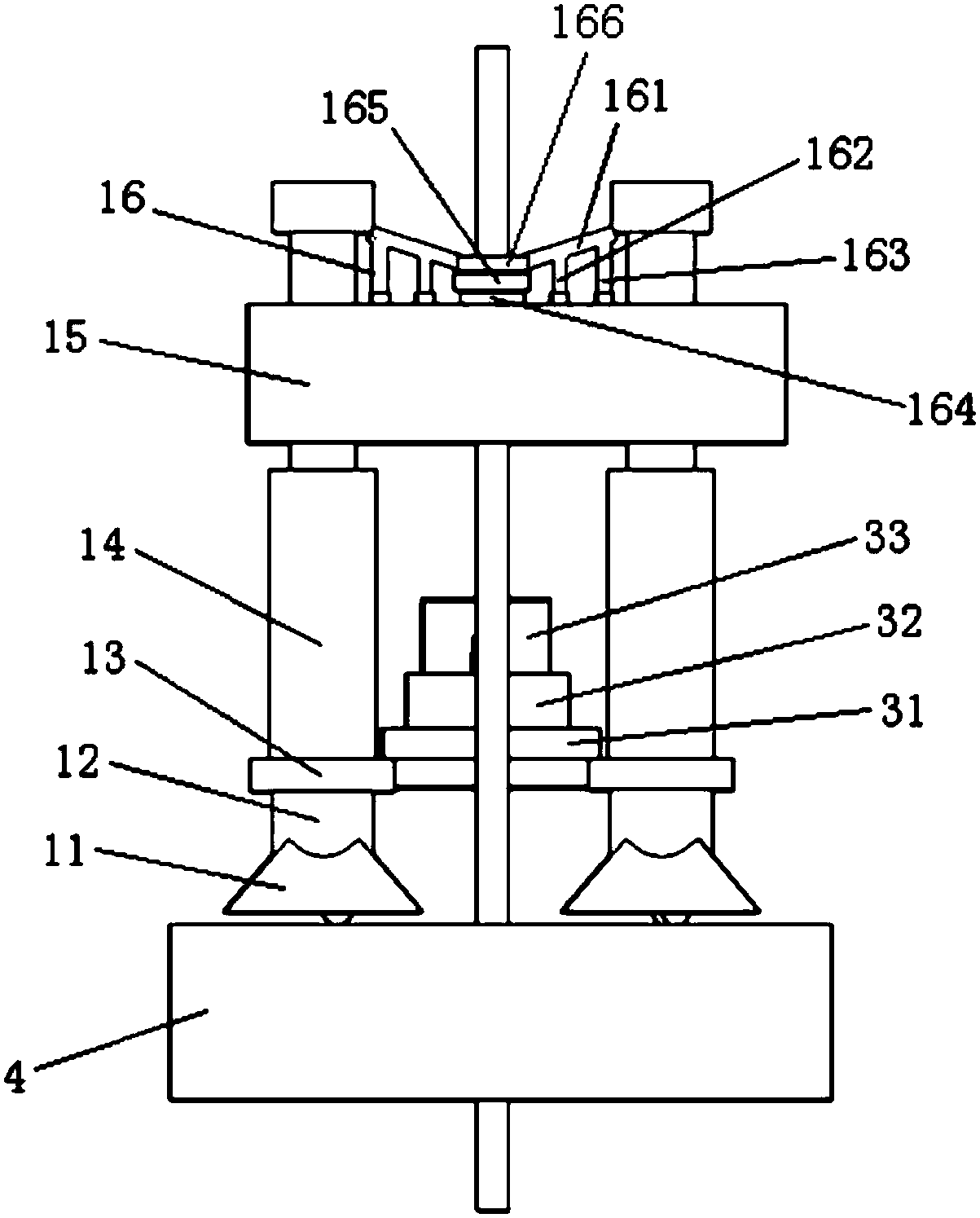

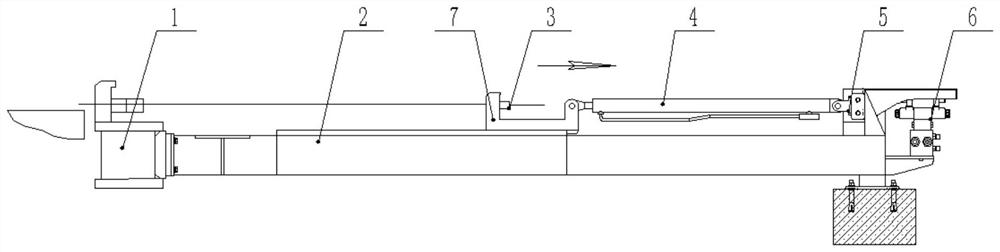

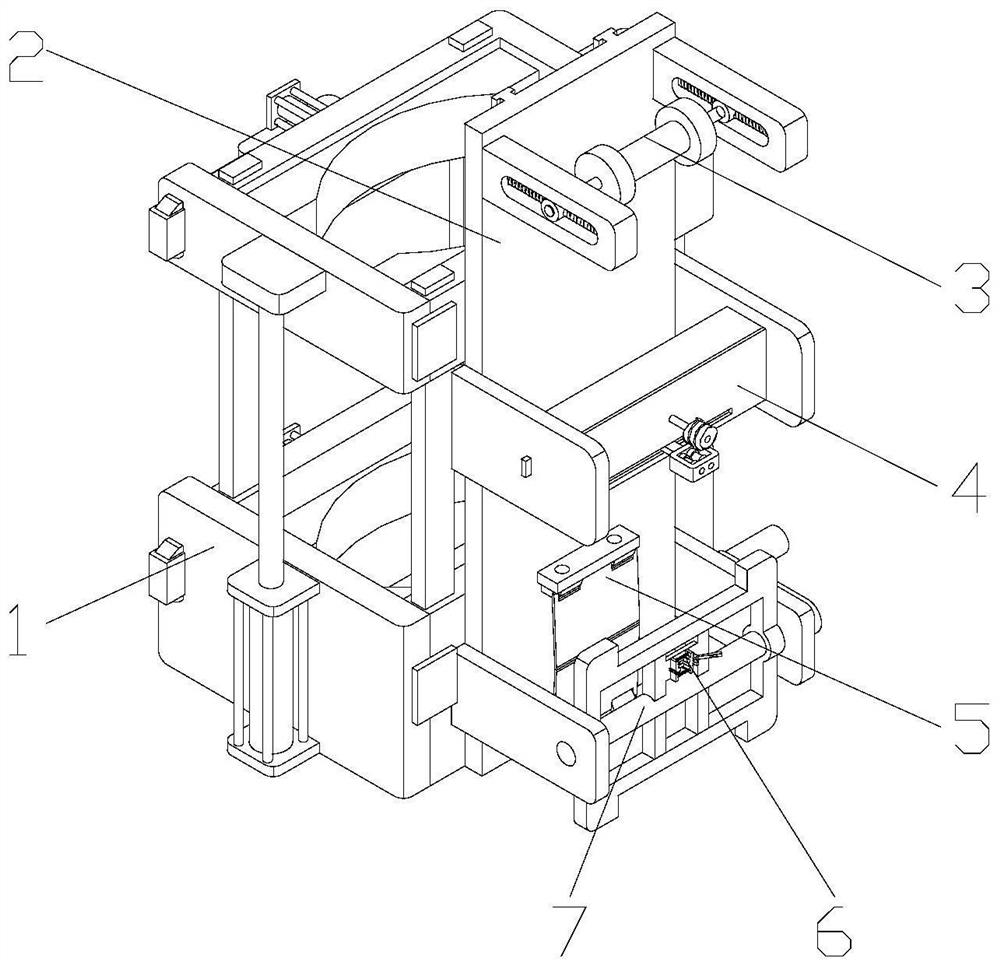

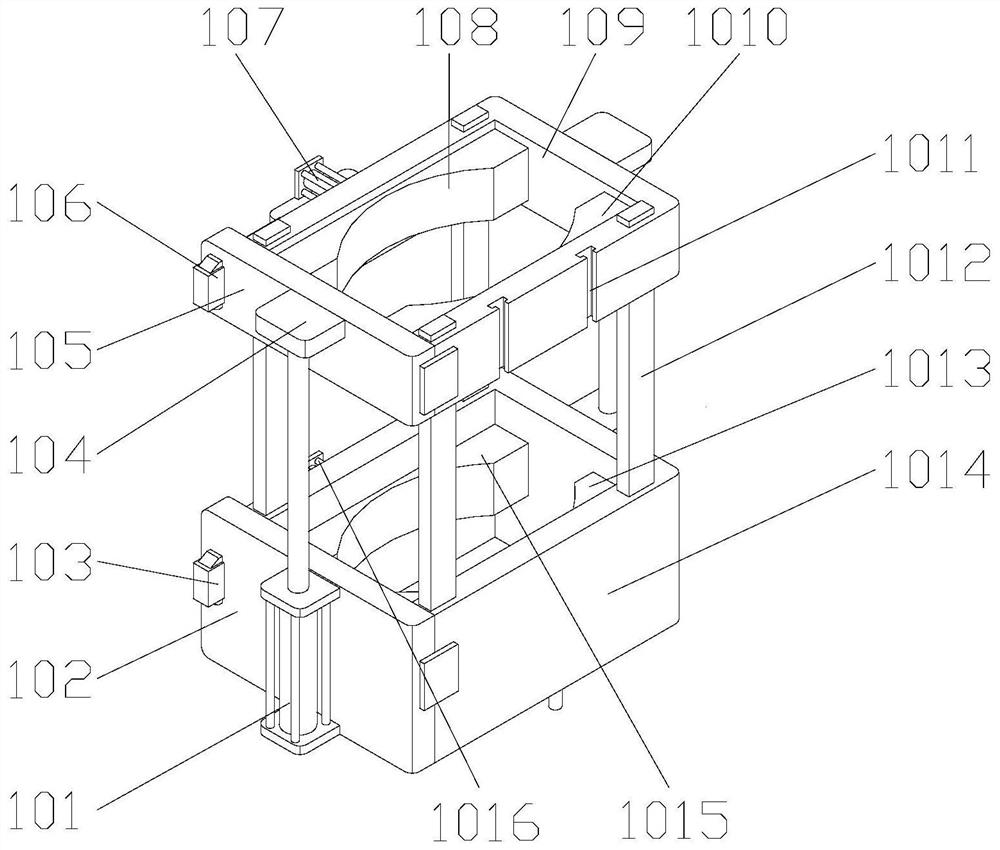

Stretching equipment for bridge vertical rebar

ActiveCN106988226AReduced construction periodReasonable structural designBridge erection/assemblyMechanical stretchingArchitectural engineering

