Pre-stressed steel frame for exerting pre-stress by support displacement method and fabrication method of pre-stressed steel frame

A technology of prestressed steel and displacement method, which is applied in the processing of building materials, construction, building construction, etc., can solve problems such as waste and large building space, achieve construction cost saving, simple and convenient operation, and ensure construction safety and convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

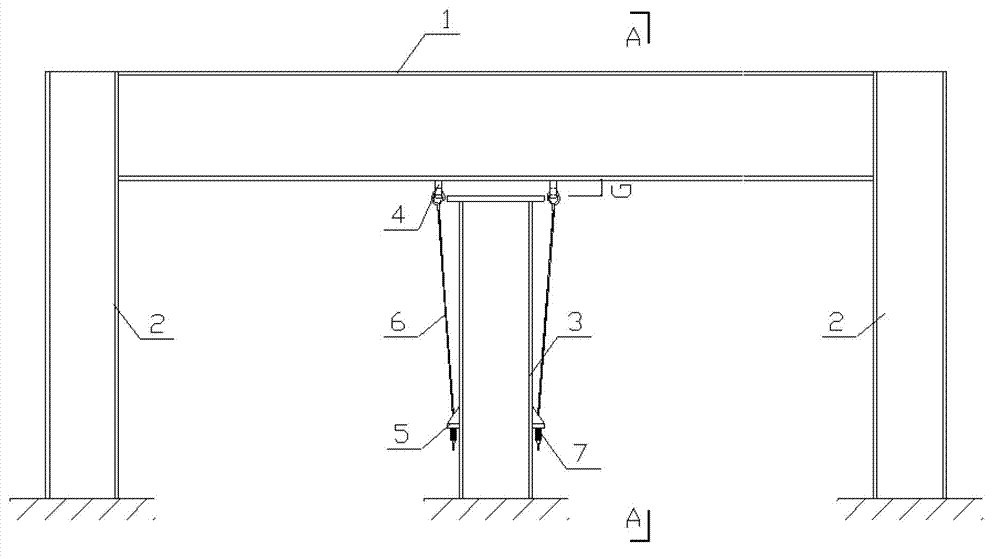

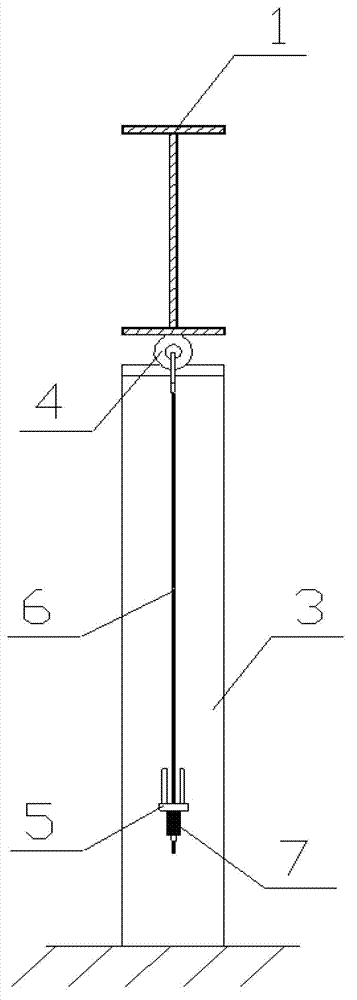

[0028] Such as figure 1 , figure 2 Shown is a single-layer prestressed steel frame prestressed by the bearing displacement method, which is composed of fixedly connected beam 1, side column 2 and center column 3, and beam 1, side column 2 and center column 3 are all welded combinations H section steel.

[0029] The lower flange of the beam 1 is vertically welded with connecting plates 4 at 150 mm from the left and right sides of the central column 3, and the connecting plates 4 are steel plates in a large semicircular shape with a round hole in the middle (such as figure 2 shown). The left and right sides of the center column 3 are welded at a height of 1m from the ground. The combined connecting plate 5 is a U-shaped connecting plate formed by welding two right-angled triangle steel plates and a rectangular steel plate with holes.

[0030] The drag cable 6 is a steel wire rope with a rigid cable hook at one end, which is flexibly connected to the connecting plate 4 throu...

Embodiment 2

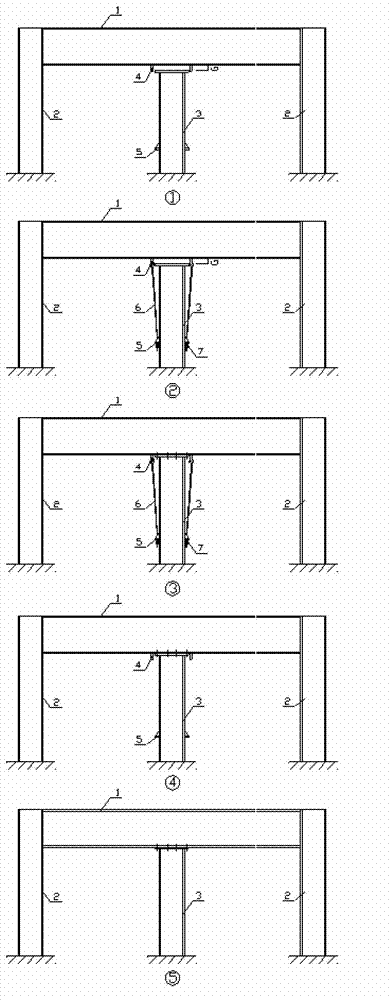

[0055] The composition of the two-layer prestressed steel frame structure member that adopts the support displacement method to apply prestress is the same as that of embodiment 1, and the specific construction steps are as follows Figure 4 shown.

[0056] ① After the beam 1, side column 2, and center column 3 are finished in the factory, the mid-span of the beam 1 is reversed in advance during factory production (the height of the reverse arch in the middle span is equal to the value of the reserved gap G), or the center column 3 is shortened (shortened The length is equal to the value of the reserved gap G), and the connecting plate 4 is welded on the bottom surface of the beam 1, and the combined connecting plate 5 is welded on the side of the central column 3. On site, first install the side column 2 of the two floors, the beam 1 of the first floor, the foot of the side column 2 is fixedly connected to the ground, the two ends of the beam 1 of the first floor are fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com