Method for reinforcing bonded prestressing force of transversely tensioning epoxy coating reinforcing steel bar of concrete beam slab

A technology of transverse tensioning and epoxy coating, which is applied in the field of reinforcement of buildings and other building structures, reinforced concrete and prestressed concrete bridges, and can solve the problems of high reinforcement cost, inconvenient reinforcement construction, and material utilization efficiency. Low-level problems, to achieve the effect of simplifying the tensioning procedure, facilitating the layout of prestressed steel bars, and improving the tensioning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

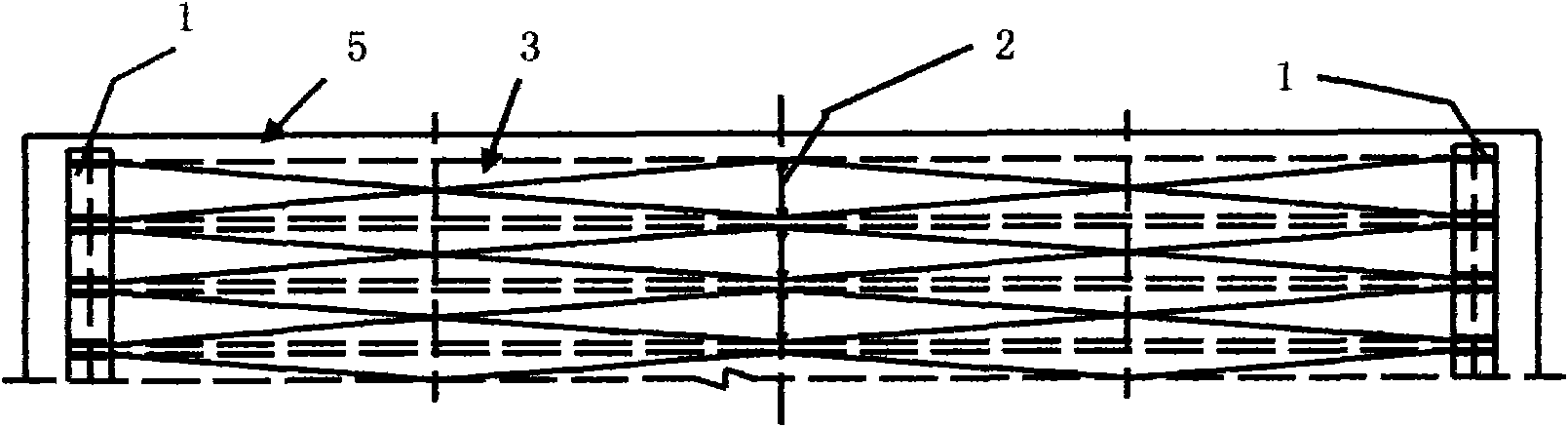

[0028] The process of strengthening the flexural bearing capacity of the positive section of the simply supported concrete hollow slab beam is as follows: (see figure 1 )

[0029] 1) According to the bridge inspection and bearing capacity evaluation report, determine the reinforcement area of the beam body 5 .

[0030] 2) Calculate the corresponding cross-sectional area of prestressed steel bar according to "Code for Design of Highway Bridge Strengthening" JTG / TJ22-2008.

[0031] 3) Select the epoxy-coated steel bar 3 of appropriate diameter as the spare prestressed steel bar material.

[0032] 4) Making the steel strip 1 anchored by the prestressed steel bar, the thickness of the steel strip is not less than 10mm, and the length is equal to the width of the area where the prestressed reinforcement beam body 5 is arranged.

[0033] 5) Install the prepared anchor steel strips 1 at both ends of the designed position of the reinforcement area. The steel strip 1 is bonded t...