The invention relates to stretching equipment for bridge vertical rebar. The stretching equipment comprises a stretching device, a walking device and a power and hydraulic device. The stretching device is installed on a bridge top plate and comprises a pair of support bases, a support hydraulic rod, a hydraulic-rod support disk, a stretch hydraulic rod, a stretching platform and a steel lever component, wherein the pair of support bases are disposed in the width direction of the bridge top-plate top surface, the support hydraulic rod is vertically fixed on the top of the support bases, the hydraulic-rod support disk is vertically fixed on the upper end of the support hydraulic rod, the stretch hydraulic rod is vertically fixed on the top of the hydraulic-rod support disk, the stretching platform is installed in the middle portion of the stretch hydraulic rod, and the steel lever component is disposed on the stretching platform. The walking device is disposed on the bridge top plate and at one side of the walking device, and comprises a walking frame, universal wheels and a plate. The power and hydraulic device is mounted on the walking device and comprises a hydraulic device, a storage battery and a display. The stretching equipment for the bridge vertical rebar has the advantages of convenient operation, good controllability and high stretching efficiency, and can achieve mechanical stretching of the vertical rebar, replace manual labor, guarantee tension prestress quality, thereby saving construction cost.

Owner:贵州顺康检测股份有限公司

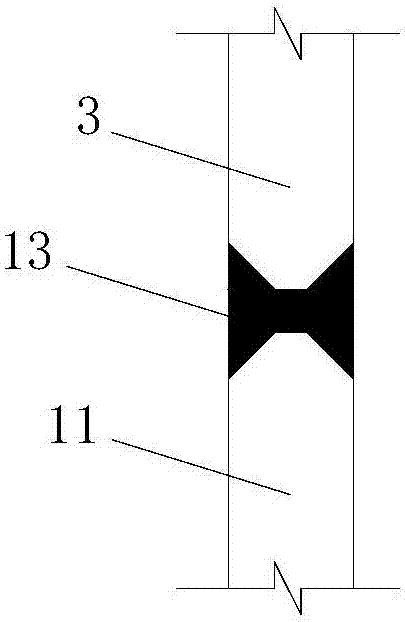

Pre-stressed steel frame for exerting pre-stress by support displacement method and fabrication method of pre-stressed steel frame

InactiveCN102864840AAnti-arch removalEliminate backlashBuilding material handlingPre stressPre stressing

The invention discloses a pre-stressed steel frame for exerting pre-stress by a support displacement method and a fabrication method of the pre-stressed steel frame. The pre-stressed steel frame comprises a girder and two edge posts fixedly connected with the girder; a central cylinder is also arranged between the two edge posts; a gap G is reserved between an upper end face of the central cylinder and a bottom surface of the girder; a combined connection plate is respectively fixedly connected with left and right sides of the middle of a lower end of the central cylinder; the bottom surface of the girder corresponding to the upper end face of the central cylinder is vertically fixedly connected with the connection plate corresponding to the combined connection plate; an inhaul cable is arranged between the combined connection plate and the connection plate; one end of the inhaul cable is hooked with the connection plate; the other end penetrates through a hole arranged on the combined connection plate to be mutually clamped with a center hole jack arranged below the combined connection plate; the gap G is removed by a traction effect of the center hole jack, and contact and fixed connection of the upper end face of the central cylinder and the bottom surface of the girder are achieved. The pre-stress is exerted to the steel frame by a support displacement method principle; internal force distribution is uniformly adjusted; a structural material is saved; and the pre-stressed steel frame is convenient to operate and suitable for a multi-storey steel frame structure with more than two spans.

