Horizontal curve prestress device of hollow large cantilever structure

A large cantilever and prestressed technology, applied in special structures, building components, building structures, etc., can solve the problems of high structural cost and large cross-section of steel components, so as to reduce construction difficulty, save steel consumption, reduce The effect of bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

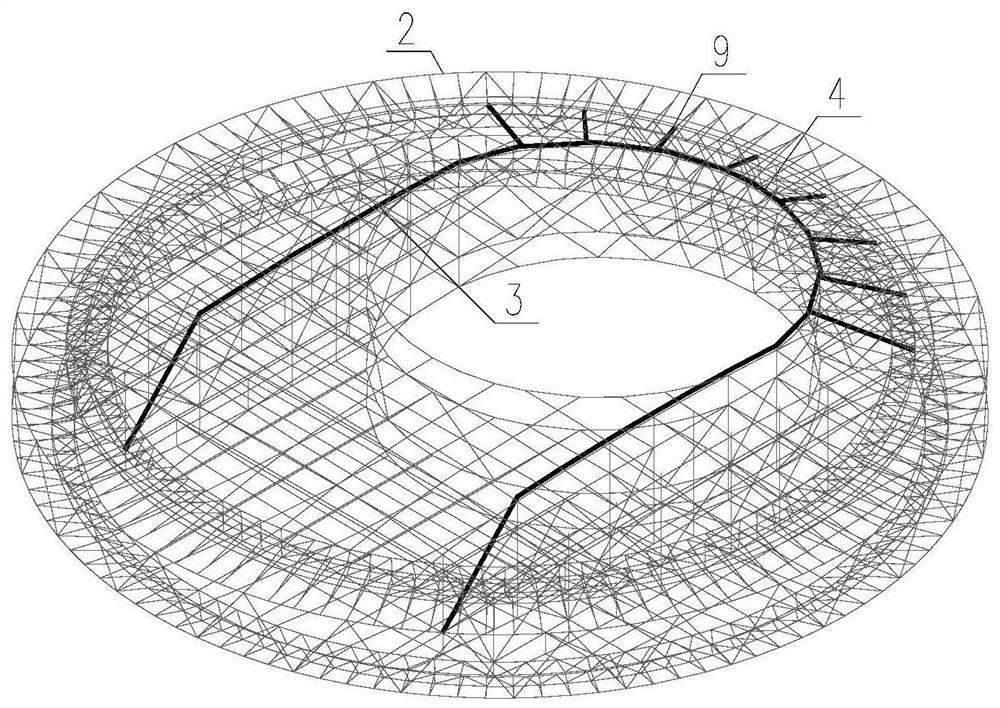

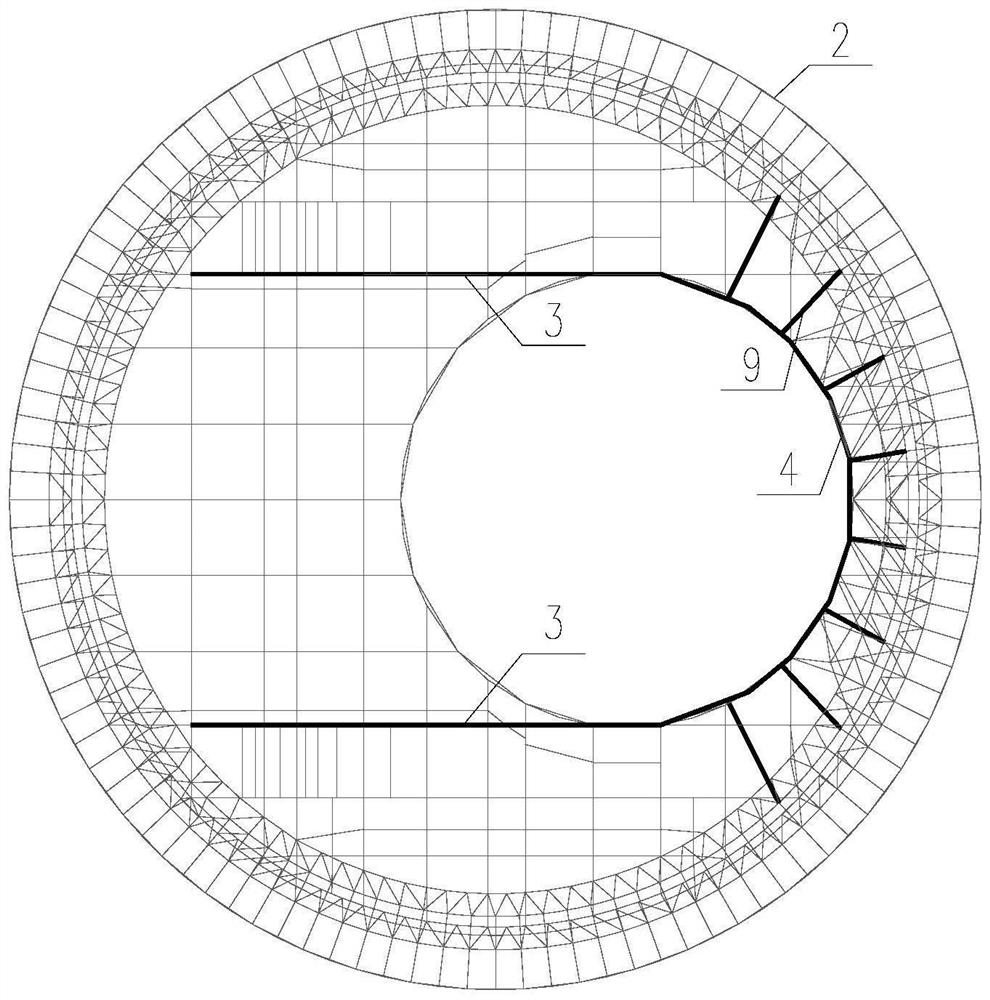

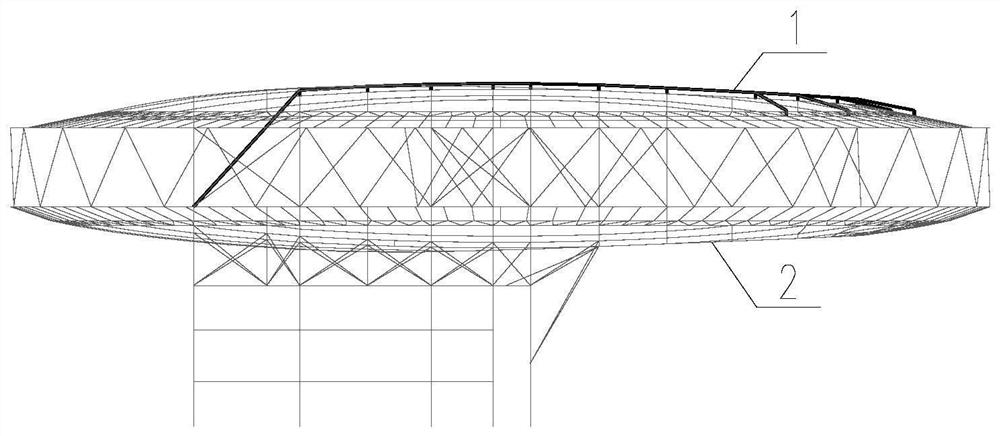

[0033] The invention relates to a horizontal curve prestressing device of a hollow large overhang structure. The horizontal curve prestressing device arranged above the neutral axis of the hollow large overhang structure includes a horizontal curve cable, a straight cable, a ring cable clamp node, and a straight cable clamp Nodes, oblique cable clamp nodes and tension end nodes are characterized in that: the horizontal curved cable is an unclosed curve, and the two ends are connected with straight cables; In the non-cantilever position of the large cantilever structure, set the tension end node to connect with the hollow large cantilever structure; set the ring cable clamp node to connect with the hollow large cantilever structure for the curved cable; set the straight cable clamp node and the hollow large cantilever structure for the straight cable Connection; set the oblique cable clip node at the intersection of the straight cable and the curved cable to connect with the hol...

specific Embodiment approach 2

[0042] The invention relates to a horizontal curve prestressing device of a hollow large overhang structure. The horizontal curve prestressing device arranged above the neutral axis of the hollow large overhang structure includes a horizontal curve cable, a straight cable, a ring cable clamp node, and a straight cable clamp Nodes, oblique cable clamp nodes and tension end nodes are characterized in that: the horizontal curved cable is an unclosed curve, and the two ends are connected with straight cables; In the non-cantilever position of the large cantilever structure, set the tension end node to connect with the hollow large cantilever structure; set the ring cable clamp node to connect with the hollow large cantilever structure for the curved cable; set the straight cable clamp node and the hollow large cantilever structure for the straight cable Connection; set the oblique cable clip node at the intersection of the straight cable and the curved cable to connect with the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com