Embodiment 2

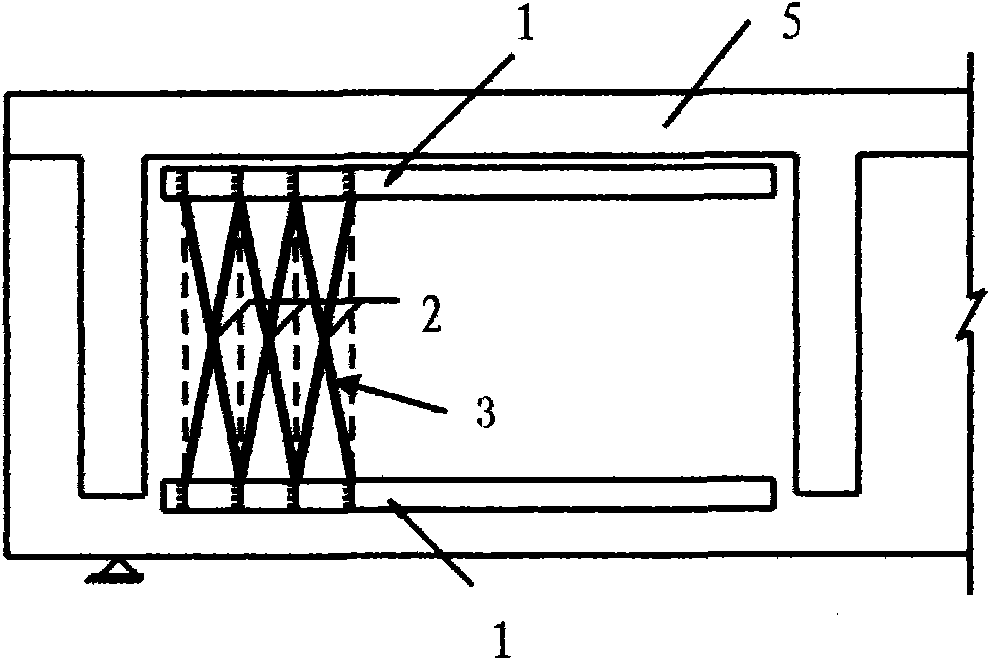

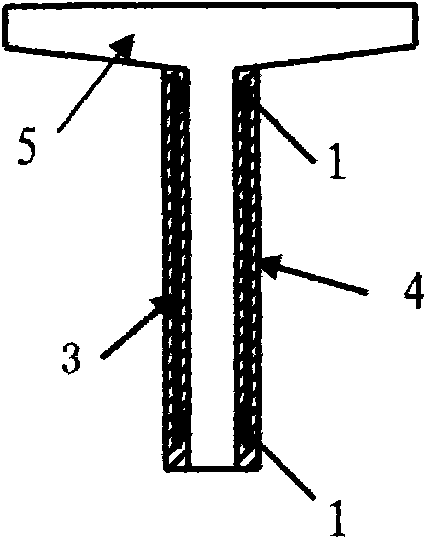

[0038] Diagonal section strength for strengthening T-beam and box girder bridges ( figure 2 , image 3 shown)

[0039] For the shear reinforcement of the oblique section of T-beam and box girder bridge 5, the construction steps and methods are similar to those in Embodiment 1. The difference is that in the construction step 8), the method of reinforcing the prestressed steel bars 3 is arranged on both sides of the web (or in the box), and the composite mortar (or concrete) 4 protective layer can be constructed by the plastering method.

Embodiment 3

[0041] Multi-span simply supported slab and girder bridges from simply supported to continuous reinforcement

[0042] Multi-span simply supported slab and girder bridge 5 are reinforced by simply supported to continuous method, and the construction steps and methods are similar to those in Embodiment 1. The difference is that in the construction step 8), the method of reinforcing the prestressed steel bars is to arrange the reinforced prestressed bars 3 on the pier tops of the adjacent spans in the middle, and directly pour cement-based crystalline molded steel bars on them after the steel bars are stretched. Concrete 4 pavement layer of waterproof material to enhance the crack resistance of the bridge deck.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com