Owner:JIANGSU UNIV OF SCI & TECH

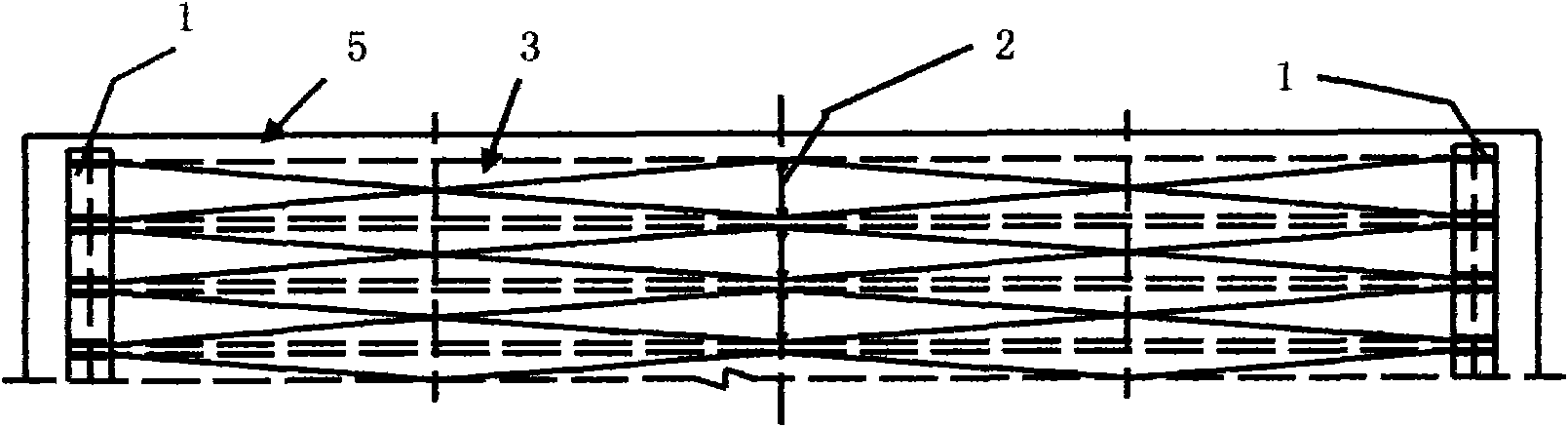

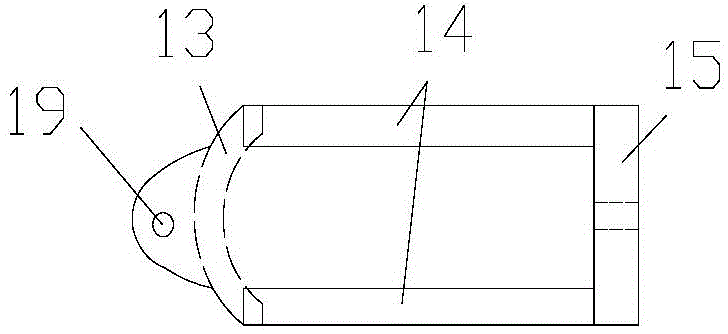

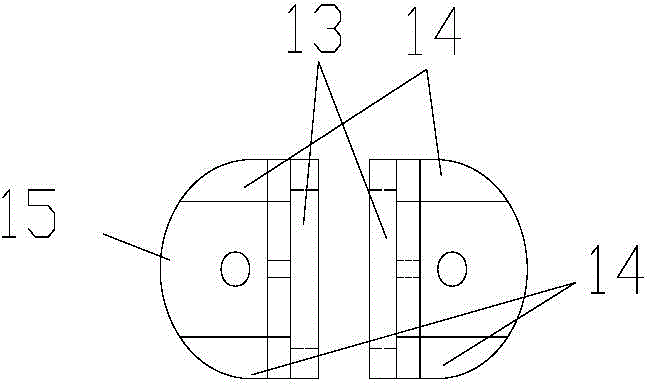

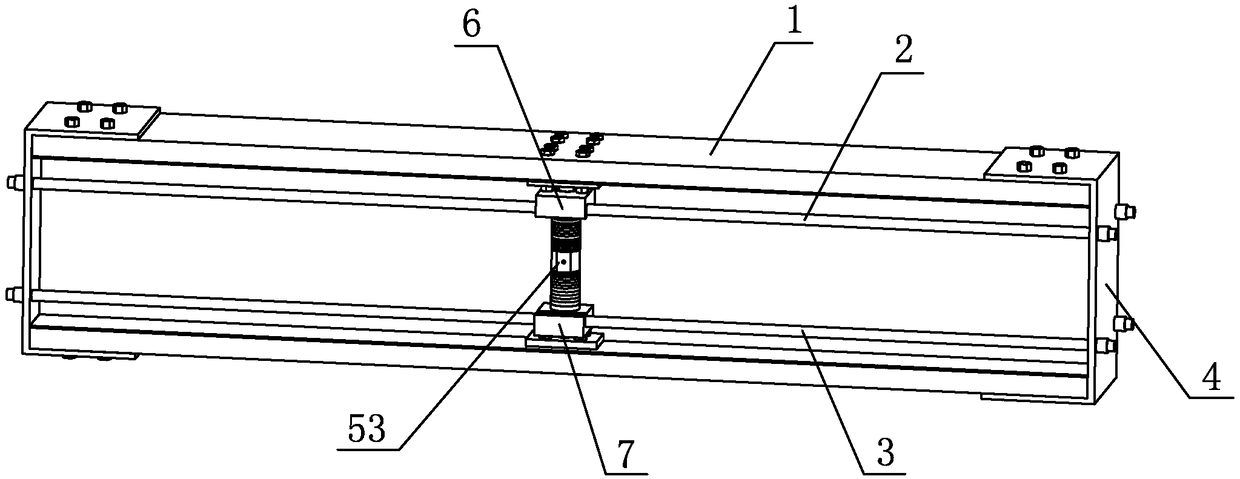

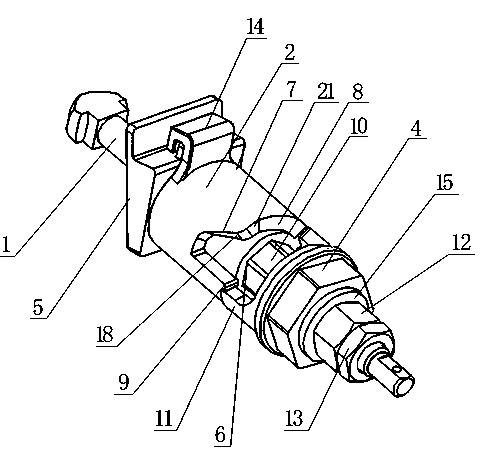

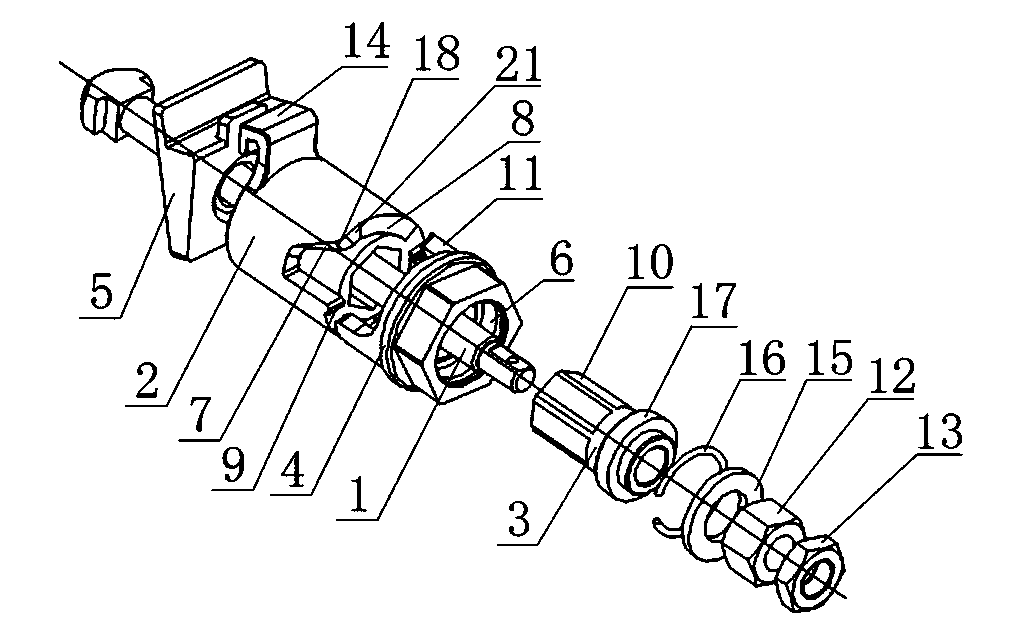

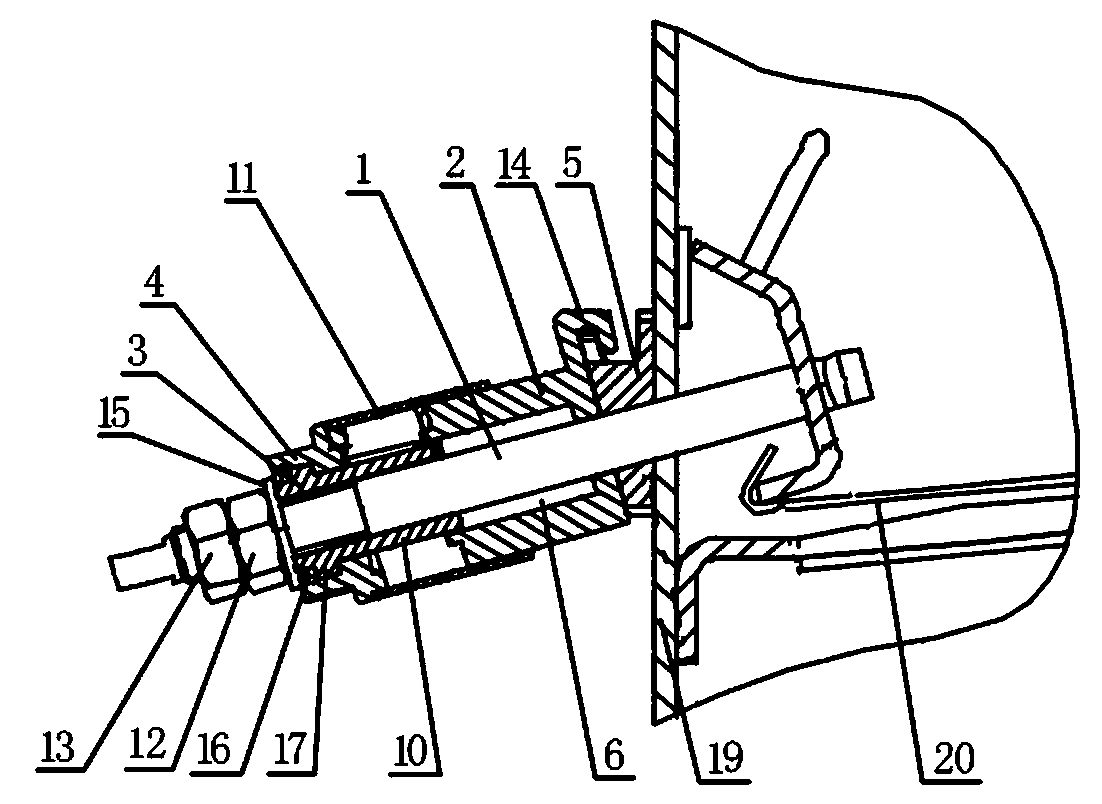

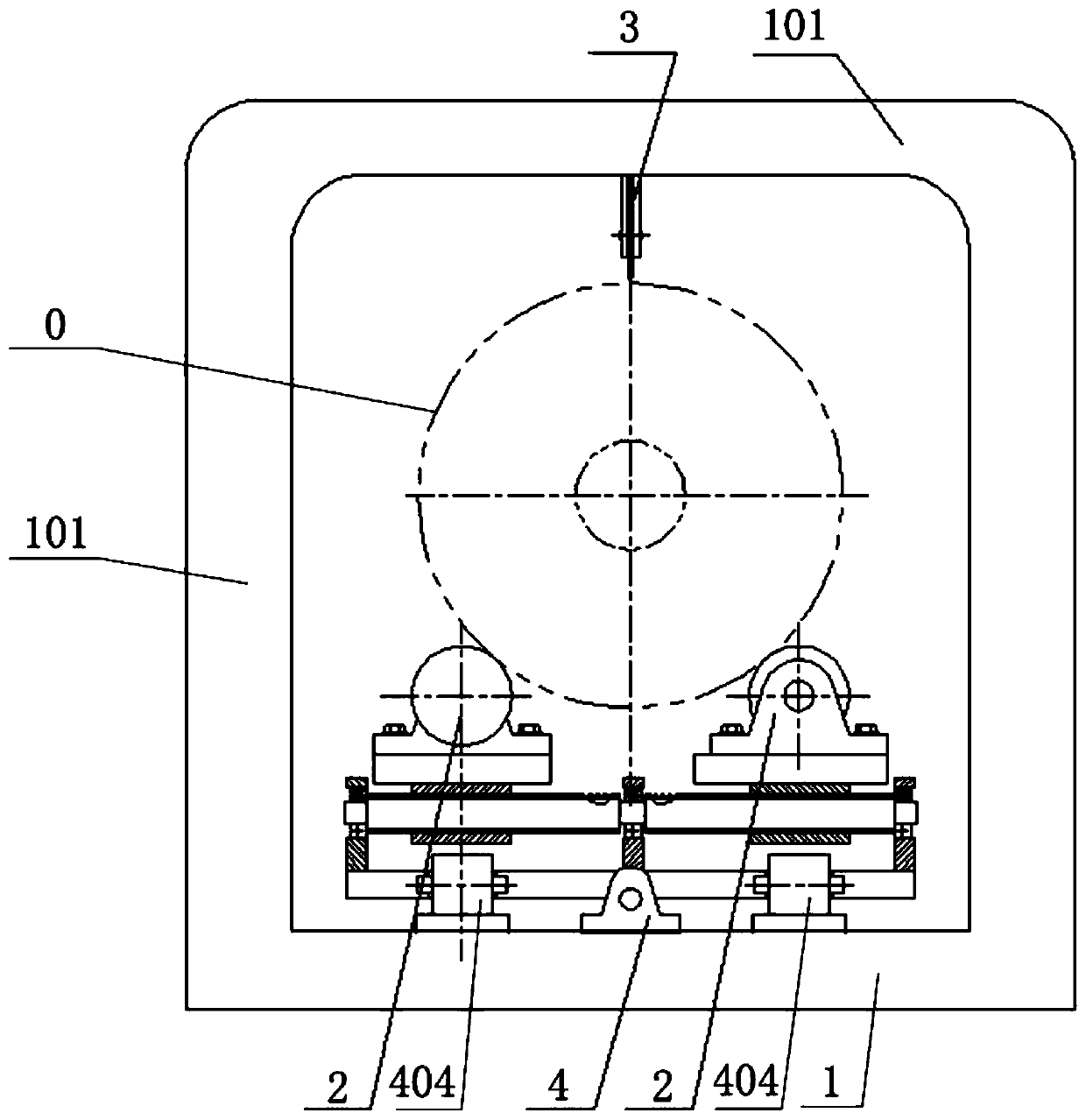

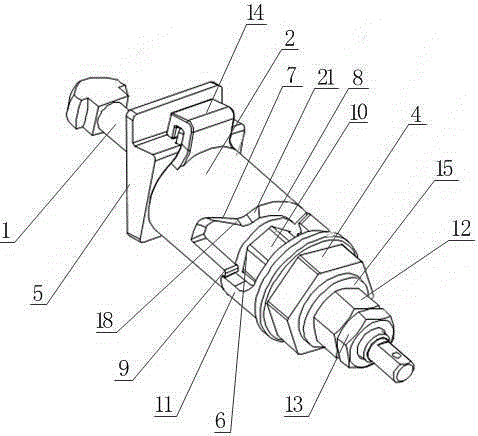

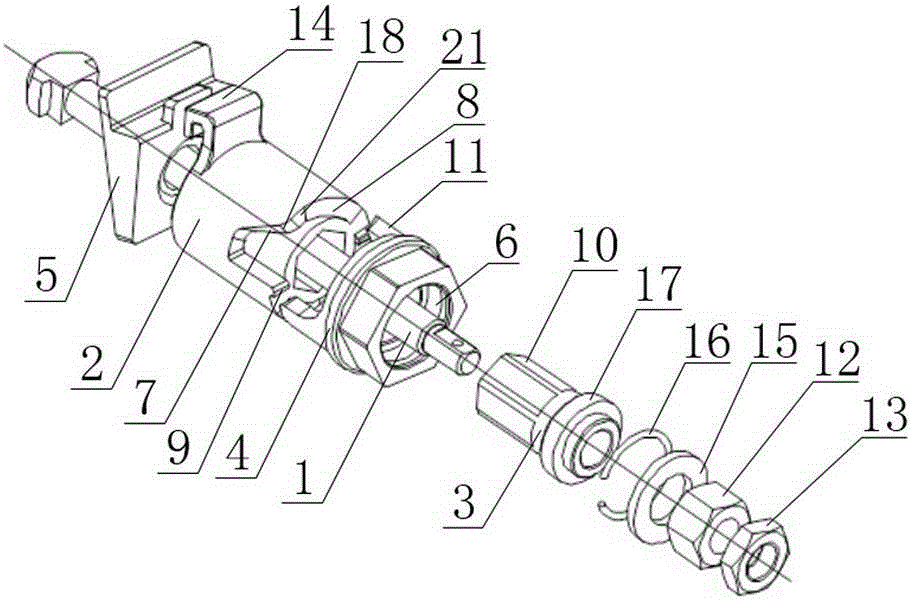

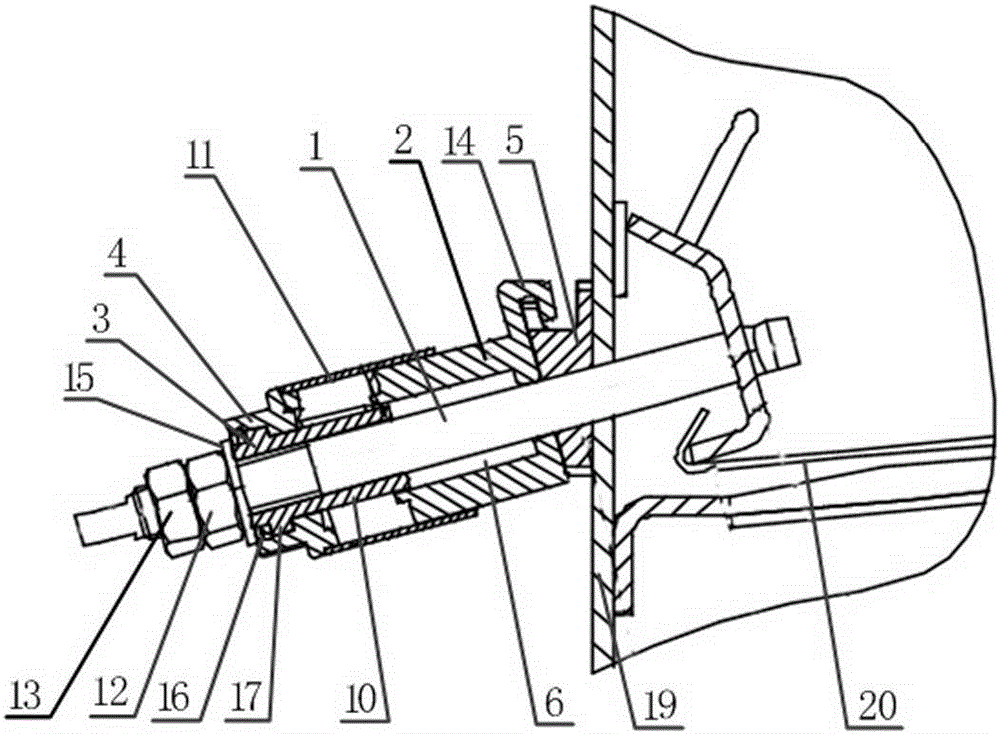

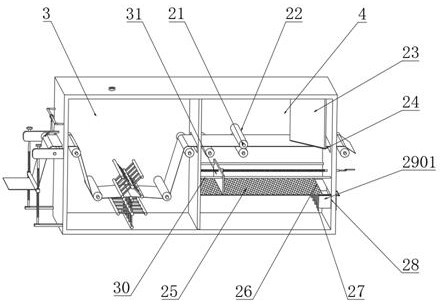

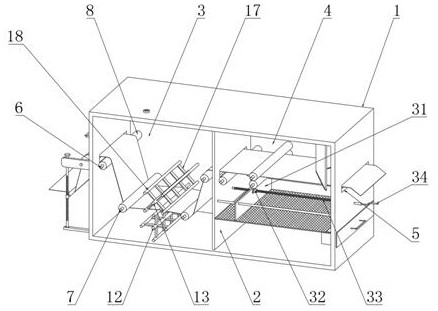

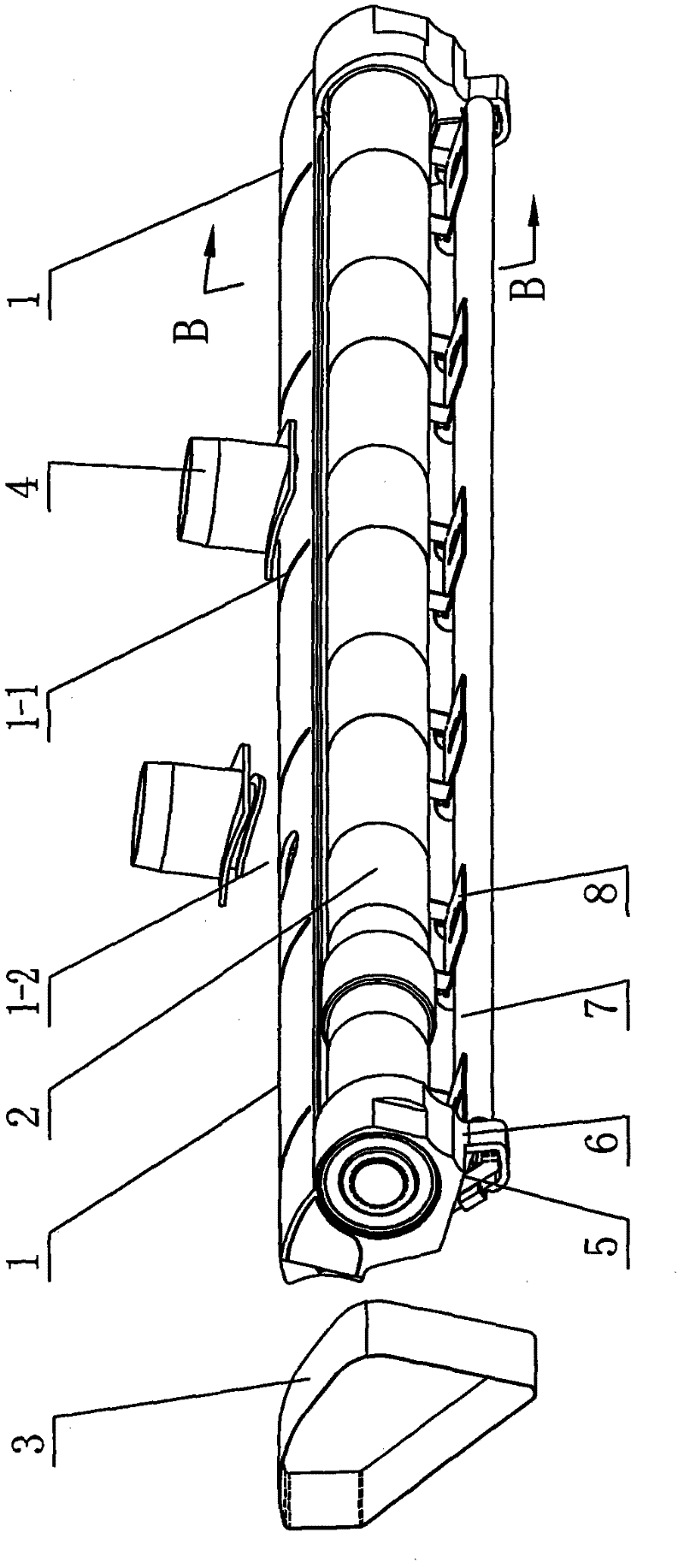

Rapid tensioning device of screen cloth of vibrating screen

ActiveCN104107803AAchieve fast tensioningImprove tensioning efficiencySievingScreeningCamMechanical engineering

The invention discloses a rapid tensioning device of screen cloth of a vibrating screen. The rapid tensioning device comprises a tensioning bolt (1), an end face cam (2), a stress sleeve (3), a rotary head (4), a flat washer (15), an adjusting nut (12) and a locking nut (13). The rotary head (4) is rotated to adjust the axial position of the tensioning bolt (1), so that the screen cloth (20) is tensioned and released. The rapid tensioning device has the advantages of being compact in structure and high in tensioning efficiency of the screen cloth of the vibrating screen, and reducing labor amount of workers.

Owner:CHENGDU WEST PETROLEUM EQUIP

A kind of construction method of high-altitude zipline without support with two-way single-layer cable net structure

The invention discloses a support-free overhead zip line construction method of a two-way single-layer cable net structure. An overhead zip line manner is adopted for sequentially installing track cables and stabilization cables, middle nuts and end nuts are arranged on high-strength bolts, and cable clamps are fastened twice in the achieving process for clamping the track cables and the stabilization cables correspondingly. The method includes the steps that firstly, the track cables are straightly expanded on the ground, bottom boards and middle boards of the cable clamps are installed and fastened, and the track cables are sequentially installed at the designed positions through guide cables and traction cables to be connected with and anchored to outer pressing rings; and then the stabilization cables are straightly expanded on the ground, catwalks are laid on the installed track cables in the directions of the stabilization cables, the stabilization cables are dragged to the overhead catwalks to be expanded, top boards of the cable clamps are installed and fastened, the stabilization cables are tensioned to be connected with and anchored to the outer pressing rings, and therefore the structure is tensioned and formed. By the adoption of the method, no support or large-area work face is needed, main equipment and tools are used in a circulating manner, and the input is small; inhaul cables run overhead, and protection is easy; and construction is easy and convenient, efficiency is high, the measure cost is low, and a construction period is short.

Owner:SOUTHEAST UNIV

Integrated composite spinning device of ring spinning frame

The invention relates to an integrated composite spinning device of a ring spinning frame. The device comprises a special-shaped tube, a grid ring, an integrated composite roller and a tension supporting mechanism; negative pressure integrated composite tubes are positioned at two ends of a front tube wall on one side of a fiber whisker outlet line and provided with two extended roller supportingseats with closed peripheries, tension supporting seats are arranged below the two roller supporting seats, and the negative pressure integrated composite tubes are provided with more than two positioning surfaces; the tension supporting mechanism comprises a tension supporting frame and two positioning spring plates; the tension supporting frame comprises a tension rod and more than three limit sliding seats arranged transversely at intervals along the tension rod; the limit sliding seats are propped on the lower part of the tension rod by adjusting springs, and the bottom of each limit sliding seat is provided with a stop block; and the connecting surfaces of the two positioning spring plates are connected with the two tension supporting seats respectively, and the adjusting and installation surfaces of the two positioning spring plates are in pressing connection with two ends of the tension rod respectively. The device can improve the assembly precision, adjust the axial position of the grid ring in time and conveniently adjust the tension of the grid ring.

Owner:常州市同和纺织机械制造有限公司

Control rope tensioning device

InactiveCN112431048APrevent springbackImprove tensioning efficiencyFilament handlingRope making machinesElectric machineryStructural engineering

The invention provides a control rope tensioning device. The control rope tensioning device comprises a carrier plate, a rope feeding assembly used for guiding a control rope to move is installed on one side face of the carrier plate, a first rope locking assembly used for preventing the control rope from rebounding is arranged obliquely below the rope feeding assembly, a second rope locking assembly used for preventing the control rope from rebounding is installed on the side, away from the first rope locking assembly, of one side face of the carrier plate, a first conical wheel and a secondconical wheel which rotate oppositely and are used for tensioning the control rope are arranged between the first rope locking assembly and the second rope locking assembly, the side, facing the carrier plate, of the first conical wheel is connected with the output end of a first gear motor through a rotating shaft, and the side, facing the carrier plate, of the second conical wheel is connected with the output end of a second gear motor through a rotating shaft. Compared with the prior art, the control rope tensioning device has the following beneficial effects that the tensioned control ropeis prevented from rebounding, the tensioning efficiency of the control rope is improved, step-by-step tensioning is achieved, and the stress of the control rope is evenly increased.

Owner:台州市和德绳业有限公司

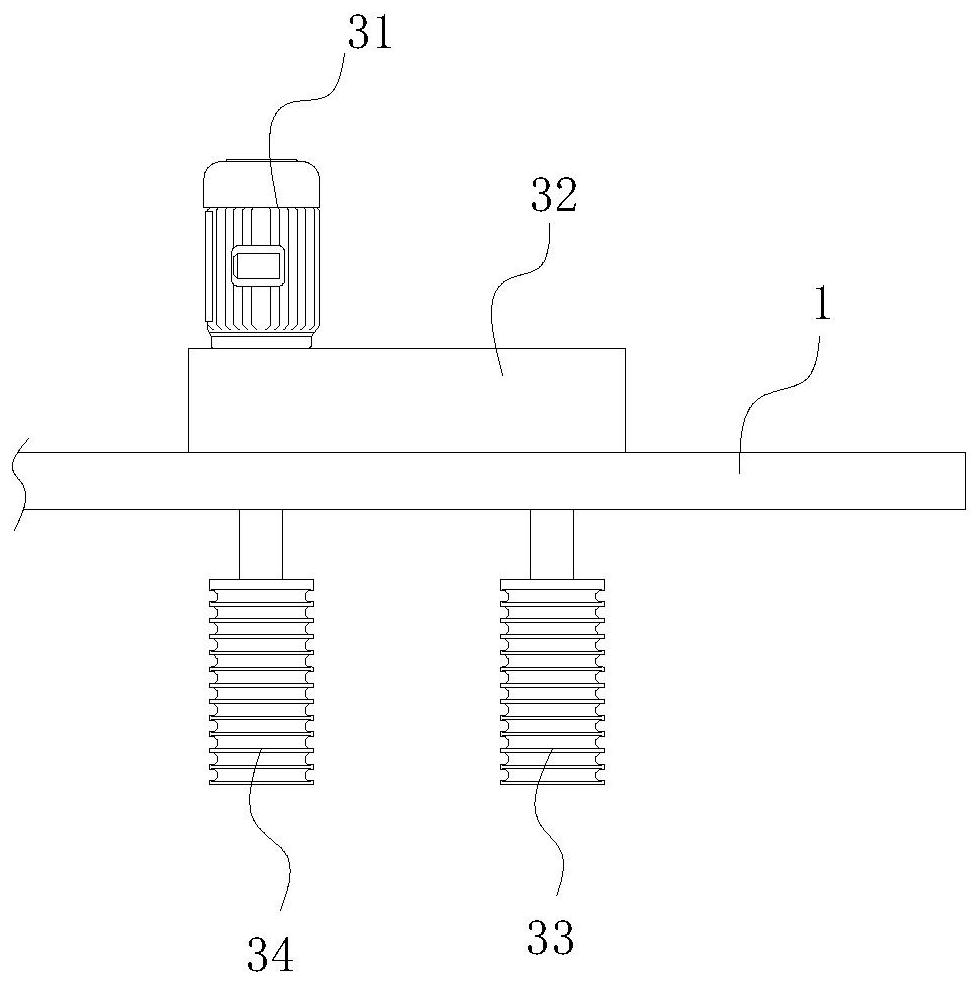

Horizontal overhead tensioning device for motor rotor conducting bars

InactiveCN110417202AImprove tensioning efficiencyEliminate potential safety hazardsManufacturing cage rotorsReciprocating motionEngineering

The invention discloses a horizontal overhead tensioning device for motor rotor conducting bars, which comprises a machine body base, supporting and rotating mechanisms, an axial movement mechanism and a rolling mechanism, wherein the supporting and rotating mechanisms are arranged on two sides of the surface of the machine body base and used for horizontally supporting and circumferentially rotating a rotor workpiece, the axial movement mechanism is arranged on the surface of the machine body base and used for driving the supporting and rotating mechanism to drive the rotor workpiece to movein the axial direction in a reciprocating mode, and the rolling mechanism is erected on the machine body base, positioned above the supporting position of the rotor workpiece and used for being tightly abutted against each conducting bar on the rotor workpiece so as to enable the conducting bars to be tensioned in iron core grooves through reciprocating rolling. The device disclosed by the invention provides horizontal support and circumferential rotation driving for the rotor workpiece through the supporting and rotating mechanisms, enables the rotor workpiece and the rolling mechanism to form relative reciprocating movement by using the axial movement mechanism, and enables the rolling mechanism to perform rolling and tensioning on the conducting bars one by one, so that the tensioning efficiency of the motor rotor conducting bars is improved, the uniform and consistent tensioning degree and the uniform and continuous tensioning deformation of the conducting bars are ensured, and thepotential safety hazards are eliminated.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

Horizontal curve prestress device of hollow large cantilever structure

ActiveCN112982668AImprove economyImprove securityExtraordinary structuresBuilding material handlingClassical mechanicsCantilever

The invention relates to a horizontal curve prestress device of a hollow large cantilever structure. The horizontal curve prestress device arranged above a neutral axis of the hollow large cantilever structure comprises a horizontal curved cable, straight cables, annular cable clamp nodes, straight cable clamp nodes, inclined cable clamp nodes and tension end nodes; and the horizontal curve prestress device is characterized in that the horizontal curved cable is a non-closed curve, two ends of the horizontal curved cable are connected with the straight cables, the straight cables are arranged in the tangential direction of the end points of the horizontal curved cable and extend to the non-cantilever position of the hollow large cantilever structure from the end points of the curved cable, the tension end nodes are arranged to be connected with the hollow large cantilever structure, the curved cable is provided with the annular cable clamp nodes to be connected with the hollow large cantilever structure, the straight cables are provided with the straight cable clamping nodes to be connected with the hollow large cantilever structure, the inclined cable clamping nodes are arranged at the intersection points of the straight cables and the curved cable and are connected with the hollow large cantilever structure, the straight cables and the curved cable can slide in the cable clamp nodes in the tensioning process, the annular cable clamp nodes, the straight cable clamp nodes and the inclined cable clamp nodes are welded with the hollow large cantilever structure without relative deformation, and the tensioning end nodes are arranged at the end points of the straight cables.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

A fast tensioning device for vibrating screen mesh

ActiveCN104107803BAchieve fast tensioningImprove tensioning efficiencySievingScreeningEngineeringCam

The invention discloses a rapid tensioning device of screen cloth of a vibrating screen. The rapid tensioning device comprises a tensioning bolt (1), an end face cam (2), a stress sleeve (3), a rotary head (4), a flat washer (15), an adjusting nut (12) and a locking nut (13). The rotary head (4) is rotated to adjust the axial position of the tensioning bolt (1), so that the screen cloth (20) is tensioned and released. The rapid tensioning device has the advantages of being compact in structure and high in tensioning efficiency of the screen cloth of the vibrating screen, and reducing labor amount of workers.

Owner:CHENGDU WEST PETROLEUM EQUIP

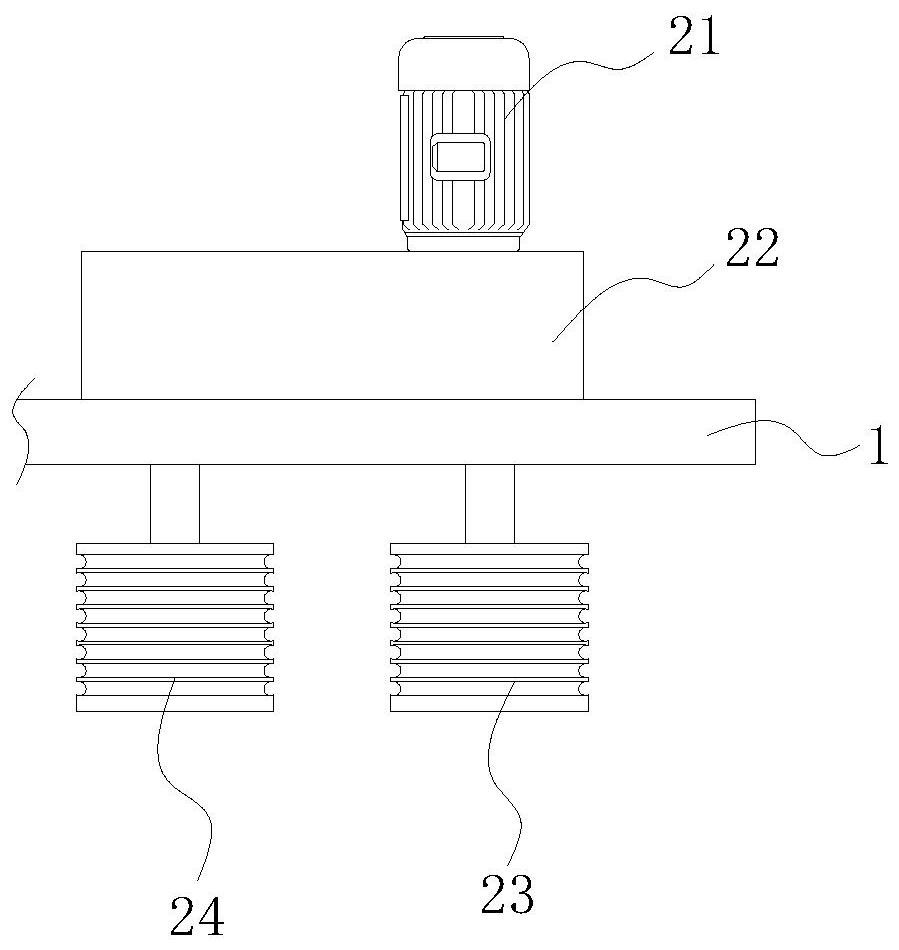

Horizontal side-arranged tensioning device for motor rotor conducting bars

InactiveCN110417201AAvoid vibrationAvoid shockManufacturing cage rotorsReciprocating motionEngineering

The invention discloses a horizontal side-arranged tensioning device for motor rotor conducting bars, which comprises a machine body base, a supporting and rotating mechanism, axial movement mechanisms, rolling mechanisms and an auxiliary pressing mechanism, wherein the supporting and rotating mechanisms are arranged at two sides of the surface of the machine body base and used for horizontally supporting and circumferentially rotating a rotor workpiece, the axial movement mechanism is used for driving the supporting and rotating mechanisms to drive the rotor workpiece to move in the axial direction in a reciprocating mode, the rolling mechanisms are erected on the machine body base, positioned at two radial sides of the rotor workpiece and used for being tightly abutted against each conducting bar on the rotor workpiece so as to enable the conducting bars to be tensioned in iron core grooves through reciprocating rolling, and the auxiliary pressing mechanism is erected on the machinebody base and used for pressing the surface of the rotor workpiece so as to prevent the rotor workpiece from generating radial or axial runout in the reciprocating movement process. The device disclosed by the invention can improve the tensioning efficiency of the motor rotor conducting bars, prevent the rotor from generating axial or radial runout, ensure the uniform and consistent tensioning degree and uniform and continuous tensioning deformation of each conducting bar and eliminate the potential safety hazards caused by a tensioning punch in the tensioning operation process.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

A steel-ultra-high-performance concrete composite continuous beam bridge structure and its construction method

InactiveCN105839510BSimple structureLow input costBridge structural detailsBridge materialsPre stressPre stressing

The invention discloses a steel-ultra-high-performance concrete combined continuous beam bridge structure and a construction method thereof. The combined continuous beam bridge structure comprises a continuous beam formed by splicing M steel-ultra-high-performance concrete combined beam sections and (M+1) steel-high-intensity concrete combined beam sections; the steel-ultra-high-performance concrete combined beam sections and the steel-high-intensity concrete combined beam sections are distributed in a staggered manner and M is more than or equal to 2; the M steel-ultra-high-performance concrete combined beam sections are supported on M bridge piers respectively; each steel-ultra-high-performance concrete combined beam section comprises a second steel beam segment and an ultra-high-performance concrete board; the construction method comprises the following steps: 1, prefabricating and machining; 2, mounting a lower part beam body and a first steel beam segment; 3, hoisting a high-intensity concrete board; 4, mounting a steel-ultra-high-performance concrete combined section; 5, carrying out wet joint construction. The steel-ultra-high-performance concrete combined continuous beam bridge structure and the construction method thereof have the advantages of reasonable design, simplicity and convenience in construction and good utilization effect, and the problem that a hogging moment region of an existing steel-concrete continuous beam bridge is cracked and the problem that the pre-stress efficiency is low can be solved.

Owner:XIAN HIGHWAY INST +1

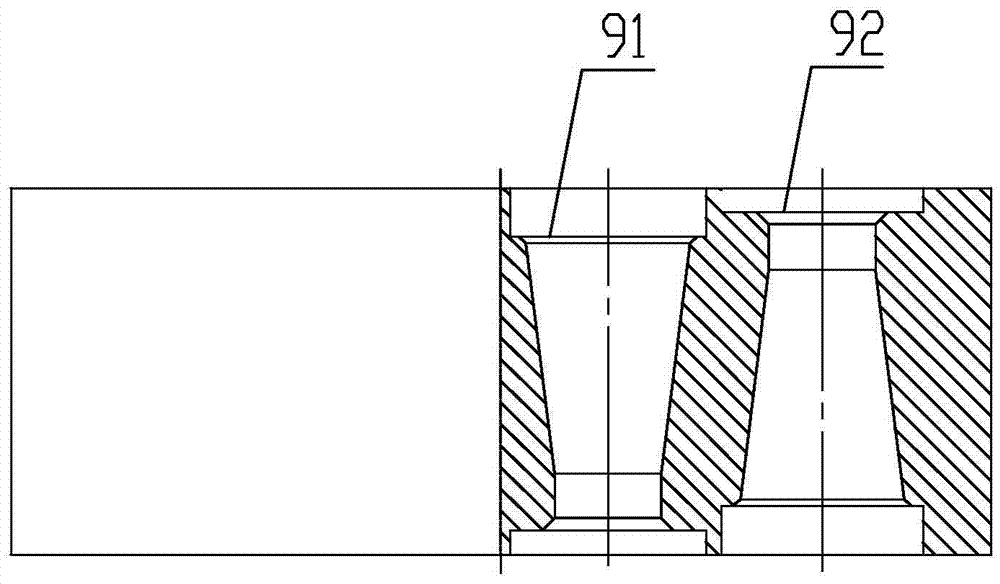

A non-bonded rib ring anchor sealing system and its installation and construction method

An unbounded bar circular anchor sealing system comprises anchor plates used for anchoring unbounded bars, clamping pieces, transition tubes, tight coupling tubes, bolts, pressing plates and sealing rings, wherein step holes are formed in the large taper hole end and the straight hole end of each anchoring plate respectively, and each unbounded bar is sleeved with a corresponding locking ring, the corresponding transition tube, the corresponding pressing plate, and the corresponding tight coupling tube provided with the corresponding sealing ring in sequence in the installation state; each unbounded bar extends into a corresponding hole of the corresponding anchoring plate, the end face of each clamping piece sinks to the position below the end face of the corresponding anchoring plate after being completely tensioned, each pressing plate tightly presses the corresponding tight coupling tube through the corresponding bolt, each sealing ring is matched with a counter bore of the corresponding anchoring plate, and each clamping piece end is arranged in a sealing sleeve to achieve clamping piece end radial seal; the small end of corresponding tight coupling tube is of a conical structure and in expanding fit with the corresponding transition tube in a sealed mode; each unbounded bar with a PE tube stripped off as the requirement of tensioning construction is held by the corresponding transition tube, each transition tube is then in lap joint with the PE tube of the corresponding unbounded bar and locked by the corresponding locking ring, and an unbounded bar and clamping and anchoring unit fully-independent sealed structure is formed by each unbounded bar. The installation and construction method is simple, and construction efficiency can be improved greatly.

Owner:LIUZHOU OVM MASCH CO LTD

A bridge vertical reinforcement tensioning equipment

ActiveCN106988226BReduced construction periodReasonable structural designBridge erection/assemblyMechanical stretchingArchitectural engineering

The invention relates to stretching equipment for bridge vertical rebar. The stretching equipment comprises a stretching device, a walking device and a power and hydraulic device. The stretching device is installed on a bridge top plate and comprises a pair of support bases, a support hydraulic rod, a hydraulic-rod support disk, a stretch hydraulic rod, a stretching platform and a steel lever component, wherein the pair of support bases are disposed in the width direction of the bridge top-plate top surface, the support hydraulic rod is vertically fixed on the top of the support bases, the hydraulic-rod support disk is vertically fixed on the upper end of the support hydraulic rod, the stretch hydraulic rod is vertically fixed on the top of the hydraulic-rod support disk, the stretching platform is installed in the middle portion of the stretch hydraulic rod, and the steel lever component is disposed on the stretching platform. The walking device is disposed on the bridge top plate and at one side of the walking device, and comprises a walking frame, universal wheels and a plate. The power and hydraulic device is mounted on the walking device and comprises a hydraulic device, a storage battery and a display. The stretching equipment for the bridge vertical rebar has the advantages of convenient operation, good controllability and high stretching efficiency, and can achieve mechanical stretching of the vertical rebar, replace manual labor, guarantee tension prestress quality, thereby saving construction cost.

Owner:贵州顺康检测股份有限公司

Unbounded bar circular anchor sealing system and installation and construction method thereof

An unbounded bar circular anchor sealing system comprises anchor plates used for anchoring unbounded bars, clamping pieces, transition tubes, tight coupling tubes, bolts, pressing plates and sealing rings, wherein step holes are formed in the large taper hole end and the straight hole end of each anchoring plate respectively, and each unbounded bar is sleeved with a corresponding locking ring, the corresponding transition tube, the corresponding pressing plate, and the corresponding tight coupling tube provided with the corresponding sealing ring in sequence in the installation state; each unbounded bar extends into a corresponding hole of the corresponding anchoring plate, the end face of each clamping piece sinks to the position below the end face of the corresponding anchoring plate after being completely tensioned, each pressing plate tightly presses the corresponding tight coupling tube through the corresponding bolt, each sealing ring is matched with a counter bore of the corresponding anchoring plate, and each clamping piece end is arranged in a sealing sleeve to achieve clamping piece end radial seal; the small end of corresponding tight coupling tube is of a conical structure and in expanding fit with the corresponding transition tube in a sealed mode; each unbounded bar with a PE tube stripped off as the requirement of tensioning construction is held by the corresponding transition tube, each transition tube is then in lap joint with the PE tube of the corresponding unbounded bar and locked by the corresponding locking ring, and an unbounded bar and clamping and anchoring unit fully-independent sealed structure is formed by each unbounded bar. The installation and construction method is simple, and construction efficiency can be improved greatly.

Owner:LIUZHOU OVM MASCH CO LTD

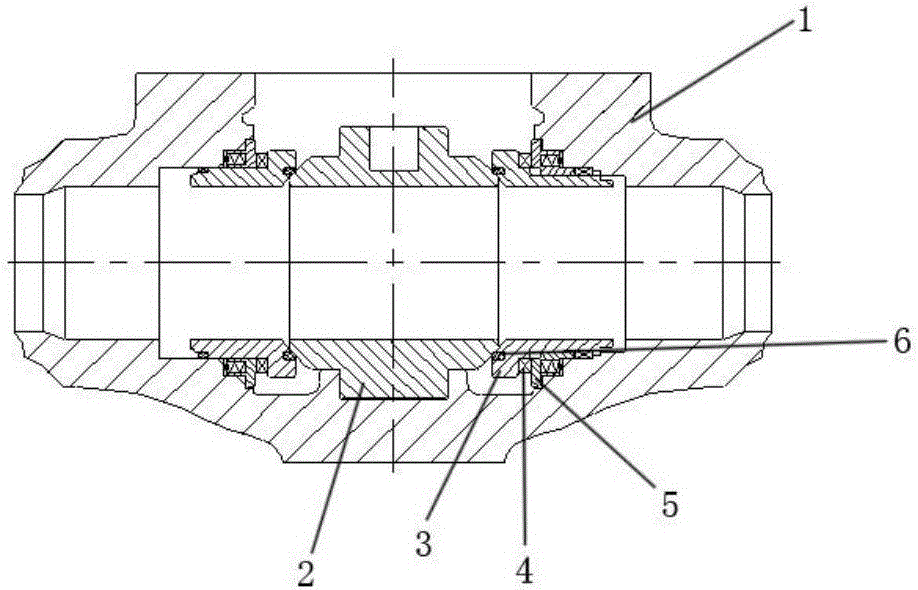

A ball valve disassembly tooling and installation and disassembly method

ActiveCN104084931BRealize disassemblyAchieve opposite motionMetal-working hand toolsEngineeringPower apparatus

The invention provides a ball valve installing and dismantling tool which comprises a tensioning device used for tensioning a fixer (3) and a stretching device used for stretching a spring seat (5) open, wherein the tensioning device and the stretching device cooperate to achieve opposite movement of the spring seat (5) and the fixer (3), the tensioning device comprises a rotating device (30), a screw (12) and a movable part (11), and the movable part (11) is connected with the fixer (3) through a second matching structure; the stretching device comprises a power device (60), an ejector rod (15) and an abutting part (14), one end of the abutting part (14) is connected with the ejector rod (15), and the other end of the abutting part abuts against the spring seat (5). The ball valve installing and dismantling tool can save labor, is convenient to use and can be used online. In addition, the invention provides a ball valve installing and dismantling method.

Owner:NEWAY VALVE SUZHOU

A high-efficiency and high-stability oil immersion device for chemical fiber production and its application method

ActiveCN109811488BSmooth transmissionFor the purpose of tighteningTextile treatment containersLiquid/gas/vapor removal by squeezing rollersFiberOil can

The invention discloses a high-efficiency and high-stability oil immersion device for chemical fiber production and a use method thereof, comprising a box body, a partition plate is welded in the middle of the box body, and a side of the box body corresponding to the partition plate is arranged It is an oil immersion chamber, a driving shaft is installed at the bottom of the oil immersion chamber, a driven shaft is installed at the position above the driving shaft corresponding to the bottom of the oil immersion chamber, and the end of the driven shaft is sleeved at the position corresponding to the driving gear. A driven gear is connected, and a beating column is welded at one end of the connecting rod. The structure of the present invention is scientific and reasonable, and it is safe and convenient to use. The driving motor drives the driving shaft to rotate, and the driving shaft drives the driven shaft to rotate through the action of the driving gear and the transmission gear. The relative rotation of the driven shaft and the driving shaft makes the slapping column slap the chemical fiber product, and through intermittent slapping, the oil liquid can be more effectively immersed in the chemical fiber product, so that the oil immersion efficiency of the chemical fiber product is improved, and an efficient immersion effect is achieved. purpose of the oil.

Owner:龙岩东腾再生资源科技有限公司

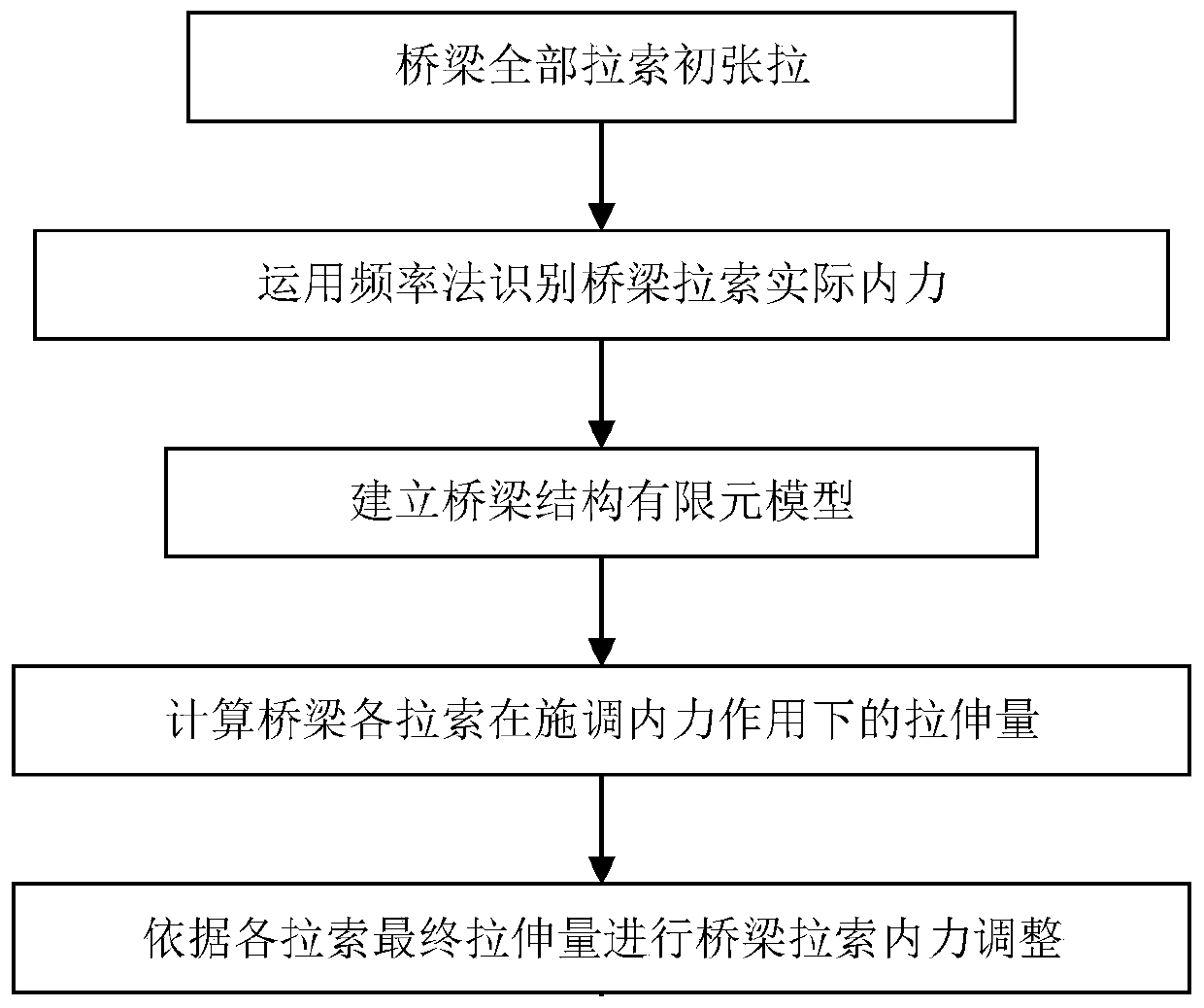

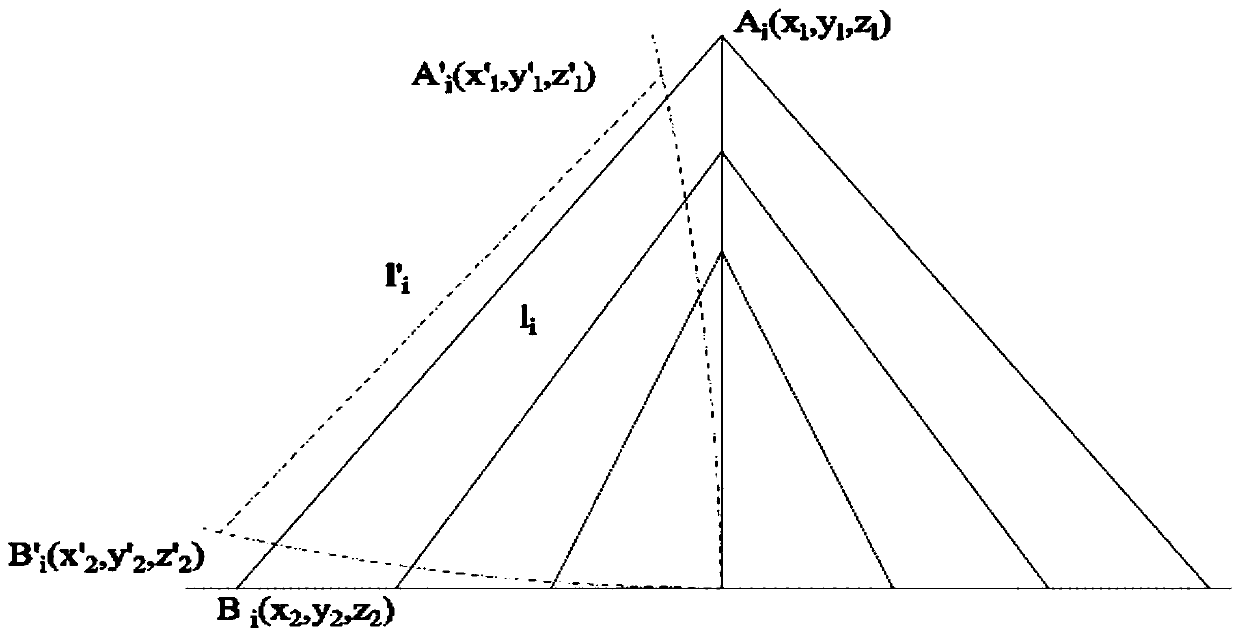

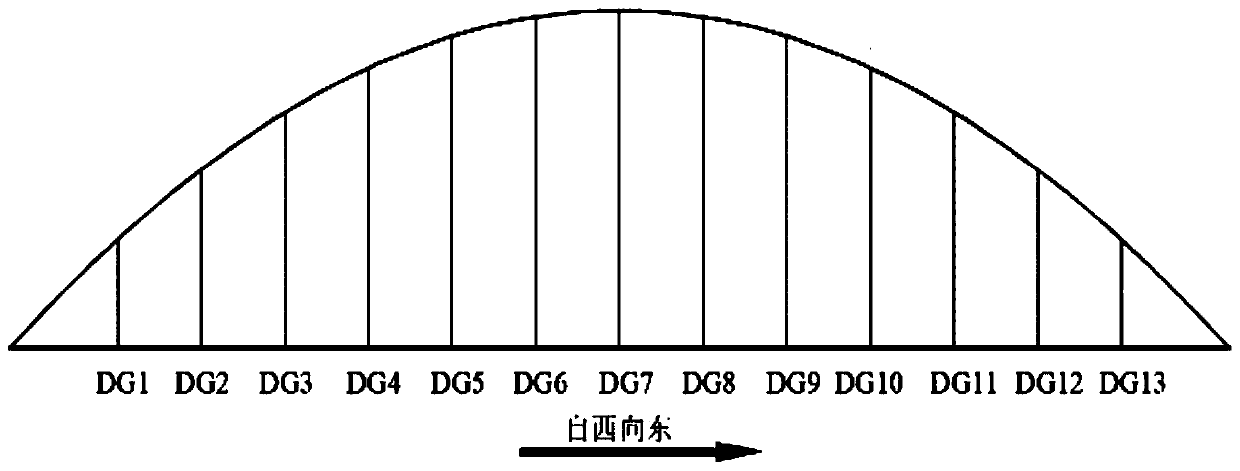

Adjustment Method of Cable Internal Force of Bridge with Continuous Deck Structure

InactiveCN108460229BImprove tensioning efficiencyGuaranteed accuracyGeometric CADBridge structural detailsElement modelBridge deck

The invention provides an adjusting method of continuous deck structure bridge inhaul cable internal force. The adjusting method is characterized by including following steps: step 1, after all inhaulcables of a bridge are tensioned for the first time, adopting a frequency method to recognize actual internal force of each inhaul cable; step 2, building a bridge structure finite element model; step 3, in consideration of temperature impact, analyzing and calculating final tension amount of each inhaul cable of the bridge under action of applied and adjusted internal force on the basis of the bridge structure finite element model; step 4, adjusting the bridge inhaul cable internal force according to the final tension amount of each inhaul cable: converting the tension amount of each inhaulcable into rotating angle of an anchor head nut of the inhaul cable, and adjusting the bridge inhaul cable internal force according to the nut rotating angles acquired by calculation. The method can ensure accuracy of inhaul cable internal force adjustment and substantially improve tension efficiency of the inhaul cables, is quite convenient to implement and has great popularization and application value in inhaul cable internal force adjustment of bridge newly-building or old bridge cable replacing projects.

Owner:WUHAN UNIV OF TECH

Tension support mechanism of compact spinning device

InactiveCN102031601BEffective control of axial movementImprove tensioning efficiencyDrafting machinesEngineeringMesh grid

Owner:常州市同和纺织机械制造有限公司

a pre-tensioning machine

ActiveCN109025314BStable direction of movementSame pretensionBuilding material handlingPull forceClassical mechanics

The invention discloses a pre-tensioning machine, which comprises a base frame, a linear stretching device and a steel bar fixing piece. The first end of the base frame is provided with an end seat anchorage, the second end is provided with a fixing seat, the linear stretching device and The steel bar fixing parts are respectively located between the first end and the second end of the bottom frame. One end of the linear stretching device is connected with the fixing seat, and the other end is connected with the steel bar fixing parts. The guide mechanism is guided by the movement of the steel bar, and the moving direction of the steel bar fixing part is consistent with the stretching direction of the linear stretching device. With this device, one end of the steel bar is fixed by the end seat anchorage, and the other end is fixed by the steel bar fixing piece. The linear stretching device drives the steel bar fixing piece to perform pre-tensioning. The guiding mechanism on the bottom frame guides the movement of the steel bar fixing piece. Prevent the linear stretching device from shifting when pulling the steel bar, ensure the same pre-tensioning force of the steel bar, improve the tensioning efficiency of the steel bar, and the structure of the device is simple without frequent setting of suspension counterweights.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

A cable tensioning device for high-altitude power construction

ActiveCN112909830BReduce labor intensityPrevent rotationApparatus for overhead lines/cablesControl theoryElectric cables

The invention discloses a cable tensioning device for high-altitude electric power construction, which includes a traveling mechanism and a supporting plate, the supporting plate is installed on one side of the traveling mechanism, and a steering mechanism, a swinging mechanism, and a winding mechanism are installed on the supporting plate. mechanism and anti-return mechanism, the steering mechanism is installed on one end of the support plate, the swing mechanism is installed on one side of the steering mechanism, and cooperates with the winding mechanism, and the winding mechanism is installed on one side of the swing mechanism . The invention can move to the utility pole by itself without the need for the staff to carry it, which greatly reduces the labor intensity of the staff, and the winding mechanism in the device can tighten the cable, and the swing mechanism can ensure that when the cable is tightened, The cable is evenly wound on the winding mechanism, which is convenient for the follow-up staff to deal with the cables uniformly. The anti-loop mechanism can prevent the winding mechanism from turning, and release the rolled cable again to ensure the tension of the cable. Quality, improving the efficiency of cable tensioning.

Owner:国网山东省电力公司曹县供电公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com